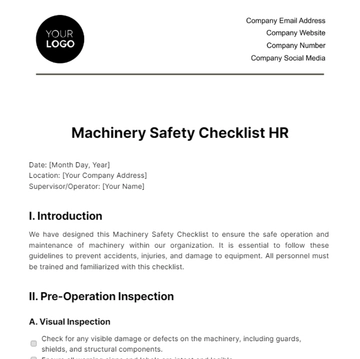

Free Machinery Safety Checklist HR

Date: [Month Day, Year]

Location: [Your Company Address]

Supervisor/Operator: [Your Name]

I. Introduction

We have designed this Machinery Safety Checklist to ensure the safe operation and maintenance of machinery within our organization. It is essential to follow these guidelines to prevent accidents, injuries, and damage to equipment. All personnel must be trained and familiarized with this checklist.

II. Pre-Operation Inspection

A. Visual Inspection

Check for any visible damage or defects on the machinery, including guards, shields, and structural components.

Ensure all warning signs and labels are intact and legible.

Verify that emergency stop buttons and switches are accessible and functional.

B. Safety Devices

Confirm that safety interlocks, sensors, and emergency stop systems are operational.

Test the functionality of safety alarms and warning lights.

C. Power Supply

Check the power source for proper voltage and grounding.

Inspect power cables and connectors for damage.

D. Fluids and Lubrication

Verify fluid levels (e.g., oil, coolant, hydraulic fluid) are within the recommended range.

Ensure that an employee has adequately greased the lubrication points.

III. Start-Up Procedures

A. Operator Training

Ensure only trained and authorized personnel operate the machinery.

Confirm that operators are wearing appropriate personal protective equipment (PPE).

B. Clear Work Area

Remove any obstacles or debris in the vicinity of the machinery.

Maintain clear walkways and emergency exits.

C. Machine Startup

Follow the manufacturer's recommended startup procedure.

Monitor for abnormal noises, vibrations, or leaks during startup.

IV. During Operation

A. Operating Conditions

Monitor machinery for unusual vibrations, sounds, or odors.

Pay attention to warning indicators and alarms.

B. Emergency Response

Know the location and proper use of emergency stop buttons.

Be prepared to shut down the machinery in case of an emergency.

V. Maintenance and Shutdown

A. Regular Maintenance

Follow the manufacturer's maintenance schedule.

Ensure maintenance personnel are trained and equipped for their tasks.

B. Shutdown Procedure

Follow the manufacturer's recommended shutdown procedure.

Turn off power sources and lockout/tagout equipment if necessary.

VI. Post-Operation Inspection

A. Visual Inspection

Inspect the machinery for any damage or wear and tear.

Ensure all employees have removed all the tools and equipment from the machine.

B. Safety Devices

Verify that all safety devices and guards are in place.

Confirm that someone has reset the emergency stop systems.

C. Documentation

Record any issues or maintenance performed during the shift.

Report any abnormalities to the supervisor or maintenance department.

VII. Reporting and Documentation

A. Incident Reporting

Report any accidents, near-misses, or safety concerns immediately to the supervisor.

Complete incident reports as required.

B. Record Keeping

Maintain records of inspections, maintenance, and incidents for compliance and auditing purposes.

VIII. Conclusion

This Machinery Safety Checklist is an essential tool for promoting a safe working environment. Regular inspections and adherence to safety protocols are critical to preventing accidents and ensuring the longevity of our machinery. If you have any questions or concerns regarding machinery safety, please contact the HR department or your supervisor.

_______________________

[Your Name]

[Month Day, Year]

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Discover the ultimate safeguard for your workplace with Template.net's Machinery Safety Checklist HR Template. Crafted for efficiency, it's fully editable and customizable, tailored to your needs. Seamlessly integrate AI Editor Tool for precision and speed. Ensure compliance effortlessly. Protect your team, enhance productivity—get your customizable Machinery Safety Checklist HR Template now, exclusively on Template.net.

