24+ Research Statement Templates in PDF | DOC

In a statement of purpose for research, you would like to try an in-depth analysis of knowledge and stats. You…

Sep 05, 2023

For the quality checking of the manufactured products and avoidance of problems, you need a quality assurance statement. The quality control department checks on the quality of the product. It is a way of preventing mistakes and damages. The quality assurance is for your manufacturing product after you have the output in hand. The quality of the product depends on the goodness and firmness of it. For that, quality assurance takes place after production.

imperial.uk

imperial.uk glenassociates.uk

glenassociates.uk assets.publishing.service.gov

assets.publishing.service.gov healtheffects.org

healtheffects.org communityresolve.com

communityresolve.com dcu.ie

dcu.ie epa.gov

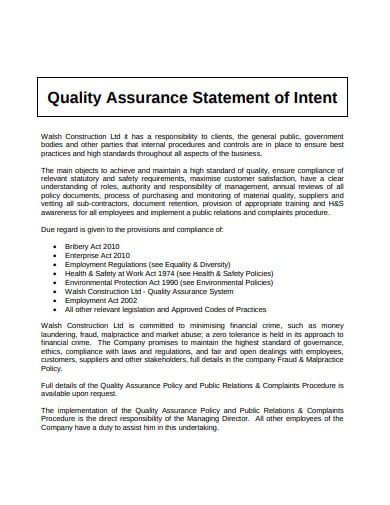

epa.gov walshconstruction.uk

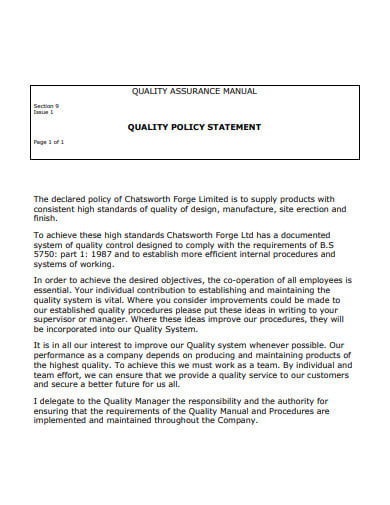

walshconstruction.uk chatsworthforge.uk

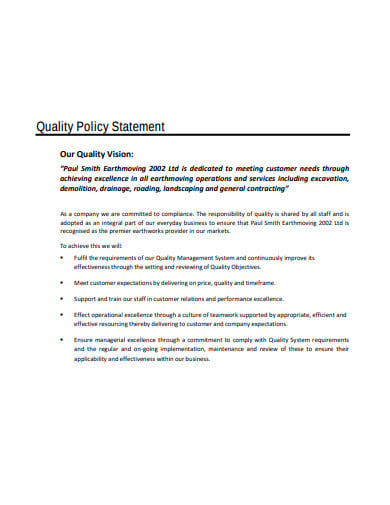

chatsworthforge.uk paulsmithearthmoving.co.nz

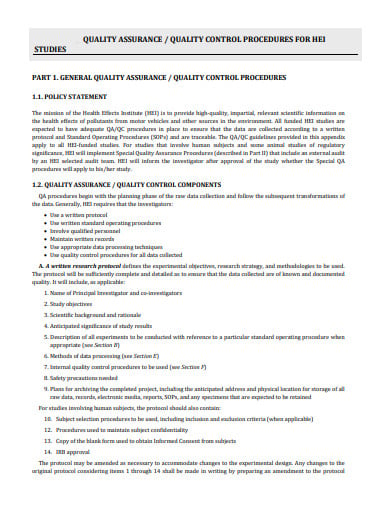

paulsmithearthmoving.co.nzThere are different categories of activities in the assurance process. In the first place, the division of activities into three parts. The parts of the activities include the management plan, improvement plan, etc.

There is the division in the input like the quality management plan, process improvement plan, quality metric, quality control management, project document, etc. Above is the division of various evaluation in the process of quality assurance.

There is a division of tools and techniques in the process of quality assurance. Auditing and analyzation are the tools and techniques for the quality assurance process. With these, you evaluate the quality of the product.

