Free AI Case Study Generator

Create Case Studies, Edit Online with AI-Powered Case Study Editor

Template.net’s Free AI Case Study Generator helps you draft high-quality case studies in seconds. Edit online with your brand logo, fonts, tone, and custom elements to ensure every study is personalized and professional. Whether you're creating business analyses, academic research, client success stories, or marketing case studies, stay on-brand and on-point. Download in multiple formats, share instantly, and present insights with clarity and confidence.

Write Custom, Professional Case Studies in Seconds

From customer journeys to research-backed insights, our AI-powered document writer helps you craft polished, on-brand case studies in any format, tone, or language, no blank pages, no formatting guesswork.

AI Brand Voice

Choose from formal, conversational, persuasive, or empathetic tones. AI reviews your input to match your message intent, whether it’s a client success story or a general market study. You can also give specific context on your brand voice, competitive goals, and message needs for total consistency.

AI-Smart Formatting Suggestions

Get instant suggestions for improving structure, layout, headings, and more, especially useful for long-form, professional documents.

Multiple Document Types Supported

Generate a wide range of professional formats including case studies, business reports, marketing reviews, research summaries, client stories, and more.

Professional Case Study Formatting

Use clean, structured layouts for executive summaries, challenges, solutions, and results, designed for customer stories, business use cases, or product success narratives.

Smart Personalization

Auto-fill names, dates, job titles, companies, and other context, tailored to focus areas and reduce repetitive work.

Auto-Suggested Visuals & Headers

Let AI recommend headings, subheadings, and visual structure to make your document more readable and engaging.

Multilingual Document Generation

Create reviews instantly in 20+ global languages using text or voice prompts.

Languages supported: English, Spanish, French, Hindi, Arabic, Chinese, Portuguese, Bengali, Russian, Japanese, German, Korean, Italian, Turkish, Vietnamese, Urdu, Persian, Polish, Thai, and Punjabi. Perfect for multilingual outreach or international collaboration.

Voice-Powered Drafting

Don’t sit down and just speak your prompt and let the AI generate your case document, hands-free and instant.

