Free Safety Compliance Study

1. Executive Summary

This Safety Compliance Study presents an analysis and strategic approach towards achieving and maintaining the highest standards of workplace safety and regulatory compliance. Our objective is to foster an environment that not only adheres to legal requirements but also proactively addresses potential safety risks, ensuring the well-being of all employees and stakeholders.

In this study, we delve into a systematic evaluation of our current safety protocols, identifying areas of strength and opportunities for improvement. Key aspects include a thorough review of our compliance with Occupational Safety and Health Administration (OSHA) standards, state and local safety regulations, as well as adherence to globally recognized industry benchmarks such as ISO 45001 for occupational health and safety management systems.

2. Introduction

This study is a critical evaluation of the current safety practices at [Your Company Name], located at [Your Company Address], in light of local, state, and federal regulations, as well as industry-specific safety standards.

3. Compliance Overview

In this section of the Safety Compliance Study, we delve into the comprehensive evaluation of [Your Company Name]'s adherence to both legal and industry-specific safety standards. Ensuring compliance is not just a regulatory obligation but a fundamental aspect of our commitment to upholding the highest levels of safety and well-being in our workplace.

Legal Requirements

This subsection provides a detailed analysis of our alignment with essential legal frameworks, such as the Occupational Safety and Health Administration (OSHA) standards, which constitute the bedrock of federal regulations for workplace health and safety. Additionally, we assess our compliance with local safety laws that are pertinent to our specific location. For each of these legal requirements, we present a clear description, our current compliance status, and an actionable plan to address any areas where improvement is needed.

Requirement | Description | Compliance Status |

OSHA Standards | Federal regulations for workplace health and safety | Compliant |

Local Safety Laws | Specific safety laws applicable in [State/Jurisdiction] | Compliant |

Industry Standards

This standard represents a global benchmark for effective occupational health and safety management systems. Adhering to such standards not only demonstrates our commitment to maintaining international levels of safety excellence but also reflects our proactive approach to integrating best practices in safety management into our operational framework. Similar to the legal requirements, we provide a detailed overview of each standard, our compliance status, and strategic actions for continuous improvement.

Standard | Description | Compliance Status |

ISO 45001 | International standard for occupational health and safety | Compliant |

4. Risk Assessment

Methodology

For [Your Company Name], the methodology adopted for conducting the risk assessment was a comprehensive and systematic approach, integrating both qualitative and quantitative analysis. This approach enabled us to thoroughly evaluate the potential hazards within the workplace, considering various factors such as the nature of work, the physical work environment, and the potential impact on employees. The specific areas of focus included:

Workplace Environment: Assessing the physical layout, machinery, and equipment used.

Operational Processes: Evaluating the procedures and tasks inherent to our business operations.

Employee Interaction: Considering the dynamics of employee activities and interactions.

External Factors: Factoring in elements such as environmental conditions

and external stakeholders.

This multifaceted methodology ensured a holistic understanding of potential risks, thereby allowing us to implement effective control measures.

Findings

The following table summarizes the key findings from our risk assessment:

Risk Area | Potential Hazard | Severity | Likelihood | Control Measures |

Machinery Operation | Injury from machinery operation | High | Moderate | Regular maintenance, safety training, PPE usage |

Chemical Handling | Exposure to hazardous chemicals | Moderate | Low | Proper storage, labeling, safety gear, training |

Ergonomic Hazards | Repetitive strain injuries | Low | High | Ergonomic assessments, frequent breaks, training |

Electrical Systems | Electrical shock or fire | High | Low | Regular inspections, safety protocols, training |

Emergency Evacuation | Inadequate evacuation process | Moderate | Low | Evacuation drills, clear signage, accessible exits |

Each identified risk area has been meticulously analyzed, with the severity and likelihood of potential hazards being evaluated based on current workplace practices and historical data. The proposed control measures are tailored to mitigate these risks effectively, encompassing a range of strategies from employee training and personal protective equipment (PPE) usage to procedural changes and infrastructure improvements.

5. Safety Policies and Procedures

Our safety policies and procedures are integral to our commitment to ensuring a secure and healthy work environment. These policies are not only designed to comply with regulatory standards but also to embed a culture of safety within the organization. The following sections provide an overview of key policy areas, with more detailed information available in the attached document.

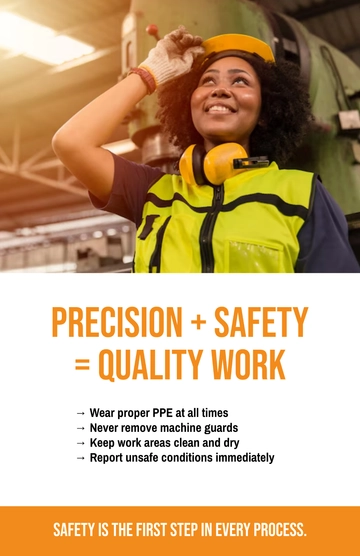

Policy Area 1: Workplace Safety

Our Workplace Safety Policy is focused on creating a hazard-free environment. This policy covers areas such as:

Personal Protective Equipment (PPE): Requirements for PPE usage, including guidelines for proper selection, use, and maintenance.

