Workplace Safety and Health User Guide

I. Introduction to Workplace Safety

Overview of Safety Policies

Our organization prioritizes the safety and well-being of all individuals on our premises. This guide outlines essential safety practices and policies applicable to all employees, contractors, and visitors.

Importance of Safety in the Workplace

Workplace safety is vital to prevent accidents and illnesses, ensuring a productive and harmonious work environment. Adhering to these guidelines is a shared responsibility, fostering a culture of safety and respect.

II. General Safety Rules

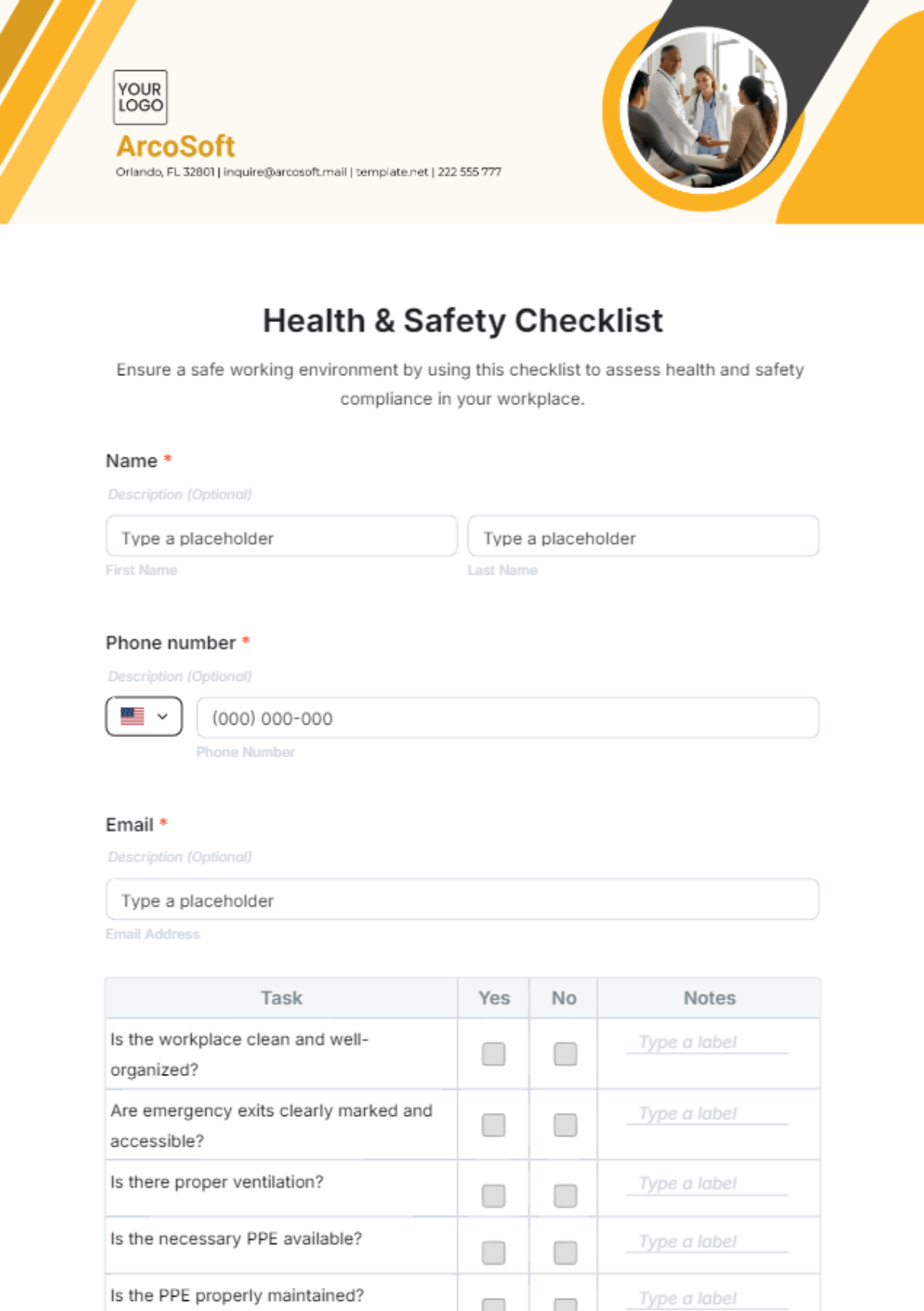

Personal Protective Equipment (PPE)

