Free Equipment Safety Checklist

Welcome to the Equipment Safety Checklist for [the Industrial Press Machine]. This comprehensive tool is designed to ensure the proper functioning and safety of our equipment. Please conduct regular inspections using this checklist to maintain a secure working environment.

Equipment Information

Equipment Name: | [Name of the Equipment] |

Manufacturer: | [Name of Manufacturer] |

Model/Serial Number: | [Model or Serial Number] |

Date of Last Inspection: | [Month Day, Year] |

Inspector's Name: | [Name of Inspector] |

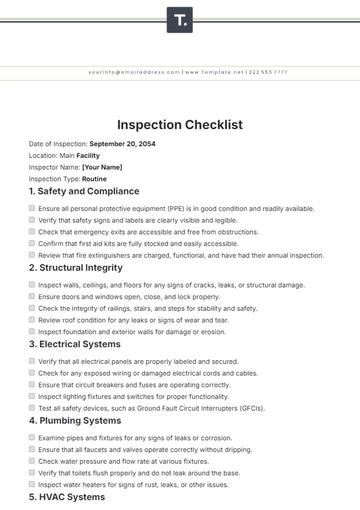

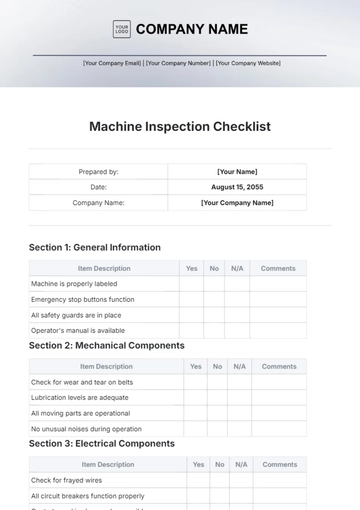

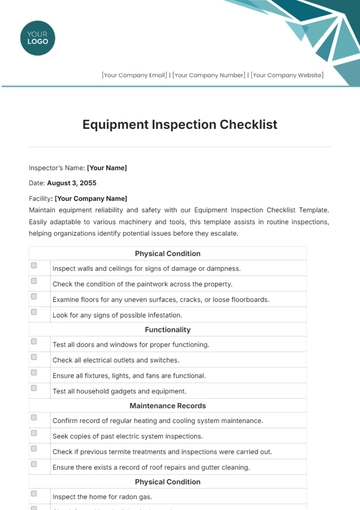

General Condition

No visible damage, cracks, or deformities.

All external components securely fastened.

No signs of leaks or spills.

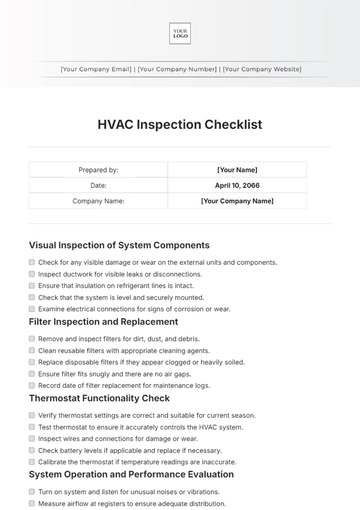

Operational Controls

All switches, buttons, and controls operate smoothly.

Emergency stop feature tested and functional.

Control labels are legible and in good condition.

Power Sources

Power cords and plugs are free of frays or damage.

Battery levels within the specified range.

Grounding is intact for electrically powered equipment.

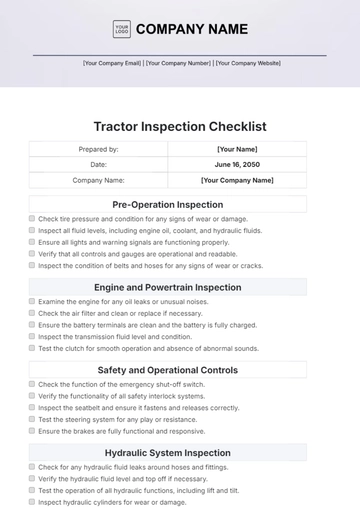

Emergency Stop Mechanism

Emergency stop button is easily accessible.

