Free Equipment Maintenance Inspection Checklist

Purpose:

The purpose of this Equipment Maintenance Inspection Checklist is to provide a structured guide for inspecting and maintaining industrial equipment systematically. By following this checklist, you can ensure the optimal performance, reliability, and safety of your equipment. This checklist aims to:

Identify and address potential issues proactively.

Minimize downtime and disruptions.

Enhance safety in the workplace.

Extend the lifespan of industrial equipment.

Establish a systematic approach to equipment care.

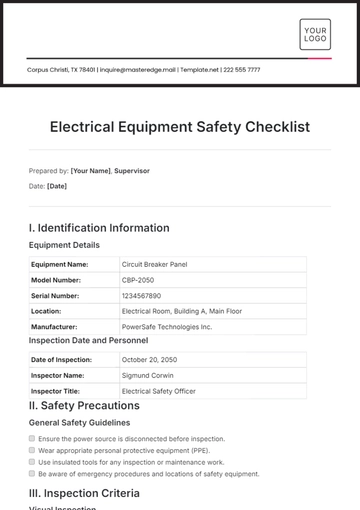

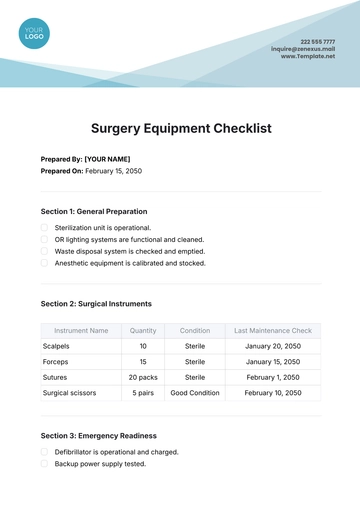

Electrical Inspection

Inspect wiring for any signs of damage or wear

Check circuit breakers for proper operation

Ensure all electrical connections are secure

Perform insulation resistance test

Check for any potential electrical hazards

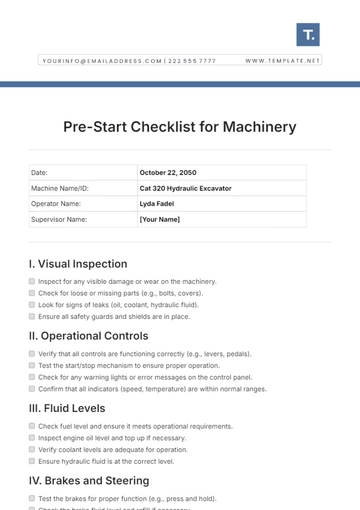

Mechanical Inspection

Check all moving parts for proper alignment and looseness

Inspect gears and belts for any signs of wear or damage

Perform oil and lubrication service

Check for any mechanical noises or vibrations

Ensure all safety guards are in place and functional

General Maintenance and Service

Perform routine cleaning of equipment

Ensure equipment is operating within specified temperature ranges

Inspect equipment for any leaks or spills

Check all controls for proper operation

Verify all meters and indicators are working correctly

Date of Inspection:

Inspection Notes:

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Ensure the reliability and performance of your equipment with our Equipment Maintenance Inspection Checklist Template from Template.net. This comprehensive and customizable template empowers you to create detailed checklists for equipment inspections and maintenance. With editable features, tailor the checklist to meet the specific requirements of your machinery.

