Safety Audit Guide

I. Introduction

A. Purpose of the Safety Audit Guide

This guide is designed to assist in the systematic evaluation of our safety management system, practices, and processes to ensure a safe and healthy work environment.

B. Scope and Applicability

This guide is applicable to all departments and operations within [Your Company Name]. It covers various aspects of safety, including regulatory compliance, leadership commitment, hazard identification, emergency preparedness, and continuous improvement.

C. Overview of the Audit Process

The audit process outlined in this guide provides a structured approach for assessing and enhancing safety performance. It aims to identify potential hazards, ensure compliance with safety regulations, and promote a culture of continuous improvement.

II. Regulatory Compliance

A. Overview of Relevant Safety Regulations and Standards

[Your Company Name] is committed to upholding the highest standards of safety in accordance with Industry Regulations and Standards. These regulations and standards provide the framework for our safety management system, ensuring the well-being of our employees and compliance with legal requirements.

B. Documentation of Compliance Requirements

To demonstrate our commitment to regulatory compliance, [Your Company Name] maintains comprehensive documentation outlining specific compliance requirements. This document serves as the foundation for our safety practices and is readily available for review.

C. Procedures for Staying Informed About Regulatory Changes

Staying abreast of regulatory changes is a crucial aspect of our commitment to continuous improvement. To achieve this, [Your Company Name] has established a systematic process for monitoring and disseminating information regarding any updates to safety regulations and standards. This process includes regular reviews of regulatory websites, participation in industry forums, and subscription to relevant publications.

III. Safety Management System (SMS)

A. Description of the Organization's SMS

[Your Company Name] has developed a robust Safety Management System (SMS) that serves as the cornerstone of our commitment to safety excellence. Our SMS encompasses comprehensive policies, procedures, and protocols designed to identify, mitigate, and manage risks across all aspects of our operations.

B. Policies and Procedures in Place

Our safety policies and procedures are aligned with industry best practices and regulatory requirements. These documents are accessible to all employees, emphasizing transparency and accountability in our safety initiatives.

C. Roles and Responsibilities within the SMS

To ensure the effective implementation of our SMS, clear roles and responsibilities have been defined for all levels of the organization. From leadership to front-line employees, each individual plays a crucial role in contributing to the success of our safety initiatives.

IV. Leadership and Commitment

A. Management Commitment to Safety

At [Your Company Name], safety is a core value ingrained in our organizational culture. The leadership team is dedicated to fostering a safe work environment, providing the necessary resources, and championing safety as a top priority.

B. Involvement of Leadership in Safety Initiatives

Leadership actively participates in safety initiatives, engaging with employees at all levels. This involvement includes regular safety meetings, site visits, and open communication channels to address any safety concerns or suggestions from the workforce.

C. Communication of Safety Values and Expectations

We communicate our safety values and expectations through various channels, including employee handbooks, safety orientation programs, and prominently displayed safety posters throughout our facilities. This ensures that every employee understands the importance of safety in their daily activities.

V. Employee Involvement

A. Mechanisms for Involving Employees in Safety Programs

Employees are integral to our safety programs. Safety Committees and Suggestion Boxes are in place to encourage active participation and input from employees in shaping and improving our safety initiatives.

B. Communication Channels for Safety Concerns and Suggestions

An open-door policy and confidential reporting mechanisms enable employees to raise safety concerns or provide suggestions without fear of reprisal. This ensures a culture of trust and collaboration in maintaining a safe work environment.

