Free Equipment Maintenance Checklist

Follow the instructions listed in each category to ensure thorough equipment maintenance. Check the boxes as each task is completed. Remember, regular checking and logging of these maintenance tasks is vital to keep equipment running at tip-top condition.

Equipment Subjected to this Checklist:

Engine Unit: This is the core component of machinery that converts energy into useful work.

Fluid Systems: These include hydraulics, coolant, and oil systems integral to equipment operations.

Calibration Equipment: Devices used to adjust the accuracy of machine output.

Engine Unit Maintenance

Inspect the engine unit for any visible damages or signs of wear

Lubricate all moving parts according to the manufacturer's manual instructions

Record engine performance data, including temperature, pressure, and any anomalies

Conduct a comprehensive test of the engine unit following maintenance tasks

Replace any worn-out or damaged parts identified during the inspection

Clean engine components, including air filters and intake systems, to ensure optimal airflow and combustion

Inspect engine belts and tensioners for proper alignment and tension, adjusting or replacing as necessary

Check and replace engine fluids (e.g., engine oil, coolant) according to the recommended maintenance schedule

Fluid Systems Check

Inspect fluid systems for any signs of leaks or potential damage

Check fluid levels (hydraulic, coolant, oil) and top up as needed according to specifications

Perform pressure tests on hydraulic systems to ensure proper functioning

Record data related to fluid levels, pressure tests, and any maintenance performed

Replace or repair damaged hoses or connectors to prevent leaks and ensure system integrity

Inspect fluid reservoirs for contaminants or debris, and clean or flush if necessary

Test the functionality of fluid system components, such as pumps, valves, and filters

Inspect fluid system hoses and fittings for signs of degradation or deterioration, and replace them if needed

Calibration Equipment Assessment

Check calibration equipment for precision and accuracy before use

Calibrate machinery according to the instructions provided in the user manual or equipment specifications

Document calibration results, including adjustments made and any deviations from standards

Test the machinery after calibration to verify accuracy and performance

Replace calibration equipment if it is found to be faulty or unable to meet accuracy requirements

Verify the accuracy of calibration standards and reference materials used in the calibration process

Perform a traceability check to ensure that calibration equipment is calibrated to recognized standards

Document any adjustments made during calibration, including the date, time, and personnel involved

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Maximize operational efficiency with our Equipment Maintenance Checklist Template from Template.net. This versatile tool, customized to your specific needs, ensures precise equipment upkeep. Seamlessly personalize it with our intuitive Ai Editor Tool, facilitating thorough maintenance routines and comprehensive equipment care in a user-friendly interface, enhancing productivity and minimizing downtime.