You may also like

- Cleaning Checklist

- Daily Checklist

- Travel Checklist

- Self Care Checklist

- Risk Assessment Checklist

- Onboarding Checklist

- Quality Checklist

- Compliance Checklist

- Audit Checklist

- Registry Checklist

- HR Checklist

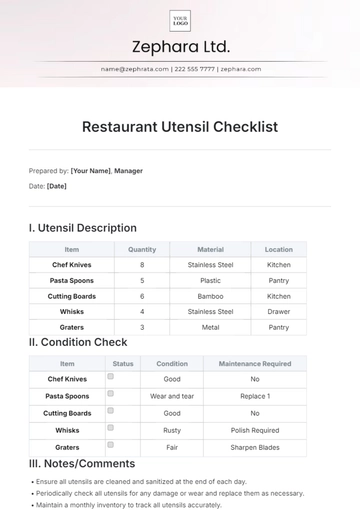

- Restaurant Checklist

- Checklist Layout

- Creative Checklist

- Sales Checklist

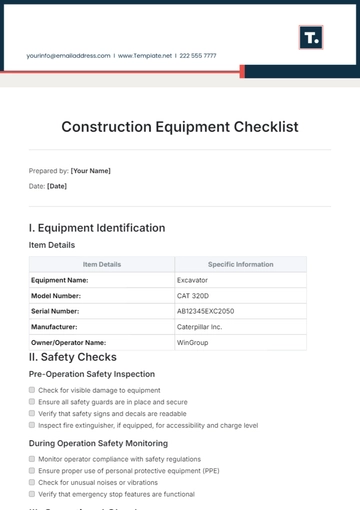

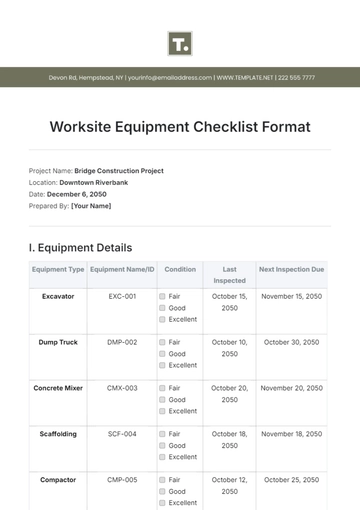

- Construction Checklist

- Task Checklist

- Professional Checklist

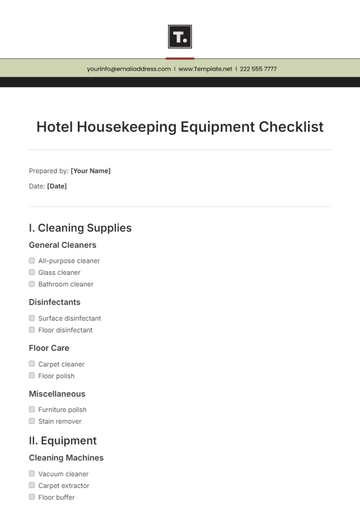

- Hotel Checklist

- Employee Checklist

- Moving Checklist

- Marketing Checklist

- Accounting Checklist

- Camping Checklist

- Packing Checklist

- Real Estate Checklist

- Cleaning Checklist Service

