PPE Management Journal

I. Introduction

A. Purpose of the PPE Management Journal

Primary Objective: The PPE Management Journal serves as a document designed to track, analyze, and enhance the organization's Personal Protective Equipment (PPE) management strategies.

Secondary Objectives:

a. Continuous Improvement: Facilitate a culture of continuous improvement by systematically reviewing and refining PPE-related processes.

b. Regulatory Compliance: Ensure adherence to local, state, and federal safety regulations by maintaining detailed records of PPE activities.

c. Risk Mitigation: Identify and mitigate potential risks associated with PPE usage through regular assessments and incident reports.

B. Overview of the Organization's Safety Policy

Safety Commitment: The organization is steadfast in its commitment to fostering a safe and secure working environment for all employees.

Proactive Measures: The Safety Policy emphasizes a proactive approach to risk management, with a focus on preventive measures, employee education, and timely responses to safety concerns.

C. Legal and Regulatory Framework

Legal Context: The PPE Management Journal operates within the legal framework set forth by occupational safety and health regulations. This framework is designed to ensure the highest standards of safety and efficacy in the use of PPE in various industrial and healthcare settings.

The regulations mandate strict adherence to guidelines on the manufacture, distribution, and use of PPE, thereby safeguarding the well-being of workers and end-users.

Regulatory Compliance: Regular updates to the PPE Management Journal ensure the organization's ongoing compliance with changing safety standards and guidelines.

D. Documentation Accessibility

Centralized Repository: All relevant personnel have access to the centralized repository where the PPE Management Journal is securely stored.

User-Friendly Format: The document is structured in a user-friendly format, facilitating ease of access, navigation, and retrieval of critical information.

E. Integration with Safety Culture

Employee Involvement: Encourage active participation and feedback from employees to cultivate a safety culture that values the importance of PPE in preventing workplace incidents.

Communication Channels: Utilize various communication channels to keep employees informed about PPE updates, training sessions, and safety initiatives.

F. Continuous Improvement Cycle

Feedback Mechanisms: Establish mechanisms for employees to provide feedback, ensuring that the PPE Management Journal remains a dynamic tool that evolves based on real-world experiences.

Regular Reviews: Commit to regular reviews of the PPE Management Journal to identify areas for enhancement, incorporate best practices, and align with organizational goals.