In the output, the process of activities is the change request, project management plan updates, project document updates, organizational process updates, etc.

When you complete the process of quality assurance, then you save the obtained results in the file. The result is necessary for later on.

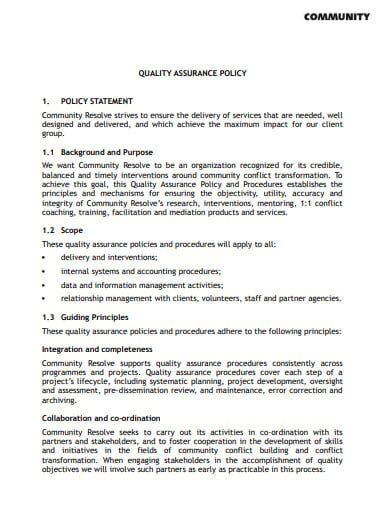

The term of quality assurance and quality control used interchangeably. But these two-term depend on each other when using. The quality checking is the tool or medium used after the product manufactured. The quality assessment department analyzes and then checks the quality. It helps in increasing the total margin of the sales and marketing of the product.

The benefit of quality assurance is to provide a quality product to the customers and users. Production and management use it to gain quality products and services.

There are various uses of the Quality Assurance Statement in and after the production process. The statement assists in creating a record or track of the result after a quality check. The quality assurance checks the quality of raw materials, products, and components, management, etc. The use of the quality assurance statement gives you the surety of the quality check of the product or item in a systemized manner. Nowadays, there is software that evaluates the quality and records the result online.

There is a minor difference between the term quality control and quality assurance. In the quality control process, the entity looks after the quality of all factors involved in the production. It includes the testing of the unit and pays attention to the specification required for the final product.

Whereas, the quality assurance is commonly known as QA Testing. It is an action to assure the customer that the company is providing the best and quality product to customers. It mainly focuses on the process that delivers a quality product to the consumers.

There are a few examples of quality assurance to make you explain the process clearly. The activities that associate with the processing like the process checklist, process standards, process documentation, are in the quality assurance process. The assurance includes the audit of the whole production process of the product. It is the process that ensures product or service excellence.

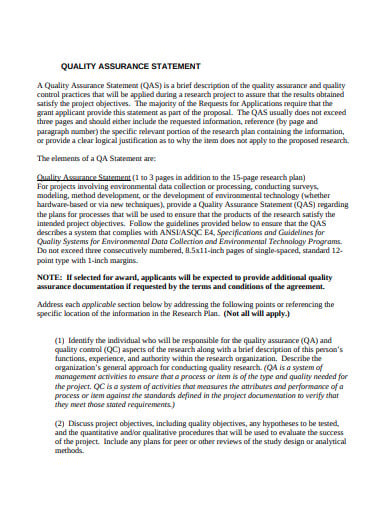

The statements of quality assurance are there for you to use it in the production process. It helps in making the records of the various process involved in quality assurance. It is the process of auditing the quality of the product. The checking assists the maintenance of the quality of the item manufactured. The department of the quality check gives preference and priority to the best quality product.

And that product is then launched in the market for the consumer to buy. This process helps make more and more sales of the product. Statements are there for formal and official use in the production process to note down the various procedure of quality assurance systems.

In a statement of purpose for research, you would like to try an in-depth analysis of knowledge and stats. You…

A suitable statement for employment outlines any supporting explanation of your skills, proving that you are ideal for the employment…

The written statement is a legal statement that the people have to go through when they face some legal ups…

A disclosure statement is the synopsis of the terms, conditions, risks, and rules that are involved in any financial transactions…

A salary statement is a form that provides different components of an employee’s salary and the cost incurred payments. It…

A document that explains the significance of the research work you did is known as an impact statement. It is…

Statement of Expenditure is a multi-column self-balancing monthly statement of expenditures of an operative level workplace. It is created to…

When you write a sworn statement or testimony, you’re testifying beneath oath, and your words can become a part of…

A purpose statement announces the aim, scope, and direction of the paper. It tells the reader what to expect in…