Operations Supply Chain Feasibility Study

I. Executive Summary

This feasibility study provides a comprehensive assessment of the proposed implementation of a Just-In-Time (JIT) inventory system. The company has been facing challenges with high storage costs and product availability issues. The JIT system, by reducing inventory levels and enhancing supply chain efficiency, could potentially address these problems.

The study covers various aspects of the proposed operation. It includes a market analysis that examines the demand for the company’s products, current market trends, and future projections. The technical feasibility assessment evaluates the company’s facilities, equipment, and software needs. The operational feasibility assessment looks at the logistics, delivery systems, and process flows. The financial feasibility assessment analyzes the costs and potential savings associated with implementing the JIT system. Lastly, the study considers the legal and regulatory implications of implementing the JIT system.

The findings suggest that the company has the necessary resources and capabilities to implement the JIT system. While there are significant upfront costs, the potential savings in storage costs and lost sales could make it a financially viable option. The company has also considered potential legal and regulatory implications and has plans in place to ensure compliance. Therefore, the study concludes that the implementation of the JIT system is feasible. However, careful planning and execution will be required for successful implementation.

II. Introduction

A. Purpose of the Study

The objective of this feasibility study is to assess the practicality of implementing a Just-In-Time (JIT) inventory system. The company has been grappling with high storage costs and issues related to product availability. The proposed JIT system could potentially alleviate these challenges by reducing inventory levels and enhancing supply chain efficiency.

B. Business Problem

Over the past fiscal year, the company has experienced a 20% increase in storage costs due to excess inventory. This has not only impacted the bottom line but also led to product availability issues, with popular items often out of stock while less popular items remain unsold in the warehouse. These challenges have underscored the need for a more efficient inventory management system. The proposed JIT system is expected to address these issues by aligning inventory levels more closely with market demand. This feasibility study will provide a comprehensive assessment of the proposed system, examining its technical, operational, and financial viability, as well as any potential legal or regulatory considerations. The findings of this study will inform the decision on whether to proceed with the implementation of the JIT system.