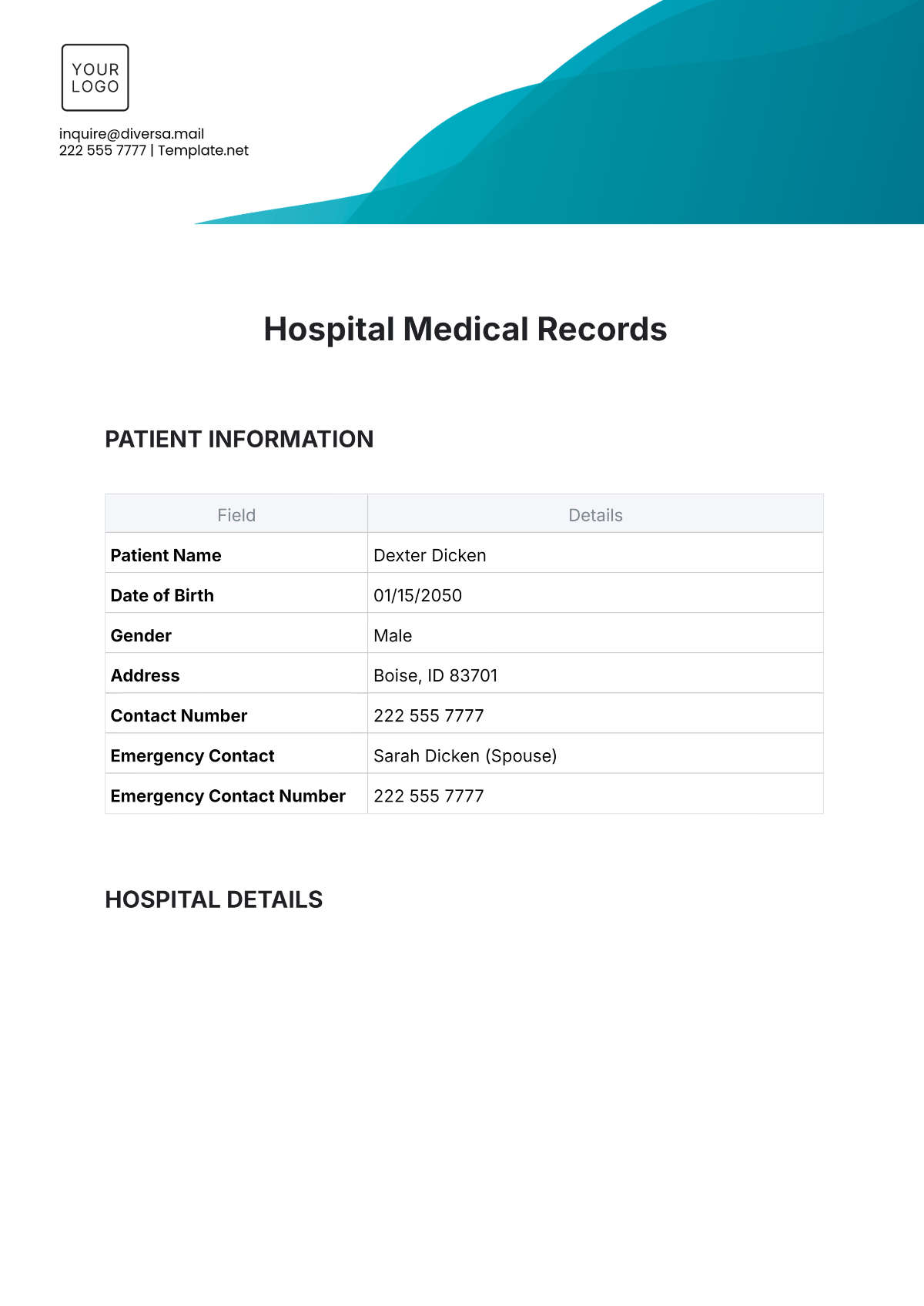

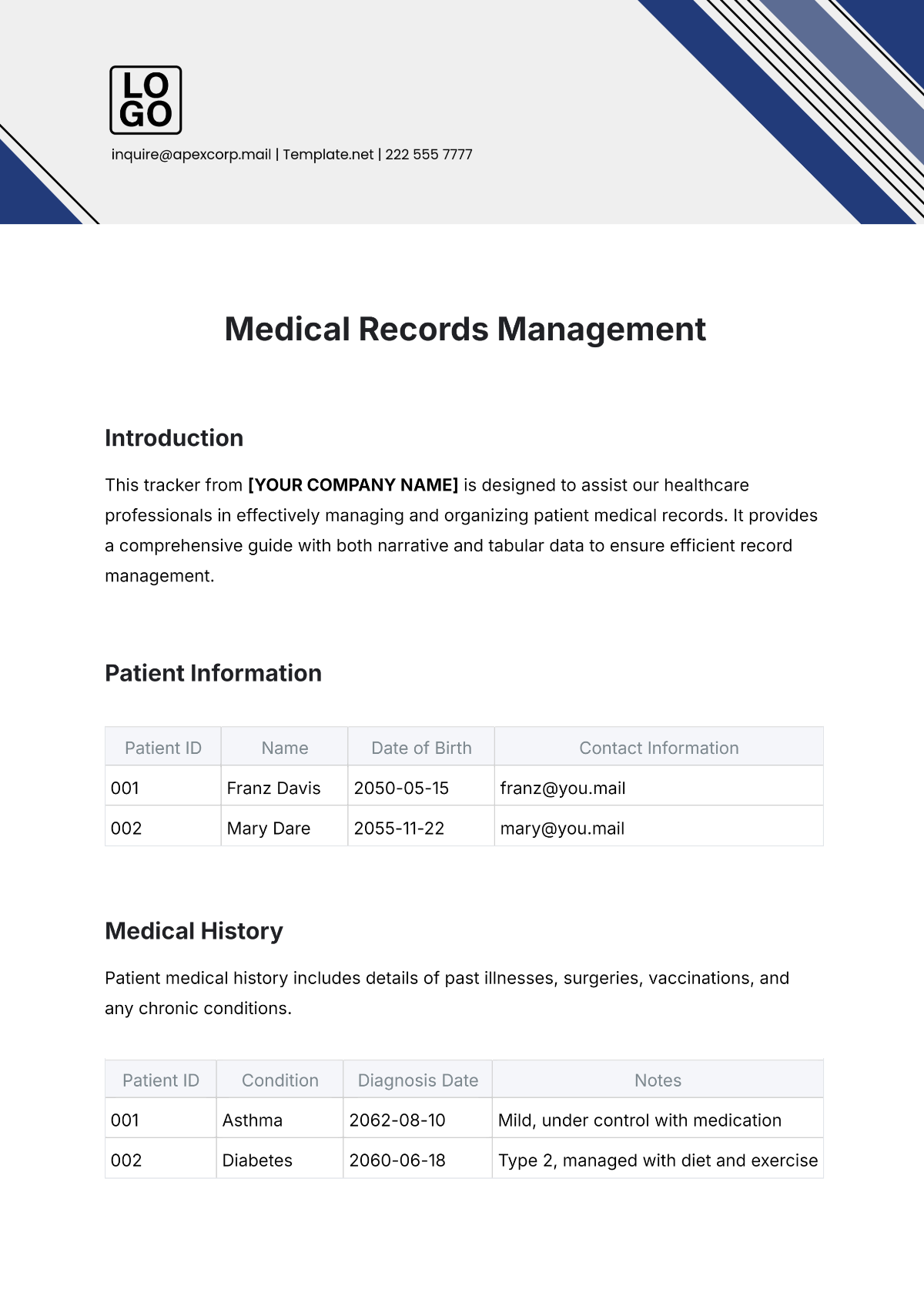

II. Personnel Information

Employee Details

Name: | [Employee’s Name] |

