Startup Supply Chain Management Guide

Guide Version: [x]

Introduction

The ability to handle supply chain management effectively is critical to the success of any startup. This comprehensive guide will walk you through understanding the basics, getting started, a step-by-step approach to managing your supply chain, troubleshooting common issues, and frequently asked questions. Let’s dive in on how to efficiently manage your business flow.

Getting Started

Before you start, it’s important to understand a few key concepts:

Supply Chain: This term refers to the entire process of making and selling commercial goods, including every stage from the supply of raw materials and parts to the delivery of finished products to consumers.

Supply Chain Management(SCM): This refers to the process of managing the flow of goods and services, involves the movement and storage of raw materials, work-in-process inventory, and finished goods from point of origin to point of consumption.

Supply Chain Management, in Detail

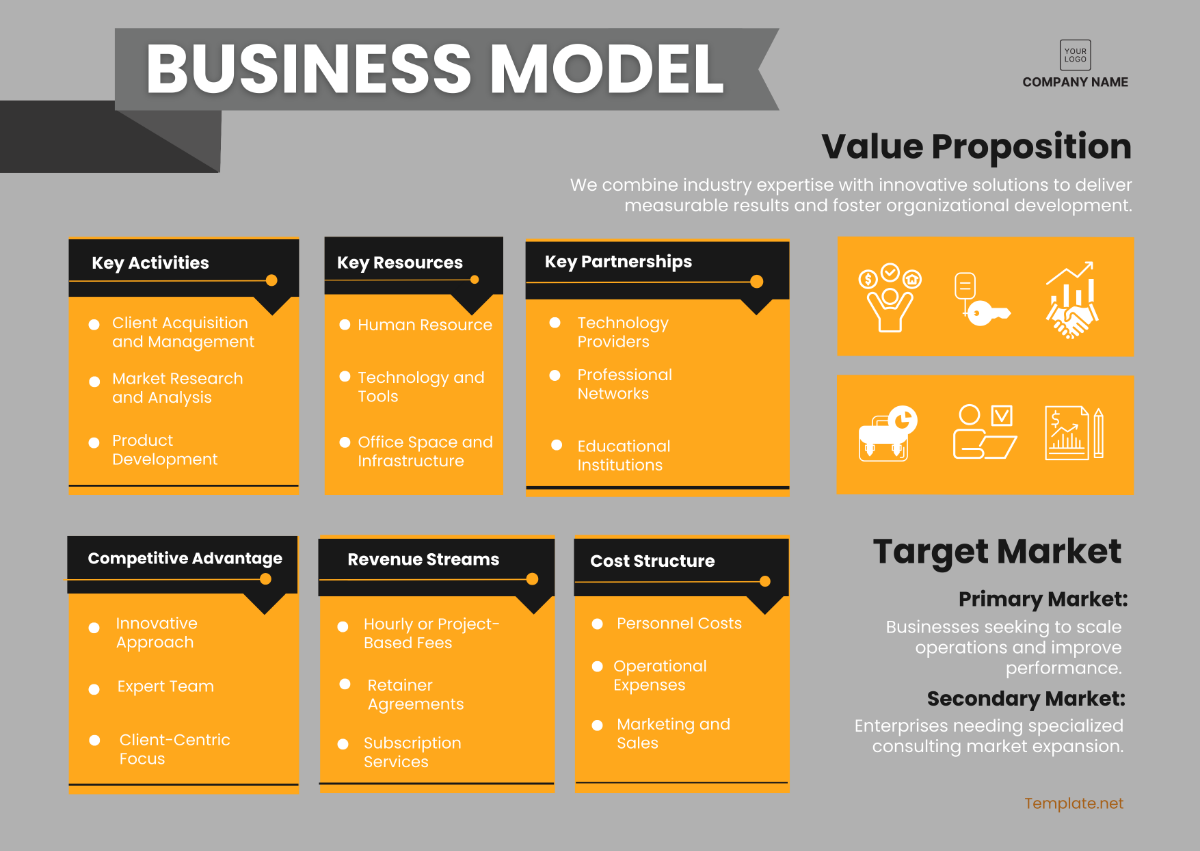

Definition of Supply Chain Management: Supply chain management (SCM) encompasses the end-to-end coordination and optimization of all activities involved in sourcing, procurement, production, logistics, and distribution of goods or services. It involves the strategic planning and execution of processes to ensure the efficient flow of materials, information, and capital from suppliers to customers.