III. Project Description

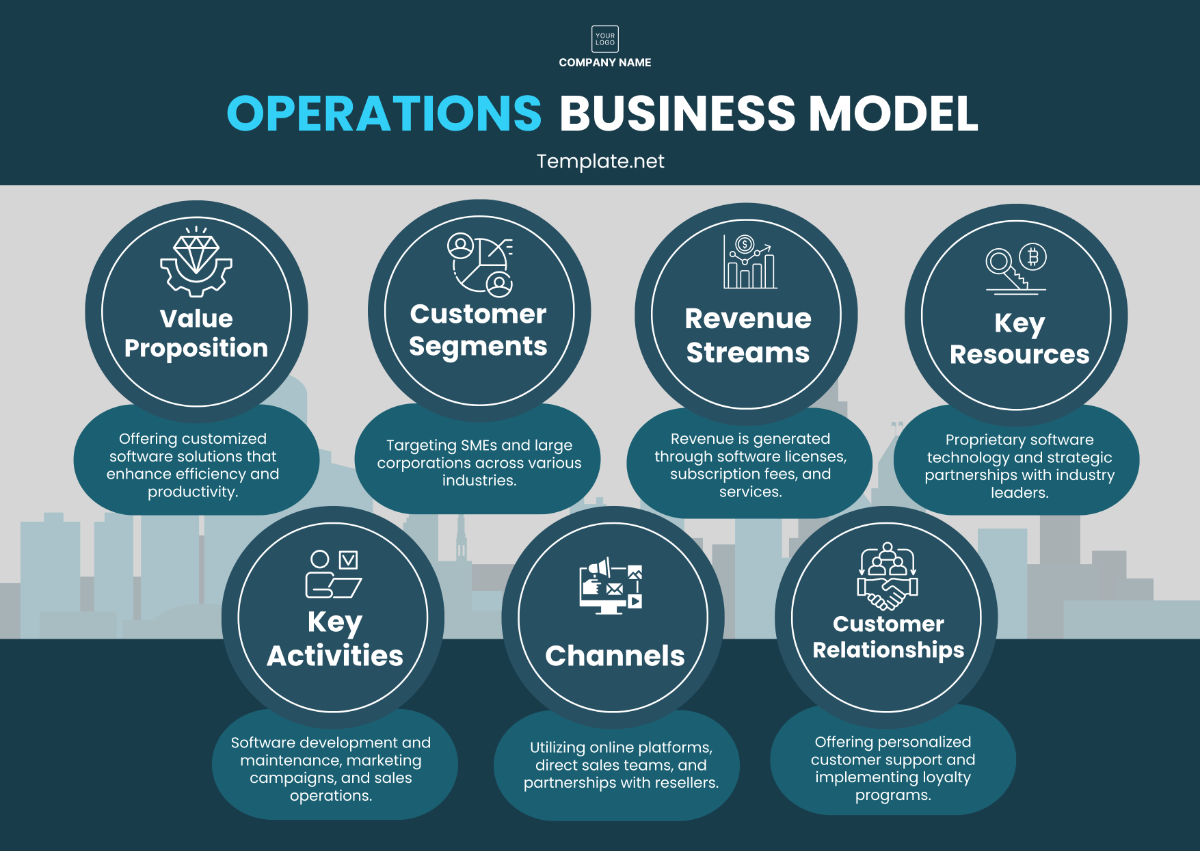

A. Proposed Operation

The proposed operation involves the implementation of a Just-In-Time (JIT) inventory system. This system is designed to streamline the company’s supply chain by ensuring that inventory levels are closely aligned with market demand. The JIT system aims to reduce storage costs and improve product availability by minimizing the amount of inventory that needs to be stored and by ensuring that products are produced and delivered just in time to meet customer demand.

B. Products or Services

The company offers a diverse range of products, which are subject to varying levels of demand. The JIT system will be applied across all product lines to ensure a consistent approach to inventory management. This includes:

High-demand products: These are often out of stock. The JIT system aims to improve the availability of these products.

Low-demand products: These often remain unsold in the warehouse. The JIT system aims to reduce the amount of these products that need to be stored.

By implementing the JIT system, the company aims to improve customer satisfaction and result in cost savings.