- New Employee Checklist

- Food Checklist

- Home Inspection Checklist

- Advertising Checklist

- Event Checklist

- SEO Checklist

- Assessment Checklist

- Inspection Checklist

- Baby Registry Checklist

- Induction Checklist

- Employee Training Checklist

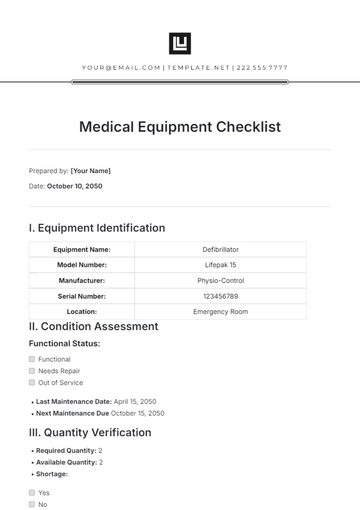

- Medical Checklist

- Safety Checklist

- Site Checklist

- Job Checklist

- Service Checklist

- Nanny Checklist

- Building Checklist

- Work Checklist

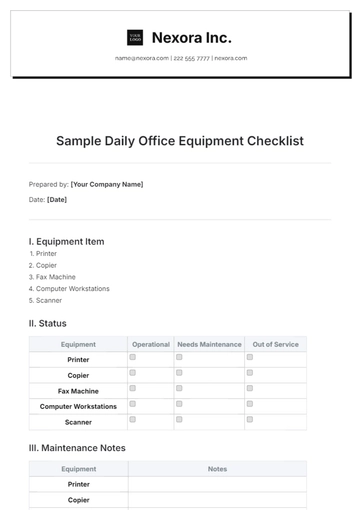

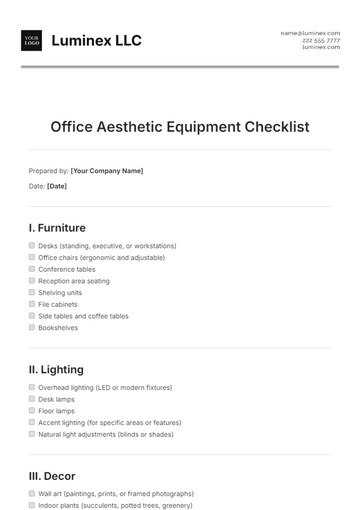

- Office Checklist

- Training Checklist

- Website Checklist

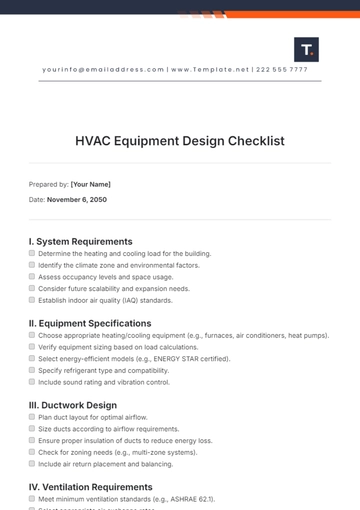

- IT and Software Checklist

- Performance Checklist

- Project Checklist

- Startup Checklist

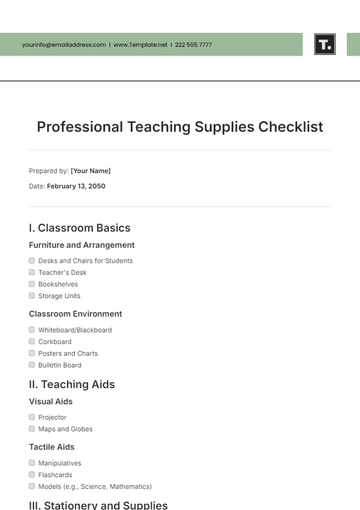