PPE is essential for employee safety. The following table outlines the mandatory equipment for various departments:

Department | Required PPE |

Construction | Helmets, Safety Glasses |

Warehouse | Steel-toed Boots, Gloves |

Laboratory | Lab Coats, Goggles |

Housekeeping and Cleanliness

Regular cleaning schedules and clutter-free zones are crucial for safety and efficiency. Each department must adhere to the following standards:

Daily waste disposal.

Clear labeling of all storage areas.

Immediate cleaning of spills.

III. Emergency Procedures

Emergency preparedness is essential to effectively handle unforeseen events and ensure the safety of all personnel.

Evacuation Plan

An effective evacuation plan is a cornerstone of emergency preparedness. Key elements include:

Evacuation Routes:

Clearly marked and regularly inspected paths leading to safety. Maps are displayed in every room and common area.

Assembly Points:

Designated safe areas outside the building for gathering after evacuation. These are marked on maps and known to all employees.

Drills and Training:

Regular evacuation drills are conducted quarterly to ensure that everyone knows the procedures. Special training sessions are held for handling persons with disabilities during an evacuation.

First Aid and Medical Emergency Response

First-Aid Kits:

Fully stocked first-aid kits are located throughout the workplace. Their locations are clearly marked and known to all employees.

Emergency Contacts:

A list of emergency contacts, including local hospitals, fire departments, and police, is posted in common areas and included in the employee handbook.

Training:

Employees are offered first-aid training, including CPR and AED (Automated External Defibrillator) usage. Regular refresher courses are conducted to keep these skills up to date.

Incident Command System (ICS):

An ICS is in place to manage emergency responses. This includes designating a safety officer as the incident commander who coordinates the response efforts during an emergency.