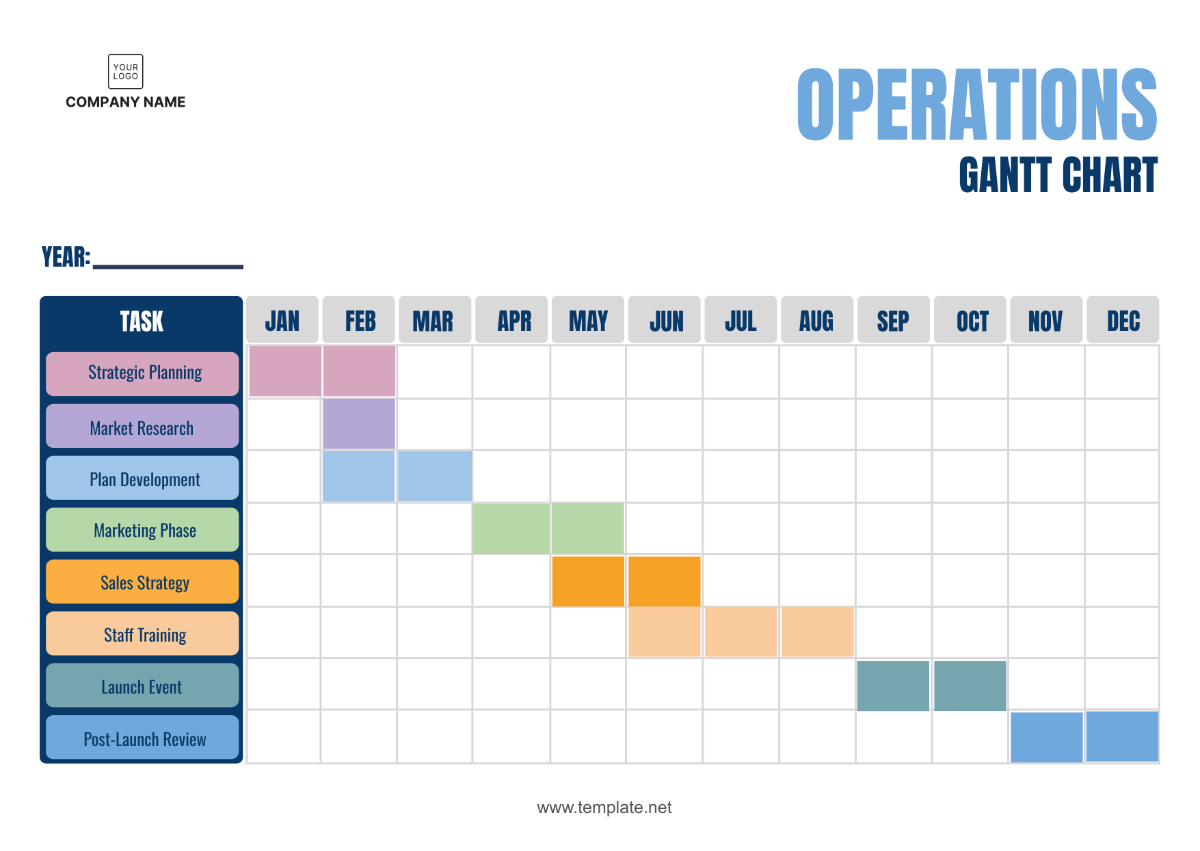

C. Implementation Plan

The implementation of the JIT system will involve several key steps:

Investment in advanced inventory management software: This software can accurately forecast market demand and automate the ordering process.

Establishing strong relationships with reliable suppliers: These suppliers can deliver high-quality materials on short notice.

Staff training: The company will need to train its staff on the new system and processes to ensure a smooth transition.

IV. Market Analysis

The market demand for the company’s products is a critical factor in the feasibility of the proposed JIT inventory system. Understanding the demand patterns can help the company align its inventory levels more closely with market demand, thereby reducing storage costs and improving product availability.

The following table presents a summary of the sales figures and revenue trends for the company’s top products over the past fiscal year:

Product | Q1 Sales (units) | Q2 Sales (units) | Q3 Sales (units) | Q4 Sales (units) | Total Sales (units) | Total Revenue |

|---|---|---|---|---|---|---|

A | 5,000 | 5,500 | 6,000 | 6,500 | 23,000 | $460,000 |

Product A has shown a steady increase in sales over the four quarters of the past fiscal year, starting from 5000 units in Q1 and reaching 6500 units in Q4. This indicates a growing demand for Product A in the market. The total sales for the year amounted to 23000 units, generating a total revenue of USD 460,000. This suggests that Product A is a high-demand product and contributes significantly to the company’s revenue.

The increasing sales trend for Product A over the four quarters suggests that the market demand for this product is strong and growing. This is a positive sign for the proposed JIT inventory system, as it indicates that the company can expect a steady flow of orders for this product, allowing it to maintain low inventory levels and reduce storage costs. Furthermore, the high revenue generated by Product A underscores its importance to the company’s financial performance. Implementing the JIT system could help the company meet the growing market demand for this product more efficiently and cost-effectively, thereby enhancing its profitability.

In general, the sales figures and revenue trends for the company’s products provide valuable insights into market demand. These insights can inform the implementation of the JIT inventory system, helping the company align its inventory levels more closely with market demand. By doing so, the company can reduce storage costs, improve product availability, and enhance its financial performance. The feasibility of the proposed JIT system will depend on a variety of factors, including the demand patterns for the company’s products, the reliability of its suppliers, and the capabilities of its inventory management software. This market analysis is a crucial step in assessing the feasibility of the proposed operation.

V. Technical Feasibility

A. Facilities

The company’s facilities are well-equipped to handle the rapid turnover of inventory that characterizes a JIT system. The facilities have sufficient space for receiving, storing, and dispatching goods, and the necessary equipment for handling these goods efficiently.

Receiving Area: The receiving area is designed to efficiently handle the frequent delivery of small quantities of goods. It has enough space for the goods to be checked and sorted upon arrival.

Storage Area: The storage area is well-organized, allowing for easy access and movement of goods. It is designed to accommodate the minimal storage space required by a JIT system.

Dispatch Area: The dispatch area is capable of handling multiple dispatches of goods per day. It has efficient systems for packing and loading goods, and easy access for transport vehicles.

B. Equipment

The company has invested in reliable and efficient equipment for the smooth operation of a JIT inventory system. This includes both the physical equipment used in the handling of goods and the software systems used in the management of inventory.

Handling Equipment: The company has reliable forklifts, pallet jacks, and other equipment used in the moving of goods. These ensure the quick movement of goods required in a JIT system.

Inventory Management Software: The company uses a sophisticated inventory management software system that accurately tracks inventory levels, automates the ordering process, and provides real-time data on the status of goods.

C. Software Needs

The company has invested in advanced inventory management software that is capable of accurately forecasting market demand, automating the ordering process, and providing real-time data on inventory levels. The software is user-friendly and has been easily integrated with the company’s existing systems.