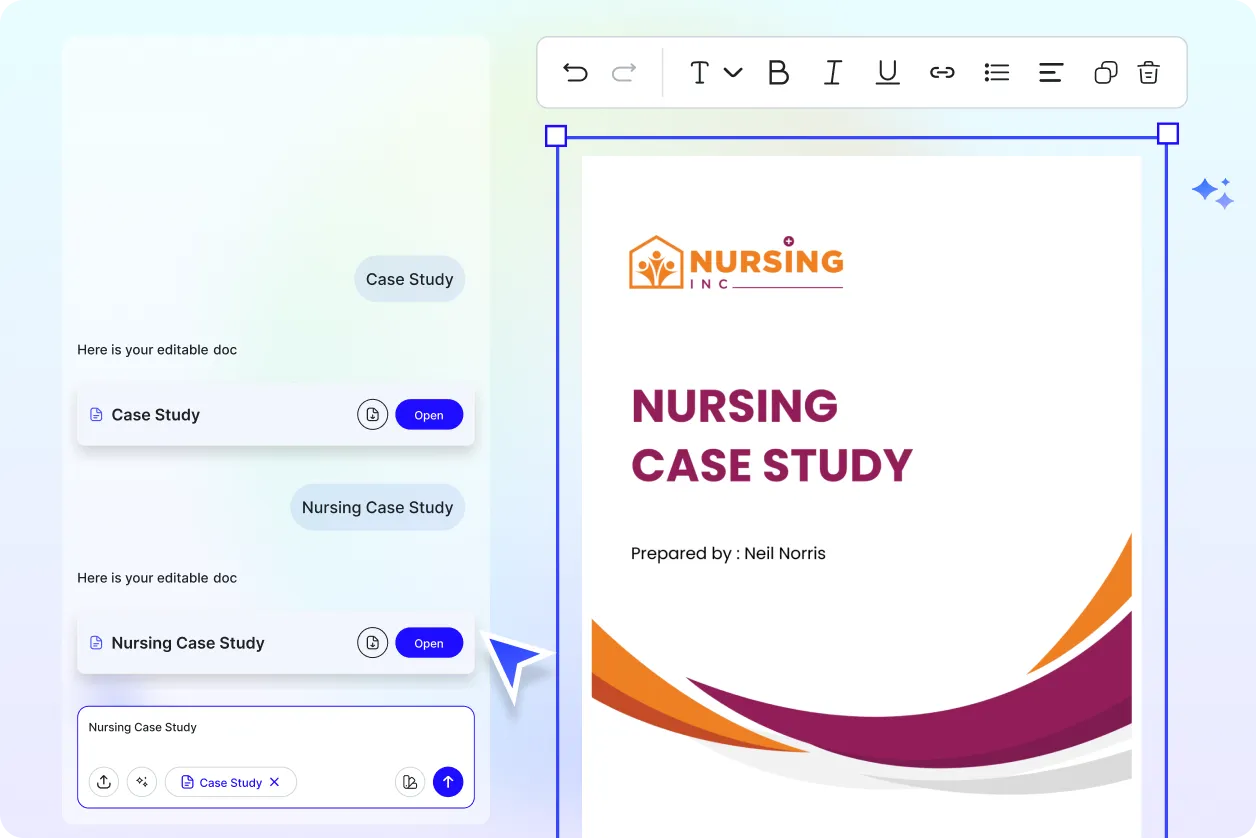

Fully Customizable Text, Styles and Design

Easily update fonts, headings, colors, and layout styles. Apply consistent branding using built-in design controls. Add from hundreds of customizable Header and cover page designs.

Branding and Visual Control

Apply your logo, brand fonts, and colors automatically to maintain visual consistency across all documents.

Add References & Proof Points

Easily include URLs, reports, data sources, or evidence to support your claims and improve case study credibility.

Real-Time Proofreading

Check for spelling, grammar, punctuation, and tone in real-time, no need for external grammar tools.

Rewriting & Content Expansion

Ask AI to rephrase, shorten, or expand any section with tone and content awareness.

