Workplace Case Study on Safety Improvements

1. Introduction

At [Your Company Name], an electronics manufacturing company, we identified a critical need to enhance workplace safety in our facility, which employs 200 staff and has experienced a higher than industry-average rate of accidents. This was primarily attributed to outdated safety protocols and equipment.

2. Identification of Safety Risks

At [Your Company Name], our comprehensive risk assessment revealed several critical areas that required immediate attention:

Electrical Hazards

Issue: Aging and poorly maintained electrical equipment had led to increased risks of shorts and electrical fires.

Statistics: Over the past year, 15 incidents of electrical malfunction were recorded, two of which resulted in minor injuries.

Chemical Exposure

Issue: The storage and handling of chemicals, particularly solvents and acids, were found to be inadequate. Improper labeling and storage had led to several near-miss incidents.

Statistics: Chemical spills increased by 20% over the last two years, indicating a growing problem in chemical management.

Physical Hazards

Issue: Cluttered walkways and insufficient lighting in several production areas contributed significantly to trips and falls.

Statistics: Trip and fall incidents constituted 30% of all workplace accidents reported in the previous year.

Risk Assessment Summary Table

Hazard Type | Identified Problems | Incidents in the Past Year | Potential Consequences |

Electrical | Aging equipment, lack of maintenance | 15 | Shocks, burns, electrical fires |

Chemical | Inadequate storage, improper labeling | 18 (incl. near misses) | Burns, inhalation hazards, environmental damage |

Physical (Trips & Falls) | Cluttered walkways, poor lighting | 24 | Bruises, fractures, long-term disabilities |

3. Implementation of New Safety Policies

To address these identified risks, [Your Company Name] has implemented several new safety policies:

Comprehensive Safety Training

Description: A revamped training program covering electrical, chemical, and general safety. Includes both theoretical and practical components.

Implementation: Monthly training sessions with mandatory attendance for all new and existing employees.

Regular Equipment Maintenance

Description: Introduction of a stringent maintenance schedule for all electrical and production equipment to prevent malfunctions and accidents.

Implementation: Bi-weekly inspections and servicing by the maintenance team, logged and monitored through a digital tracking system.

Enhanced Chemical Management

Description: Overhaul of chemical storage and handling procedures, including proper labeling, segregated storage, and spill management protocols.

Implementation: Immediate reorganization of the chemical storage area and quarterly audits for compliance.

Safety Policy Implementation Table

Policy Component | Action Items | Responsible Departments | Timeline |

Safety Training | Develop and execute training modules | HR and Health & Safety | Monthly |

Equipment Maintenance | Schedule and conduct maintenance | Technical and Maintenance | Bi-weekly |

Chemical Management | Revise and enforce new protocols | Production and Safety Teams | Immediate/Quarterly Audits |

4. Safety Training Program

At [Your Company Name], we have significantly enhanced our Safety Training Program to address the specific risks identified in the workplace. This program is now more comprehensive and interactive, ensuring higher engagement and retention of safety practices among employees.

Electrical Safety Training

Objective: To educate employees on the risks associated with electrical equipment and to train them in emergency response procedures.

Content: Training modules include understanding electrical hazards, emergency shutdown procedures, and the use of protective equipment.

Frequency: Conducted quarterly for all employees, with additional sessions for new hires.

Chemical Safety Workshops

Objective: To ensure safe handling, storage, and disposal of chemicals used in our manufacturing processes.

Content: Workshops cover topics such as reading Material Safety Data Sheets (MSDS), spill response techniques, and proper usage of personal protective equipment (PPE).

Frequency: Bi-annual workshops, with refresher courses offered annually.

General Safety Awareness

Objective: To create a workplace culture that prioritizes safety in everyday activities.

Content: Training includes identifying common workplace hazards, ergonomics, first aid, and fire safety basics.

Frequency: Annual sessions for all staff, with specific training for departments based on their unique risk profiles.