Department/Team: | |

Job Title: | |

Date of Hire: | |

Previous Experience: |

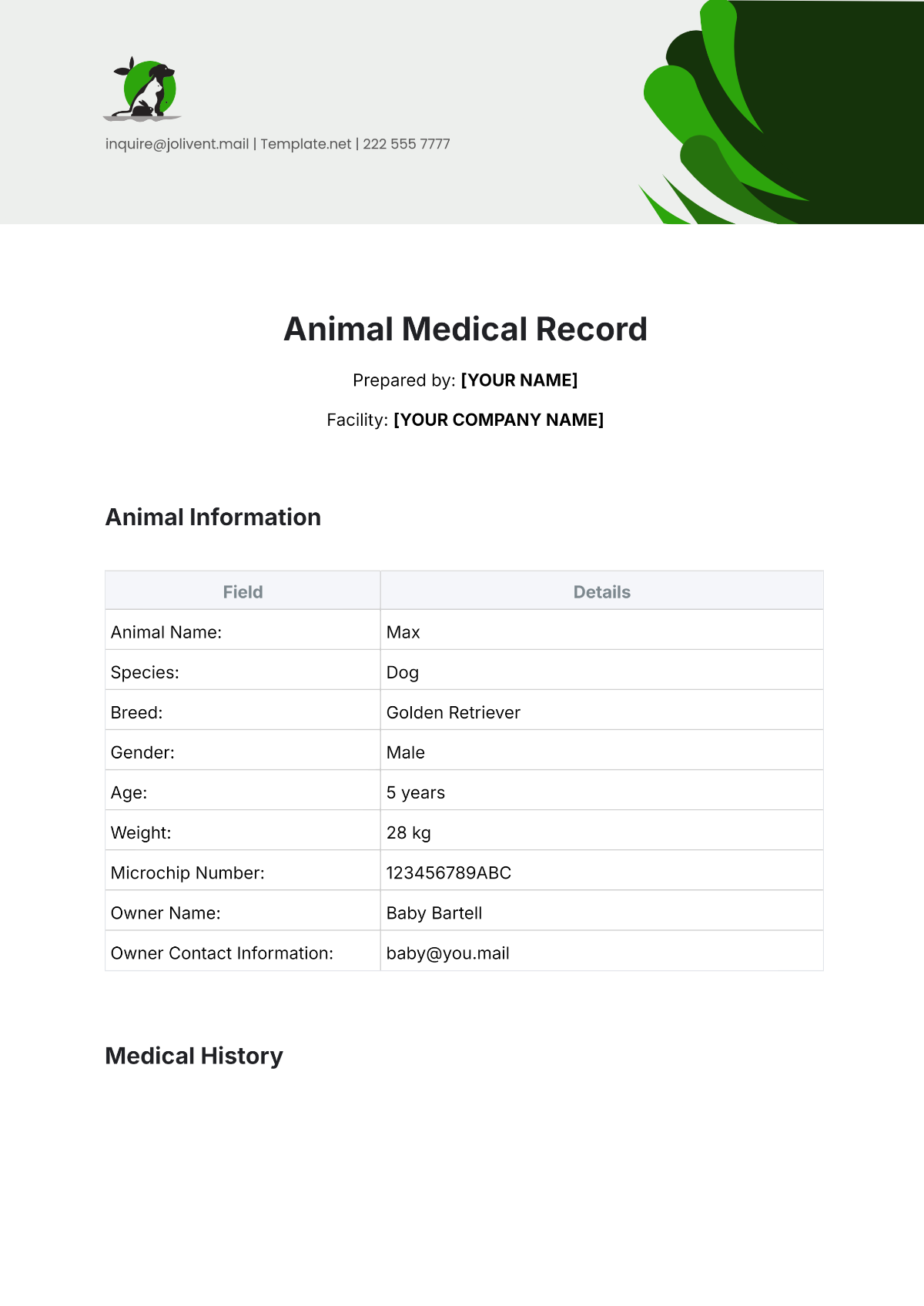

III. PPE Inventory

Comprehensive List of PPE:

