40+ Word Checklist Templates

Due to limited memory and attention, we humans often forget to do tasks which we were supposed to perform. Our…

May 16, 2024

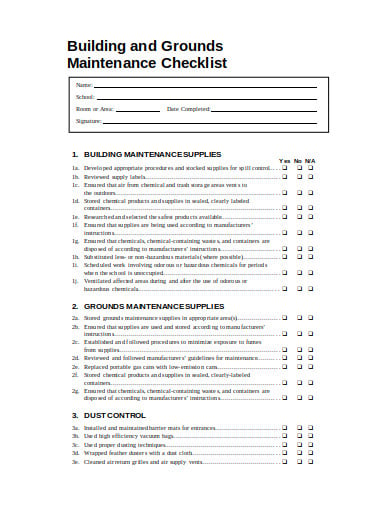

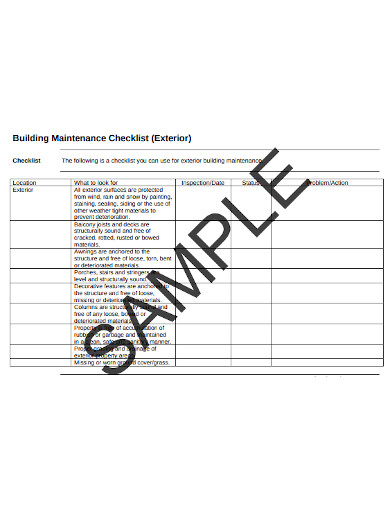

A facility maintenance checklist is a priceless defense means to keep a building reliable and safe by periodical planning, checkups, and preservation projects. It is also referred to as a preventative maintenance checklist. Have a look at the building maintenance checklist templates provided down below and choose the one that best fits your purpose. You may also see more on maintenance checklists in word.

