PPE Maintenance Guide

1. Introduction

Welcome to the Personal Protective Equipment (PPE) Maintenance Guide of [Your Company Name]. As an organization committed to the highest standards of workplace safety, we recognize the critical role that properly maintained PPE plays in protecting our employees from potential hazards in their work environment.

Purpose of This Guide

The purpose of this guide is to provide comprehensive and easy-to-follow instructions for the proper care, maintenance, and storage of the PPE used by our team members. By adhering to these guidelines, we aim to ensure that our PPE remains in optimal condition, offering maximum protection at all times.

Importance of PPE Maintenance

PPE is an essential line of defense against workplace accidents and injuries. Regular maintenance is crucial to ensure that each piece of equipment functions as intended. This guide highlights the importance of routine inspections, timely cleaning, and proper storage of PPE, which are key to prolonging its lifespan and maintaining its effectiveness.

Scope of the Guide

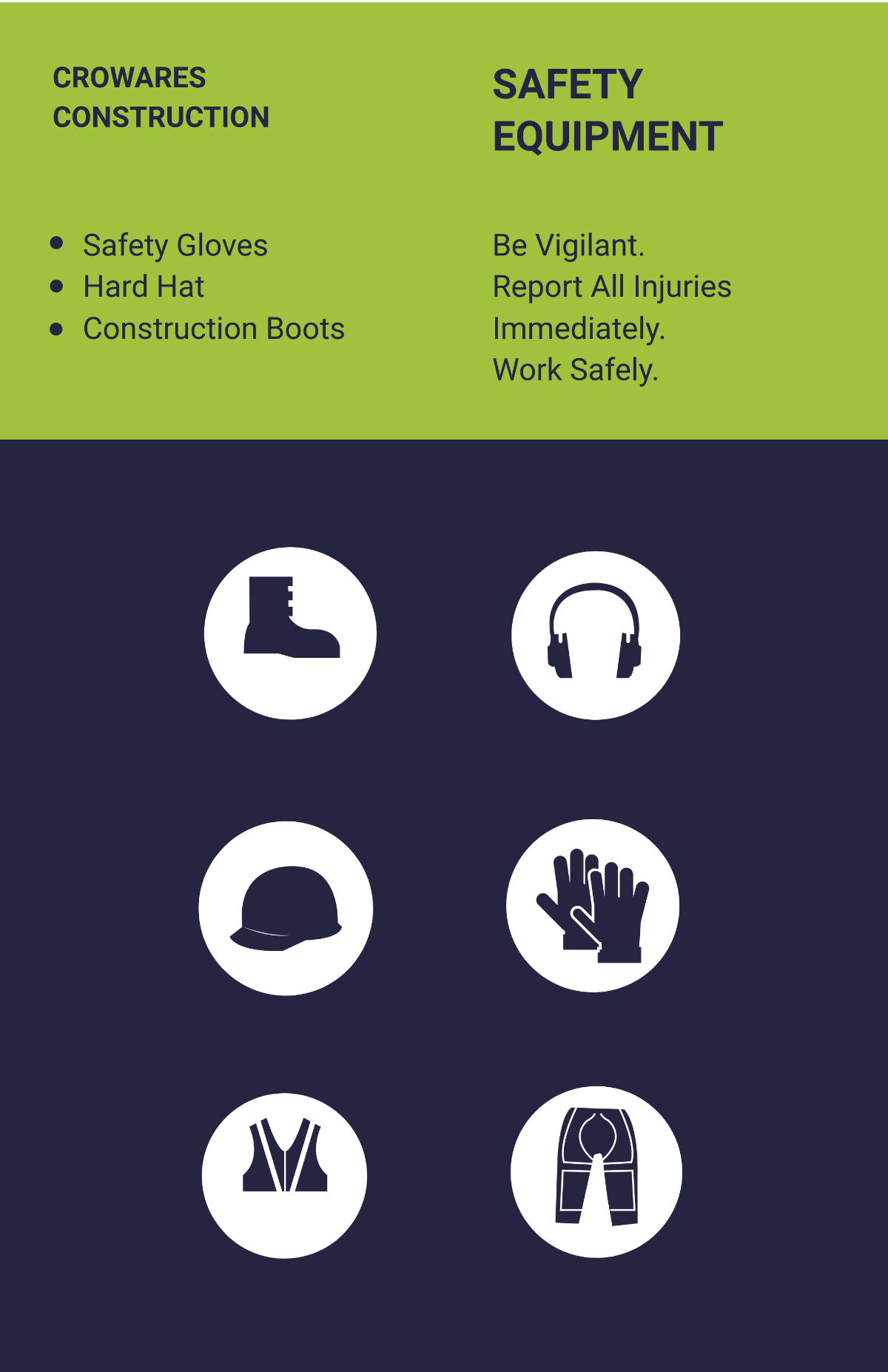

This guide covers a range of PPE items used in our company, including but not limited to helmets, safety glasses, face shields, gloves, respiratory protection, and protective clothing. For each category of PPE, we provide specific maintenance instructions, inspection checklists, and criteria for replacement.

Commitment to Safety

At [Your Company Name], our commitment to safety is unwavering. This guide reflects our dedication to ensuring that every employee has the knowledge and resources necessary to maintain their PPE properly. We believe that a safe workplace is a productive and positive environment, and proper PPE maintenance is a vital part of achieving this goal.

We encourage all employees to familiarize themselves with this guide and incorporate these practices into their daily routine. Together, we can create a safer workplace for everyone.

2. PPE Maintenance Guidelines

Effective maintenance of PPE is not just a regulatory requirement but a cornerstone in ensuring the safety and well-being of our workforce. Here, we outline the key practices for the general upkeep of PPE, including inspection frequency, cleaning procedures, and protocols for repair and replacement. These guidelines are designed to be straightforward to implement, ensuring that our PPE remains in optimal condition to offer maximum protection.

General Maintenance Overview