Importance of Effective Supply Chain Management for Startups: Efficient supply chain management is critical for startups to compete effectively in the marketplace. It impacts various aspects of the business, including cost management, customer satisfaction, product quality, and market responsiveness. By streamlining operations, startups can minimize lead times, reduce costs, improve product availability, and enhance overall competitiveness.

Components of a Supply Chain

A typical supply chain consists of several interconnected components:

Component | Description |

|---|---|

Sourcing and Procurement | Identifying suppliers, negotiating contracts, managing supplier relationships, and procuring raw materials or services. |

Production and Operations | Transforming raw materials into finished products through manufacturing processes. |

Inventory Management | Balancing supply and demand to optimize inventory levels while minimizing holding costs. |

Warehousing and Distribution | Storing, handling, and transporting goods to distribution centers or directly to customers. |

Information Flow | Communicating and sharing data across the supply chain to enable coordination and decision-making. |

Logistics and Transportation | Managing the movement of goods between suppliers, manufacturers, warehouses, and customers. |

Designing Your Supply Chain

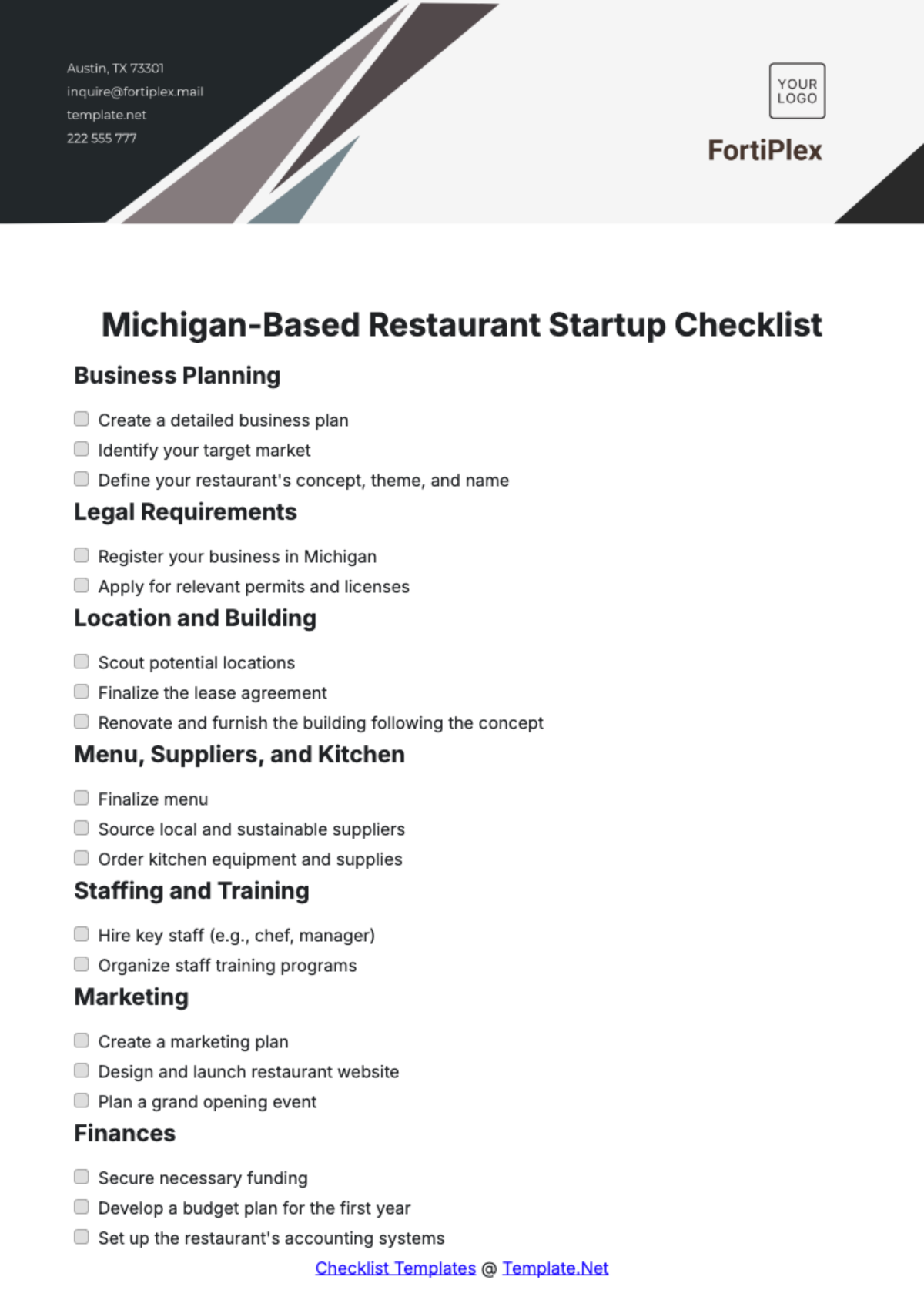

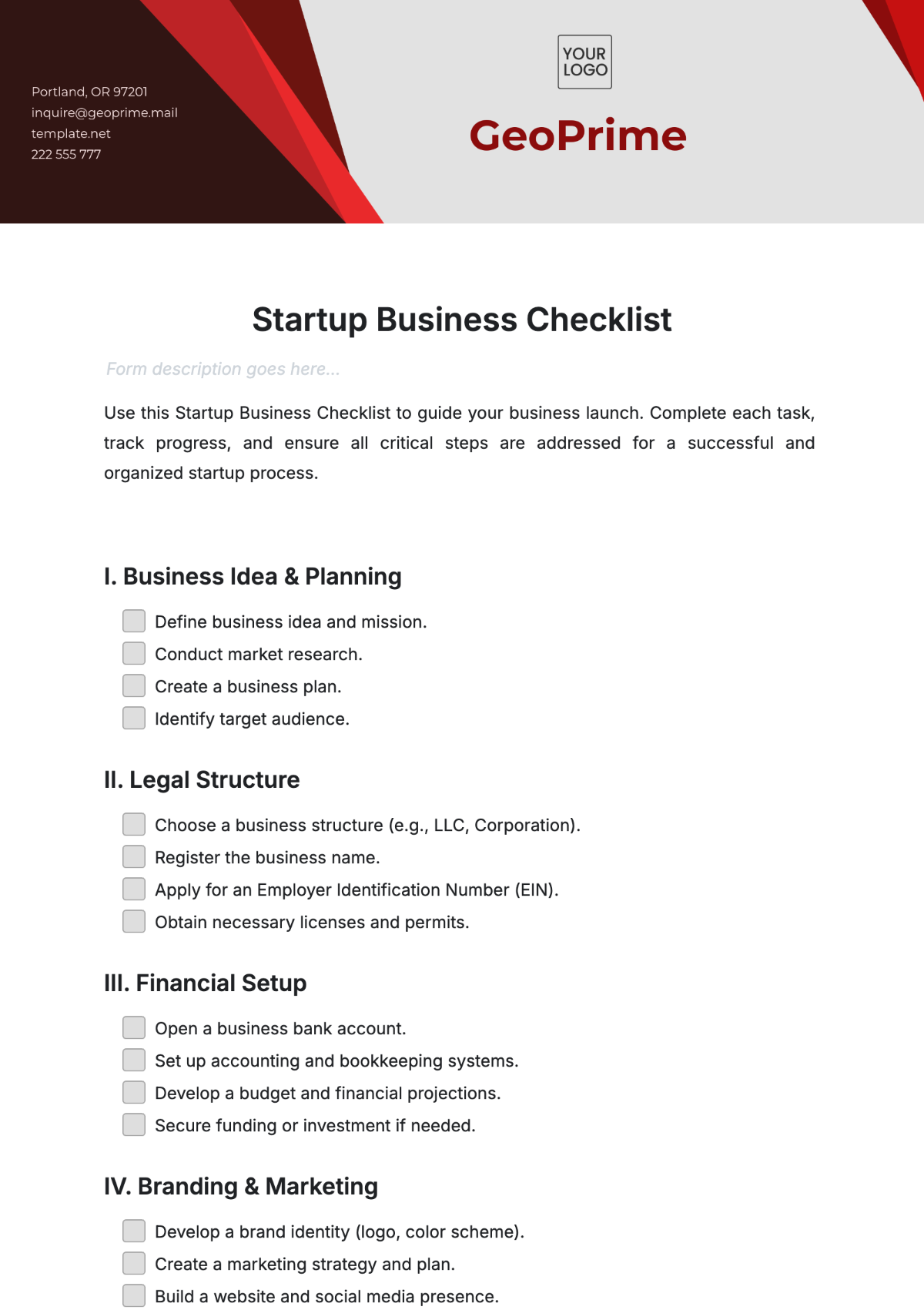

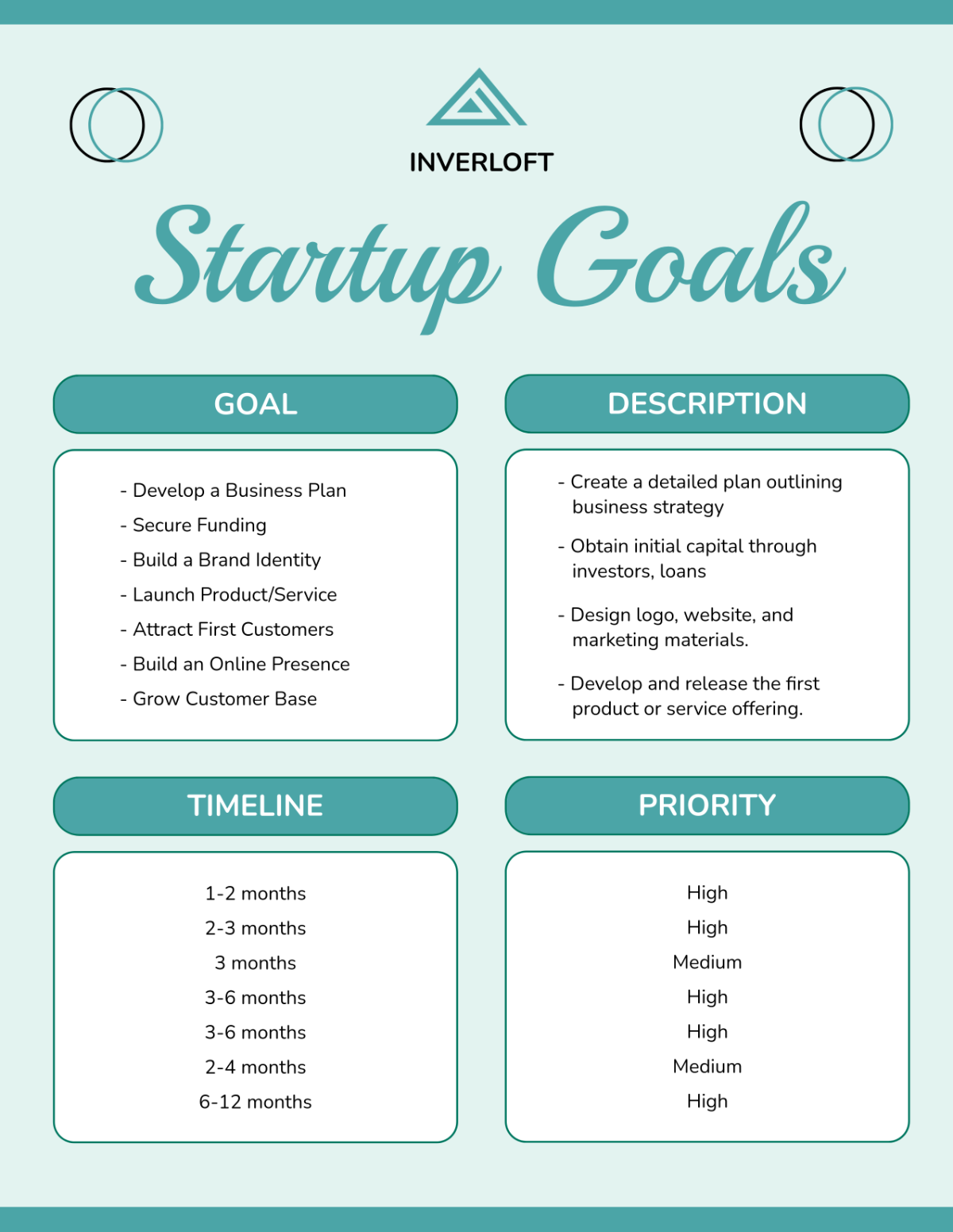

Determining Your Supply Chain Objectives and Goals: Startups should define clear supply chain objectives aligned with their overall business goals. Whether it's minimizing costs, improving customer service, or achieving sustainability targets, setting specific, measurable, achievable, relevant, and time-bound (SMART) objectives provides direction for supply chain design and management.