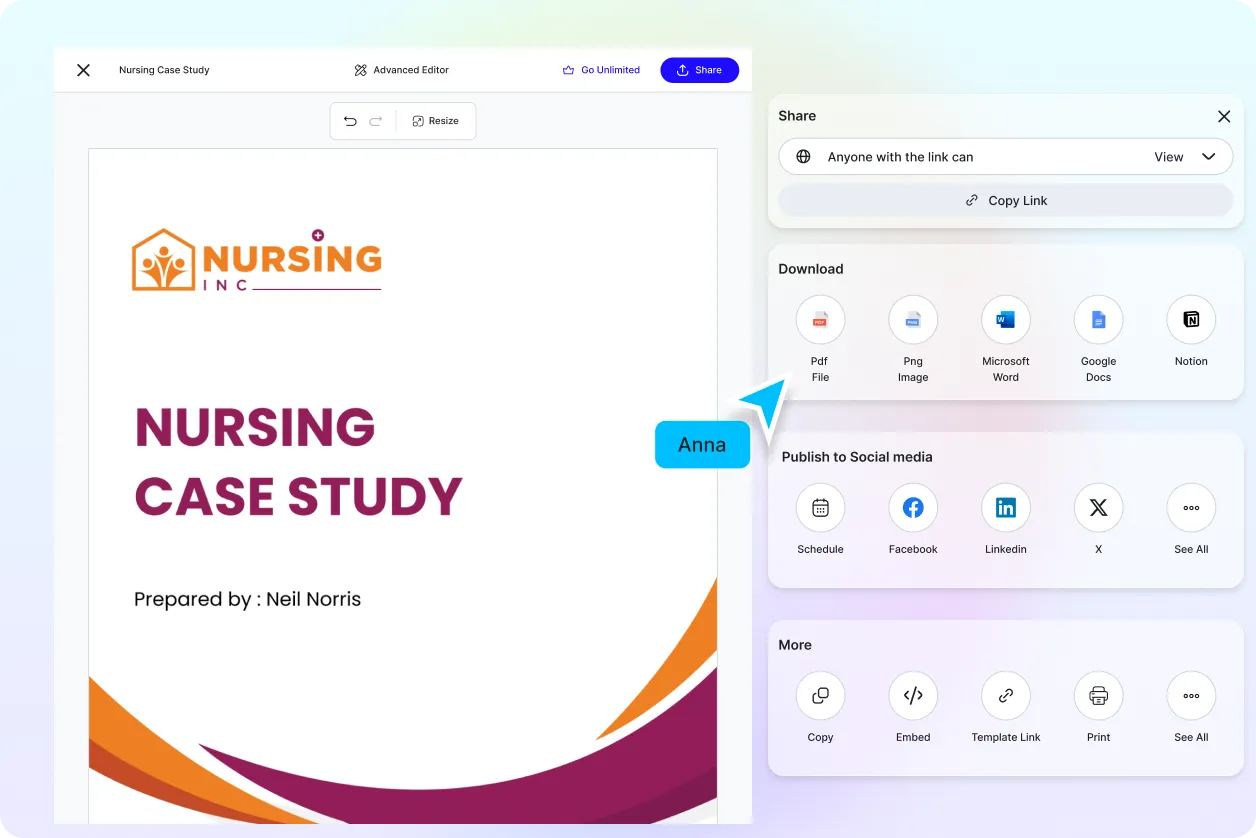

Export in Multiple Formats

Download the case document in DOCX, PDF, TXT, PNG, HTML formats. Seamlessly export to Google Docs, Dropbox, OneDrive, Notion, or email.

Real-Time Collaboration

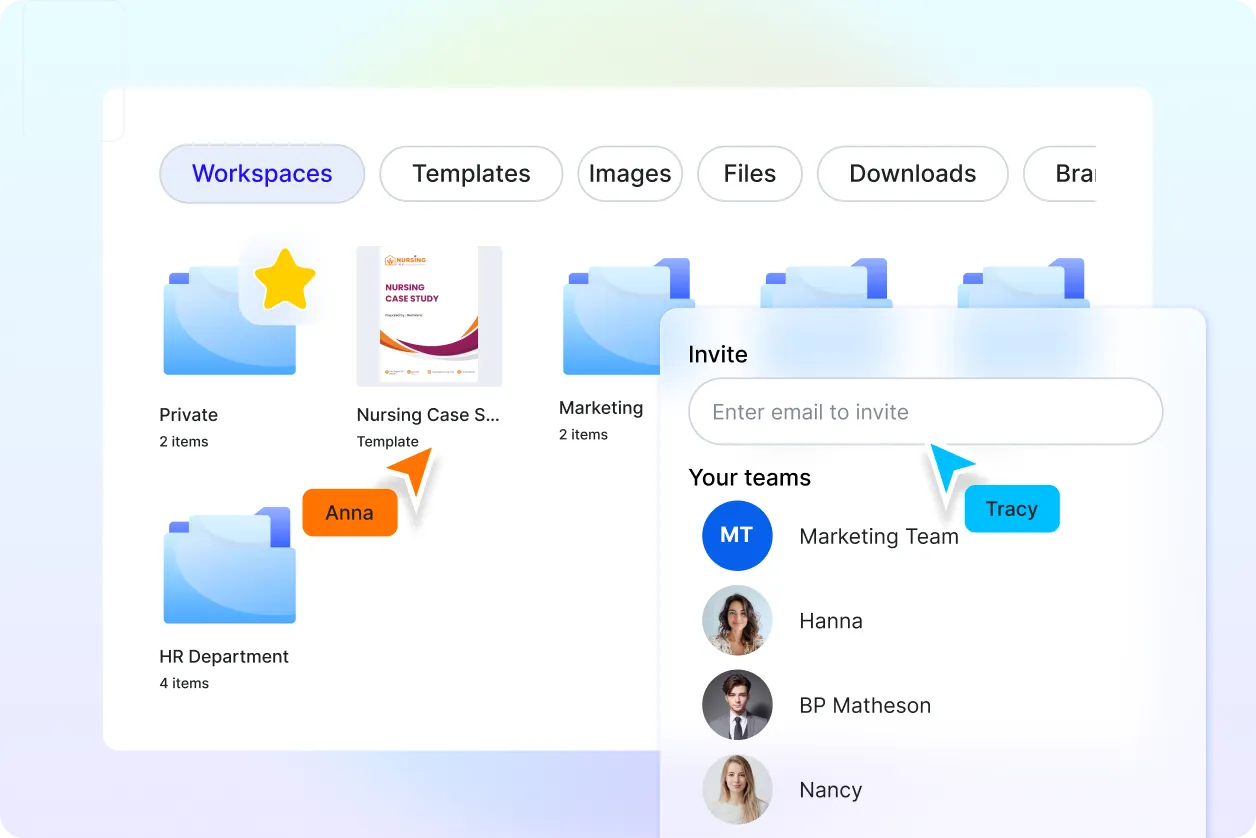

Collaborate live with clients or teammates. Add comments, make edits, and finalize together in one shared workspace.