Proper maintenance of PPE is a continuous process, vital for ensuring the equipment's functionality and longevity. This section provides a comprehensive overview of the essential maintenance practices for PPE, including regular inspections, cleaning, and the management of wear and tear. By adhering to these guidelines, employees can significantly contribute to their safety and the overall safety culture at [Your Company Name].

General Maintenance Guidelines:

Maintenance Aspect | Description and Guidelines |

Inspection Frequency | Before and After Use: Inspect PPE before each use and again after use to identify any immediate damage or wear Periodic Detailed Inspections: Conduct detailed inspections at intervals of [specify period, e.g., monthly], to assess the overall condition and identify any less obvious damage or wear. |

Cleaning Procedures | Routine Cleaning: Rinse PPE with clean, lukewarm water after use Use of Detergents: Apply a mild detergent if necessary, following the manufacturer's guidelines Drying: Allow PPE to air dry thoroughly before storage or next use. Do not be exposed to direct heat or strong sunlight during drying. |

Repair and Replacement | Reporting Damages: Any damage or defect noticed during inspections must be reported immediately

Handling Repairs: Repairs should only be carried out by qualified personnel. If PPE is beyond repair, it must be replaced Replacement Criteria: Follow manufacturer’s guidelines and industry standards for when to replace PPE. |

Adherence to these general maintenance guidelines is essential for the efficacy and durability of PPE. Regular inspections, proper cleaning, and timely repairs or replacements are fundamental practices that help in preserving the integrity of the protective gear. Every employee at [Your Company Name] plays a critical role in this process, contributing to a safer and more secure work environment.

3. Specific PPE Maintenance

In this chapter of the PPE Maintenance Guide for [Your Company Name], we focus on the specific maintenance requirements for different types of Personal Protective Equipment (PPE). Each type of PPE has unique characteristics and requires specific care to maintain its protective qualities. Understanding these specific maintenance requirements is crucial for ensuring the long-term effectiveness and safety of the PPE.

Specific PPE Maintenance Overview:

While general maintenance practices are essential, specific maintenance tailored to each type of PPE is equally important. This section provides detailed guidelines on maintenance actions, inspection points, and replacement criteria for various PPE items. These guidelines are designed to ensure that each item of PPE receives the appropriate care and attention, thereby maximizing its protective capabilities and lifespan.