Head Protection: | Hard Hat (Adjustable, ANSI Z89.1-2014 compliant) |

Eye and Face Protection: | |

Hand Protection: | |

Foot Protection: | |

Respiratory Protection: |

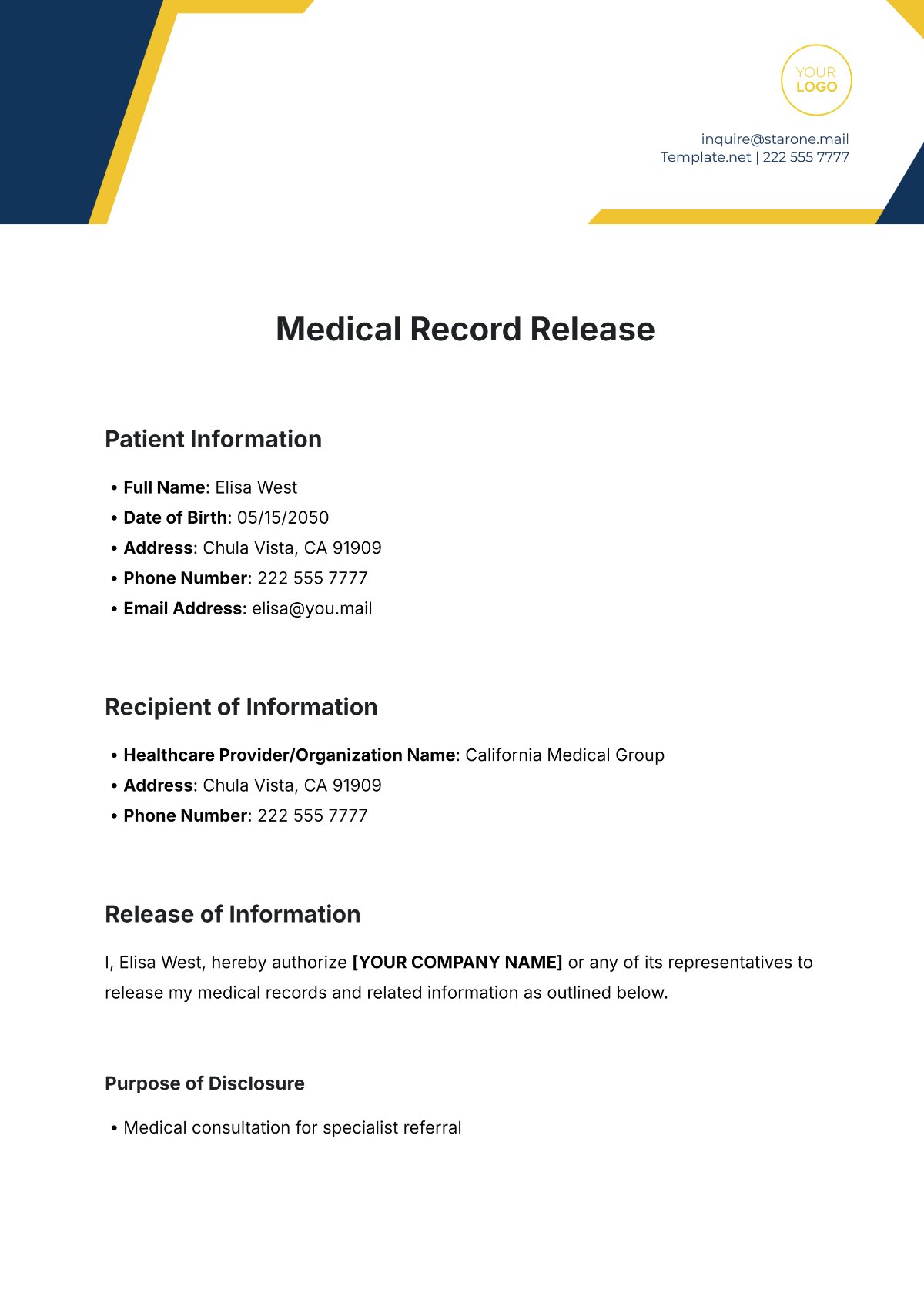

IV. PPE Issuance

Record of PPE Issued to Employees:

