PPE Utilization Study

I. Introduction

At [Your Company Name], we hold an unwavering commitment to the safety and well-being of our employees. As we continually strive for excellence in workplace safety, the pivotal role played by Personal Protective Equipment (PPE) in mitigating potential hazards cannot be overstated. This PPE Utilization Study is an integral initiative, rooted in our dedication to fostering a workplace environment where every employee can perform their duties with the utmost protection and confidence. By comprehensively evaluating the effectiveness and efficiency of our current PPE practices, we embark on a journey to strengthen our safety protocols and ensure the highest standards of employee protection.

II. Objectives

A. Effectiveness Evaluation:

Our primary goal is to assess the efficacy of our existing PPE measures in safeguarding employees against a spectrum of workplace hazards. This evaluation aims to validate the impact of our current PPE protocols on minimizing risks and enhancing workplace safety.

B. Compliance Assessment

We seek to gauge the extent to which employees adhere to prescribed PPE requirements, aligning with established safety protocols and regulatory standards. This assessment will provide insights into the level of commitment to safety practices within our workforce.

C. Identification of Gaps

By scrutinizing the utilization of PPE, we aim to identify any gaps or deficiencies that may exist in our current approach. Pinpointing these areas will enable us to implement targeted improvements and bolster our overall safety framework.

D. Training Needs

Recognizing the critical role of knowledge in safety, this study will assess the need for additional training and education on proper PPE use. Identifying areas where enhanced employee awareness is required will contribute to a more informed and safety-conscious workforce.

E. Continuous Improvement

We view this study as a catalyst for continuous improvement in our safety protocols and procedures. Insights gained from the evaluation will guide our ongoing efforts to adapt and elevate our PPE practices, fostering a proactive approach to workplace safety.

III. Methodology

A. Data Collection Methods

In our pursuit of a thorough assessment, we will employ a multi-faceted approach to data collection, combining quantitative and qualitative methods:

1. Observations

Our team of trained safety officers will conduct on-site observations, providing a firsthand look at PPE usage across diverse work areas and tasks.

Employee Interviews

Structured interviews with a representative sample of employees will offer valuable qualitative insights into their experiences with PPE utilization, shedding light on real-world challenges and successes.

Document Reviews

A meticulous examination of existing safety protocols, training records, and incident reports will complement our observational and interview data, offering a comprehensive view of our current safety landscape.

B. Sampling

To ensure a representative and inclusive study, we will select a diverse sample of employees from various departments and roles. This strategic sampling approach will provide a holistic understanding of PPE utilization across the company, capturing nuances specific to different job functions.

C. Data Analysis

Our data analysis methodology will encompass both quantitative and qualitative techniques. This inclusive approach involves categorizing patterns of PPE usage, identifying trends, and exploring potential correlations between compliance and various contextual factors. This comprehensive analysis aims to uncover actionable insights that will inform our future safety initiatives.