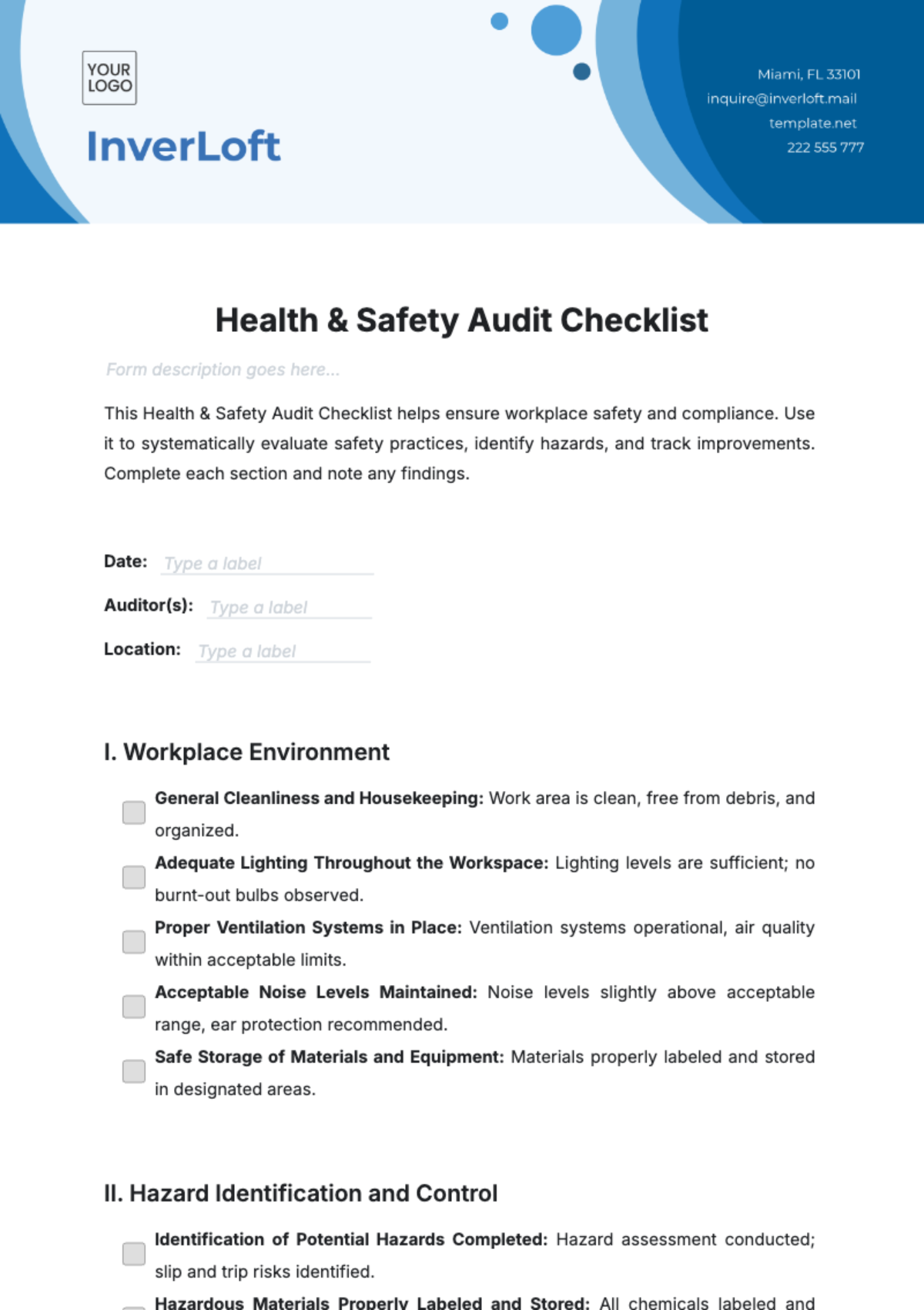

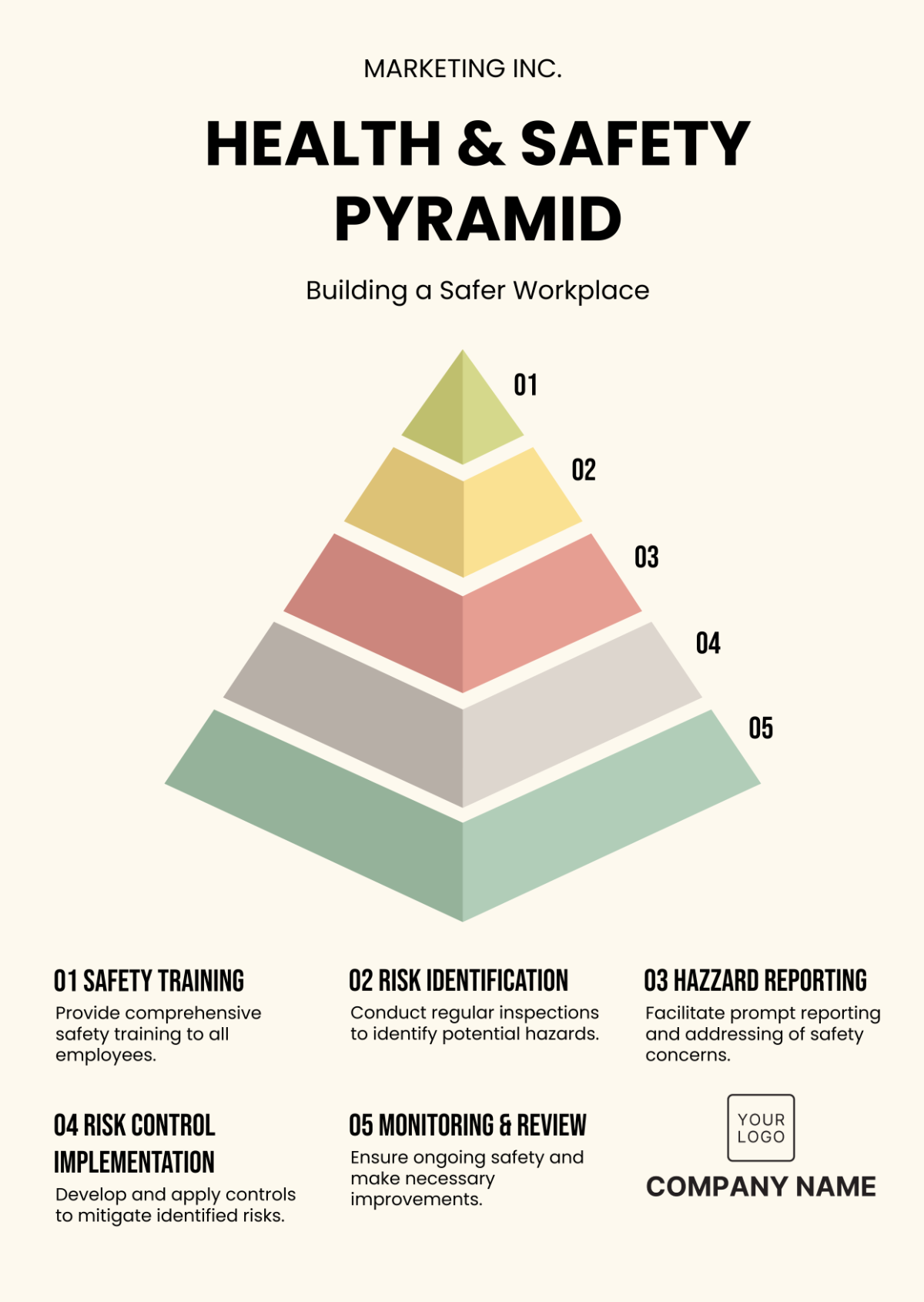

IV. Hazard Identification and Risk Assessment

Identifying potential hazards and assessing risks are crucial for preventing workplace accidents and ensuring employee safety.

Recognizing Workplace Hazards

Awareness and identification of hazards are the first steps in risk management.

Employee Training:

Regular training sessions are held to educate employees about common workplace hazards. This includes identification of potential chemical, physical, biological, and ergonomic risks.