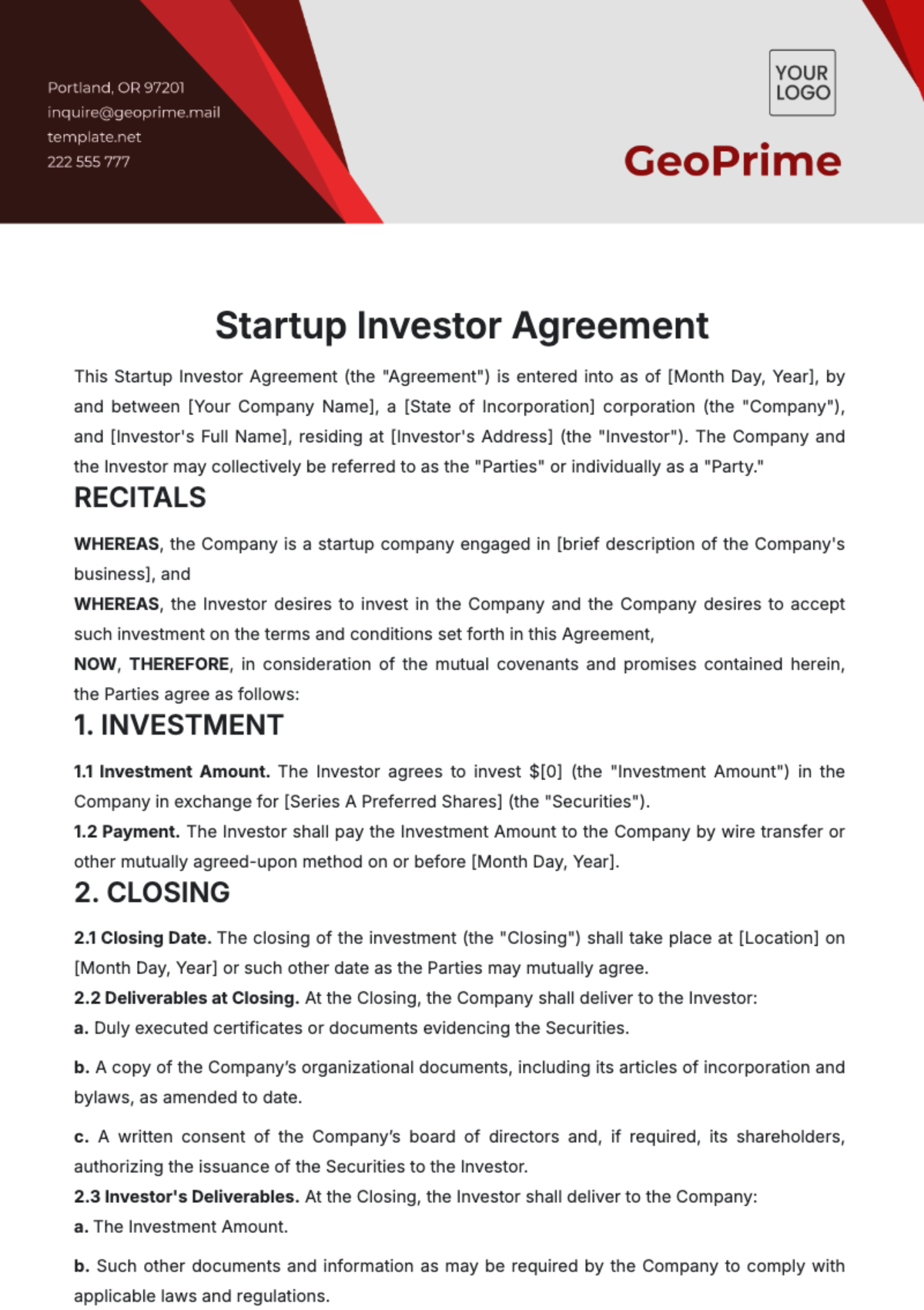

Selecting Suppliers and Partners: Choose suppliers and partners carefully based on factors such as reliability, quality, cost, and alignment with your values and objectives. Conduct thorough supplier assessments and due diligence to ensure compatibility and mitigate risks associated with supply chain disruptions.

Designing the Flow of Goods and Information: Map out the flow of materials, information, and financial transactions across the supply chain. Design efficient processes for order fulfillment, production scheduling, inventory replenishment, and demand forecasting to minimize lead times, reduce bottlenecks, and optimize resource utilization.

Establishing Inventory Management Practices: Implement inventory management practices that balance the costs of holding inventory with the risks of stockouts or excess inventory. Utilize techniques such as ABC analysis, economic order quantity (EOQ), and just-in-time (JIT) inventory management to optimize inventory levels and improve cash flow.