Date of Issuance: | [Month Day, Year] |

Type of PPE: | |

Serial/ID Number: | |

Condition of PPE at Issuance: | |

Employee's Acknowledgment: |

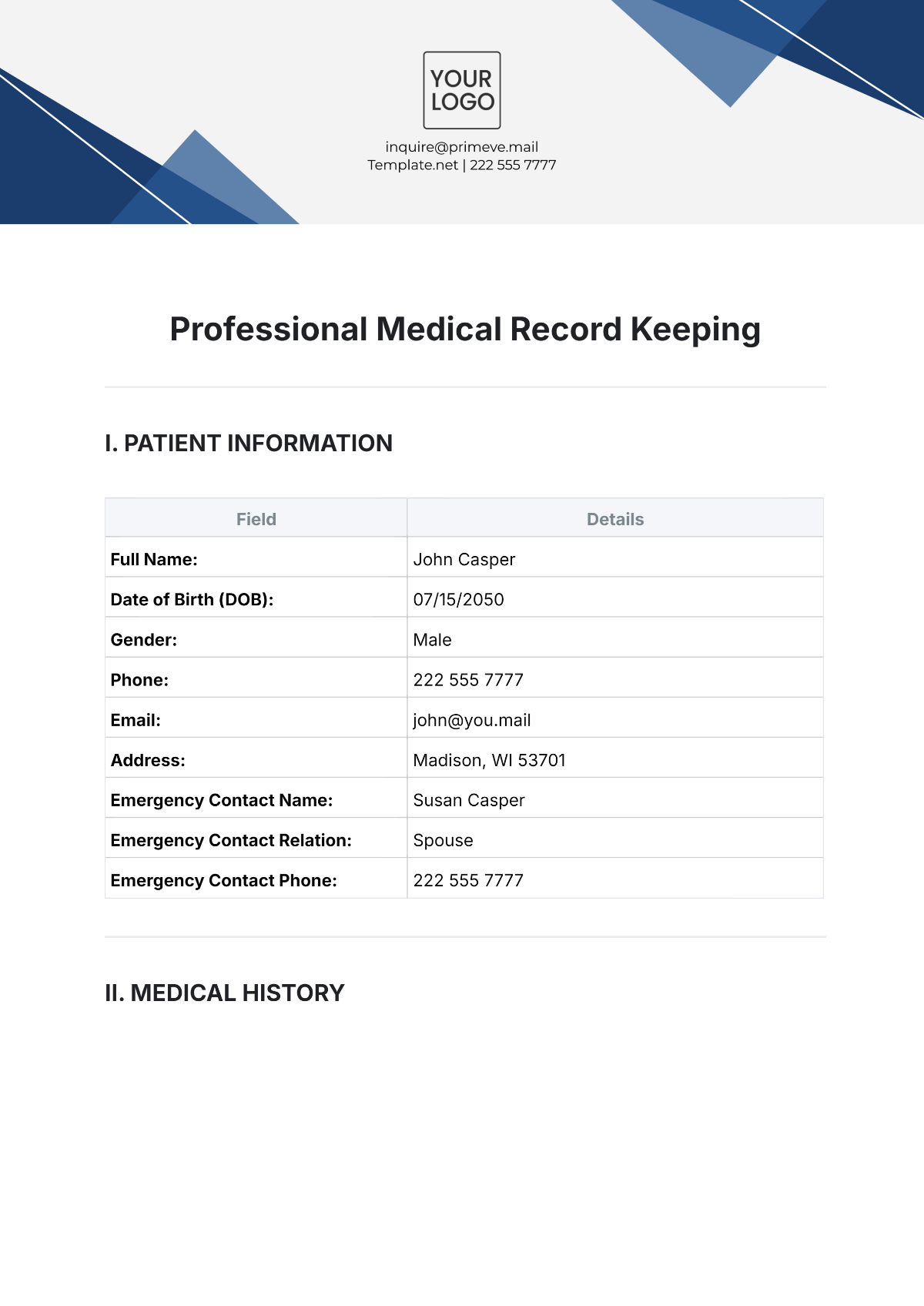

V. Inspections and Maintenance

A. Regular Inspection Records:

Frequency of Inspections: Conducted monthly to ensure continuous operational integrity and safety.

Inspection Checklist:

a. Visual examination for wear, cracks, or other forms of damage.

b. Functional assessment, including verification of straps, fastenings, and other critical components.

Condition Report for [Month Year]: All PPE items met or exceeded inspection standards, with no deficiencies detected.

Any Defects or Issues Identified: None identified in the [Month Year] inspection. Any defective items are promptly replaced to maintain safety standards.

B. Maintenance and Repairs:

Replacement of Damaged PPE: No repairs were necessary in the preceding quarter, indicating high durability and quality of PPE.

Verification of Compliance with Manufacturer's Guidelines: Annual inspection by a certified Safety Officer to confirm adherence to manufacturer’s guidelines, with detailed documentation filed on [Month Day, Year].

VI. PPE Upgrades and Replacements

A. Records of Upgrades or Changes in PPE Models:

There have been no reports of upgrades or changes in PPE models in the past year, indicating stability in the current PPE inventory.

B. Criteria for Replacement:

When PPE shows signs of deterioration beyond the manufacturer's recommended limits.

Introduction of new PPE technologies that offer enhanced safety or usability.

Addressing issues of discomfort or inadequacy as reported by employees, ensuring their well-being and compliance.

C. Communication with Employees Regarding Changes:

Changes in PPE are communicated through various channels:

Safety meetings for direct engagement and discussion.

Email notifications for detailed and accessible communication.

Posted notices in common areas for continuous awareness.