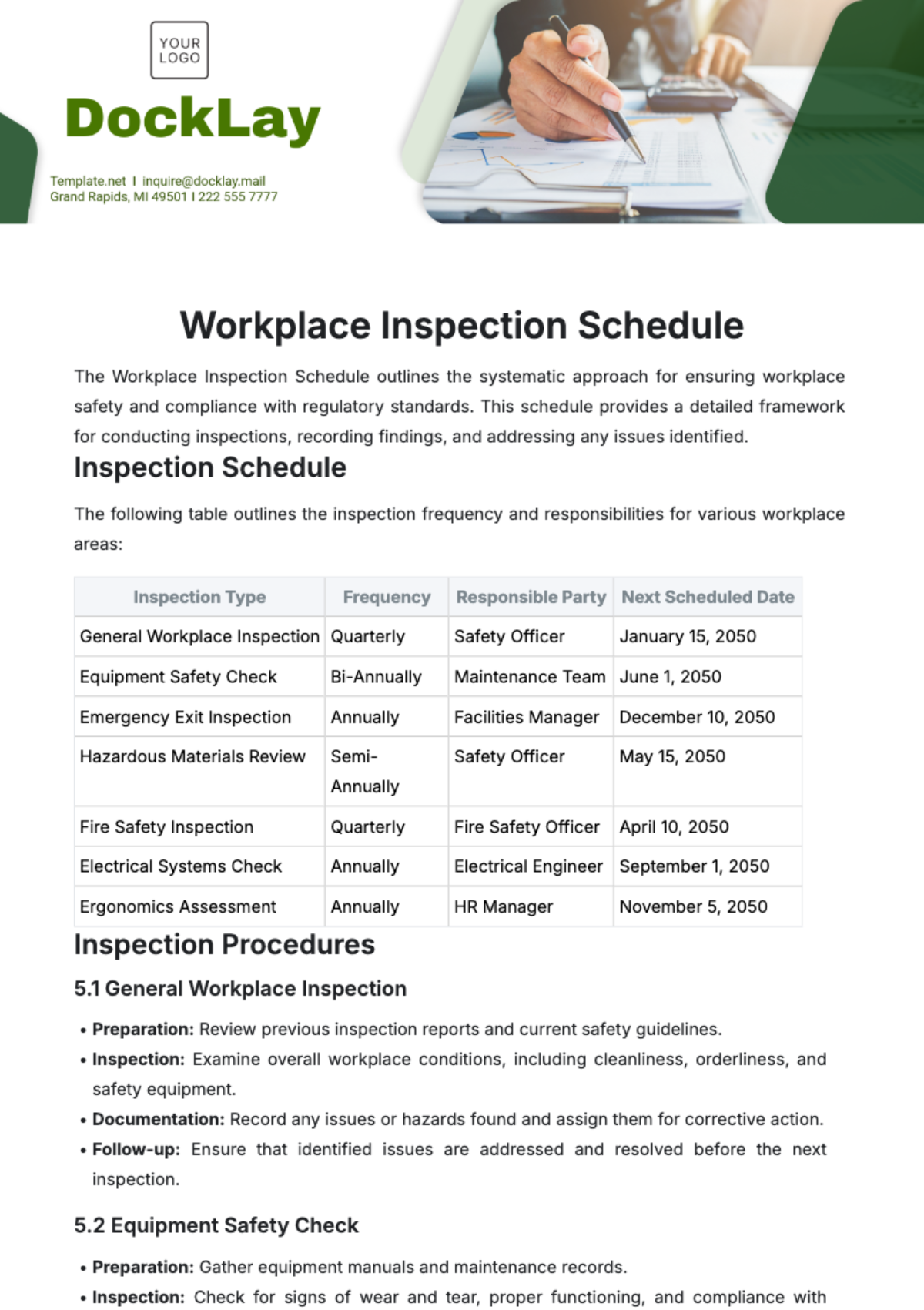

Inspection Schedules:

Regular workplace inspections are conducted to identify new or overlooked hazards. These inspections are carried out by trained safety officers or external consultants.

Employee Reporting System:

A system is in place for employees to report hazards anonymously. This encourages reporting of potential risks without fear of reprisal.

Conducting Risk Assessments

Regular risk assessments help in prioritizing and mitigating risks.

Assessment Teams:

Cross-functional teams are formed to conduct comprehensive risk assessments. These teams include members from different departments to provide diverse perspectives.

Risk Evaluation:

Risks are evaluated based on the likelihood of occurrence and potential impact. This helps in prioritizing which risks need immediate attention.

Control Measures:

After evaluation, appropriate control measures are implemented. This could range from engineering controls, administrative controls such as training and procedure changes, to personal protective equipment.

Documentation and Review:

All findings and actions from the risk assessments are documented. These documents are reviewed regularly to ensure that control measures are effective and updated as necessary.

V. Ergonomics and Workspace Safety

Proper Workspace Setup

Ergonomically designed workspaces help in reducing work-related injuries. This includes:

Chairs and Desks:

Ensure chairs and desks are adjustable to accommodate different body types and postures, promoting comfort and reducing physical strain.

Lighting:

Implement proper lighting solutions to minimize eye strain and enhance visibility, crucial for maintaining focus and reducing errors.

Equipment Placement:

Position equipment strategically to minimize repetitive movements and awkward postures, thereby reducing the risk of musculoskeletal disorders.

Preventing Repetitive Strain Injuries

Employees are encouraged to adopt the following practices to prevent repetitive strain injuries:

Regular Breaks:

Integrate short, frequent breaks into the work schedule, ideally every hour, to alleviate muscle fatigue and increase circulation.

Stretching Exercises:

Incorporate stretching exercises into daily routines to maintain flexibility and reduce the risk of strain injuries.

Ergonomic Accessories:

Utilize ergonomic keyboards and mouse devices, designed to maintain natural wrist and hand positions, thereby reducing the risk of strain.

VI. Fire Safety Management

Fire Prevention Techniques

Our fire prevention strategy includes:

No Smoking Enforcement:

Rigorously enforce no smoking policies within the premises to prevent fire hazards.

Electrical Safety Inspections:

Conduct regular safety checks of electrical systems to identify and rectify potential fire risks.

Storage of Flammable Materials:

Ensure flammable materials are stored properly in designated, safe areas to minimize the risk of accidental ignition.

Use of Fire Extinguishers

Fire extinguisher locations are clearly marked. Training includes:

Extinguisher Training:

Provide thorough training in the proper use of fire extinguishers, ensuring all employees are equipped with essential firefighting skills.