Machinery and Equipment Safety: Procedures for the safe operation of machinery, including training requirements and maintenance protocols.

Workplace Ergonomics: Guidelines to prevent ergonomic injuries, including workstation setup and regular ergonomic assessments.

Aspect | Description | Guidelines/Procedures |

PPE Usage | Mandatory use of PPE in designated areas | Specific PPE types for various operations |

Machinery Safety | Safe operation of workplace machinery | Training, maintenance schedules, etc. |

Ergonomic Assessment | Reducing ergonomic risks | Regular assessments, workstation setup |

Health and Environmental Safety

This policy area addresses health and environmental concerns, including:

Chemical Handling and Storage: Guidelines for the safe handling and storage of hazardous materials.

Waste Management: Procedures for the disposal and management of waste, emphasizing environmental sustainability.

Occupational Health: Policies related to employee health, including prevention of occupational diseases and management of workplace-related health issues.

Aspect | Description | Guidelines/Procedures |

Chemical Handling | Safe handling and storage of chemicals | Handling protocols, storage guidelines |

Waste Management | Environmentally responsible waste disposal | Segregation, disposal methods, recycling |

Occupational Health | Managing health risks in the workplace | Health screenings, disease prevention |

The implementation of these policies and procedures is regularly monitored and reviewed to ensure their effectiveness and to make necessary adjustments in response to new challenges and regulatory changes. Employee training sessions are conducted to familiarize staff with these policies, ensuring that everyone at [Your Company Name] understands their role in maintaining a safe and healthy workplace.

6. Training and Awareness

Training and awareness at [Your Company Name] are a cornerstone of our safety compliance strategy. We recognize that informed and well-trained employees are essential to maintaining a safe working environment. Our training program is designed to ensure that every member of our team is equipped with the knowledge and skills necessary to identify and mitigate risks effectively.

Training Program Overview

Our training sessions are scheduled on a regular basis and are mandatory for all employees. These sessions cover a wide range of topics, each tailored to specific aspects of workplace safety and compliance. The key training topics include:

Training Topic 1: Safety Protocols and Emergency Response

This training module covers essential safety protocols and emergency response procedures. Key areas include:

Understanding and following safety protocols.

Emergency evacuation procedures.

First aid and basic medical response.

Handling and reporting emergencies or incidents.

Training Topic 2: Hazard Identification and Risk Management

In this module, employees are trained on identifying potential hazards in the workplace and effective risk management strategies. The focus areas are:

Recognizing potential safety hazards.

Risk assessment and management techniques.

Reporting and addressing identified risks.

Preventative measures to minimize risks.

Training Schedule and Format:

Training Topic | Frequency | Format | Duration |

Safety Protocols and Emergency Response | Biannually | In-person/Online | [2 Hours] |

Hazard Identification and Risk Management | Annually | In-person/Online | [3 Hours] |

The training sessions are conducted in both in-person and online formats, accommodating the diverse needs and schedules of our employees. Interactive elements such as workshops, simulations, and quizzes are integrated into the training to enhance engagement and retention of information.

7. Emergency Preparedness

Emergency Preparedness at [Your Company Name] is a critical component of our overall safety strategy. We prioritize the development and implementation of robust emergency protocols to ensure the safety and well-being of our employees, clients, and visitors in the event of an emergency. Our approach is designed to address a range of potential scenarios, ensuring a swift, efficient, and coordinated response.

Key Emergency Protocols

Protocol 1: Fire Emergency Response

The Fire Emergency Response Protocol is designed to mitigate the risks associated with fire incidents. Key components include:

Evacuation Plan: A detailed plan outlining evacuation routes and assembly points.

Fire Safety Training: Regular training sessions on fire safety, including the use of fire extinguishers and identifying fire hazards.

Fire Drills: Conducting periodic fire drills to ensure all employees are familiar with evacuation procedures.

Protocol 2: Medical Emergency Response

This protocol provides guidelines for responding to medical emergencies within the workplace. It encompasses:

First Aid Stations: Strategically located first aid stations equipped with essential medical supplies.

Emergency Contact List: A list of emergency contacts, including local hospitals and emergency services.

Employee Training: Training employees in basic first aid and CPR.