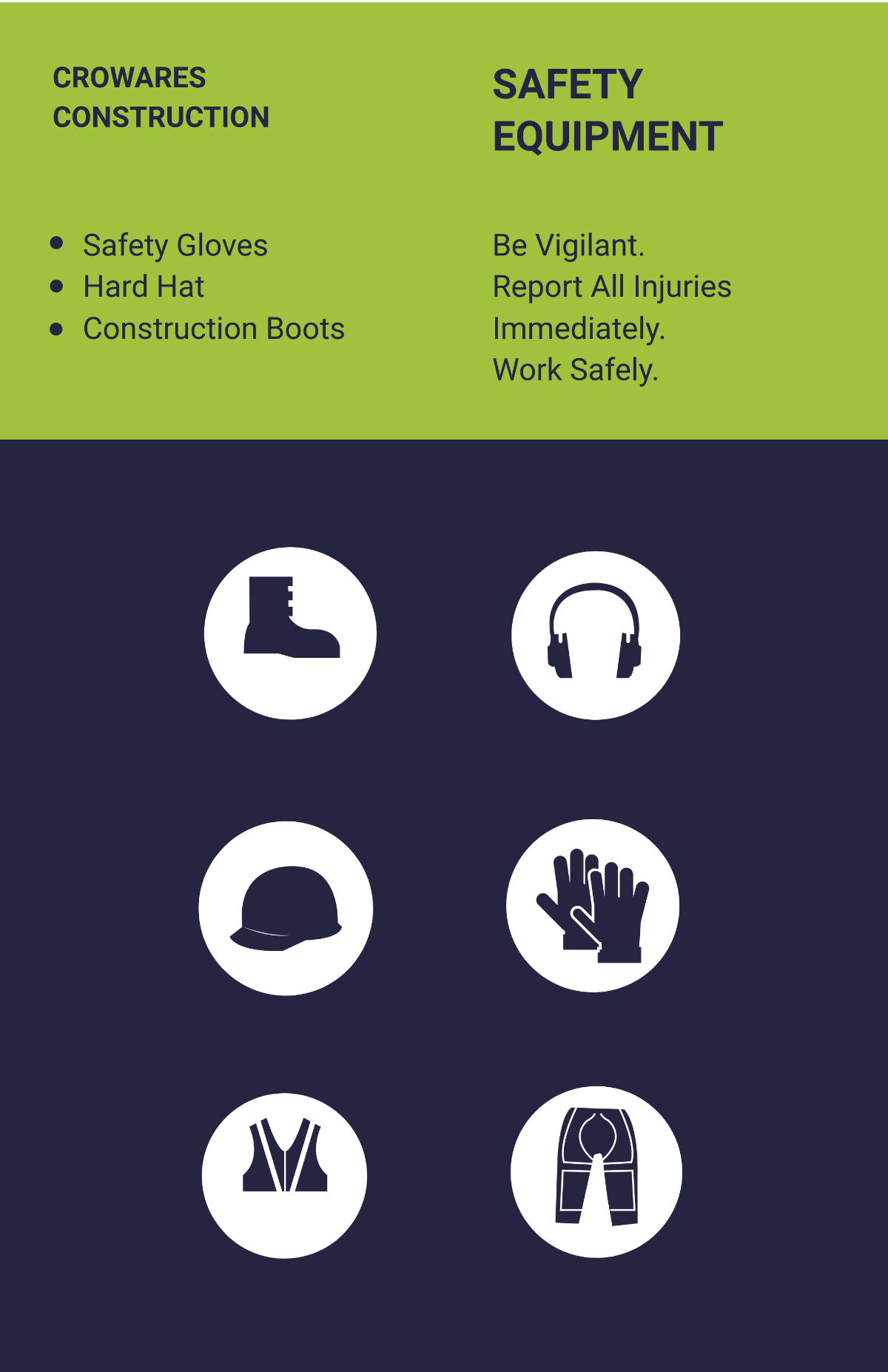

C. Employee Training and Awareness Programs

Regular training programs are conducted to enhance employee awareness and competence in safety matters. These programs cover topics such as hazard recognition, emergency response, and the proper use of personal protective equipment (PPE).