IV. PPE Assessment

A. Type of PPE Used

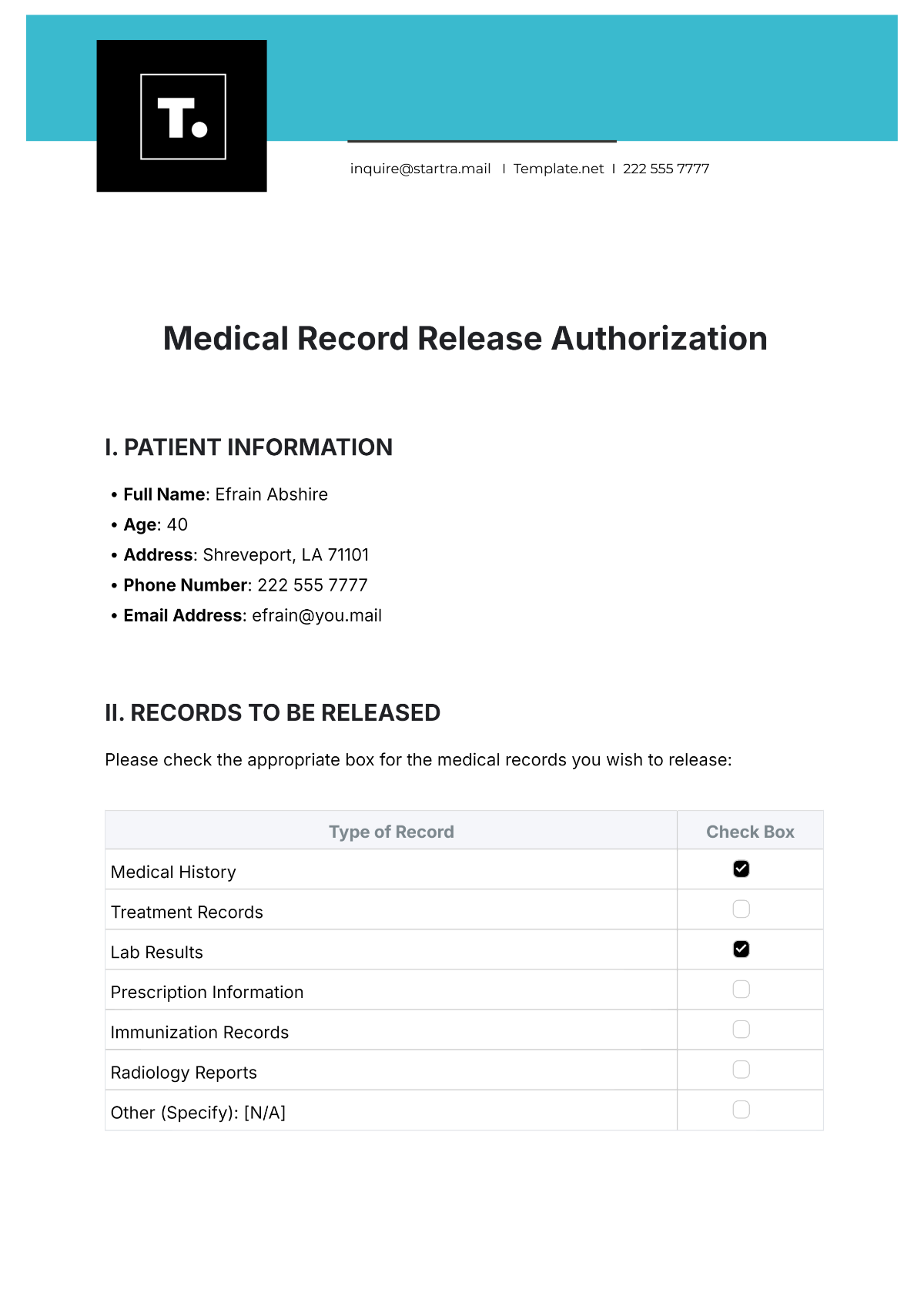

A crucial aspect of our PPE Utilization Study is the assessment of the types of PPE utilized across various work areas. The following table outlines the specific PPE items required for distinct tasks within our company:

Work Area/Task | Required PPE |

[Manufacturing Floor] | [Safety helmets, eye protection, hearing protection] |

This detailed categorization serves as a foundational reference point for evaluating the appropriateness and diversity of PPE across our company. By identifying the specific PPE items associated with each work area, we can tailor our assessment to address the unique safety needs of different departments and tasks.

