Free Air Compressor Safety Checklist

Owner: [Your Name]

Company: [Your Company Name]

Date: November 2, 2052

Objective: This checklist facilitates the inspection process for operational safety in air compressor equipment.

Pre-Operation Inspection

Visual Inspection: Check for visible damage or leakages in the air compressor.

Fluid Levels: Confirm sufficient oil and fuel levels for operation.

Belt Tension: Ensure the compressor's belt is properly tensioned without signs of wear.

Safety Relief Valves: Test safety relief valves for proper operation.

Guidelines Review: Review manufacturer's instructions and safety guidelines.

During Operation Checks

Pressure Monitoring: Monitor the pressure gauge to stay within safe operating limits.

Ventilation: Verify compressor use only in well-ventilated areas.

Optimal Speed: Operate the compressor at optimal speed as per the built-in regulator.

Protective Equipment: Confirm users wear suitable protective equipment.

Noise and Vibration: Listen for any unusual noises or vibrations from the compressor.

Post-Operation Procedures

Shutdown Procedure: Ensure proper shutdown following manufacturer's guidelines.

Cool Down: Allow the compressor to cool down before cleaning or maintenance.

Post-Operation Inspection: Inspect for wear or potential issues post-operation.

Documentation: Document findings, observations, and actions taken during the inspection.

Storage: Store the air compressor in a safe and dry location.

By adhering to this checklist, we prioritize the safety and optimal functioning of air compressor equipment. Regular inspections and documented actions contribute to equipment longevity and user safety.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Ensure workplace safety with the use of Template.net "Air Compressor Safety Checklist Template." Customizable and downloadable, this checklist streamlines safety inspections for air compressor usage. Tailor it effortlessly using the help of our AI Editor Tool, addressing specific safety concerns. Download now from Template.net to enhance safety measures, prevent accidents, and create a very secure work environment for your team.