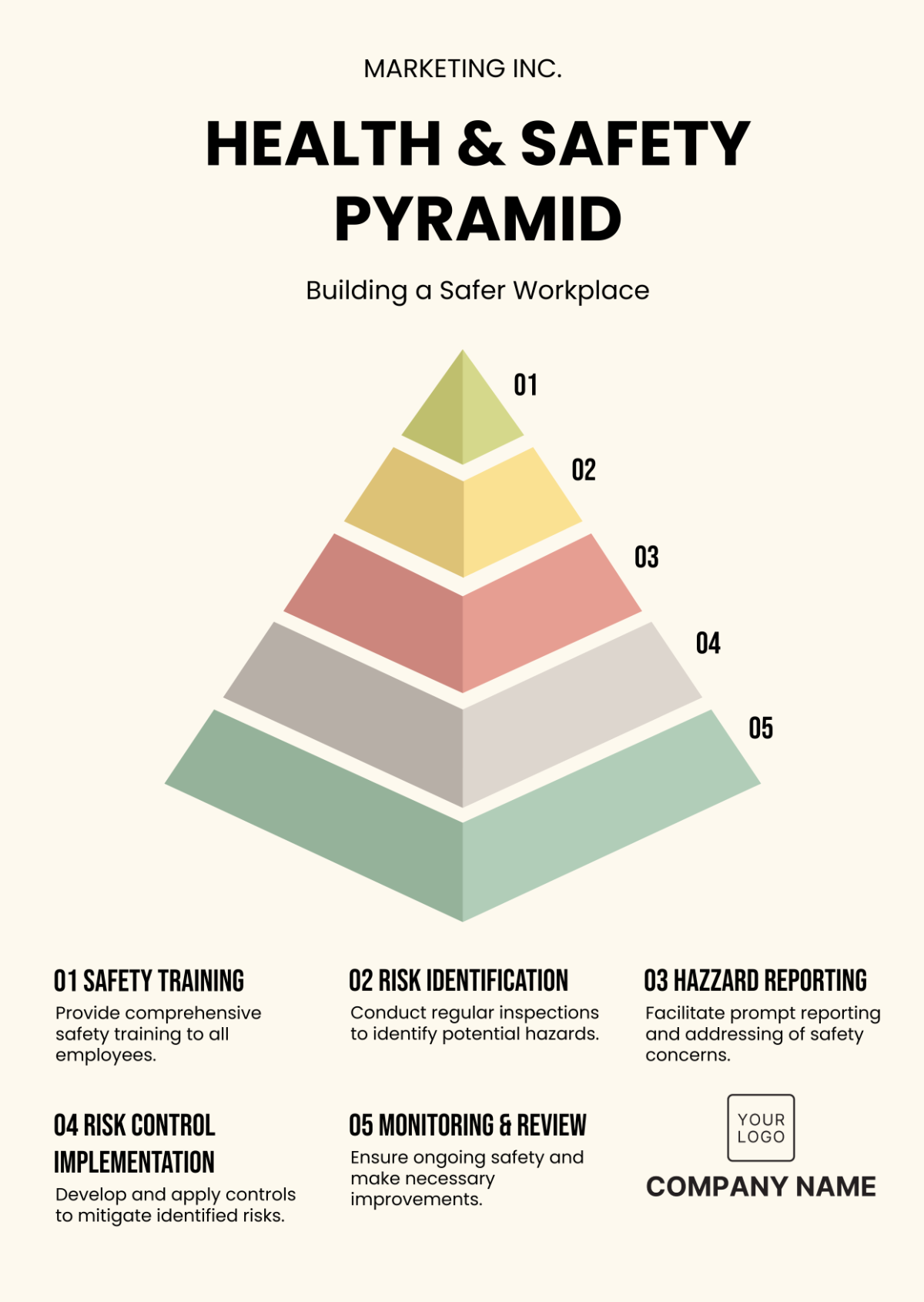

VI. Hazard Identification and Risk Assessment

A. Procedures for Identifying and Assessing Workplace Hazards

[Your Company Name] employs a systematic approach to identify and assess workplace hazards. Regular risk assessments are conducted, involving employees in the identification process, and findings are documented for further analysis.

B. Risk Assessment Methodologies Used

Our risk assessment methodologies include HAZID and Job Safety Analysis, ensuring a comprehensive understanding of potential risks associated with our operations.

C. Documentation of Identified Hazards and Associated Risks

Identified hazards and associated risks are documented in a centralized database accessible to relevant stakeholders. This documentation aids in tracking the status of mitigation measures and facilitates continuous improvement.

VII. Training and Competence

A. Training Programs in Place for Employees

[Your Company Name] provides a range of training programs to equip employees with the necessary skills and knowledge to perform their duties safely. These programs are regularly updated to reflect changes in procedures and regulations.

B. Evaluation of Employee Competence

Competence assessments are conducted periodically to ensure that employees maintain the required skills and knowledge. This evaluation process is tailored to each job role within the organization.

C. Documentation of Training Record

Accurate and up-to-date training records are maintained for each employee. These records include details such as training dates, content covered, and any certifications obtained.

VIII. Emergency Preparedness

A. Emergency Response Plans and Procedures

Comprehensive emergency response plans are in place, covering a range of potential scenarios. These plans outline specific actions to be taken by employees in the event of an emergency and are regularly tested through drills.

B. Emergency Drills and Training Exercises

Regular emergency drills and training exercises are conducted to ensure that employees are familiar with emergency procedures and can respond effectively in high-stress situations.

C. Communication Systems During Emergencies

Robust communication systems, including PA Systems and Two-Way Radios, are in place to facilitate clear communication during emergencies. Regular checks and maintenance activities are conducted to ensure the reliability of these systems.

IX. Incident Reporting and Investigation

A. Procedures for Reporting Incidents and Near Misses

Employees are encouraged to report all incidents and near misses promptly. A well-defined reporting process ensures that incidents are documented accurately, and lessons learned are used to improve safety measures.