D. Technical Skills

The staff has been trained and possesses the necessary technical skills to operate the new system. They understand the principles of JIT inventory management, can operate the inventory management software, and handle the physical equipment.

The technical feasibility assessment shows that the company has the necessary facilities, equipment, software, and skills to implement the JIT system. The potential technical challenges have been anticipated and plans have been put in place to address them. Therefore, from a technical perspective, the implementation of the JIT system is feasible.

VI. Operational Feasibility

A. Logistics

The logistics of the proposed JIT system involve the efficient movement of goods from suppliers to the company and from the company to the customers. The company has established strong relationships with reliable suppliers who can deliver high-quality materials on short notice. The company also has an efficient dispatch system that can handle multiple dispatches of goods per day.

Supplier Relationships: The company has established strong relationships with reliable suppliers who can deliver high-quality materials on short notice. This is crucial for a JIT system, which relies on timely deliveries to maintain low inventory levels.

Dispatch System: The company has an efficient dispatch system that can handle multiple dispatches of goods per day. This ensures that products are delivered to customers in a timely manner, improving customer satisfaction and reducing the need for storage.

B. Delivery

The delivery aspect of the JIT system involves the timely and efficient delivery of products to customers. The company has a reliable delivery system that ensures products reach customers as quickly as possible after they are ordered. This reduces the need for storage and improves customer satisfaction.