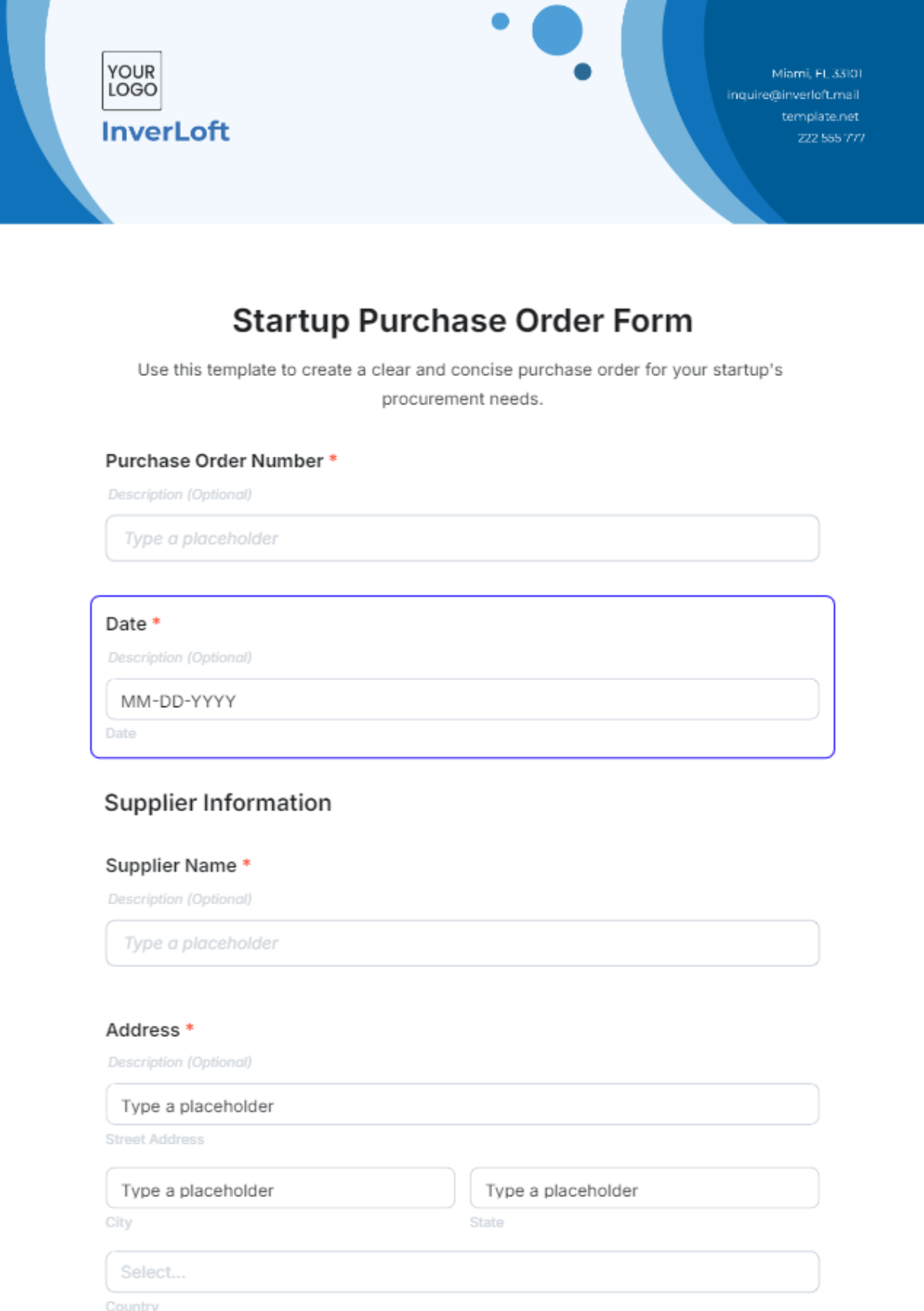

Procurement and Sourcing

Strategic Sourcing Strategies: Develop a strategic approach to sourcing that aligns with your startup's goals and values. This involves conducting thorough market research, identifying potential suppliers, and evaluating their capabilities, reliability, and cost-effectiveness. Implement strategies such as supplier consolidation, long-term partnerships, and global sourcing to optimize procurement processes and enhance supply chain efficiency.

Supplier Relationship Management: Cultivate strong relationships with key suppliers based on trust, transparency, and mutual benefit. Regular communication, performance evaluations, and feedback mechanisms are essential for maintaining positive supplier relationships. Collaborate with suppliers to drive innovation, improve quality, and mitigate risks, ensuring a seamless flow of goods and services throughout the supply chain.

Negotiation Techniques: Master negotiation techniques to secure favorable terms and conditions with suppliers while maintaining a win-win relationship. Prepare thoroughly, establish clear objectives, and leverage market insights to negotiate pricing, payment terms, delivery schedules, and service levels. Effective negotiation skills can lead to cost savings, improved quality, and enhanced supplier collaboration.

Production and Operations Management

Lean Manufacturing Principles: Adopt lean manufacturing principles to eliminate waste, optimize processes, and improve productivity throughout the production process. Implement practices such as value stream mapping, 5S methodology, and continuous flow production to streamline operations, reduce lead times, and enhance flexibility in responding to customer demand.

Just-in-Time (JIT) Inventory Management: Embrace JIT inventory management to minimize inventory holding costs while ensuring timely availability of materials and products. Maintain lean inventories by synchronizing production with customer demand, reducing excess inventory levels, and establishing efficient replenishment systems. JIT principles enable startups to reduce waste, improve cash flow, and enhance overall supply chain responsiveness.