You may also like

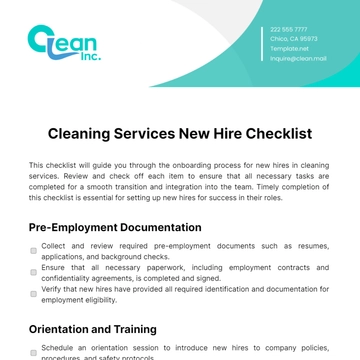

- Cleaning Checklist

- Daily Checklist

- Travel Checklist

- Self Care Checklist

- Risk Assessment Checklist

- Onboarding Checklist

- Quality Checklist

- Compliance Checklist

- Audit Checklist

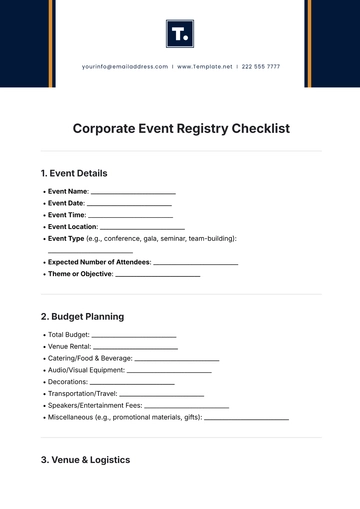

- Registry Checklist

- HR Checklist

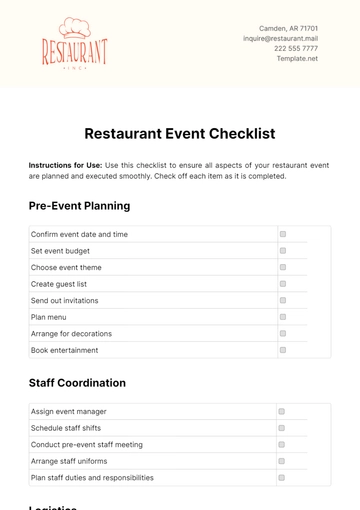

- Restaurant Checklist

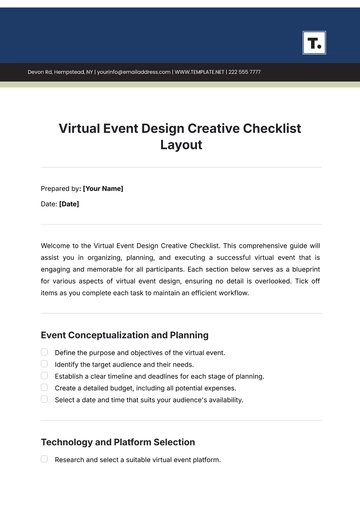

- Checklist Layout

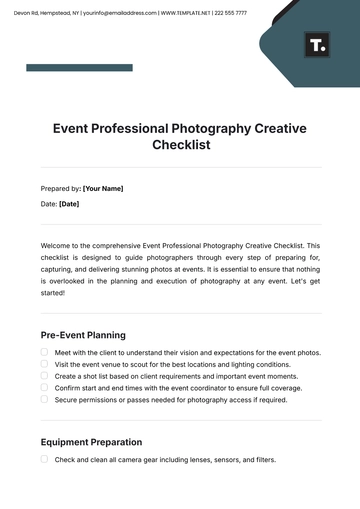

- Creative Checklist

- Sales Checklist

- Construction Checklist

- Task Checklist

- Professional Checklist

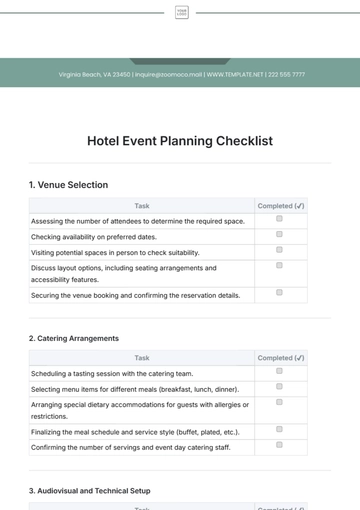

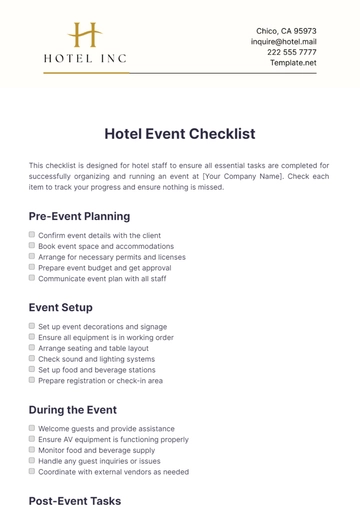

- Hotel Checklist

- Employee Checklist

- Moving Checklist

- Marketing Checklist

- Accounting Checklist

- Camping Checklist

- Packing Checklist

- Real Estate Checklist

- Cleaning Checklist Service

- New Employee Checklist