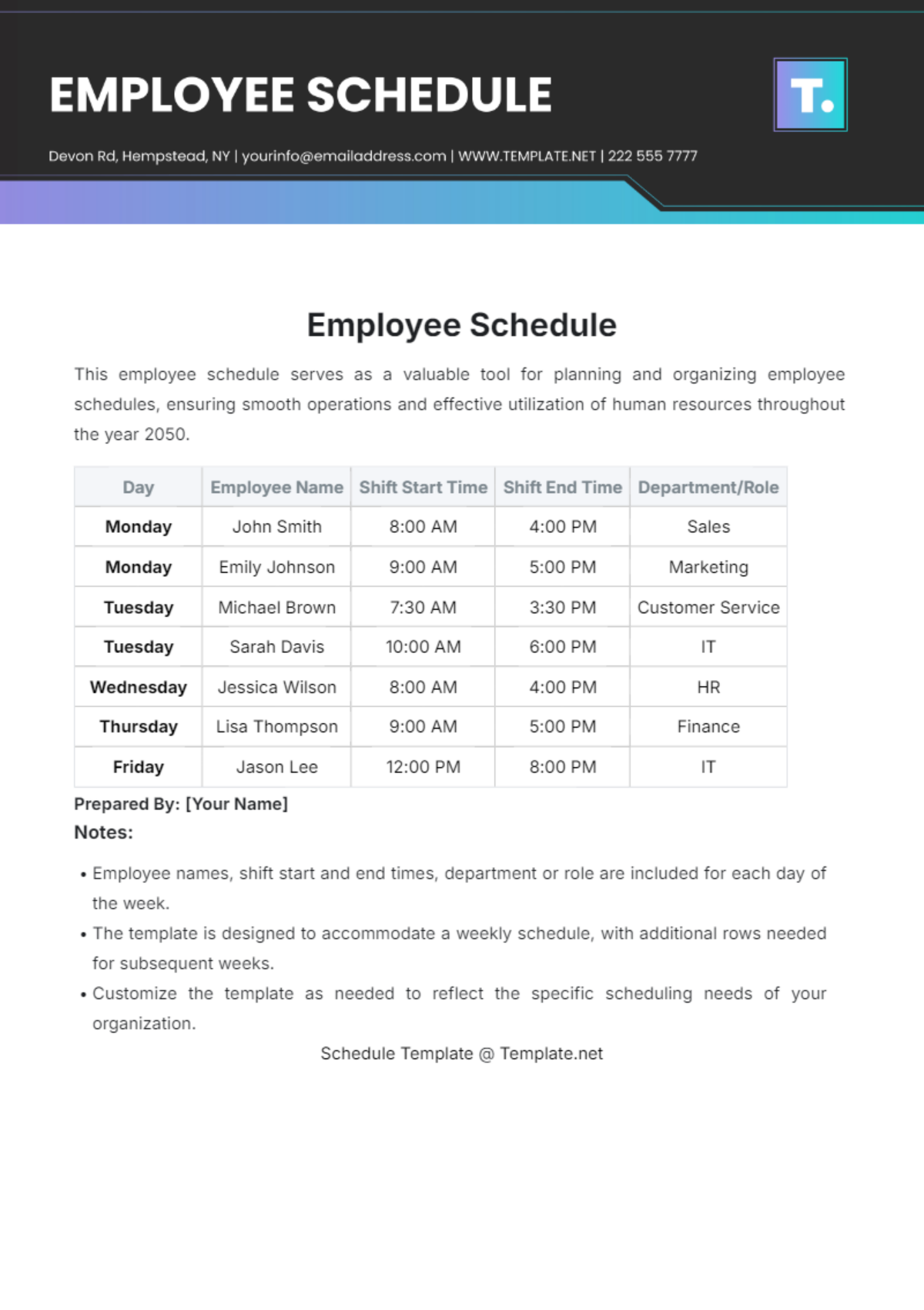

Safety Training Program Schedule

Training Type | Participants | Frequency | Duration | Key Topics Covered |

Electrical Safety | All Employees | Quarterly | 2 Hours | Electrical Hazards, Emergency Procedures, PPE Use |

Chemical Safety | Handling Staff | Bi-annually | 3 Hours | MSDS, Spill Response, PPE Use |

General Safety | All Employees | Annually | 1 Hour | Workplace Hazards, Ergonomics, First Aid, Fire Safety |

5. Equipment Maintenance Schedule

To mitigate the risks associated with equipment malfunction, [Your Company Name] has developed a detailed Equipment Maintenance Schedule. This schedule is designed to ensure all equipment is operating safely and efficiently.

Routine Maintenance Checks

Purpose: Regular inspections and repairs to prevent breakdowns and hazards.

Details: Includes checking wiring, safety guards, and operational efficiency.

Responsible Team: Maintenance Department.

Preventive Maintenance

Purpose: To proactively service and replace parts before they fail.

Details: Focuses on critical machinery and includes updating safety features.

Responsible Team: Engineering and Technical Maintenance.

Emergency Repairs

Purpose: Rapid response to unforeseen equipment malfunctions.

Details: Establishing a protocol for immediate action in case of equipment failure.

Responsible Team: On-call Maintenance Technicians.

Equipment Maintenance Schedule Table

Equipment Type | Maintenance Type | Frequency | Responsible Department | Checklist Items |

Production Machinery | Routine Maintenance | Monthly | Maintenance | Safety Guards, Operational Efficiency |

Electrical Systems | Preventive | Quarterly | Engineering | Wiring Inspections, Feature Updates |

Safety Alarms | Emergency Repairs | As Needed | Security | Immediate Response, Functionality Checks |

6. Chemical Storage Improvements

[Your Company Name] has overhauled its chemical storage facilities to significantly reduce the risk of accidents and ensure compliance with regulatory

standards.