Emergency Preparedness Table:

Emergency Type | Key Actions | Personnel Involved | Equipment/Tools |

Fire Emergency | Evacuation, fire extinguishing | All Employees, Safety Officers | Fire extinguishers, alarms |

Medical Emergency | First aid, emergency contact notification | Trained First Aiders, All Employees | First aid kits, defibrillators |

Regular Reviews and Updates

Our emergency protocols are regularly reviewed and updated to reflect any changes in our operational environment or in response to feedback from drills and actual incidents. We ensure that all new employees receive training on these protocols as part of their induction process, and we provide refresher courses for existing staff.

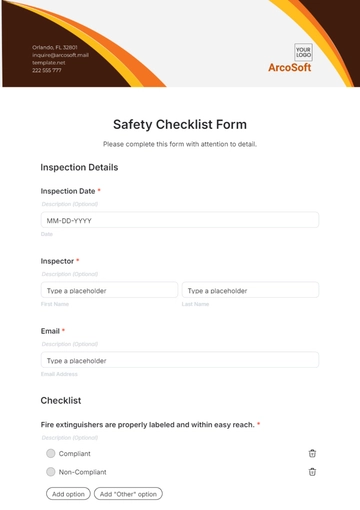

8. Incident Reporting and Investigation

Initial Report

The initial report is the first step in our incident management process. It involves the following steps:

Immediate Notification: Employees are required to report any incident, no matter how minor, to their immediate supervisor or designated safety officer as soon as possible.

Preliminary Assessment: The supervisor or safety officer conducts a preliminary assessment to understand the nature and severity of the incident.

Formal Reporting: The involved parties complete an Incident Report Form, providing detailed information about the incident, including time, location, and any witnesses.

Investigation

Following the initial report, a thorough investigation is conducted:

Investigation Team Formation: A team, typically comprising safety officers and department heads, is formed to investigate the incident.

Evidence Collection: The team collects evidence, which may include photographs, witness statements, and physical evidence from the incident site.

Analysis: The team analyzes the evidence to determine the cause of the incident and identify any contributing factors.

Documentation

Comprehensive documentation is a critical part of the process:

Incident Log: All incidents are logged in a central Incident Register for record-keeping and trend analysis.

Investigation Report: A detailed report is compiled, summarizing the findings of the investigation, including causes and contributing factors.

Action Plan: Based on the findings, an action plan is developed to address the identified issues and prevent recurrence.

Incident Reporting and Investigation Table:

Step | Description | Responsible Party | Documentation |

Initial Report | Immediate notification and assessment | Employee, Supervisor | Incident Report Form |

Investigation | Evidence collection and analysis | Safety Officers, Department Heads | Investigation Report |

Documentation | Recording and action planning | Safety Department | Incident Log, Action Plan |

Continuous Improvement

Our Incident Reporting and Investigation process is not static; it is subject to continuous review and improvement. Feedback from these processes informs our safety training and policy updates, fostering a proactive culture of safety and compliance.

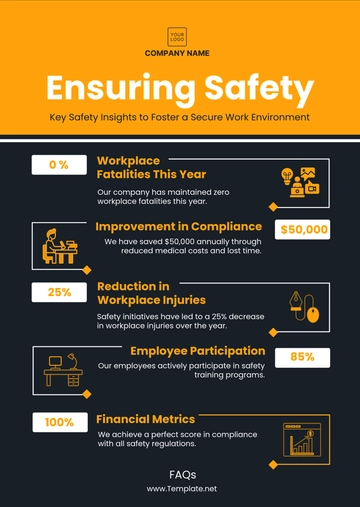

9. Performance Monitoring

In our commitment to maintaining and enhancing workplace safety, [Your Company Name] employs a robust Performance Monitoring system. This system is pivotal in evaluating the effectiveness of our safety policies and procedures. We utilize Key Performance Indicators (KPIs) to measure our safety performance, ensuring that we not only comply with regulations but also continuously improve our safety standards.

Continuous Monitoring and Improvement

Our performance monitoring system is dynamic, allowing for regular reviews and updates. We analyze the data from these KPIs to identify areas for improvement in our safety protocols. Additionally, we conduct periodic safety audits and employee feedback surveys to gain a comprehensive understanding of our safety culture and practices.

10. Conclusion

This Safety Compliance Study encapsulates the steadfast commitment of [Your Company Name] to cultivating and maintaining a workplace where safety and compliance are paramount. By rigorously adhering to legal requirements, implementing robust safety policies, conducting thorough risk assessments, and engaging in continuous training and awareness programs, we demonstrate our ongoing commitment to the well-being of our employees and stakeholders. [Your Company Name] remains resolute in its pursuit of elevating safety standards, ensuring that it remains an integral part of our organizational culture and operational excellence.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Explore Template.net's Safety Compliance Study Template, a comprehensive tool for analyzing and improving safety protocols. Effortlessly customize and edit studies with our AI Editor Tool to suit your organization's needs. Enhance compliance and safety standards with this editable and customizable solution, facilitating thorough safety assessments and improvements.