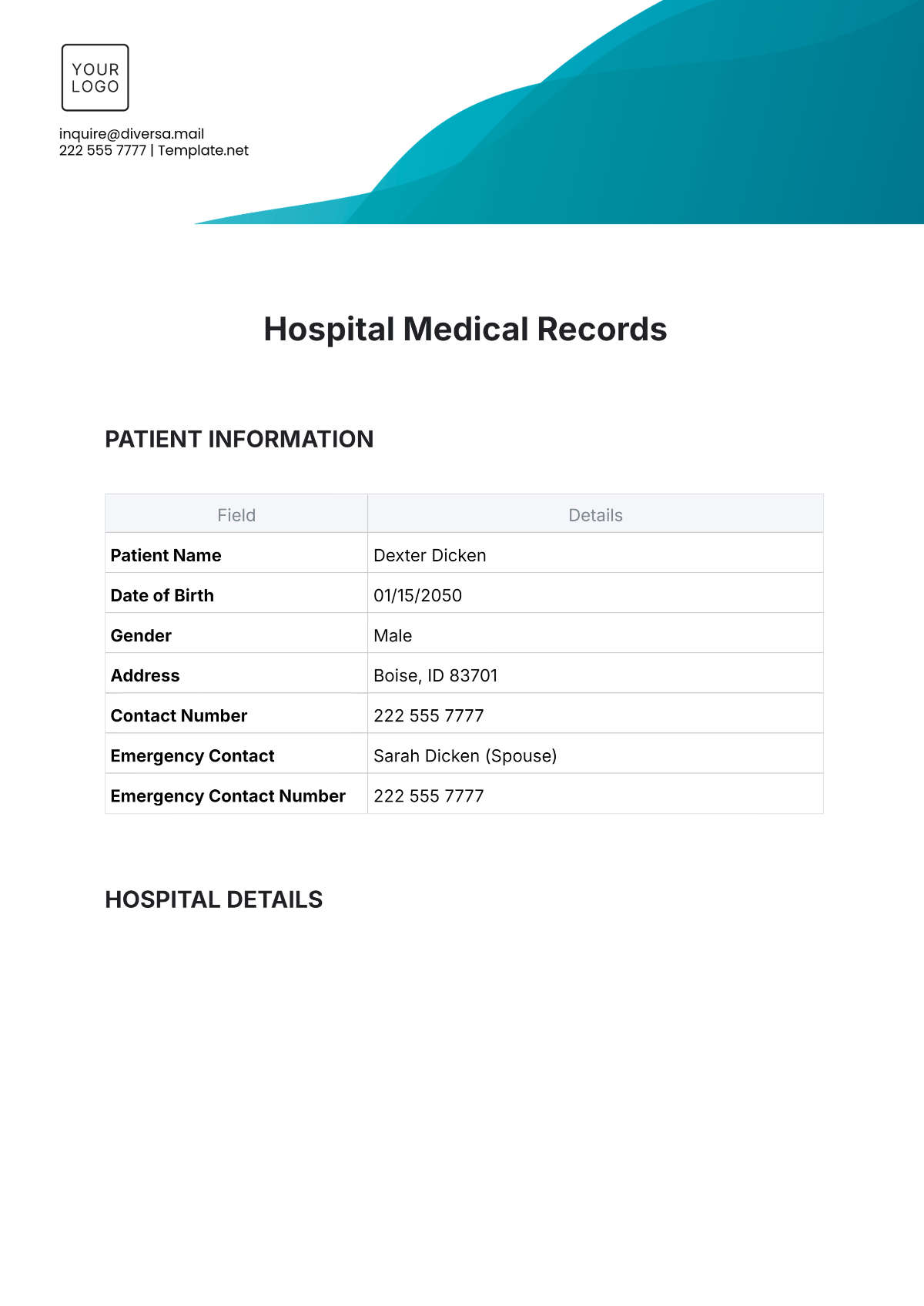

B. Condition of PPE

Simultaneously, we turn our focus to the condition of the existing PPE within our company. The table below classifies the condition of PPE items:

| Condition | Notes | ||

Good | Fair | Poor | ||

[Safety Helmets] | [Passed safety standards] | |||

This PPE Assessment serves as our foundational step, setting the stage for subsequent sections that delve into compliance, training, and employee feedback, ultimately contributing to a more comprehensive and informed safety strategy. The evaluation of PPE conditions reveals that a significant portion is in good working order, indicating proactive maintenance efforts.

However, identifying items categorized as fair or poor condition prompts a closer examination of these instances to determine whether replacement or repair is necessary. This nuanced understanding is crucial for maintaining a high standard of safety, as even minor wear on PPE can impact its protective efficacy.

V. Compliance Analysis Results

A. Adherence to PPE Protocols

A. Direct Observations

The direct observations revealed a commendable overall adherence to prescribed PPE protocols within our company. Across various work areas, employees consistently demonstrated compliance with safety regulations, wearing the required protective gear in line with their specific job roles. Noteworthy practices included the consistent use of safety helmets on the manufacturing floor and the conscientious application of lab coats, gloves, and eye protection in laboratory settings.

B. Employee Interviews

Insights gathered from employee interviews provided valuable qualitative data on the factors influencing PPE adherence. Employees expressed a strong awareness of the importance of safety protocols and emphasized a collective commitment to creating a secure work environment. Additionally, interviews highlighted a positive perception of the existing PPE training programs, contributing to a culture where safety is prioritized.

C. Data Analysis

Quantitative data analysis corroborated the positive trend observed in direct observations and employee interviews. Compliance rates were consistently high across departments, indicating a robust adherence to PPE protocols. Categorizing data based on job roles and specific PPE requirements revealed uniformity in adherence patterns, further validating the effectiveness of current safety practices.

B. Identification of Non-Compliance

A. Patterns Categorization of Non-Compliance

Instances of non-compliance were infrequent, and when identified, were primarily associated with minor deviations rather than systemic issues. Non-compliance patterns were categorized based on the nature of the deviation, with most instances involving unintentional oversights rather than intentional disregard for safety protocols.

B. Root Cause Analysis

Root cause analysis aimed to understand the factors contributing to non-compliance. The identified root causes were predominantly linked to momentary lapses in attention, environmental challenges, or instances where specific PPE items required replacement. Addressing these root causes would involve targeted interventions such as reminders, environmental adjustments, and timely equipment maintenance.