Specific PPE Maintenance Guidelines:

PPE Type | Maintenance Actions | Inspection Points | Replacement Criteria |

Helmets | Clean with mild soap. Check for cracks. | Shell, harness, suspension system. | Cracks, dents, or any deformity. |

Gloves | Wash gently. Inspect for tears. | Surface integrity, and flexibility. | Tears, holes, or severe wear. |

Safety Shoes | Clean regularly. Check soles and laces. | Sole integrity, insole condition. | Worn soles, damaged upper part. |

Goggles | Wipe with anti-fog solution. Inspect for scratches. | Lens clarity, strap elasticity. | Scratches, clouded lenses. |

Respirators | Clean after each use. Replace filters as per guidelines. | Filter efficiency, face seal, straps. | Damaged seal, worn-out filters. |

Maintenance Actions Explained:

Helmets: Regular cleaning with mild soap helps to maintain the structural integrity of the helmet. Regular checks for cracks or dents are crucial, as these can compromise the helmet's protective capability.

Gloves: Gentle washing is necessary to maintain the material's integrity. Regular inspection for tears or holes is essential to ensure hand protection.

Safety Shoes: Regular cleaning is important to maintain hygiene and material integrity. Checking the soles and laces for wear ensures the shoes continue to provide the necessary support and protection.

Goggles: Regular wiping with an anti-fog solution maintains visibility. Inspecting for scratches or cloudiness is crucial for clear vision.

Respirators: Cleaning after each use is critical for hygiene. Regular replacement of filters and inspection of the face seal and straps ensures the respirator functions correctly to protect the wearer.

Adhering to these specific maintenance guidelines is essential for the care and longevity of each type of PPE. Regular and appropriate maintenance not only extends the life of PPE but also ensures it provides maximum protection. As employees of [Your Company Name], it is our collective responsibility to maintain our PPE meticulously, thereby safeguarding our health and safety in the workplace.

4. Storage

Proper storage of Personal Protective Equipment (PPE) is as vital as its maintenance. The way PPE is stored can significantly impact its longevity and effectiveness. This section provides detailed guidelines on the best practices for storing PPE to ensure it remains in optimal condition and ready for use whenever needed.

Overview of PPE Storage

Effective storage of PPE involves more than just finding a place to keep it when not in use. It requires consideration of factors like environment, exposure to elements, and the physical condition of the storage space. The following guidelines are designed to help employees store their PPE correctly, thus preserving its integrity and functionality.

Storage Guidelines:

Dry, Clean, and Well-Ventilated Area

Importance of Environment: PPE should always be stored in a place that is dry, clean, and well-ventilated. A damp or dirty environment can lead to the degradation of materials, while poor ventilation can cause the buildup of harmful substances or moisture, potentially compromising the PPE’s protective qualities.

Recommended Practices: Employees should ensure that the storage area is regularly cleaned and free from any contaminants. Adequate ventilation should be provided to prevent any accumulation of moisture or fumes that could damage the PPE.

Avoid Direct Sunlight and Extreme Temperatures

Effects of Sunlight and Temperature: Prolonged exposure to direct sunlight can cause materials to fade and weaken, especially in PPE like helmets and goggles. Similarly, extreme temperatures – both hot and cold – can alter the physical properties of PPE, reducing its effectiveness.

Storage Conditions: It is essential to store PPE in an area where it is not exposed to direct sunlight or subjected to extreme temperatures. A consistent, moderate temperature is ideal for prolonging the life of PPE.

Storage Manner to Prevent Deformation

Preventing Deformation: PPE must be stored in a manner that prevents deformation. For example, gloves should be laid flat and not crumpled, while helmets should be placed on a stable surface to avoid pressure on any one side.

Organized Storage Solutions: Using dedicated racks, shelves, or hooks for different types of PPE can help maintain their shape and functionality. Employees should be trained to place PPE back in its designated spot after use and inspection.

