PPE Program Documentation

I. Introduction

The purpose of this Personal Protective Equipment (PPE) Program is to establish guidelines and procedures for the proper selection, use, and maintenance of PPE in [Your Company Name]. This program aims to ensure the safety and well-being of our employees by mitigating workplace hazards and complying with relevant occupational health and safety regulations.

II. Scope and Applicability

A. Scope

This PPE Program applies to all employees of [Your Company Name] who are exposed to potential workplace hazards that necessitate the use of personal protective equipment.

B. Applicability

This program applies to tasks or work areas where hazards have been identified through risk assessments, as outlined in Section V.

III. Regulatory Framework

[Your Company Name] is committed to complying with all relevant local, regional, and national regulations governing the use of personal protective equipment. This program aligns with [List applicable standards and guidelines].

IV. Roles and Responsibilities

A. OHS Coordinator Responsibilities

As the OHS Coordinator, [Coordinator's Name] is responsible for overseeing the development, implementation, and periodic review of the PPE Program. This includes coordinating risk assessments, training initiatives, and ensuring ongoing compliance.

B. Departmental Supervisors and Manager's Responsibilities

Departmental supervisors and managers are responsible for communicating and enforcing PPE requirements within their respective departments. They play a key role in identifying unique hazards and ensuring proper PPE usage.

C. Employee Responsibilities

Employees are responsible for adhering to PPE requirements, attending training sessions, and reporting any concerns or incidents related to PPE use promptly.

D. Safety Committee Involvement

The Safety Committee, composed of representatives from various departments, will participate in the periodic review and improvement of the PPE Program. Their insights will contribute to the overall effectiveness of the program.

V. Risk Assessment

A. Overview of the Risk Assessment Process

Risk assessments will be conducted annually to identify and evaluate workplace hazards. The findings will guide the determination of PPE requirements for different tasks or work areas.

B. Identification of Workplace Hazards

Hazard Identification:

a. Engage employees and relevant stakeholders in identifying potential hazards associated with their respective work areas.

b. Conduct regular walkthroughs and inspections to assess physical, chemical, biological, ergonomic, and psychosocial hazards.

Risk Analysis:

a. Assess the severity and likelihood of each identified hazard.

b. Prioritize hazards based on their potential impact on employee safety.

Determination of PPE Requirements:

a. Collaborate with departmental supervisors and safety representatives to determine the most suitable PPE for each identified hazard.

b. Consider engineering and administrative controls before relying on PPE alone.

C. Determination of PPE Requirements

Eye and Face Protection: Safety glasses with side shields for tasks involving [specific hazards].

Head Protection: Hard hats for employees working in [designated areas].

Respiratory Protection: N95 masks for situations where [specific airborne hazards] are present.

Hand Protection: Chemical-resistant gloves for handling [specific substances].

Foot Protection: Steel-toed boots for employees in [construction or heavy equipment operations].

Hearing Protection: Earplugs for areas with noise levels exceeding [decibel threshold].

VI. PPE Selection and Use Procedures

A. General PPE Selection Guidelines

Eye and Face Protection

Employees working with [hazardous substances] must wear ANSI-approved safety glasses with side shields at all times.

Head Protection

Hard hats must be worn in [construction zones, areas with overhead hazards, etc.].