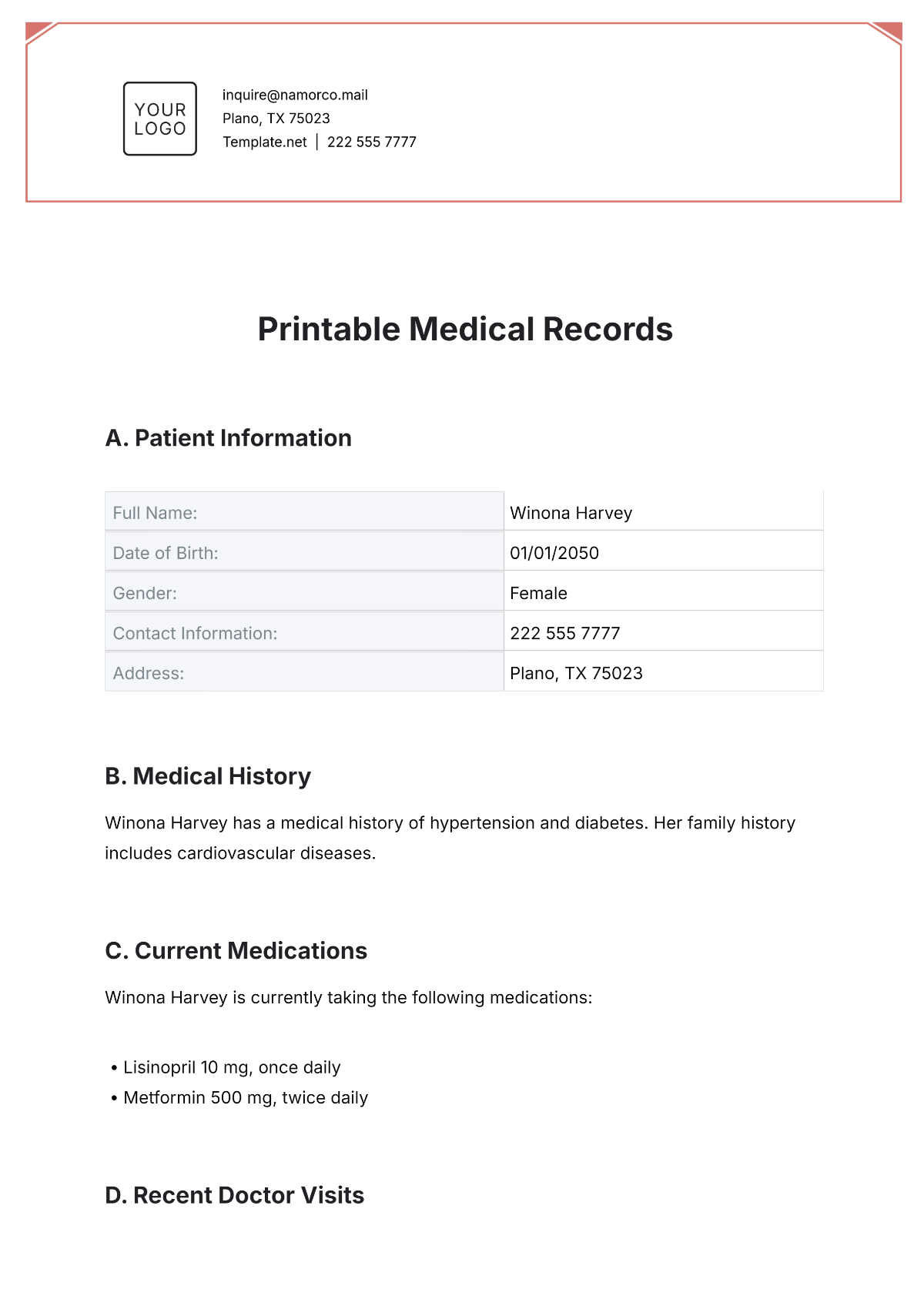

VII. Incident and Accident Reports

Documentation of PPE-Related Incidents:

A. Nature of Incident:

The event was classified as a minor impact incident, involving a falling object. Notably, there were no injuries reported, largely due to the effective use of PPE.

B. PPE Involved:

The hard hat involved in the incident played a pivotal role in preventing potential injuries, underscoring its importance in workplace safety.

C. Corrective Actions Taken:

Promptly substituting the impacted hard hat with a new one ensured continued protection and adherence to safety standards.

A team meeting was convened shortly after the incident to reinforce safety protocols. This meeting served as a platform to discuss the incident, review safety procedures, and reiterate the importance of vigilance in accident prevention.

Following the incident, we conducted specialized training sessions emphasizing the critical importance of wearing appropriate PPE in designated areas. These sessions were designed to enhance safety awareness and compliance among employees, providing them with practical insights into the role of PPE in mitigating workplace hazards.

VII. Employee Feedback

A. Mechanism for Employees to Provide Feedback on PPE:

Suggestion Box: Placed in the breakroom for anonymous submissions.

Quarterly Safety Meetings: Open forums for employees to discuss concerns and suggestions.

Anonymous Surveys: Distributed annually to gather feedback on PPE comfort, usability, and overall satisfaction.

B. Record of Feedback Received:

Positive Feedback: Numerous positive comments on the comfort and durability of the gloves, are documented in the Feedback Log.