C. Intervention Strategies

Building upon the identified root causes, intervention strategies will focus on reinforcing positive behaviors and addressing specific challenges leading to non-compliance. Proposed interventions include targeted awareness campaigns, periodic safety reminders, and streamlined processes for reporting and replacing damaged or worn-out PPE.

VI. Employee Feedback and Involvement

A. Feedback Mechanism

Establishing a robust mechanism for collecting feedback directly from employees regarding safety protocols which involves PPEs, training programs, and overall safety culture. This will involve regular surveys, focus group discussions, and suggestion boxes to ensure that employee perspectives are actively considered in the continuous improvement of safety practices.

B. Recognition Programs

Implementing employee recognition programs to acknowledge and celebrate outstanding adherence to safety protocols. This initiative aims to create a positive safety culture by highlighting and rewarding employees who consistently demonstrate a commitment to safety.

C. Safety Committees

Forming safety committees comprising representatives from different departments to actively involve employees in the decision-making process related to safety initiatives. These committees will serve as forums for discussing safety concerns, proposing improvements, and fostering collaboration between management and employees.

D. Training Participation

Encouraging active participation in safety training programs by incorporating incentives and recognition for employees who consistently engage in and excel during training sessions. Recognizing and rewarding employees for their commitment to ongoing education fosters a culture of continuous improvement and a shared responsibility for safety.

VII. Key Findings

The comprehensive Safety Utilization Study has yielded valuable insights into our company's health and safety landscape. Key findings include:

A. High Adherence to PPE Protocols

The analysis of adherence to PPE protocols indicates a commendable overall compliance across diverse work areas, reflecting a robust safety culture.