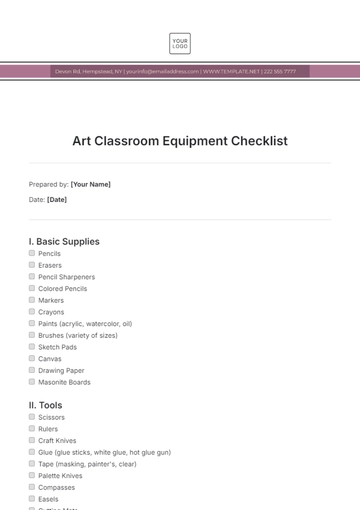

- Education Checklist

- Home Checklist

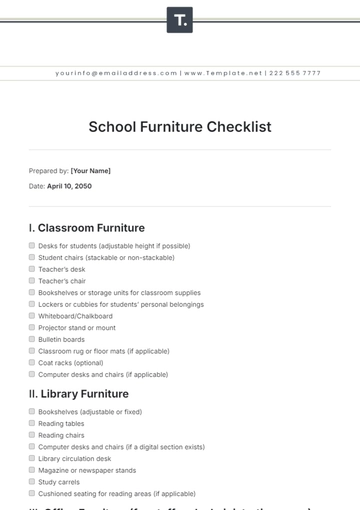

- School Checklist

- Maintenance Checklist

- Planning Checklist

- Manager Checklist

- Wedding Checklist

- Vehicle Checklist

- Travel Agency Checklist

- Vehicle Inspection Checklist

- Interior Design Checklist

- Backpacking Checklist

- Business Checklist

- Legal Checklist

- Nursing Home Checklist

- Weekly Checklist

- Recruitment Checklist

- Salon Checklist

- Baby Checklist

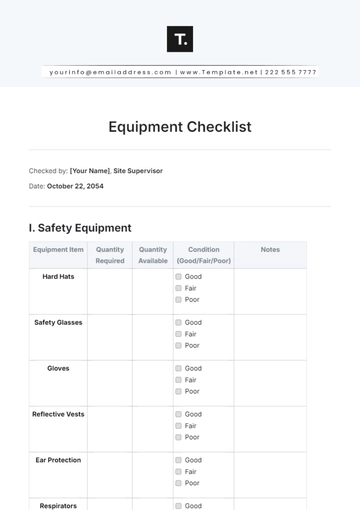

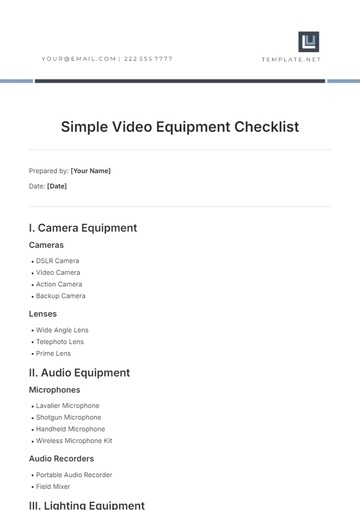

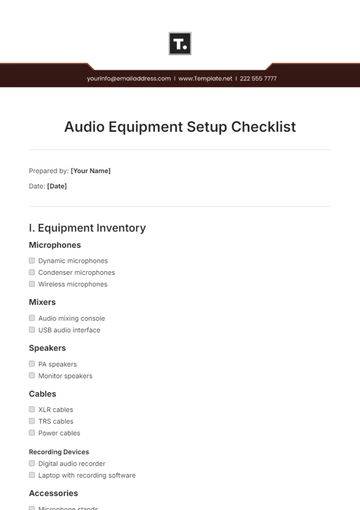

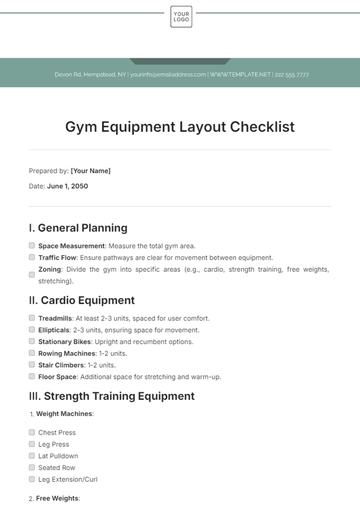

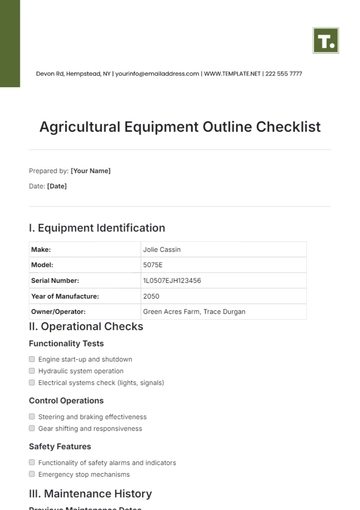

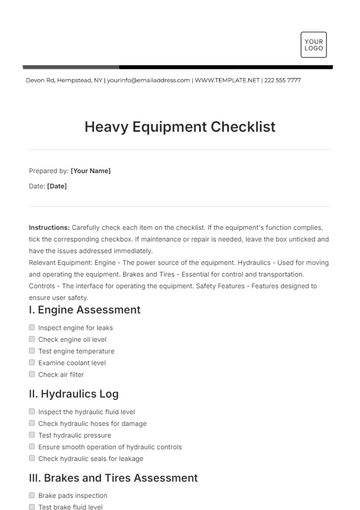

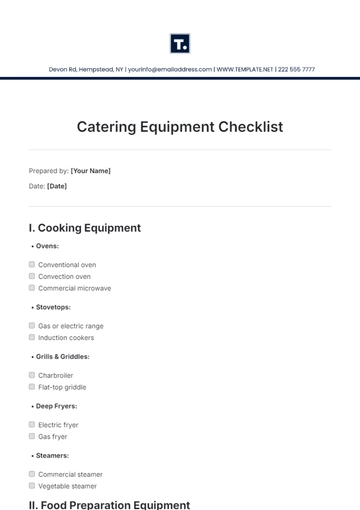

