Free Health and Safety Risk Assessment

Date: May 10, 2090

Prepared By: [Your Name]

I. Introduction

Welcome to the Health and Safety Risk Assessment conducted by [Your Company Name]. The primary objective of this assessment is to identify and evaluate potential workplace risks and hazards by US health and safety laws and standards. By systematically assessing and addressing these risks, we are committed to ensuring the safety, health, and well-being of our employees and stakeholders. This document outlines our comprehensive approach to risk management within our organization.

A. Scope

This Health and Safety Risk Assessment encompasses all aspects of our operations at [Your Company Name]. It includes an in-depth evaluation of potential risks and hazards in our workplace environments, such as offices, production facilities, and field operations. The assessment also considers the health and safety of all employees, contractors, and visitors on our premises.

B. Objectives

Identify Hazards: To systematically identify and document all potential workplace hazards, including physical, chemical, biological, ergonomic, and psychosocial factors.

Assess Risks: To assess the severity, likelihood, and consequences of identified hazards, using industry-recognized criteria, and prioritize them accordingly.

Implement Control Measures: To propose and implement effective control measures and strategies to mitigate or eliminate identified risks, in compliance with US health and safety laws and regulations.

II. Legal and Regulatory Framework

1. Federal Regulations

Occupational Safety and Health Act (OSHA): Our organization adheres to OSHA standards for workplace safety, including regulations on hazard communication, PPE, and safety training, with regular sessions for employee awareness and compliance.

Environmental Protection Agency (EPA): We rigorously adhere to EPA regulations for the safe handling and disposal of hazardous materials in our chemical manufacturing to minimize environmental risks.

2. State Regulations

California Code of Regulations, Title 8: We’ve implemented detailed protocols per California’s Title 8, Section XYZ on hazardous materials, emphasizing compliance crucial for our state operations.

New York State Department of Labor Regulations: We comply with New York State regulations, including the Department of Labor's workplace safety Regulation ABC, to ensure a safe working environment.

3. Industry Standards

ANSI/AIHA Z10: Our organization follows the ANSI/AIHA Z10 standard for a systematic approach to occupational health and safety management.

International Organization for Standardization (ISO) 45001: We follow ISO 45001 to continuously enhance our safety performance and ensure employee well-being.

III. Risk Identification

Hazard Category | Specific Hazards/Risks | Associated Areas/Processes |

Physical Hazards | Machinery operation hazards | Manufacturing floor |

Slips, trips, and falls | Common areas | |

Chemical Hazards | Chemical exposure risks | Laboratory and storage areas |

Hazardous material handling | Chemical storage facilities | |

Biological Hazards | Exposure to biological agents | Healthcare facilities |

Ergonomic Hazards | Repetitive motion injuries | Office workstations |

Improper lifting techniques | Warehouse operations | |

Psychosocial Hazards | Workplace stress | High-demand job roles |

Harassment and bullying | Office environments |

IV. Risk Assessment Criteria

Risk Category | Likelihood | Consequences | Risk Level |

Low | Low | Minor | Low Risk |

Low | Low | Major | Moderate Risk |

Low | Moderate | Minor | Moderate Risk |

Low | Moderate | Major | High Risk |

Moderate | Low | Minor | Moderate Risk |

Moderate | Low | Major | High Risk |

V. Risk Assessment Methodology

Hazard Identification: We begin by identifying potential hazards through regular workplace inspections, incident reports, and safety data analysis. This proactive approach helps us pinpoint risks across various aspects of our operations.

Data Analysis: We leverage historical incident data and near-miss reports to identify patterns and trends, allowing us to address underlying causes and emerging risks.

Stakeholder Engagement: Interviews and feedback sessions with employees, contractors, and stakeholders provide valuable insights into potential risks and safety concerns.

Regulatory Compliance: We continuously monitor and assess our operations to ensure compliance with federal and state regulations, as well as industry-specific standards.

VI. Risk Evaluation

Risk ID | Risk Description | Likelihood | Consequences | Risk Level | Immediate Action Required |

R001 | Machinery operation hazards | Low | Major | High Risk | Yes |

R002 | Slips, trips, and falls | Moderate | Minor | Moderate | No |

R003 | Chemical exposure risks | High | Major | High Risk | Yes |

R004 | Hazardous material handling | Moderate | Major | High Risk | Yes |

VII. Control Measures

Risk ID | Risk Description | Proposed Control Measures |

R001 | Machinery operation hazards | Implement machine guarding measures. Conduct regular equipment inspections and maintenance. |

R002 | Slips, trips, and falls | Maintain clean and dry walking surfaces. Install anti-slip flooring in high-risk areas. |

R003 | Chemical exposure risks | Provide proper personal protective equipment (PPE). Ensure adequate ventilation in chemical handling areas. |

R004 | Hazardous material handling | Develop and enforce strict handling protocols. Implement spill containment and cleanup procedures. |

VIII. Documentation and Record-Keeping

We'll meticulously document and maintain all risk assessments, controls, actions, and modifications to comply with standards and improve safety. This ensures transparency, accountability, and adherence to legal requirements, enhancing proactive risk management.

IX. Review and Monitoring

At [Your Company Name], we understand the importance of ongoing review and monitoring to ensure the effectiveness of our risk management efforts. We have established a systematic approach to review and monitor our risk assessment and control measures.

1. Responsibility

Internal Safety Committee: Our internal safety committee, comprising safety experts and representatives from various departments, will oversee the review and monitoring process.

External Audits: We will periodically engage external auditors to conduct independent assessments to validate our safety measures.

2. Key Elements of Review

Risk Assessment Review: We will review the risk assessment regularly to identify new risks and reassess existing ones based on changing circumstances.

Control Measures Evaluation: The effectiveness of control measures will be assessed to ensure they remain suitable and effective in reducing risk.

Incident Analysis: We will analyze incidents, near-misses, and accidents to identify areas for improvement in our safety protocols.

Regulatory Compliance: We will continuously monitor changes in federal and state regulations to ensure ongoing compliance.

X. Continuous Improvement

Based on the findings of our reviews and monitoring activities, we will implement necessary improvements to our risk management processes. This commitment to continuous improvement will help us maintain a safe and compliant workplace environment and uphold the highest standards of health and safety.

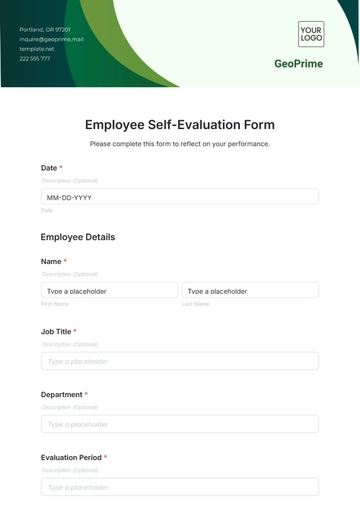

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Elevate workplace safety effortlessly with Template.net's Health and Safety Risk Assessment Template. This editable and customizable template, powered by our AI Editor Tool, simplifies risk assessment processes. Tailor it to your specific needs, ensuring comprehensive safety measures. Safeguard your team and workplace effectively with Template.net's intuitive solutions.