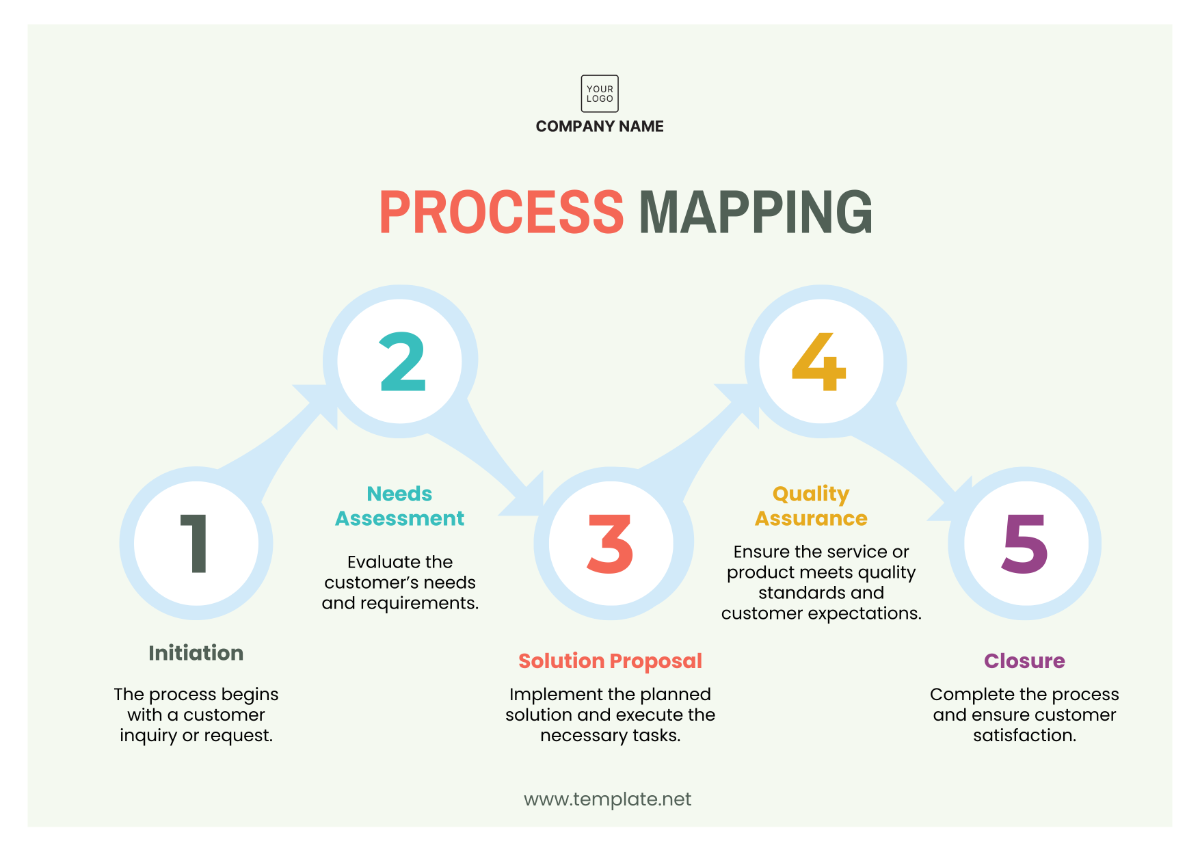

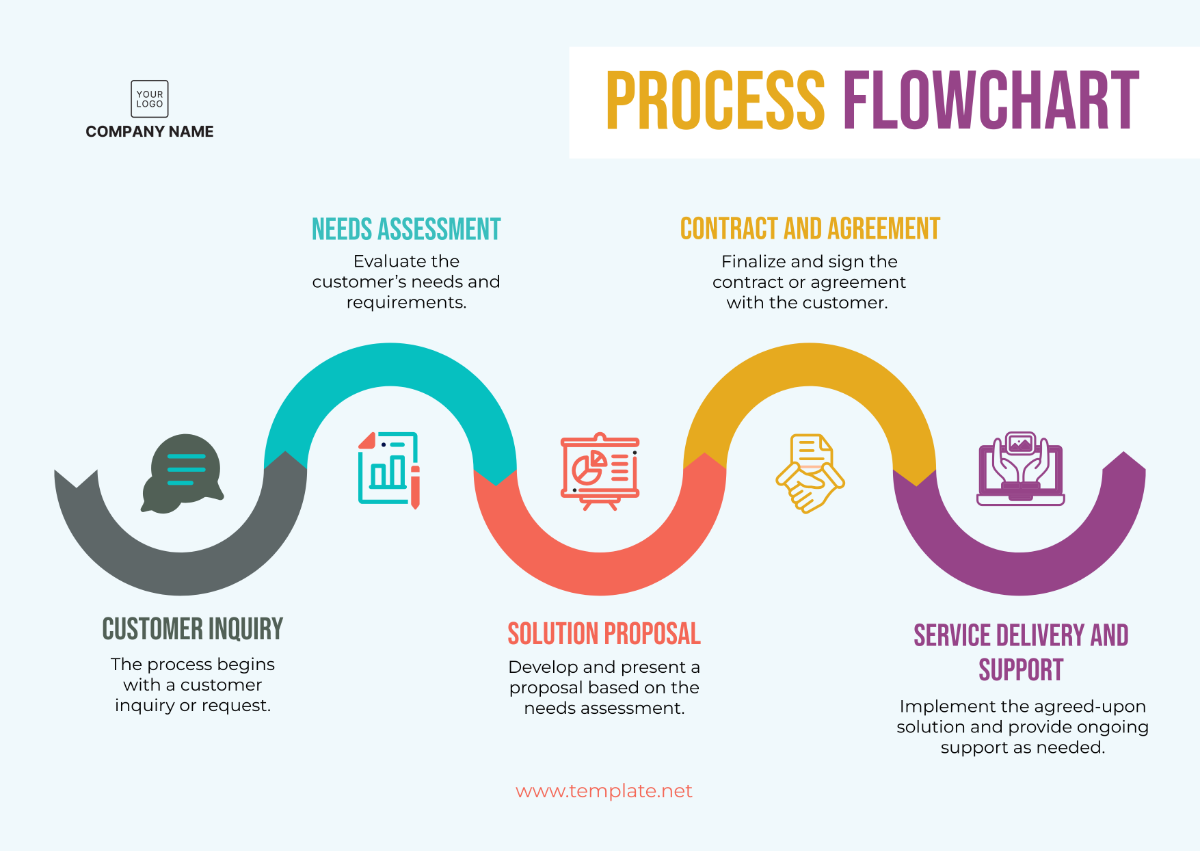

C. Process Flow

The process flow in a JIT system involves the smooth transition of goods from receiving to storage to dispatch. The company has efficient systems in place for checking and sorting goods upon arrival, storing goods in an organized manner, and packing and loading goods for dispatch.

Receiving Process: The company has efficient systems in place for checking and sorting goods upon arrival. This ensures that only high-quality goods are accepted and that they are correctly sorted for storage or dispatch.

Storage Process: The company’s storage area is well-organized, allowing for easy access and movement of goods. This is crucial for a JIT system, which requires quick movement of goods through the system.