Emergency stop function halts equipment immediately.

Visual or audible indicator confirms activation.

Guarding and Barriers

Protective guards are in place and secure.

Barriers prevent access to moving or hazardous parts.

No evidence of tampering with safety features.

Noise and Vibration

Noise levels within acceptable limits.

Vibration levels are minimal and do not indicate malfunction.

Users provided with necessary hearing protection if required.

Labels and Signage

Equipment is properly labeled with manufacturer information.

Warning labels and safety instructions are clear and intact.

Safety signage for specific hazards (e.g., high voltage) is present.

Maintenance Records

Maintenance log is up-to-date.

Regular inspections and servicing recorded.

Any outstanding maintenance issues addressed.

Training Requirements

Users have received training on equipment operation.

Training records are available and up-to-date.

Periodic refresher training conducted as needed.

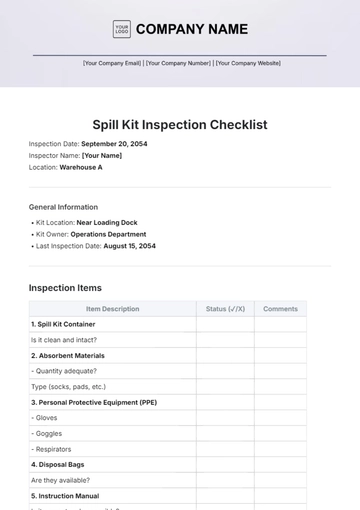

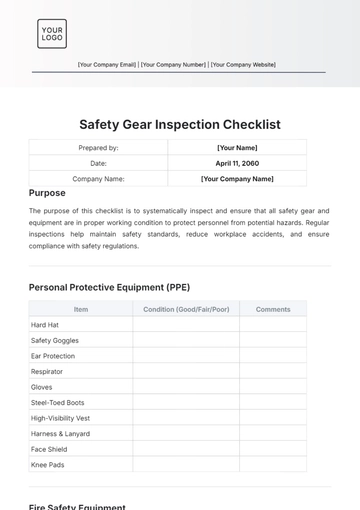

Personal Protective Equipment (PPE)

Appropriate PPE provided for users.

Users wearing required PPE during inspection.

Adequate supply of PPE available on-site.

Emergency Procedures

Users are familiar with emergency shutdown procedures.

Emergency contact information is prominently displayed.

Emergency exits and evacuation routes are clear.

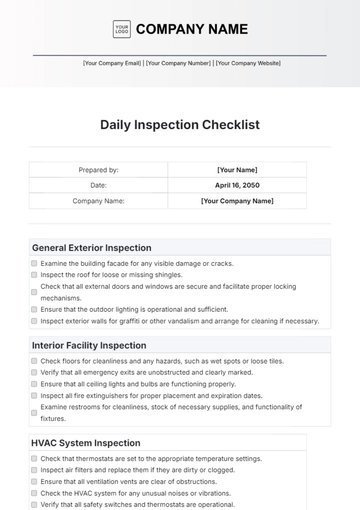

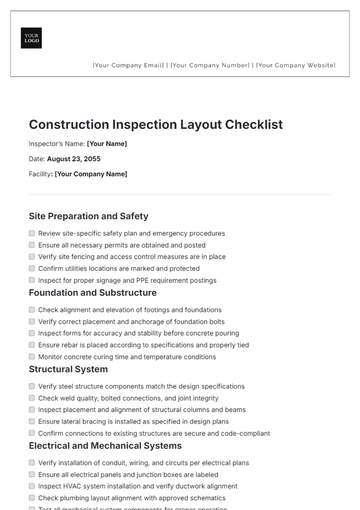

Environmental Considerations

Equipment designed for the specific environmental conditions.