Segregated Storage Facilities

Overview: We have implemented segregated storage areas based on the compatibility of chemicals. This reduces the risk of chemical reactions between incompatible substances.

Implementation: Chemicals are categorized into acids, bases, flammables, and reactives, with each category stored in a separate, clearly marked area.

Advanced Storage Conditions

Overview: Special attention is given to maintaining optimal conditions for chemical storage, including temperature control and ventilation.

Implementation: Sensitive chemicals are stored in temperature-controlled cabinets. Ventilation systems are installed to prevent the accumulation of fumes.

Regular Safety Audits

Overview: Regular inspections and audits are conducted to ensure that all storage protocols are strictly followed.

Implementation: Monthly inspections are carried out by the safety team, with a detailed checklist of compliance points.

Chemical Storage Improvement Table

Improvement Area | Details | Responsible Department | Frequency |

Segregated Storage | Categorization and separate storage of chemicals | Safety and Production | Implemented |

Storage Conditions | Temperature control and ventilation systems | Maintenance | Ongoing Checks |

Safety Audits | Compliance checks and inspections | Health & Safety | Monthly |

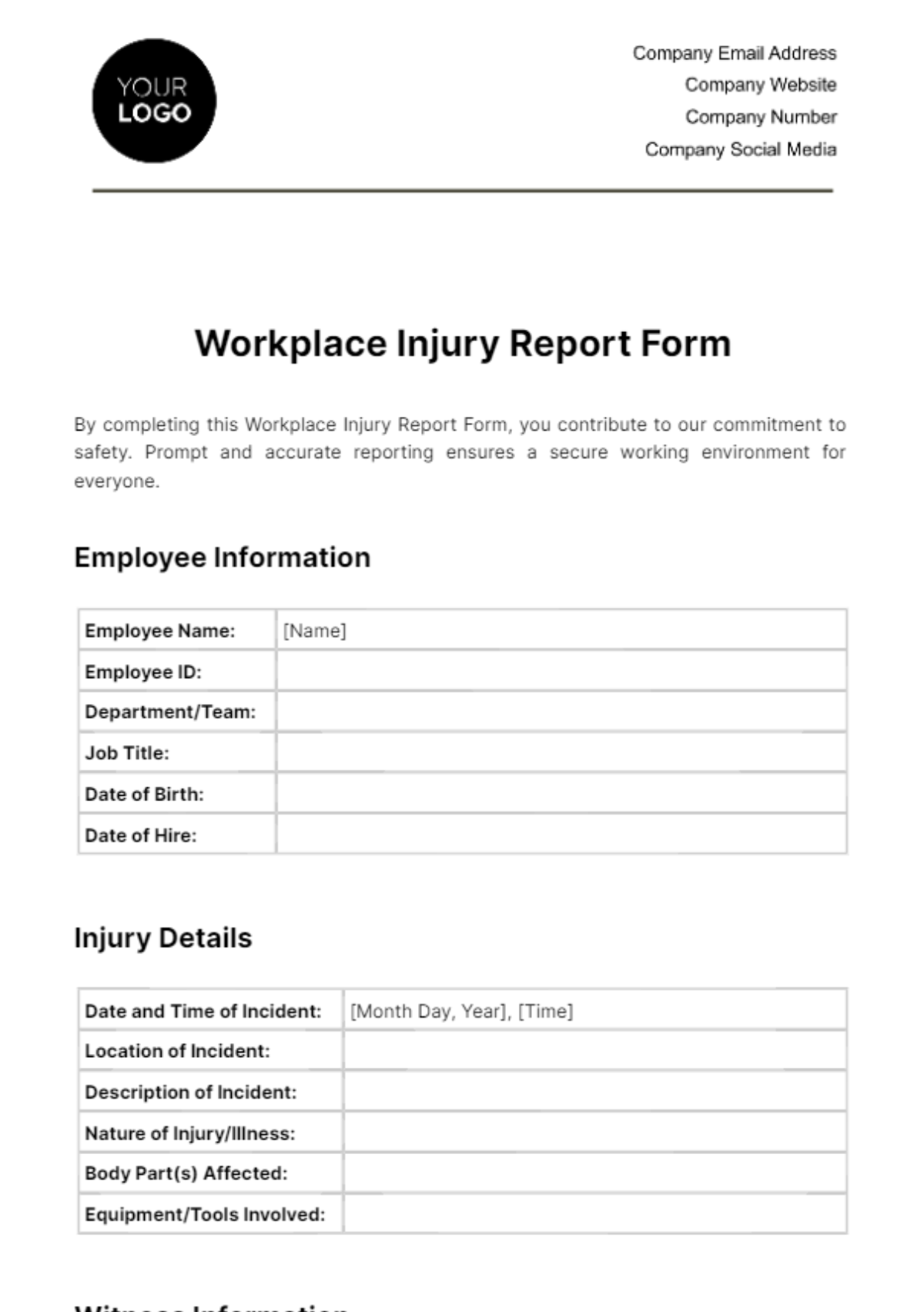

7. Incident Reporting Procedure

[Your Company Name] has refined its Incident Reporting Procedure to ensure timely and effective responses to workplace incidents.