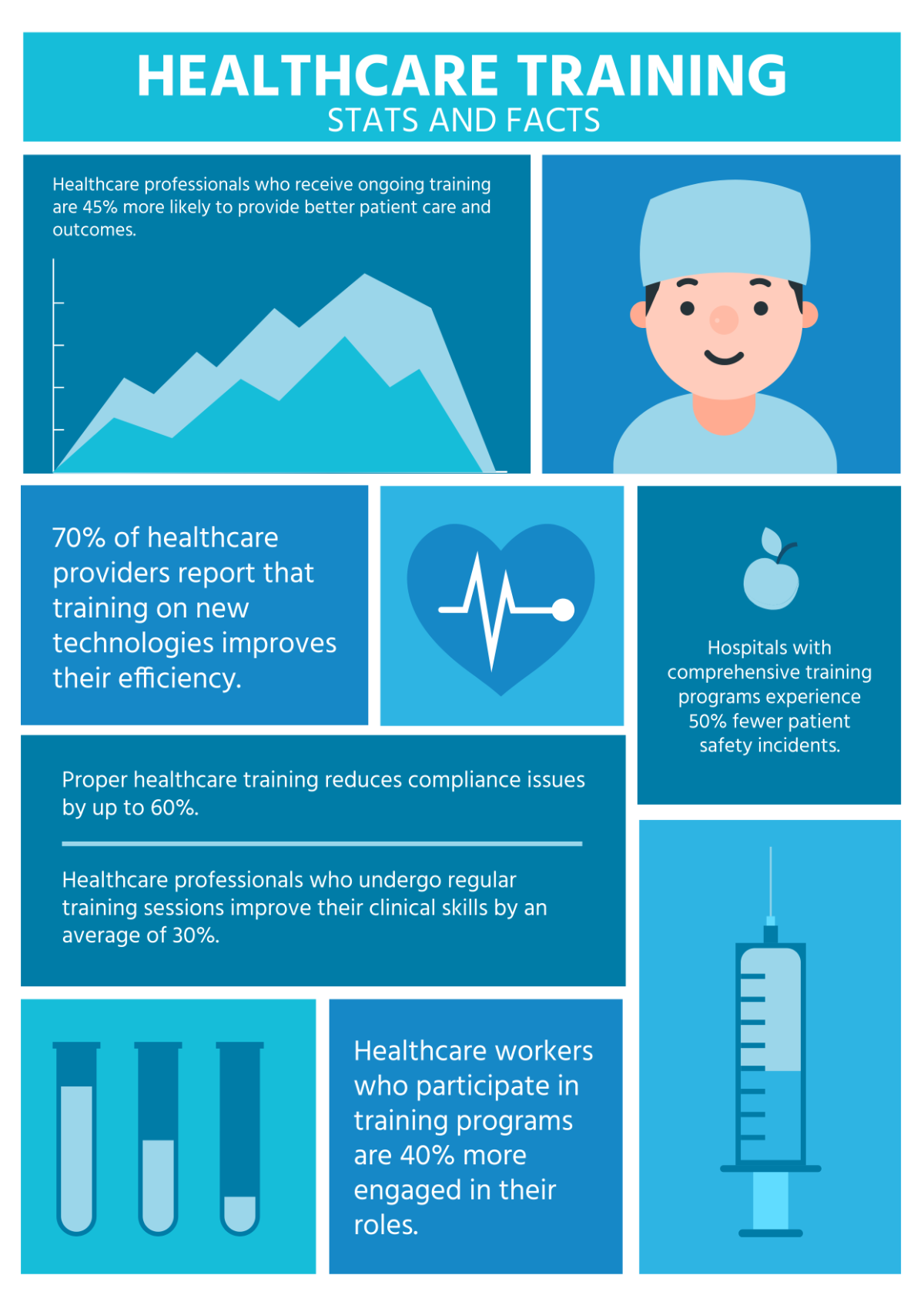

B. Effective Training Programs

The evaluation of training programs highlights their effectiveness in conveying the importance of PPE usage. Employees express a positive perception of the content and delivery methods.

C. Identified Non-Compliance Patterns

Instances of non-compliance are minimal and often associated with momentary lapses. Root cause analysis provides clarity on the factors contributing to non-compliance.

D. Positive Employee Feedback

Employee feedback is overwhelmingly positive, indicating a strong understanding of safety protocols and a commitment to maintaining a safe work environment.

E. Incident-Related Training Needs

Incident report reviews reveal specific areas where additional training modules may be beneficial to address incident-related concerns.

VIII. Recommendations

The following are the recommended solutions basing on the key findings:

A. Targeted Training Modules

Develop targeted training modules addressing specific incident-related concerns identified in the Training Evaluation. These modules should focus on practical scenarios and hands-on demonstrations to reinforce proper PPE usage in real-world situations.

B. Regular Communication Updates

Enhance regular communication updates by incorporating real-life examples, success stories, and practical tips related to safety. Utilize digital platforms and visual displays to ensure consistent and engaging communication across the company.

C. Emergency Response Drills

Increase the frequency of emergency response drills and simulations to reinforce employee preparedness. Evaluate and refine emergency response protocols based on the outcomes of these drills, ensuring alignment with industry best practices.

D. Performance-Based Incentives

Implement performance-based incentives to recognize and reward employees actively participating in safety training programs and consistently demonstrating adherence to safety protocols. This initiative aims to reinforce a positive safety culture.

E. Periodic Safety Awareness Campaigns

Launch periodic safety awareness campaigns focusing on specific safety themes or challenges identified through continuous monitoring. These campaigns can serve as reminders, reinforcing the importance of safety in day-to-day operations.

F. Continuous Improvement Forums

Establish forums for continuous improvement, encouraging employees to actively participate in identifying areas for enhancement and proposing innovative safety solutions. This collaborative approach fosters a sense of ownership and accountability.

G. Regular Updates

Ensuring that training materials are periodically reviewed and updated to reflect the latest safety standards and industry best practices. This proactive approach will guarantee that our employees receive training that is consistently aligned with evolving regulations and emerging safety protocols.

H. Enhanced Practical Sessions

Introducing more hands-on practical sessions to reinforce proper PPE usage. Active engagement with safety procedures in a controlled environment will empower employees with practical skills and confidence. These sessions will be designed to simulate real-world scenarios, allowing for a more immersive and impactful learning experience.

I. Meetings and Workshops

Integrating safety discussions into regular departmental meetings and conducting periodic workshops to address emerging safety concerns and foster a continuous dialogue.

J. Physical Inspections

Inspecting work areas to ensure compliance with safety protocols, the availability of necessary PPE, and the proper functioning of safety equipment.

K. Documentation Review

Scrutinizing safety documentation, incident reports, and training records to ensure accuracy, completeness, and adherence to regulatory requirements.

IX. Conclusion

The report has provided a detailed examination of our company's current health and safety status. The findings underscore a commendable level of adherence to PPE protocols and the effectiveness of existing training programs. Identified areas for improvement, coupled with targeted recommendations, lay the groundwork for a proactive safety culture. The proposed initiatives, ranging from targeted training modules to performance-based incentives, reflect our commitment to continuous improvement. Through collaborative efforts and a steadfast commitment to safety, we aim to create a workplace that not only meets regulatory standards but also fosters a culture where the well-being of every employee is a top priority.