- Food Checklist

- Home Inspection Checklist

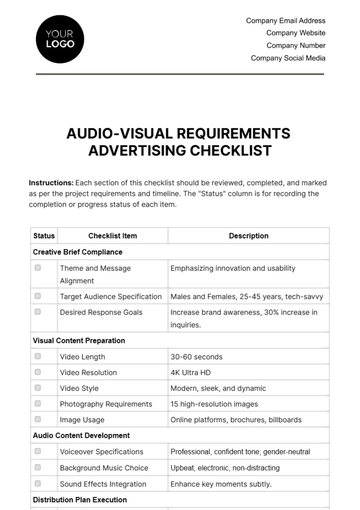

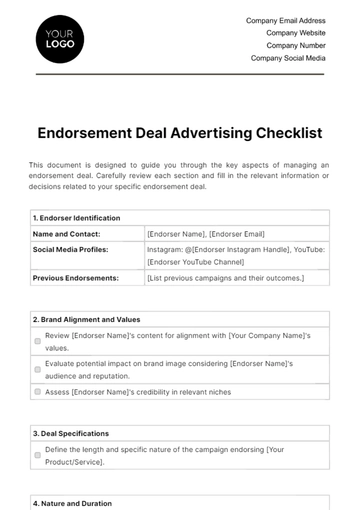

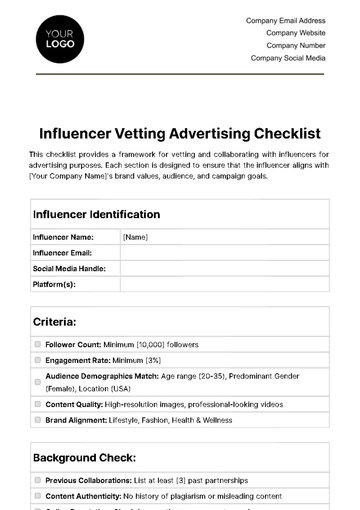

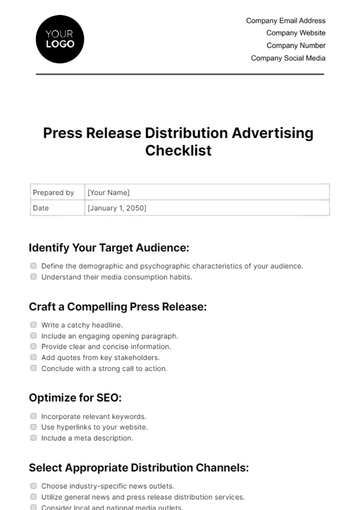

- Advertising Checklist

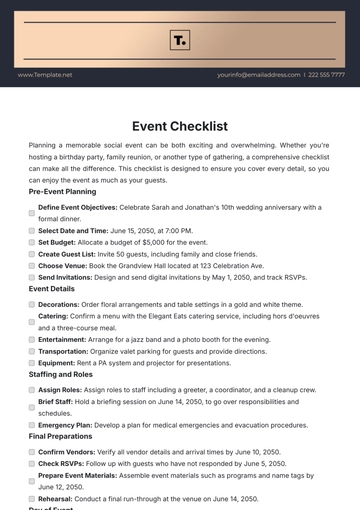

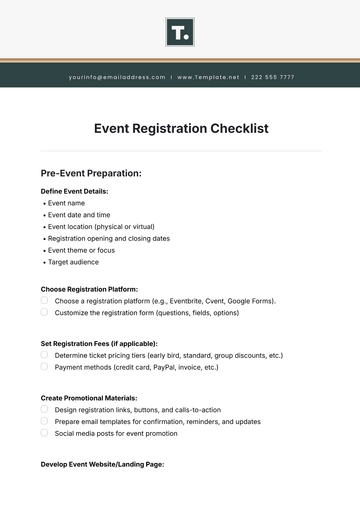

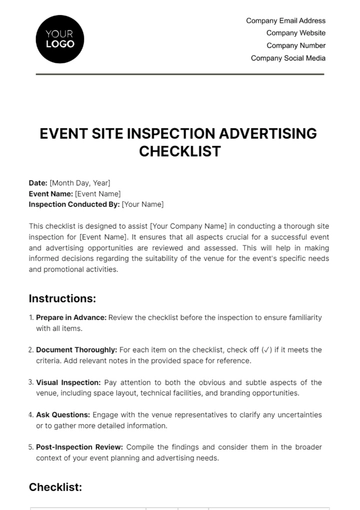

- Event Checklist

- SEO Checklist

- Assessment Checklist

- Inspection Checklist

- Baby Registry Checklist

- Induction Checklist

- Employee Training Checklist

- Medical Checklist

- Safety Checklist

- Site Checklist

- Job Checklist

- Service Checklist

- Nanny Checklist

- Building Checklist

- Work Checklist

- Office Checklist

- Training Checklist

- Website Checklist

- IT and Software Checklist

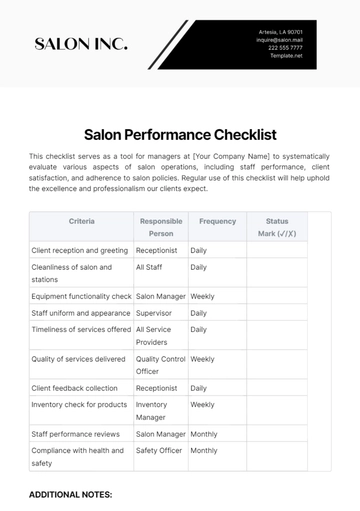

- Performance Checklist

- Project Checklist

- Startup Checklist

- Education Checklist

- Home Checklist

- School Checklist