You may also like

- Cleaning Checklist

- Daily Checklist

- Travel Checklist

- Self Care Checklist

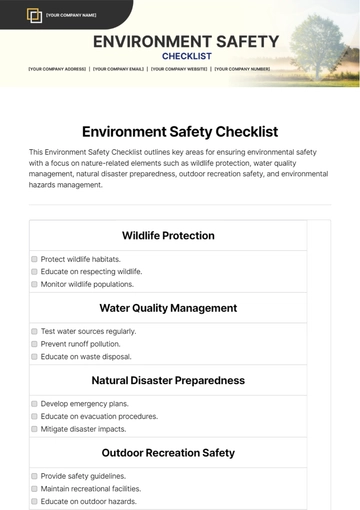

- Risk Assessment Checklist

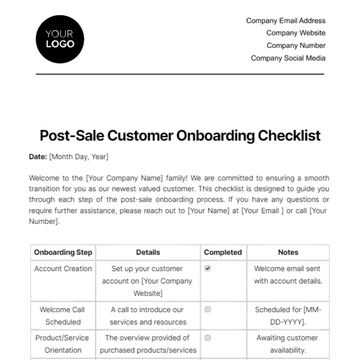

- Onboarding Checklist

- Quality Checklist

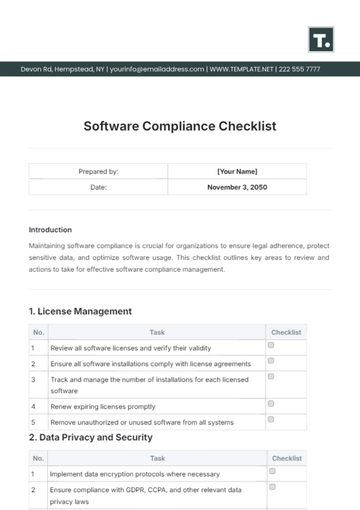

- Compliance Checklist

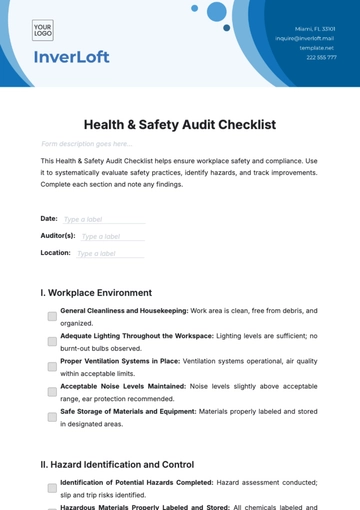

- Audit Checklist

- Registry Checklist

- HR Checklist

- Restaurant Checklist

- Checklist Layout

- Creative Checklist

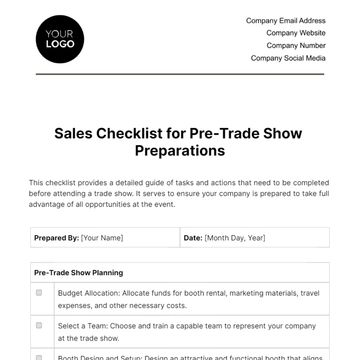

- Sales Checklist

- Construction Checklist

- Task Checklist

- Professional Checklist

- Hotel Checklist

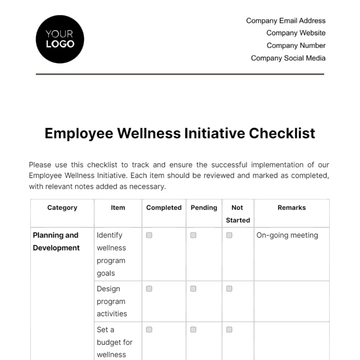

- Employee Checklist

- Moving Checklist

- Marketing Checklist

- Accounting Checklist

- Camping Checklist

- Packing Checklist

- Real Estate Checklist

- Cleaning Checklist Service

- New Employee Checklist

- Food Checklist

- Home Inspection Checklist

- Advertising Checklist

- Event Checklist

- SEO Checklist

- Assessment Checklist

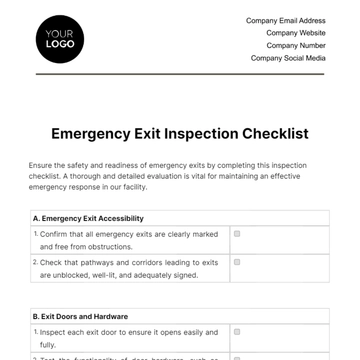

- Inspection Checklist

- Baby Registry Checklist

- Induction Checklist

- Employee Training Checklist

- Medical Checklist

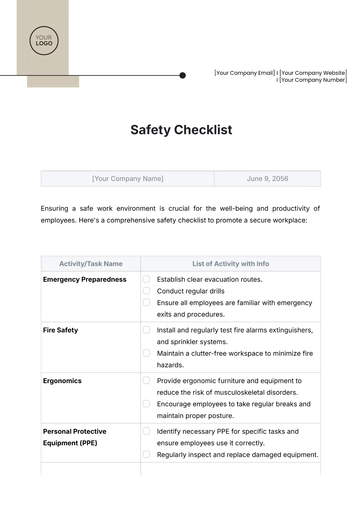

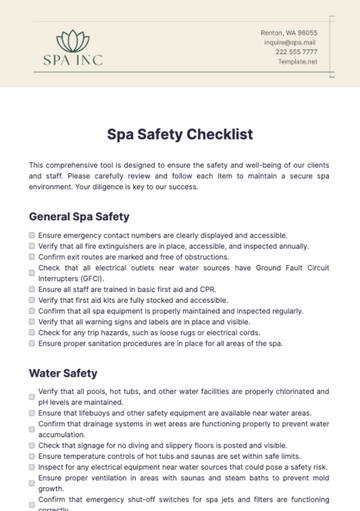

- Safety Checklist

- Site Checklist

- Job Checklist

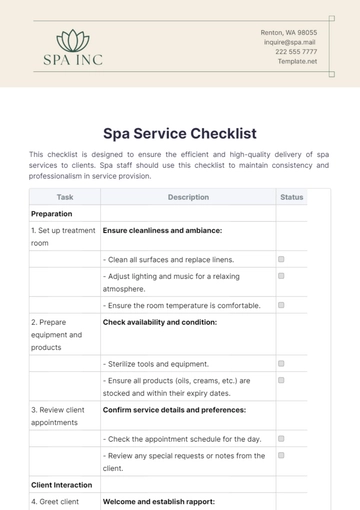

- Service Checklist

- Nanny Checklist

- Building Checklist

- Work Checklist

- Office Checklist

- Training Checklist

- Website Checklist

- IT and Software Checklist

- Performance Checklist

- Project Checklist

- Startup Checklist

- Education Checklist

- Home Checklist

- School Checklist

- Maintenance Checklist

- Planning Checklist

- Manager Checklist

- Wedding Checklist

- Vehicle Checklist

- Travel Agency Checklist

- Vehicle Inspection Checklist

- Interior Design Checklist

- Backpacking Checklist

- Business Checklist

- Legal Checklist

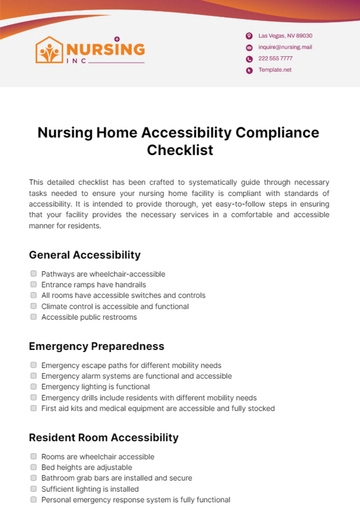

- Nursing Home Checklist

- Weekly Checklist

- Recruitment Checklist

- Salon Checklist

- Baby Checklist

- Equipment Checklist

- Trade Show Checklist

- Party Checklist

- Hospital Bag Checklist

- Evaluation Checklist

- Agency Checklist

- First Apartment Checklist

- Hiring Checklist

- Opening Checklist

- Small Business Checklist

- Rental Checklist

- College Dorm Checklist

- New Puppy Checklist

- University Checklist

- Building Maintenance Checklist

- Work From Home Checklist

- Student Checklist

- Application Checklist