Adequate ventilation provided if necessary.

Measures in place to prevent environmental impact (e.g., containment for spills).

Inspector's Signature:

Date of Inspection:

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Introducing Template.net's Equipment Safety Checklist Template: Your ultimate companion for ensuring workplace safety. This editable and customizable template, enhanced with our Ai Editor Tool, simplifies safety inspections. Seamlessly tailor it to your specific needs, streamlining safety protocols effortlessly. Protect your workforce and assets with Template.net's cutting-edge solutions.

You may also like

- Cleaning Checklist

- Daily Checklist

- Travel Checklist

- Self Care Checklist

- Risk Assessment Checklist

- Onboarding Checklist

- Quality Checklist

- Compliance Checklist

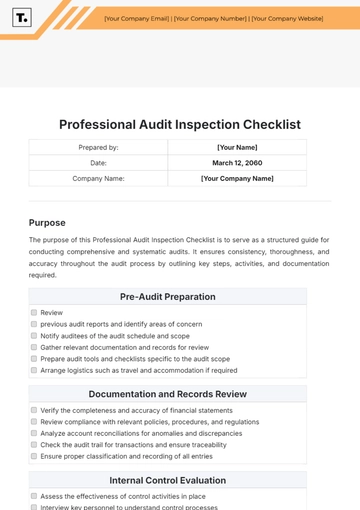

- Audit Checklist

- Registry Checklist

- HR Checklist

- Restaurant Checklist

- Checklist Layout

- Creative Checklist

- Sales Checklist

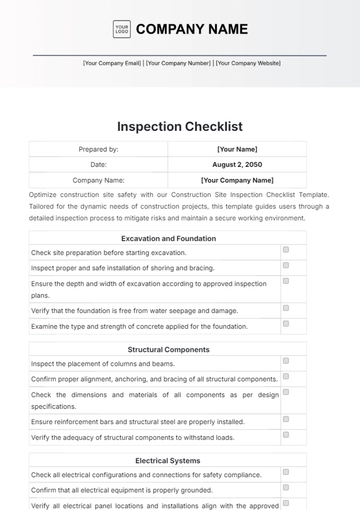

- Construction Checklist

- Task Checklist

- Professional Checklist

- Hotel Checklist

- Employee Checklist

- Moving Checklist

- Marketing Checklist

- Accounting Checklist

- Camping Checklist

- Packing Checklist

- Real Estate Checklist

- Cleaning Checklist Service

- New Employee Checklist

- Food Checklist

- Home Inspection Checklist

- Advertising Checklist

- Event Checklist

- SEO Checklist

- Assessment Checklist

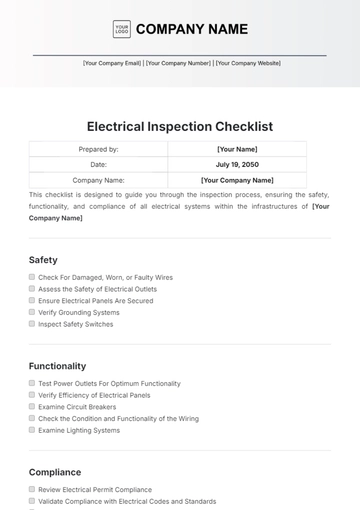