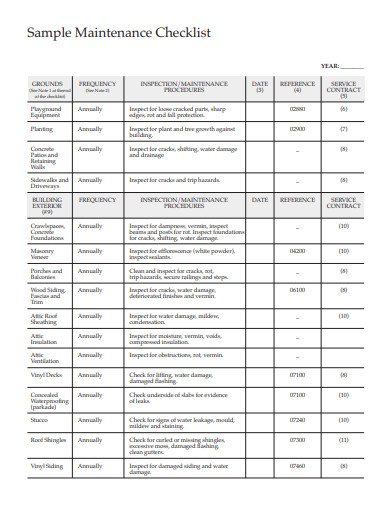

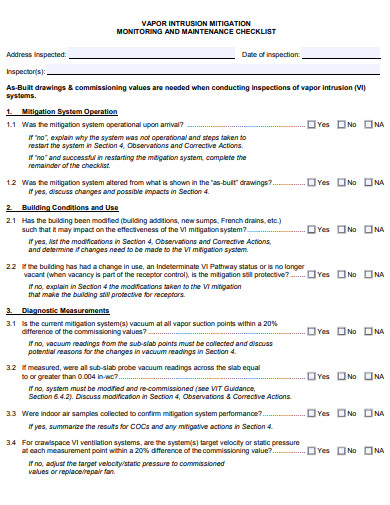

epa.gov

epa.gov naahq.org

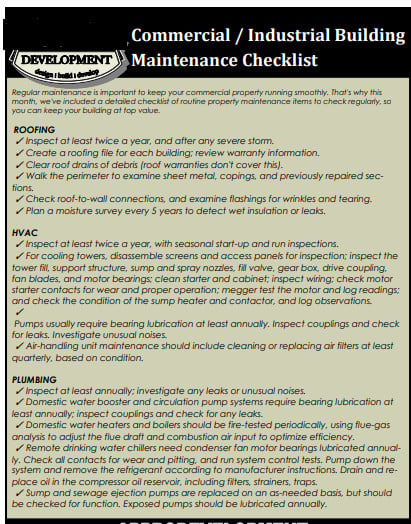

naahq.org approdevelopment.com

approdevelopment.com bchousing.org

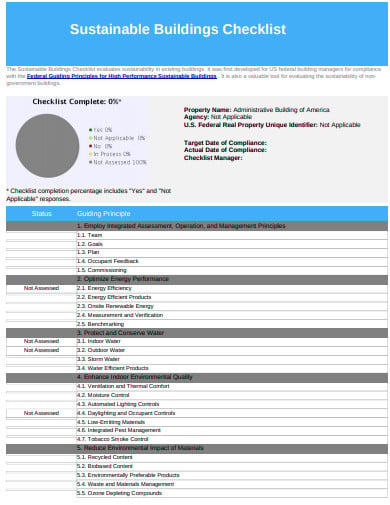

bchousing.org energy.gov

energy.gov anglican.ca

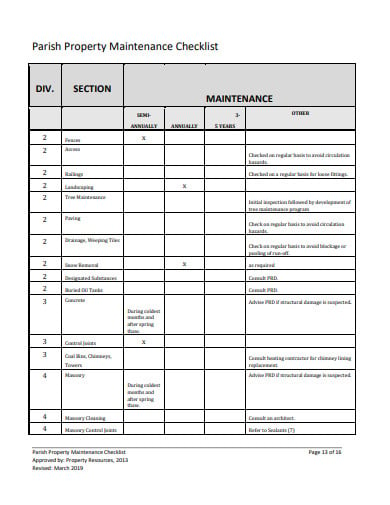

anglican.ca nj.gov

nj.gov ucaqld.com.au

ucaqld.com.au opt-osfns.org

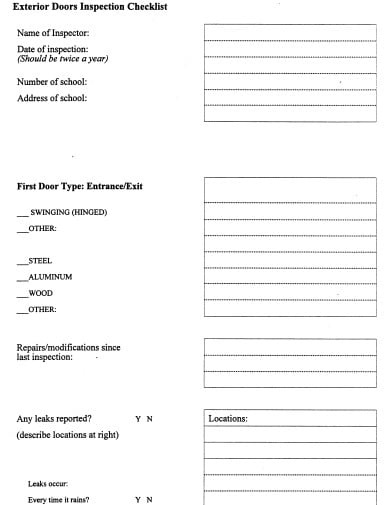

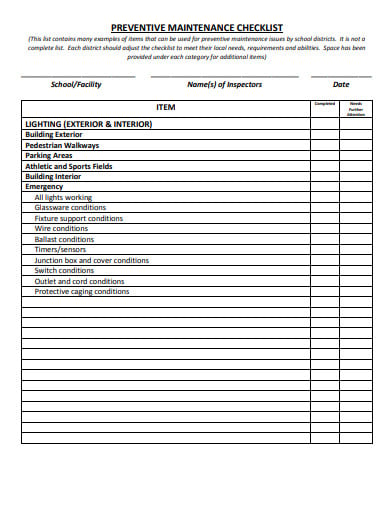

opt-osfns.org gsba.com

gsba.comA maintenance sample checklist is a record that consists of a few items to be checked or examined for maintenance like a vehicle, appliance, and much more. It also aims out the things which have been examined mostly market in order to ignore examining the same thing more than once.

General examples of facilities maintenance consist of common building repairs, maintenance of building life-safety and security alarm systems, and systems such as heating, purifying, air conditioning, plumbing, electrical and lighting, pest control and much more. For a wider selection of modern checklist templates, check out more options here.

Building maintenance is the combination of technical and administrative actions to guarantee the items and components of a building in an agreeable standard to produce its needed use.

Preventive maintenance is a type of preservation that is frequently conducted on a piece of equipment to diminish the possibility of it failing. It is completed while the equipment is still operating so that it does not break down surprisingly. Find more professional checklist templates by visiting this link.

The objective of preventive maintenance is to strive to keep the equipment in the best working conditions and to assist stop any unplanned downtime due to breakdowns. Because elements begin to fade over time, substituting parts preceding negligence can cost you far less than the possible outcomes of negligence while in service. View a wider selection of induction checklist templates right here. Some people see maintenance as an investment and it can usually be one of the first areas to undergo injuries during tough times, nevertheless, this is very much mistaken. Anticipating problems from happening will nearly always be far less than the costs you will provoke due to real failures.

Maintenance is the term whose purpose is to guarantee the entire availability of production equipment, services, and associated facilities at optimal cost and under adequate conditions of quality, safety, and protection of the environment.

Maintenance management is accountable for the stable and effective working of the industrial plant and assists in enhancing productivity. It also assists to keep the machines/equipment in their maximum operating circumstances. Explore a variety of vehicle inspection checklist templates here.

Every company or organization has some kind of composition structure outlines. The goal of picking a specific organizational sample outline is to interpret relationships, lines of authority and ways of communicating during a way that best fills the acceptable organization or enterprise.

The objective of maintenance is to maintain the basic security of your physical assets. It needs its own management process separate from maintenance. The maintenance organizational structure decision must be balanced to the activities needed to deliver the policy.

The objectives of a preventive maintenance program are as follows:

Disadvantages of Preventive Maintenance are as follows:

1.The decrease in manufacturing & more decline in the plant.

2. Many malfunctions happen with unplanned downtime.

3. Rise of the maintenance charge with direct loss of benefit.

4. Less security for workers & machines and expanding accidents.

5. Reducing the lifespan of the asset.

Due to limited memory and attention, we humans often forget to do tasks which we were supposed to perform. Our…

A facility maintenance checklist is a priceless defense means to keep a building reliable and safe by periodical planning, checkups,…

A Recruitment Checklist is the to-do-list where you list down all the important details that you need to do or…

Logistics Performance Index indicates that America is one of the leading logistics industries in the globe. Its networks coordinate with…

The best way you can make sure that all cleaning go as planned is to have a cleaning checklist samples.…

A Resume Screening Checklist is a checklist that is prepared by the recruiter to list all the important points based…

HR Compliance Checklist is the tool that is used by HR professionals to make the preparations for the HR tools.…

A retirement party is the opportunity to celebrate the retiree’s past achievements as well as their future efforts. The party…

The mortgage business has gone through a lot of chapters in the industry, combating business challenges every year. According to…