Free Workplace Machinery Incident Report

Report Date: [2053-07-15]

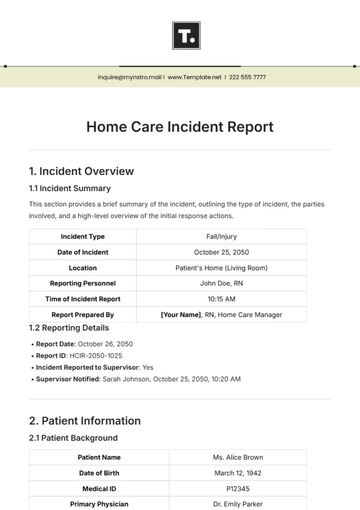

Incident Information

Location of Incident: [Your Company Address]

Time of Incident: [09:30 AM]

Description of Incident

While performing routine maintenance on the [IndustrialMaster 2000] conveyor belt system, a malfunction occurred, causing a sudden stop. The maintenance team was inspecting the conveyor's motor when it unexpectedly restarted, resulting in injuries to two employees, namely, Sarah Johnson and Michael Brown. Sarah sustained a minor hand injury, and Michael experienced a sprained ankle. Both were immediately provided with first aid.

Injuries/Fatalities

[Sarah Johnson]: [Minor hand injury, treated on-site]

[Name]: [Injury/Fatality Detail]

Witnesses

[Robert Lewis] [Supervisor]: [robert.lewis@acmesafety.com]

[Name] [Position]: [email address]

[Name] [Position]: [email address]

Machinery Information

Machine Type: [Industrial Conveyor System]

Machine Serial/ID Number: [IC2000-456789]

Machine Manufacturer: [ConveyorTech Industries]

Machine Maintenance Records

The maintenance history of the [IndustrialMaster 2000] is up-to-date and available in the maintenance logbook.

Root Cause Analysis

1. Immediate Cause

The immediate cause of the incident was a malfunction in the conveyor's control panel, leading to an unexpected restart.

2. Underlying Causes

Inadequate lockout/tagout procedures during maintenance.

Control panel malfunction due to a manufacturing defect.

Recommendations and Corrective Actions

1. Preventive Measures

Review and update lockout/tagout procedures for all machinery.

Conduct regular inspections of control panels for potential defects.

2. Corrective Actions

Enhanced lockout/tagout training for maintenance personnel.

Immediate inspection of all control panels on similar machinery.

Contact [ConveyorTech Industries] for a warranty claim on the control panel.

Follow-Up

Implement the recommended preventive and corrective measures.

Schedule a follow-up inspection of the ["IndustrialMaster 2000"] after repairs are completed.

Attachments

Photos of the malfunctioning control panel.

Maintenance logbook entry for the ["IndustrialMaster 2000."]

Report Prepared By:

[Your Name]

______________________

[Your Email]

[Your Company Number]

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Introducing the Workplace Machinery Incident Report Template by Template.net - an essential resource for workplace safety. This editable and customizable template, equipped with our Ai Editor Tool, streamlines incident reporting processes. Safeguard your workplace with precision and ease. Trust Template.net for innovative solutions in workplace safety and compliance.

You may also like

- Sales Report

- Daily Report

- Project Report

- Business Report

- Weekly Report

- Incident Report

- Annual Report

- Report Layout

- Report Design

- Progress Report

- Marketing Report

- Company Report

- Monthly Report

- Audit Report

- Status Report

- School Report

- Reports Hr

- Management Report

- Project Status Report

- Handover Report

- Health And Safety Report

- Restaurant Report

- Construction Report

- Research Report

- Evaluation Report

- Investigation Report

- Employee Report

- Advertising Report

- Weekly Status Report

- Project Management Report

- Finance Report

- Service Report

- Technical Report

- Meeting Report

- Quarterly Report

- Inspection Report

- Medical Report

- Test Report

- Summary Report

- Inventory Report

- Valuation Report

- Operations Report

- Payroll Report

- Training Report

- Job Report

- Case Report

- Performance Report

- Board Report

- Internal Audit Report

- Student Report

- Monthly Management Report

- Small Business Report

- Accident Report

- Call Center Report

- Activity Report

- IT and Software Report

- Internship Report

- Visit Report

- Product Report

- Book Report

- Property Report

- Recruitment Report

- University Report

- Event Report

- SEO Report

- Conference Report

- Narrative Report

- Nursing Home Report

- Preschool Report

- Call Report

- Customer Report

- Employee Incident Report

- Accomplishment Report

- Social Media Report

- Work From Home Report

- Security Report

- Damage Report

- Quality Report

- Internal Report

- Nurse Report

- Real Estate Report

- Hotel Report

- Equipment Report

- Credit Report

- Field Report

- Non Profit Report

- Maintenance Report

- News Report

- Survey Report

- Executive Report

- Law Firm Report

- Advertising Agency Report

- Interior Design Report

- Travel Agency Report

- Stock Report

- Salon Report

- Bug Report

- Workplace Report

- Action Report

- Investor Report

- Cleaning Services Report

- Consulting Report

- Freelancer Report

- Site Visit Report

- Trip Report

- Classroom Observation Report

- Vehicle Report

- Final Report

- Software Report