Capacity Planning and Production Scheduling: Conduct effective capacity planning and production scheduling to optimize resource utilization and meet customer demand efficiently. Utilize demand forecasting, production scheduling software, and production control techniques to balance capacity constraints, minimize bottlenecks, and optimize throughput. Strategic capacity planning ensures that startups can scale production effectively while maintaining operational efficiency and meeting customer expectations.

Warehousing and Distribution

Warehouse Layout and Design: Design warehouse layouts that optimize space utilization, material flow, and operational efficiency. Consider factors such as product characteristics, order profiles, and material handling equipment to design functional and ergonomic warehouse layouts. Implement efficient storage systems, picking strategies, and inventory management techniques to maximize throughput and minimize handling costs.

Inventory Control and Optimization: Implement robust inventory control processes to optimize inventory levels, reduce carrying costs, and minimize stockouts. Utilize inventory management software, barcode systems, and RFID technology to track inventory levels accurately, monitor stock movements, and automate replenishment processes. Adopt inventory optimization techniques such as ABC analysis, economic order quantity (EOQ), and safety stock calculation to balance inventory investment with service levels.

Order Fulfillment Processes: Streamline order fulfillment processes to ensure accurate and timely delivery of products to customers. Implement efficient order picking, packing, and shipping processes to minimize order cycle times and enhance customer satisfaction. Utilize order management systems, picking technologies, and transportation management software to optimize order routing, reduce shipping costs, and improve order accuracy and visibility.