- Maintenance Checklist

- Planning Checklist

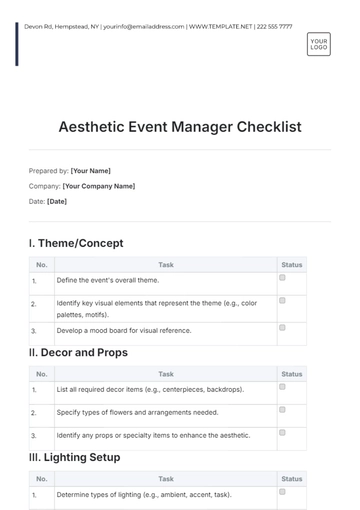

- Manager Checklist

- Wedding Checklist

- Vehicle Checklist

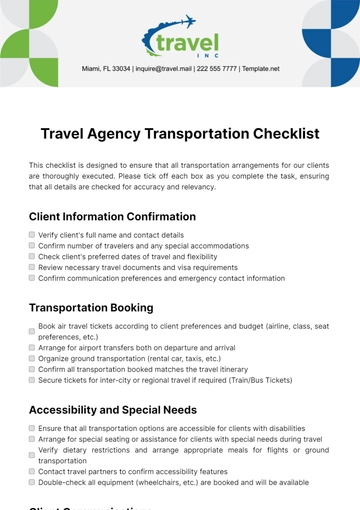

- Travel Agency Checklist

- Vehicle Inspection Checklist

- Interior Design Checklist

- Backpacking Checklist

- Business Checklist

- Legal Checklist

- Nursing Home Checklist

- Weekly Checklist

- Recruitment Checklist

- Salon Checklist

- Baby Checklist

- Equipment Checklist

- Trade Show Checklist

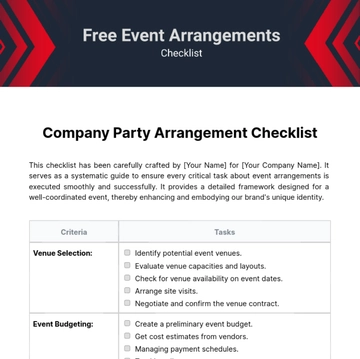

- Party Checklist

- Hospital Bag Checklist

- Evaluation Checklist

- Agency Checklist

- First Apartment Checklist

- Hiring Checklist

- Opening Checklist

- Small Business Checklist

- Rental Checklist

- College Dorm Checklist

- New Puppy Checklist

- University Checklist

- Building Maintenance Checklist

- Work From Home Checklist

- Student Checklist

- Application Checklist