- Inspection Checklist

- Baby Registry Checklist

- Induction Checklist

- Employee Training Checklist

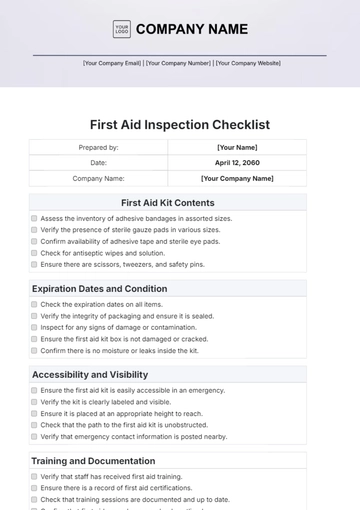

- Medical Checklist

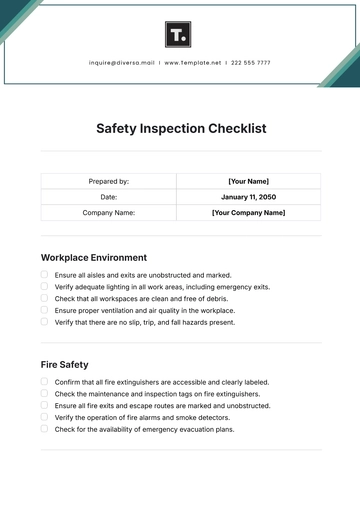

- Safety Checklist

- Site Checklist

- Job Checklist

- Service Checklist

- Nanny Checklist

- Building Checklist

- Work Checklist

- Office Checklist

- Training Checklist

- Website Checklist

- IT and Software Checklist

- Performance Checklist

- Project Checklist

- Startup Checklist

- Education Checklist

- Home Checklist

- School Checklist

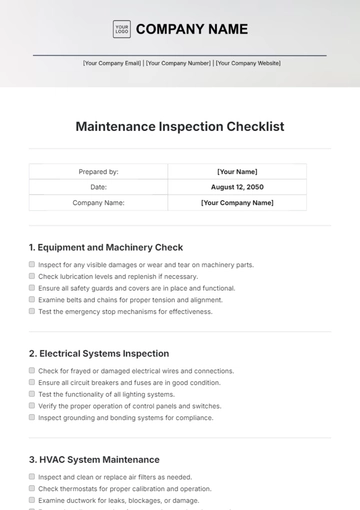

- Maintenance Checklist

- Planning Checklist

- Manager Checklist

- Wedding Checklist

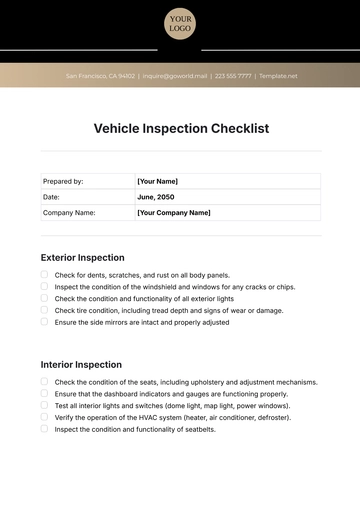

- Vehicle Checklist

- Travel Agency Checklist

- Vehicle Inspection Checklist

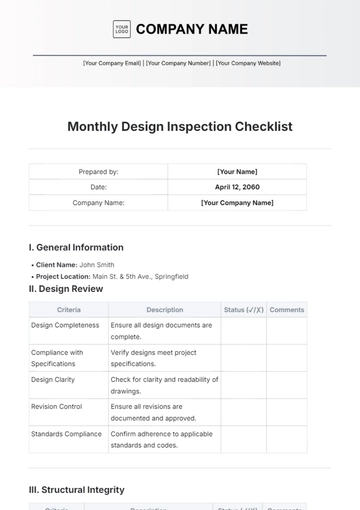

- Interior Design Checklist

- Backpacking Checklist

- Business Checklist

- Legal Checklist

- Nursing Home Checklist

- Weekly Checklist

- Recruitment Checklist

- Salon Checklist

- Baby Checklist

- Equipment Checklist

- Trade Show Checklist

- Party Checklist

- Hospital Bag Checklist

- Evaluation Checklist

- Agency Checklist

- First Apartment Checklist

- Hiring Checklist

- Opening Checklist

- Small Business Checklist

- Rental Checklist

- College Dorm Checklist

- New Puppy Checklist

- University Checklist

- Building Maintenance Checklist

- Work From Home Checklist

- Student Checklist

- Application Checklist