Immediate Reporting

Process: Employees are required to report any safety incident, no matter how minor, to their immediate supervisor or the safety officer.

Objective: To ensure that all incidents are recorded and addressed promptly.

Detailed Incident Documentation

Process: Following an incident, a detailed report is to be filled out. This includes the time, location, description of the incident, and any immediate actions taken.

Objective: To gather comprehensive data on each incident, aiding in investigation and future prevention strategies.

Investigative Follow-Up

Process: Each reported incident is followed by a thorough investigation conducted by the safety committee, which includes representatives from different departments.

Objective: To identify root causes and implement corrective actions to prevent recurrence.

Incident Reporting Procedure Table

Step | Action Required | Responsible Party | Purpose |

Immediate Reporting | Notify supervisor/safety officer | Employee | Prompt recording and initial response to incident |

Documentation | Fill out incident report form | Employee/Supervisor | Detailed recording of incident specifics |

Investigation | Conduct investigation of the incident | Safety Committee | Identify causes and develop prevention measures |

8. Emergency Response Plan

[Your Company Name] has developed a comprehensive Emergency Response Plan to ensure swift and effective action in case of an emergency.

Evacuation Procedures

Overview: Clear and well-marked evacuation routes are established, with regular drills conducted to familiarize employees.

Implementation: Evacuation maps are prominently displayed in all areas, and quarterly evacuation drills are conducted.

Emergency Contact Information

Overview: A detailed list of emergency contacts, including internal safety officers and external emergency services, is readily available.

Implementation: Emergency contact information is posted in all work areas and included in employee handbooks.

First Aid and Medical Assistance

Overview: First aid stations are established throughout the facility, and selected staff members are trained in basic first aid and CPR.

Implementation: Regular training sessions for first aid responders and routine checks of first aid supplies.

Emergency Response Plan Table

Component | Description | Implementation Detail | Frequency |

Evacuation Procedures | Well-marked routes and regular drills | Display maps, conduct quarterly drills | Quarterly Drills |

Emergency Contacts | List of key contacts | Post information, include in handbooks | Updated Annually |

First Aid Training | Equip staff with emergency skills | Conduct training, maintain first aid kits | Bi-annual Training |

9. Evaluation of Safety Improvements

To gauge the effectiveness of the safety improvements, [Your Company Name] has established a set of evaluation metrics.

Incident Reduction

Metric: Tracking the reduction in the number of safety incidents reported.

Goal: Aim to reduce workplace incidents by at least 40% within the first year.

Employee Safety Perception Surveys

Metric: Bi-annual surveys to assess employee perceptions and attitudes towards workplace safety.

Goal: Increase positive safety perception among employees by 50%.

Compliance Rates

Metric: Regular audits to assess adherence to new safety protocols and policies.

Goal: Achieve a 95% compliance rate across all departments.

Safety Improvement Evaluation Table

Evaluation Metric | Measurement Method | Target Goal |

Incident Reduction | Incident report analysis | 40% reduction |

Employee Safety Perception | Bi-annual survey results | 50% improvement |

Protocol Compliance | Safety audits | 95% compliance rate |

10. Future Safety Enhancements

[Your Company Name]. is committed to ongoing safety improvements with several future initiatives planned.

Advanced Surveillance Systems

Plan: To install high-tech surveillance systems for continuous monitoring of safety practices.

Purpose: To identify potential safety hazards in real-time and prevent accidents.

Periodic Safety Drills

Plan: Implementing regular safety drills, including fire drills and emergency response exercises.

Purpose: To ensure preparedness and familiarity with safety protocols among employees.

Reward System for Safe Practices

Plan: Introducing a reward and recognition program for departments and individuals exhibiting exemplary safety practices.

Purpose: To encourage and reinforce a culture of safety within the organization.

Future Safety Enhancement Table

Enhancement Initiative | Description | Expected Implementation Timeframe |

Advanced Surveillance | Installation of surveillance cameras | Within the next 6 months |

Periodic Safety Drills | Conducting regular safety-related drills | Bi-annually |

Reward System | Implementing a safety-focused reward program | Annually |