Negative Feedback: No negative feedback was reported; all concerns were addressed promptly.

C. Actions Taken in Response to Feedback:

Acknowledgement: Positive feedback is acknowledged during monthly team meetings, boosting employee morale.

Improvements: Acted on suggestions for additional glove options, now included in the updated PPE catalog.

Training: Conducted refresher training on proper glove selection and usage.

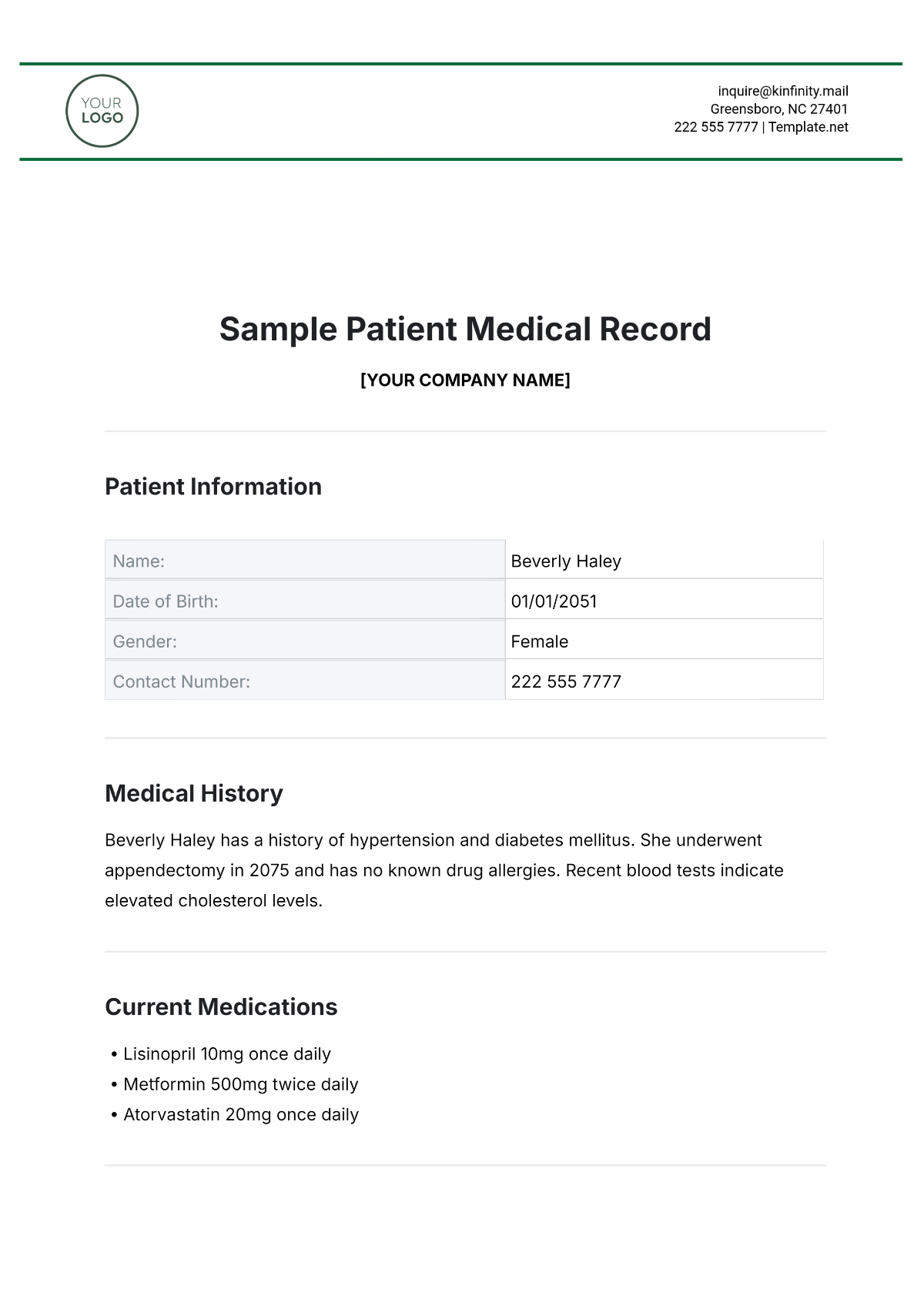

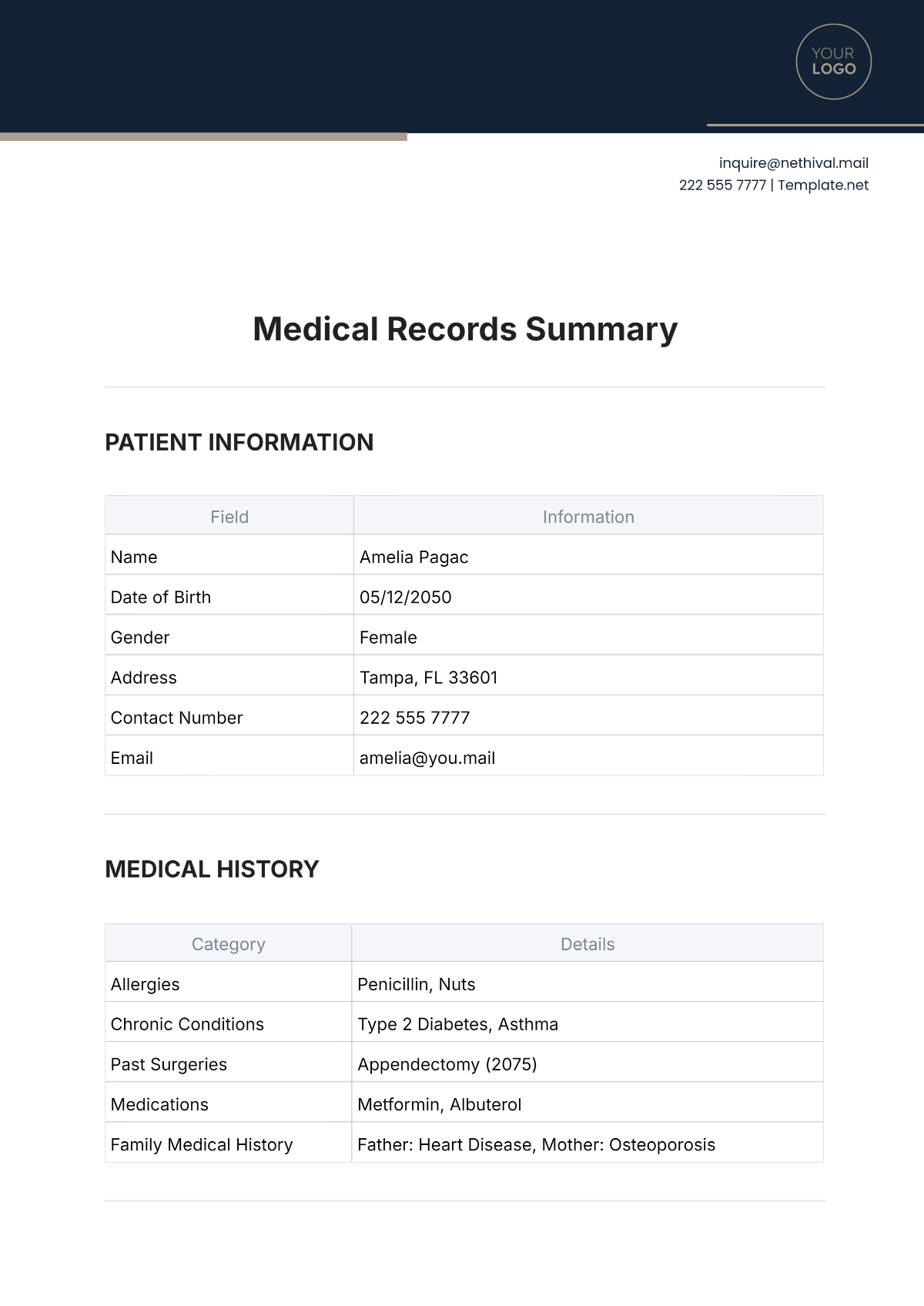

IX. Review and Evaluation

A. Periodic Review of PPE Management Journal:

Frequency: Conducted quarterly to ensure timely assessment and responsiveness.

Review Team: The review team comprises a Safety Manager, Compliance Officer, Department Supervisors, and selected Employee Representatives, ensuring a comprehensive perspective on PPE management.

Key Focus Areas:

a. Verifying adherence to current safety and health regulations.

b. Evaluating the impact and efficacy of existing training initiatives.

c. Monitoring trends in incident reports and employee feedback to identify areas for improvement.

B. Assessment of Overall Effectiveness:

Key Performance Indicators (KPIs):

a. Percentage of PPE compliance among employees.

b. Rates of incidents and accidents involving PPE.

c. Employee satisfaction scores were derived from feedback on PPE usage.

Trends and Analysis: An observed [20%] improvement in PPE compliance compared to the previous quarter, indicating positive progress.

Areas of Improvement: Ongoing focus on communication strategies, with plans for targeted training sessions.

C. Recommendations for Improvement:

Training Enhancement: Creation of specialized training modules for areas identified as high-risk, ensuring targeted learning.

Technology Integration: Exploring the integration of advanced wearable technology for real-time monitoring and enhancement of PPE effectiveness.

Employee Recognition: Introduction of an incentive scheme to recognize and reward consistent adherence to PPE protocols, fostering a culture of safety and compliance.

This robust review and evaluation framework is pivotal for continuous improvement in PPE management. It underscores a commitment to maintaining the highest standards of workplace safety and employee well-being.