B. Investigation Process for Determining Root Causes

Incident investigations are conducted by a dedicated team to determine root causes. This process includes interviewing involved parties, analyzing data, and identifying corrective actions to prevent recurrence.

C. Corrective Actions and Lessons Learned

Corrective actions arising from incident investigations are implemented promptly. Lessons learned are communicated across the organization to prevent similar incidents and enhance overall safety awareness.

X. Equipment Safety

A. Inspection and Maintenance Procedures for Equipment

Equipment inspection and maintenance are carried out according to established procedures and schedules. Regular checks and preventive maintenance activities are performed to ensure the safe operation of all equipment.

B. Equipment Safety Features and Controls

All equipment is equipped with safety features and controls designed to minimize risks. Employees are trained on the proper use of these features, and any malfunction is addressed promptly.

C. Record-keeping for Equipment Maintenance

Comprehensive records of equipment maintenance activities, including inspections, repairs, and replacements, are maintained. These records serve as a crucial reference for equipment safety history.

XI. Workplace Environment

A. Evaluation of the Physical Work Environment

Regular assessments of the physical work environment are conducted to identify and address potential safety hazards. This includes considerations for lighting, ventilation, and ergonomic factors.

B. Ergonomic Considerations

[Your Company Name] prioritizes ergonomic considerations in the design of workspaces and equipment. This includes providing ergonomic furniture and encouraging employees to report any discomfort promptly.

C. Facilities for Employee Well-being

Facilities such as break areas, restrooms, and designated spaces for relaxation contribute to employee well-being. These facilities are designed to provide a comfortable and healthy work environment.

XII. Documentation and Record Keeping

A. Documentation Requirements for Safety Processes

Clear documentation requirements are established for all safety processes. This includes the creation and maintenance of records related to safety policies, procedures, training, and incident reports.

B. Record-keeping Systems in Place

A centralized record-keeping system is utilized to store and manage safety-related documents. This system ensures easy access for auditing purposes and facilitates efficient record retrieval.

C. Accessibility of Safety Documentation for Auditors

Safety documentation is made accessible to auditors during scheduled safety audits. The auditing team is provided with the necessary access to review documentation and assess the effectiveness of safety processes.

XIII. Audit Process

A. Overview of the Audit Process

The safety audit process at [Your Company Name] follows a structured approach, encompassing pre-audit preparations, on-site inspections, data analysis, and post-audit reporting. This process is designed to thoroughly assess our safety management system and identify areas for improvement.

B. Roles and Responsibilities of Auditors

Auditors are carefully selected based on their expertise in safety management. The lead auditor is responsible for coordinating the audit team, while team members contribute their specialized knowledge during the assessment process.

C. Audit Schedule and Timeline

The safety audit is scheduled at regular intervals, aligning with industry best practices and regulatory requirements. A detailed timeline is established to ensure that the audit process is conducted efficiently and without disruption to normal operations.

XIV. Audit Findings and Recommendations

A. Presentation and Documentation of Audit Findings

Audit findings are documented comprehensively, including observations, areas of compliance, and areas requiring improvement. The presentation of findings is conducted in a clear and transparent manner, allowing stakeholders to understand the status of safety within the organization.

B. Prioritization of Recommendations

Findings are prioritized based on their severity and potential impact on safety. This prioritization assists [Your Company Name] in allocating resources effectively to address high-priority recommendations promptly.

C. Follow-up Procedures for Addressing Identified Issues

A systematic approach is employed to address identified issues. Corrective action plans are developed, implemented, and monitored to ensure the resolution of issues within specified timeframes. Follow-up audits may be conducted to verify the effectiveness of implemented corrective actions.

XV. Continuous Improvement

A. Mechanisms for Ongoing Safety Improvement

Continuous improvement is ingrained in our safety culture. [Your Company Name] encourages employees to submit suggestions for safety enhancements, and a dedicated team reviews and implements viable recommendations to drive ongoing improvement.

B. Regular Review and Updates to the Safety Audit Guide

The Safety Audit Guide is subjected to regular reviews to ensure its alignment with industry changes, regulatory updates, and organizational advancements. Updates are made promptly, and all stakeholders are informed of any modifications to the safety audit process.

C. Employee Feedback and Involvement in Improvement Initiatives

Feedback from employees is actively sought to gauge the effectiveness of safety initiatives. Employee involvement in improvement initiatives is encouraged through forums, surveys, and participation in safety committees, fostering a collaborative approach to safety enhancement.