Identification of Extinguisher Types:

Educate employees on different types of fire extinguishers and their specific applications, ensuring the right type is used for various fire scenarios.

Maintenance Protocol:

Establish a regular maintenance schedule for all fire extinguishers, ensuring they are in optimal working condition.

VII. Chemical and Hazardous Material Handling

Safe Storage Practices

Chemicals and hazardous materials must be stored as per the guidelines below:

Material Type | Storage Requirement |

Flammable Liquids | In flame-resistant cabinets |

Acids/Bases | Separate, ventilated areas |

Compressed Gasses | Secured upright positions |

Spill Response and Disposal Procedures

In case of chemical spills, follow these steps:

Evacuate and secure the area.

Use appropriate PPE.

Neutralize and clean up the spill following MSDS guidelines.

VIII. Equipment and Machinery Safety

Operation of Heavy Machinery

Operating heavy machinery poses significant risks; thus, only personnel who have undergone rigorous certification can operate these machines. The certification process includes:

Comprehensive Training:

Providing extensive hands-on and theoretical training to ensure operators are fully equipped with the necessary skills and knowledge.

Regular Skill Assessments:

Conducting periodic evaluations to ensure operators maintain high competency levels and are up-to-date with the latest safety protocols.

Emergency Shutdown Procedures:

Ensuring operators have a thorough understanding of emergency shutdown protocols to quickly and safely respond to hazardous situations.

Regular Maintenance and Safety Checks

Preventive maintenance is critical for safe operation. This includes:

Routine Inspections and Servicing:

Performing regular, systematic checks and servicing of machinery to identify and rectify potential hazards before they escalate.

Incident Logging and Resolution:

Keeping detailed logs of any irregularities or malfunctions and promptly addressing these issues to mitigate risks.

Safety Guard Verification:

Regularly verifying that all safety guards and protective measures are securely in place and functional.

IX. Health and Wellness Programs

Stress Management and Mental Health

Recognizing the importance of mental health in the workplace, our wellness programs are designed to support employees' mental well-being:

Counseling Services Access:

Providing employees with confidential access to professional counseling services for mental health support.

Stress Management Workshops:

Organizing workshops focused on effective stress management techniques and resilience building.

Flexible Work Arrangements:

Offering flexible work schedules and arrangements to promote a healthy work-life balance, reducing stress and improving overall well-being.

Physical Fitness and Health Promotion

To encourage a healthy and active lifestyle among our employees, our health promotion initiatives include:

Subsidized Gym Memberships:

Offering discounted or subsidized gym memberships to encourage physical fitness.

Regular Health Screenings:

Facilitating regular health screenings to monitor and promote employees' physical health.

Healthy Eating Options:

Providing a variety of healthy eating choices in the cafeteria, supporting nutritional well-being.

X. Reporting and Investigating Incidents

Incident Reporting Procedures

All workplace incidents, regardless of their severity, must be reported promptly and accurately. The reporting process is streamlined through a standardized form, available in every department, and encompasses the following steps:

Immediate Notification:

Ensuring the safety officer or relevant authority is immediately notified about the incident to initiate a swift response.

Comprehensive Incident Description:

Providing a detailed account of the incident, including the time, location, and circumstances, to ensure a clear understanding of what occurred.

Collection of Witness Statements:

Gathering statements from witnesses, if available, to provide additional perspectives and insights into the incident.

Investigation and Corrective Actions

After an incident, our response team will:

Conduct a Thorough Investigation:

Undertaking a detailed investigation to understand the incident's context and contributing factors.

Identification of Root Causes:

Analyzing the incident to identify underlying root causes, rather than focusing solely on the immediate reasons.

Development and Implementation of Corrective Actions:

Formulating and implementing corrective measures aimed at preventing the recurrence of similar incidents, thereby continuously improving our workplace safety standards.

XI. Conclusion

This Workplace Safety and Health User Guide serves as a resource for fostering a culture of safety and health within our organization. By integrating the outlined practices, tools, and behaviors, we empower our workforce to prioritize safety in every aspect of their work. As we move forward, continuous improvement and adaptation in response to emerging safety challenges will remain central to our approach, ensuring a safe and healthy workplace for all.