Proper storage is a key component in the life cycle of PPE. By following these guidelines, employees at [Your Company Name] can ensure their PPE is protected from environmental factors and is always ready for use. This commitment to proper storage not only extends the lifespan of the PPE but also reinforces our culture of safety and responsibility.

5. Record Keeping

Maintaining accurate and up-to-date records of PPE maintenance is essential for tracking its condition, ensuring compliance with safety regulations, and identifying potential issues before they become hazards. This section outlines the process and elements of effective PPE maintenance record keeping.

Purpose of Record Keeping

Record keeping serves several key purposes in PPE maintenance:

Tracking Maintenance: Ensures that all PPE has been regularly inspected, cleaned, and maintained.

Compliance: Helps to demonstrate compliance with industry standards and regulatory requirements.

Safety Monitoring: Allows for the monitoring of the condition of PPE over time, highlighting when replacements or repairs are necessary.

Record Keeping Guidelines

Each entry in the PPE maintenance record should include the following components:

Date | PPE Type | Maintenance Action | Performed by | Notes |

[Month Day, Year] | [PPE Type] | [Action Taken] | [Your Name] | [Any Notes] |

Explanation of Table Components:

Date: The date on which the maintenance action was performed. This helps track when each piece of PPE was last serviced.

PPE Type: The specific type of PPE that the maintenance action was performed on, such as helmets, gloves, or safety shoes.

Maintenance Action: A brief description of the maintenance action taken, such as 'cleaned', 'inspected for damage', or 'replaced filters'.

Performed by: The name of the person who performed the maintenance action. This ensures accountability and allows for follow-up if there are any questions.

Notes: Any additional notes or observations made during the maintenance action. This could include details of wear and tear, any defects noticed, or if further action is needed.

Best Practices:

Timely Updates: Update records immediately after maintenance actions are completed to ensure accuracy.

Accessibility: Keep records in a place where they are easily accessible for review by supervisors, safety officers, or regulatory bodies.

Regular Reviews: Regularly review records to monitor PPE condition and plan for future maintenance or replacements.

Effective record keeping is a fundamental component of PPE maintenance at [Your Company Name]. It not only ensures that our PPE is kept in optimal condition but also fosters a culture of accountability and safety. By diligently recording each maintenance action, we can provide the safest possible working environment for our employees.

6. Conclusion

Commitment to Excellence in PPE Maintenance:

As we conclude this PPE Maintenance Guide, we reaffirm our commitment at [Your Company Name] to maintaining the highest standards in the care and upkeep of Personal Protective Equipment (PPE). This guide has been meticulously designed to provide our employees with detailed instructions and best practices for the maintenance, storage, and record-keeping of PPE. We aim to ensure the safety and well-being of every individual in our workforce, recognizing that well-maintained PPE is a fundamental component of a safe working environment.

Upholding Safety Standards

The practices outlined in this guide are more than just procedures; they are integral to our culture of safety and responsibility. By adhering to these guidelines, we not only comply with regulatory standards but also demonstrate our dedication to the welfare of our employees. Each step taken in maintaining PPE is a step towards preventing workplace injuries and fostering a safer work environment.

Collective Responsibility:

The effectiveness of this guide relies on the collective effort of every team member at [Your Company Name]. From management to frontline workers, we all play a pivotal role in implementing these practices. We encourage every employee to take personal responsibility for their PPE, ensuring its proper maintenance and readiness for use.

Continuous Improvement:

We recognize that the standards and practices in PPE maintenance are ever-evolving. Therefore, we commit to regularly reviewing and updating this guide to reflect the latest safety standards, technological advancements, and best practices in PPE care. We welcome feedback from our employees as part of our continuous improvement process.

Final Words:

In closing, the PPE Maintenance Guide is a testament to [Your Company Name]'s unwavering dedication to maintaining a safe and healthy workplace. By following the guidelines presented in this document, we can collectively ensure that every team member is equipped with well-maintained PPE, and ready to face the challenges of the workplace with confidence and security.

Together, let's continue to prioritize safety, quality, and excellence in every aspect of our work.