Transportation and Logistics Management: Develop robust transportation and logistics strategies to optimize freight costs, transit times, and service levels. Evaluate transportation modes, carriers, and routing options to minimize transportation costs while meeting customer delivery requirements. Implement transportation management systems (TMS), route optimization software, and freight consolidation strategies to improve efficiency, visibility, and control over transportation operations. Collaborate with logistics partners and leverage technology to track shipments, monitor performance, and proactively address logistics challenges.

Information Technology in Supply Chain Management

Role of Technology: Explore how technologies such as blockchain, Internet of Things (IoT), and artificial intelligence (AI) are transforming supply chain operations by enhancing visibility, traceability, and efficiency.

Implementation of SCM Systems: Guide on selecting and implementing supply chain management software tailored to startup needs, covering aspects like cost, scalability, and integration capabilities.

Data Analytics: Discuss leveraging data analytics to gain insights into demand forecasting, inventory optimization, and performance monitoring, enabling data-driven decision-making for improved efficiency and agility.

ERP Integration: Explain the benefits of integrating supply chain management systems with enterprise resource planning (ERP) platforms for seamless data exchange and holistic business management.

Risk Management in the Supply Chain

Risk Identification: Comprehensive overview of potential risks across the supply chain, including supplier disruptions, demand fluctuations, geopolitical issues, and natural disasters, emphasizing the importance of proactive risk identification.

Risk Mitigation Strategies: Detail strategies such as diversifying suppliers, establishing contingency plans, and investing in insurance to mitigate the impact of identified risks and ensure business continuity.

Business Continuity Planning: Step-by-step guide to developing robust business continuity plans that outline procedures for responding to and recovering from supply chain disruptions, safeguarding operations against unforeseen events.

Supplier Diversity: Encourage startups to prioritize supplier diversity initiatives to reduce dependence on single suppliers and enhance resilience, while also fostering innovation and social responsibility.

Sustainability and Ethical Practices

Sustainable Supply Chain Practices: Highlight the importance of adopting sustainable practices like eco-friendly packaging, energy-efficient transportation, and waste reduction to minimize environmental impact and meet consumer expectations for ethical sourcing.

Supplier Audits: Explain the process of conducting supplier audits to assess compliance with environmental regulations, labor standards, and ethical guidelines, ensuring transparency and accountability throughout the supply chain.

Ethical Sourcing: Provide guidance on sourcing materials and labor ethically, promoting fair wages, safe working conditions, and human rights adherence to uphold corporate social responsibility principles.

Environmental Impact Reduction: Offer strategies for reducing carbon footprint and greenhouse gas emissions through initiatives such as renewable energy adoption, carbon offsetting, and supply chain optimization.

Continuous Improvement and Optimization

Performance Measurement: Identify key performance indicators (KPIs) relevant to supply chain operations, such as on-time delivery, inventory turnover, and order accuracy, to track performance and identify areas for improvement.

Continuous Improvement Methodologies: Introduce methodologies like Six Sigma, Kaizen, and Total Quality Management (TQM) for driving continuous improvement in supply chain processes through problem-solving, waste reduction, and process optimization.

Feedback Loops: Stress the importance of establishing feedback loops with suppliers, customers, and internal stakeholders to gather insights, identify pain points, and drive innovation across the supply chain ecosystem.

Benchmarking: Encourage benchmarking against industry peers and best-in-class performers to identify opportunities for improvement and implement best practices that drive competitive advantage and operational excellence.

FAQs

How do I begin improving my supply chain?

The first step towards improving your supply chain is to understand it. Analyze every component, from suppliers to customers, to identify any inefficiencies or bottlenecks.

What are Key Performance Indicators in SCM?

Key Performance Indicators (KPIs) are metrics used to quantify objectives that reflect the performance of an organization. In SCM, KPIs could include order delivery time, time taken from order to delivery, sales, etc.

Conclusion

That concludes our guide to Startup Supply Chain Management. Managing your supply chain efficiently can significantly improve your startup's performance. Remember these final tips:

Understand your supply chain's details. Never stop learning about it.

Measure performance using KPIs to identify areas of improvement.

Implement strategies that tackle the identified issues efficiently and effectively

Monitor and adjust. Continuously evaluate how your supply chain runs and make improvements as needed.