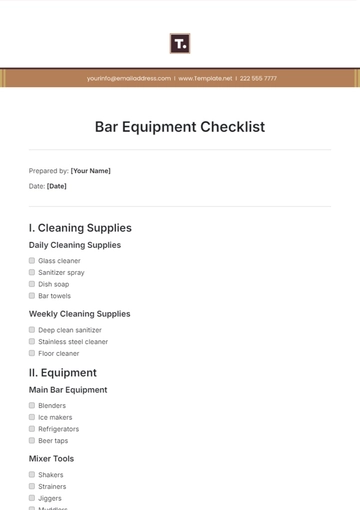

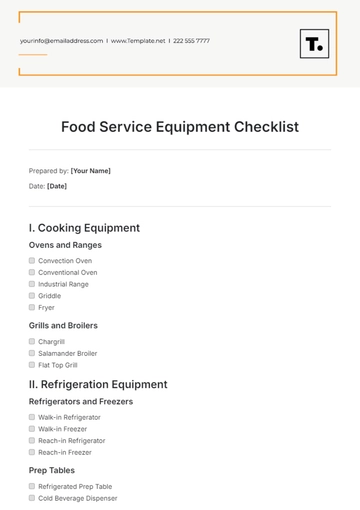

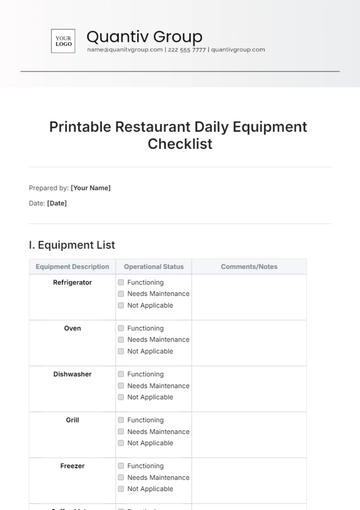

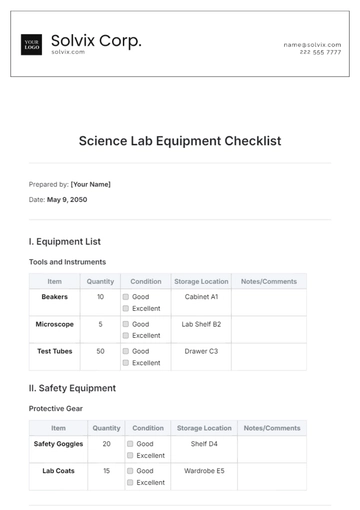

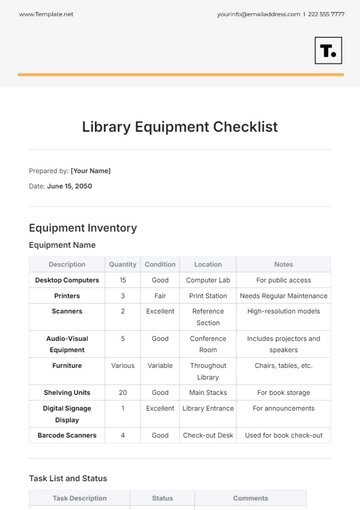

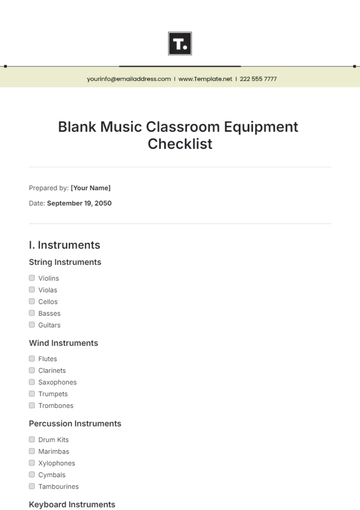

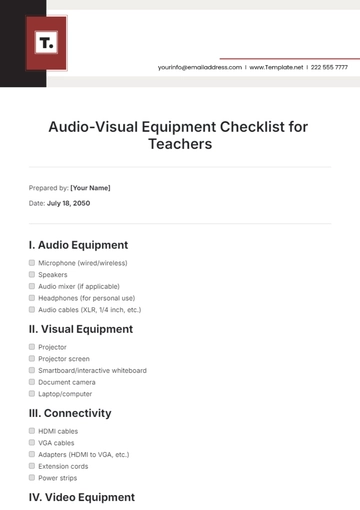

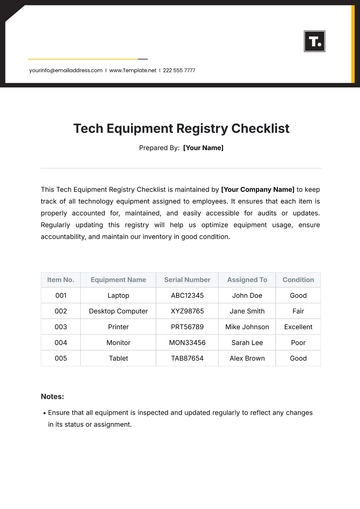

- Equipment Checklist

- Trade Show Checklist

- Party Checklist

- Hospital Bag Checklist

- Evaluation Checklist

- Agency Checklist

- First Apartment Checklist

- Hiring Checklist

- Opening Checklist

- Small Business Checklist

- Rental Checklist

- College Dorm Checklist

- New Puppy Checklist

- University Checklist

- Building Maintenance Checklist

- Work From Home Checklist

- Student Checklist

- Application Checklist