Secure Cloud Workspace

Store documents securely, assign roles, and control access for teams or clients, all protected in your cloud environment.

Translate Full Documents Instantly

Translate instant case documents with one click ideal for working with global clients or distributed teams.

Share or Embed Anywhere

Publish via link, QR code, or embed codes to include documents in websites, emails, portals, or knowledge bases.

Attach Files & Media

Upload and embed documents, PDFs, videos, audio files, or supporting materials directly into your document.

Add Signature Blocks

Insert professional e-signatures or signature placeholders into any letter or document, ideal for contracts, approval, or formal documentation.

Add Tables and Structured Data

Build clean, responsive tables to organize data, schedules, pricing, or comparisons within your document.

Add Charts and Graphs

Visualize data instantly with bar charts, pie charts, or line graphs, perfect for proposals, reports, and presentations.

Add Images and Videos

Insert photos, logos, or videos to enhance your message, great for marketing inserts or visual summaries.

Section Reordering Tool

Easily rearrange sections (Problem, Solution, Results, Testimonial) using drag-and-drop, ideal for tailoring each case study’s flow.

How to Write a Free AI-Generated Case Study

Just enter a prompt, customize the draft, and export your polished case study in minutes, no formatting, no friction.

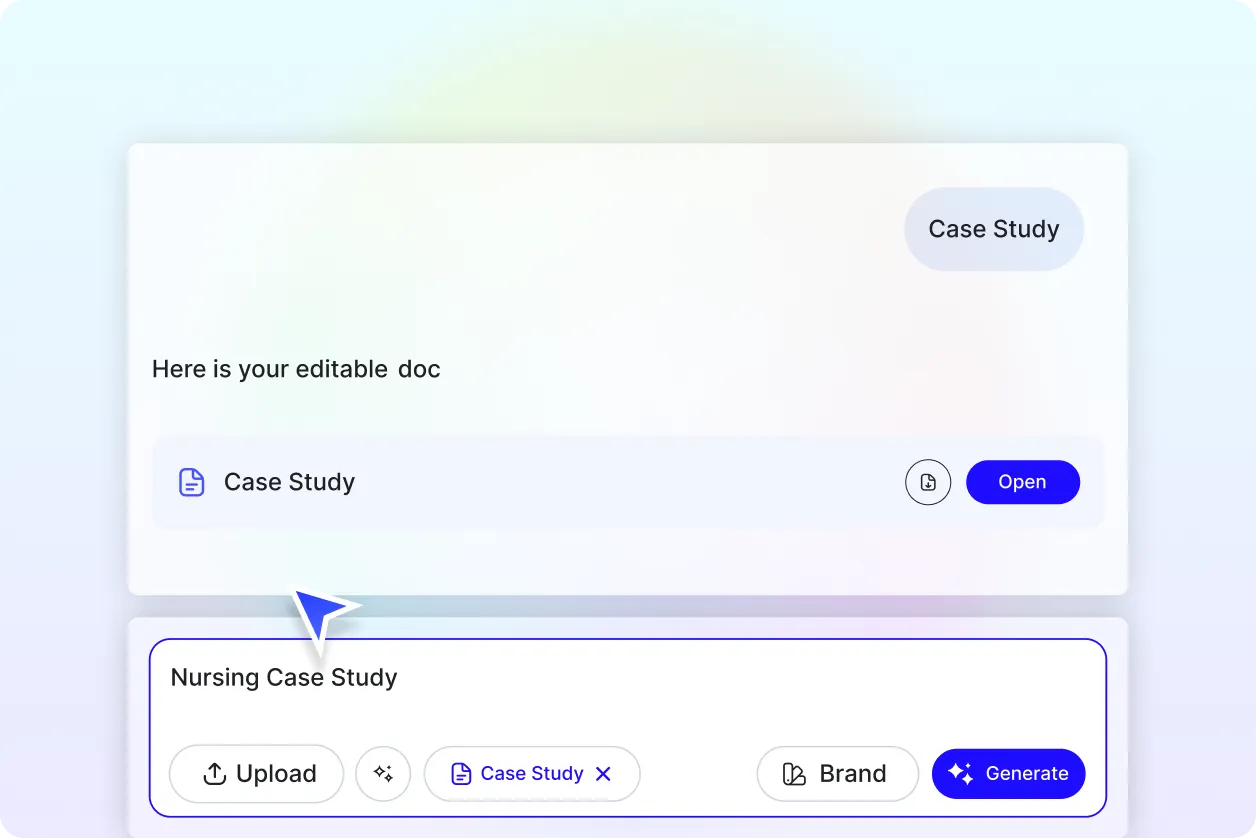

Step 1: Start with a Prompt

Type or speak your study’s purpose, such as: “Case study on e-commerce growth in India,” “User retention case for mobile app,” or “Marketing success case for our SaaS client.” AI instantly understands your direction and begins writing.

Step 2: Generate and Edit

Within seconds, you'll see a tailored, structured case study based on your topic. Refine tone, add visuals, or regenerate different versions with varied highlights.

Step 3: Finalize and Share

Add logos, brand elements, or citations. Then export in DOCX, PDF, TXT, or share it instantly via email, public link, QR code, or post to LinkedIn, WhatsApp, Facebook, Reddit, and more.

Create Case Studies in Seconds and Start Showcasing Real Results

Generate Case Studies That Represent You

Apply your company’s brand style in seconds. From headers to voice, every element of your case study reflects your identity.

Reuse, Repeat, and Scale Easily

Save high-performing case studies as reusable templates. Adjust details and resend across campaigns or departments without rewriting from scratch.