You may also like

- Cleaning Checklist

- Daily Checklist

- Travel Checklist

- Self Care Checklist

- Risk Assessment Checklist

- Onboarding Checklist

- Quality Checklist

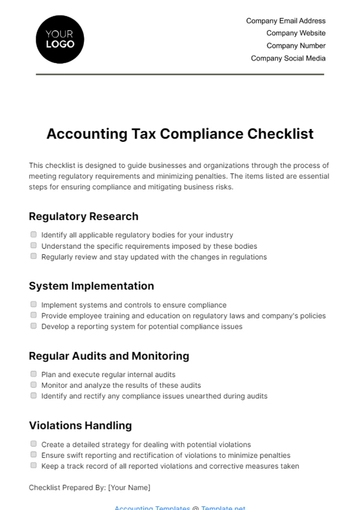

- Compliance Checklist

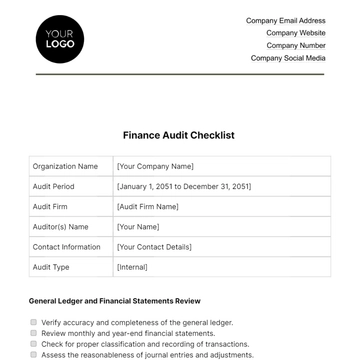

- Audit Checklist

- Registry Checklist

- HR Checklist

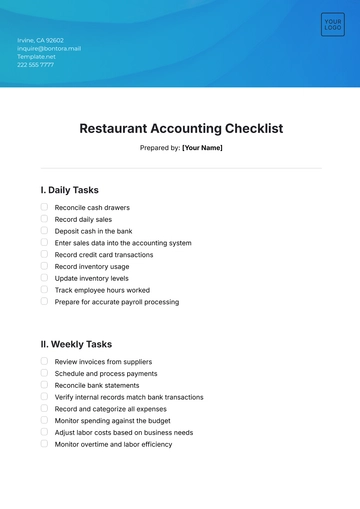

- Restaurant Checklist

- Checklist Layout

- Creative Checklist

- Sales Checklist

- Construction Checklist

- Task Checklist

- Professional Checklist

- Hotel Checklist

- Employee Checklist

- Moving Checklist

- Marketing Checklist

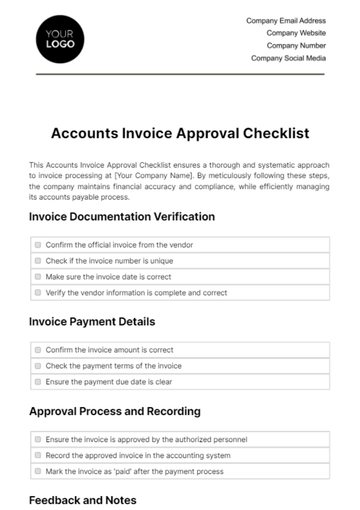

- Accounting Checklist

- Camping Checklist

- Packing Checklist

- Real Estate Checklist

- Cleaning Checklist Service

- New Employee Checklist

- Food Checklist

- Home Inspection Checklist

- Advertising Checklist

- Event Checklist

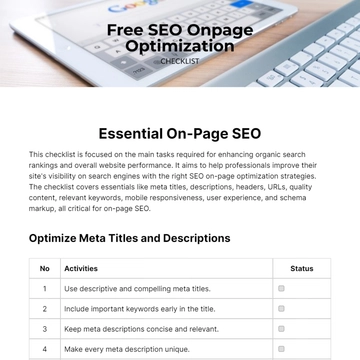

- SEO Checklist

- Assessment Checklist

- Inspection Checklist

- Baby Registry Checklist

- Induction Checklist

- Employee Training Checklist

- Medical Checklist

- Safety Checklist

- Site Checklist

- Job Checklist

- Service Checklist

- Nanny Checklist

- Building Checklist

- Work Checklist

- Office Checklist

- Training Checklist

- Website Checklist

- IT and Software Checklist

- Performance Checklist

- Project Checklist

- Startup Checklist

- Education Checklist

- Home Checklist

- School Checklist

- Maintenance Checklist

- Planning Checklist

- Manager Checklist

- Wedding Checklist

- Vehicle Checklist

- Travel Agency Checklist

- Vehicle Inspection Checklist

- Interior Design Checklist

- Backpacking Checklist

- Business Checklist

- Legal Checklist

- Nursing Home Checklist

- Weekly Checklist

- Recruitment Checklist

- Salon Checklist

- Baby Checklist

- Equipment Checklist

- Trade Show Checklist

- Party Checklist

- Hospital Bag Checklist

- Evaluation Checklist

- Agency Checklist

- First Apartment Checklist

- Hiring Checklist

- Opening Checklist

- Small Business Checklist

- Rental Checklist

- College Dorm Checklist

- New Puppy Checklist

- University Checklist

- Building Maintenance Checklist

- Work From Home Checklist

- Student Checklist

- Application Checklist