Dispatch Process: The company has efficient systems for packing and loading goods, ensuring that they are ready for dispatch as soon as they are ordered.

In a nutshell, the operational feasibility assessment shows that the company has the necessary logistics, delivery systems, and process flows to implement the JIT system. Therefore, from an operational perspective, the implementation of the JIT system is feasible.

VII. Financial Feasibility

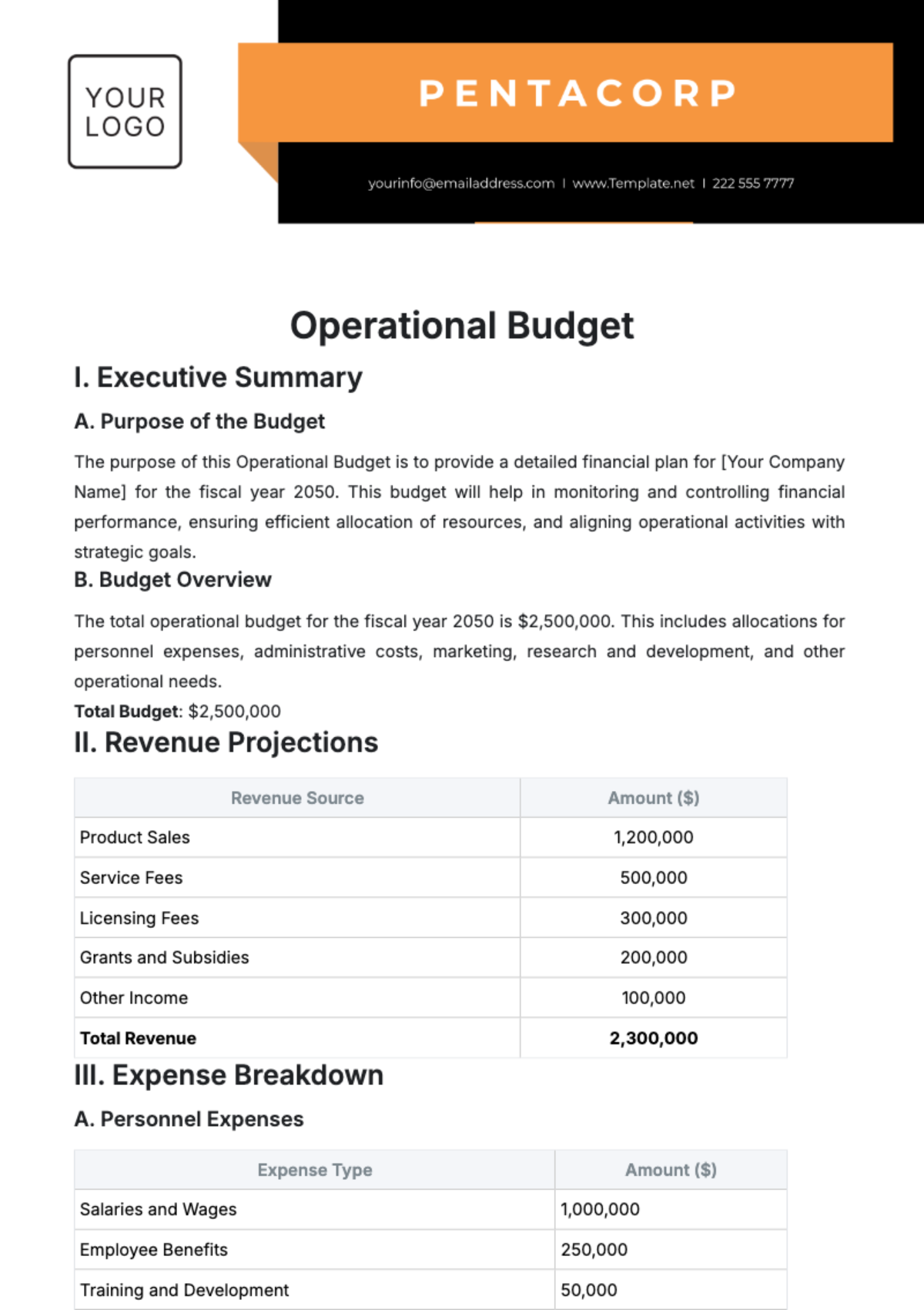

The financial feasibility of the proposed JIT system is a critical aspect of the overall feasibility study. It involves an analysis of the costs associated with implementing the system, the potential savings it could generate, and the impact on the company’s bottom line. The following table presents a summary of the estimated costs and potential savings associated with implementing the JIT system:

Cost/Savings Item | Year 1 | Year 2 | Year 3 |

|---|---|---|---|

Implementation Costs | 100,000 | - | - |

Annual Operating Costs | |||

Annual Storage Cost Savings | |||

Annual Lost Sales Cost Savings |

The implementation costs of the JIT system are estimated to be 100,000 in the first year. These costs include the investment in new inventory management software, the purchase of necessary equipment, and the training of staff. While these costs are significant, they are a one-time investment that could lead to substantial savings in the long run.