Share Instantly, Collaborate Smoothly

Download or post reports in DOCX, PDF, TXT. Share online, collaborate live, and receive feedback, without scattered files.

Smart Workspaces for Teams

Create centralized hubs for case study projects. Assign access levels, store brand elements, and keep every asset aligned across teams.

Case Study FAQ

What is a case study and how is it used?

A case study is a structured analysis of real-world scenarios, business results, or research findings, used in academia, marketing, product development, and more. It highlights challenges, solutions, and outcomes in a compelling format.

How do I write a case study using AI?

Enter a prompt like “Marketing case study on brand awareness campaign” or “Case study on AI adoption in healthcare.” Our AI builds a structured case study instantly, complete with sections, tone, and formatting.

Can I generate case studies in different languages or formats?

Yes. AI supports over 20 global languages for multilingual case studies. You can create formatted, editable case studies using either typed or spoken prompts.

Languages supported:

English, Spanish, French, Hindi, Arabic, Chinese (Simplified), Chinese (Traditional), Portuguese, Bengali, Russian, Japanese, German, Korean, Italian, Turkish, Vietnamese, Urdu, Persian (Farsi), Polish, Thai, Punjabi, Indonesian, Dutch, Romanian, Greek, Hebrew, Swedish, Tamil, Telugu, Malayalam, and Marathi.

How can I export or share my case study?

Download in DOCX, PDF, or TXT. You can also share via email, public link, QR code, or platforms like LinkedIn, WhatsApp, Facebook, X, and more.

How do I format a professional case study correctly?

AI includes structured elements: Executive Summary, Problem, Solution, Results, and Takeaways, formatted to your tone and style needs.

Can I improve or edit an existing case study with AI?

Yes. Paste your content and AI will help rephrase, refine tone, or expand on key points, while preserving your core message.

Can I add charts, visuals, or data to my case study?

Absolutely. You can embed images, graphs, tables, signatures, logos, citations, videos, and more for a polished final document.

Similar Free Document Generators

Document Generator

Resume Generator

Budget Generator

Business Name Generator

Lesson Plan Generator

Story Generator

Summarize Text Generator

Essay Generator

Mission Statement Generator

Itinerary Generator

To Do List Generator

CV Generator

Meal Plan Generator

Business Proposal Generator

Cover Letter Generator

Business Plan Generator

Checklist Generator

Smart Goals Generator

Executive Summary Generator