The implementation costs represent a significant investment in the company’s supply chain operations. However, it’s important to consider these costs in the context of the potential savings and benefits that the JIT system could bring. By reducing storage costs and lost sales, the JIT system could generate significant savings that would offset the initial implementation costs over time.

In general, the financial feasibility assessment shows that while the implementation of the JIT system involves significant upfront costs, the potential savings in storage costs and lost sales could make it a financially viable option for the company. The exact figures will depend on a variety of factors, including the company’s specific operational context and the accuracy of the cost and savings estimates. Therefore, it’s important for the company to conduct a detailed financial analysis as part of the feasibility study to ensure an informed decision.

VIII. Legal and Regulatory Considerations

Implementing a new inventory system like JIT can have legal and regulatory implications that the company needs to consider. These can range from compliance with health and safety regulations to data protection laws.

A. Health and Safety Regulations

The introduction of a JIT system could change the way goods are handled and stored, which may have implications for health and safety. The company must ensure that these changes comply with all relevant health and safety regulations to protect its employees and avoid legal issues.

Handling of Goods: The frequent movement of goods required by a JIT system could potentially increase the risk of accidents. The company must ensure that all staff are properly trained in safe handling procedures and that appropriate safety equipment is provided.

Storage of Goods: With goods being delivered and dispatched more frequently, the company must ensure that its storage facilities comply with all relevant safety regulations.

B. Data Protection Laws

The use of advanced inventory management software in a JIT system will involve the processing of large amounts of data, some of which may be sensitive or personal. The company must ensure that it complies with all relevant data protection laws.

Data Collection and Processing: The company must ensure that any data collected and processed by the inventory management software is done so in a manner that complies with data protection laws. This includes obtaining any necessary consents and providing clear information about how the data will be used.

Data Security: The company must take appropriate measures to protect the data from unauthorized access or loss. This includes implementing robust security measures and regularly reviewing and updating these measures as necessary.

X. Recommendations

The feasibility study has provided a comprehensive assessment of the proposed Just-In-Time (JIT) inventory system. Based on the findings, the implementation of the JIT system appears to be a viable option for the company. However, the successful implementation of this system will require careful planning and execution. Here are some detailed recommendations for the next steps:

A. Invest in Training

The company should invest in comprehensive training programs to ensure that all staff members understand the principles of JIT inventory management and are capable of operating the new system effectively. This could involve bringing in external experts, conducting workshops, or providing online training resources. The training should cover both the theoretical aspects of JIT inventory management and the practical skills needed to operate the new system.

B. Monitor Market Trends

The company should continue to monitor market trends and adjust its inventory levels accordingly. This will require the use of sophisticated inventory management software that can accurately forecast market demand. The company should also consider hiring or training staff to specialize in market analysis and demand forecasting. Regular reports should be produced to keep all relevant staff informed about market trends.

C. Strengthen Supplier Relationships

The company should work on strengthening its relationships with reliable suppliers. This is crucial for a JIT system, which relies on timely deliveries to maintain low inventory levels. The company could consider entering into long-term contracts with suppliers, providing regular feedback to suppliers to help them improve their service, or even investing in joint ventures with suppliers to ensure a reliable supply of goods.

D. Review Legal and Regulatory Compliance

The company should regularly review its compliance with relevant health and safety regulations and data protection laws. This will help to avoid any potential legal issues that could arise from the implementation of the JIT system. The company could consider hiring a legal expert or consultant to conduct these reviews and provide advice on compliance matters.

E. Evaluate Financial Performance

The company should regularly evaluate the financial performance of the JIT system. This includes monitoring the savings generated from reduced storage costs and lost sales, as well as the return on investment from the implementation costs. The company should consider using financial performance metrics such as return on investment (ROI), payback period, and net present value (NPV) to evaluate the financial viability of the JIT system.