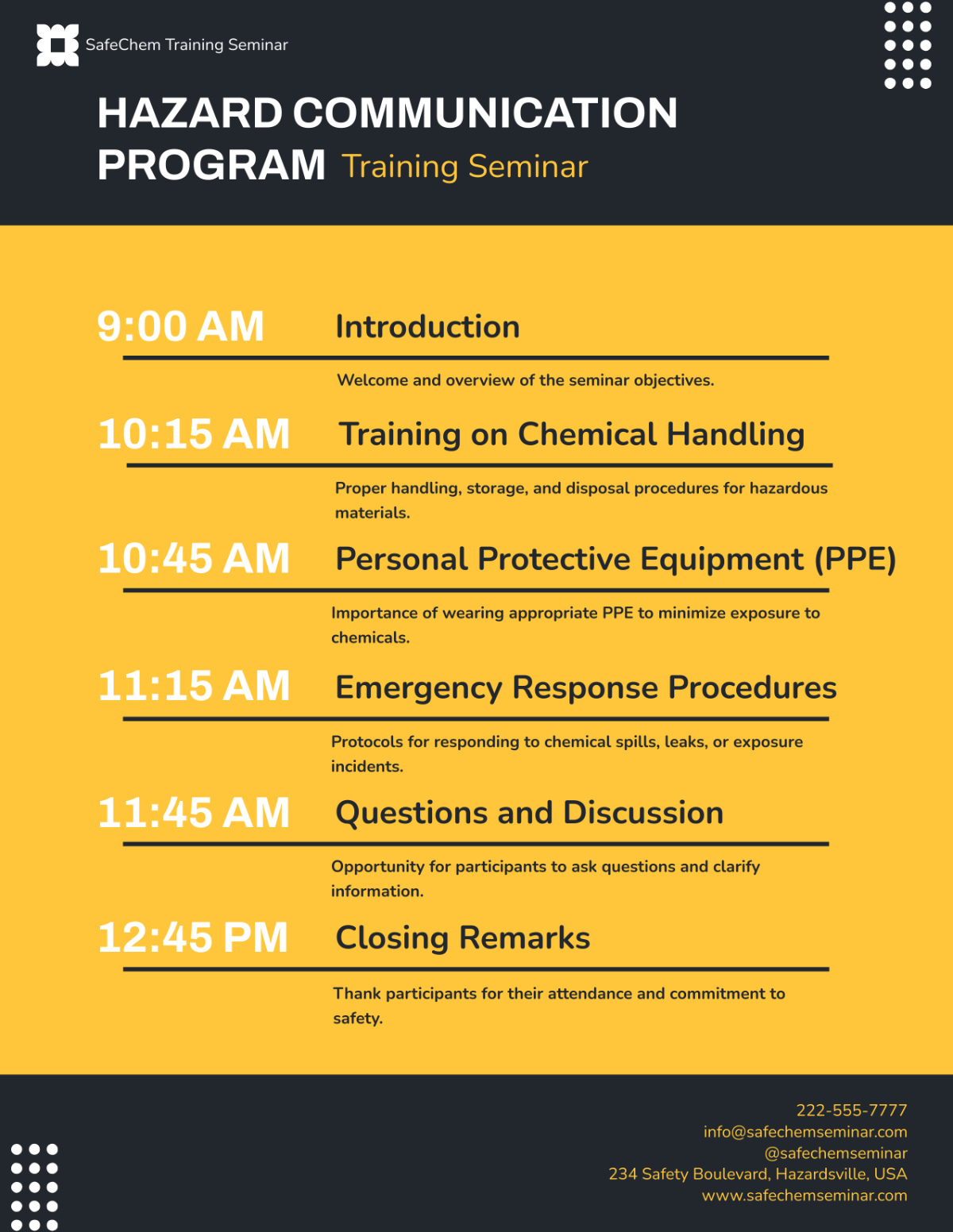

Respiratory Protection

Employees exposed to [airborne contaminants] must wear N95 masks, as specified in the respiratory protection program.

Hand Protection

Chemical-resistant gloves must be worn when handling [specific substances].

Foot Protection

Steel-toed boots are mandatory for employees engaged in [construction, warehouse activities, etc.].

Hearing Protection

Earplugs must be worn in areas where noise levels exceed [decibel threshold].

B. Specialized PPE Requirements for Unique Hazards

In addition to the general PPE selection guidelines outlined in subsection A, there are specific tasks or work areas within our organization that require specialized PPE due to unique hazards. The identification and determination of specialized PPE for these situations are essential for ensuring comprehensive employee protection. Below are the specialized PPE requirements for unique hazards:

Biohazard Exposure:

a. Specialized PPE: Full-body protective suits, gloves, and face shields.

b. Application: Employees working in areas where exposure to biological hazards, such as infectious diseases or biohazardous materials, is possible.

Electrical Hazards:

a. Specialized PPE: Insulating gloves, arc flash suits.

b. Application: Employees involved in tasks where there is a risk of electrical shock or arc flash, such as electrical maintenance or repair.

Radiation Exposure:

a. Specialized PPE: Lead aprons, thyroid shields, radiation monitoring devices.

b. Application: Employees working in areas where there is a risk of ionizing radiation, such as medical imaging or nuclear facilities.

High-Visibility Requirements:

a. Specialized PPE: High-visibility vests or clothing.

b. Application: Employees working in areas with vehicular traffic, construction zones, or other environments where visibility is crucial.

Extreme Temperatures:

a. Specialized PPE: Thermal-resistant clothing (heat-resistant or cold-resistant).

b. Application: Employees working in extreme temperature conditions, such as foundry operations or cold storage facilities.

Confined Spaces:

a. Specialized PPE: Harnesses, lifelines, atmospheric monitoring devices.

b. Application: Employees entering confined spaces where there is a risk of engulfment, hazardous atmospheres, or entrapment.

Chemical Splash Hazards:

a. Specialized PPE: Chemical-resistant aprons, face shields, chemical-resistant boots.

b. Application: Employees working with corrosive or hazardous chemicals that pose a risk of splashes.

C. Proper Fitting and Use

Employees must ensure that PPE fits properly and is worn consistently during tasks where it is required.

D. Limitations and Restrictions

PPE should not be altered, and employees must be aware of the limitations and restrictions associated with each type of PPE.

VII. Training and Education

A. Training Objectives

The primary objectives of PPE training are to educate employees on the proper selection, use, and maintenance of PPE and to create awareness of the associated hazards.

B. Training Methods

Training sessions will be conducted annually, combining both theoretical and practical elements. Hands-on demonstrations and interactive sessions will be utilized.

C. Frequency of Training

Employees will undergo initial PPE training upon hire, with refresher courses provided annually.

D. Documentation of Training

Training records will be maintained, including employee names, training dates, and topics covered.

VIII. Enforcement and Compliance

A. Measures for Ensuring Compliance

Supervisors and managers will conduct regular checks to ensure employees are wearing the required PPE. Non-compliance will result in corrective actions, as outlined in the disciplinary policy.

B. Disciplinary Actions for Non-Compliance

Disciplinary actions for PPE non-compliance may include verbal warnings, written warnings, and, if necessary, suspension.

IX. Record-Keeping

A. Maintenance of PPE Inspection Logs

Regular inspections of PPE will be documented using the provided inspection checklist. Inspections will be conducted [frequency of inspections].

B. Training Records

Training records will be maintained electronically and in hard copy, including certificates of completion for each employee.

C. Incident Reports Related to PPE

Any incidents related to PPE failure or non-compliance must be reported immediately using the organization's incident reporting system.

D. Record Retention Periods

All PPE-related records will be retained for a minimum of [X years] by regulatory requirements.

X. Inspection and Maintenance Procedures

A. Regular Inspection Schedule

PPE will be inspected [daily/weekly/monthly] by employees and more comprehensively by designated personnel on a [regular schedule].

B. Procedures for Cleaning and Maintenance

Employees are responsible for cleaning and maintaining their assigned PPE. Detailed cleaning and maintenance procedures are outlined in the PPE maintenance manual.

C. Criteria for PPE Replacement

PPE will be replaced when it shows signs of wear or damage, or if it fails inspection. Replacement will follow the guidelines outlined in the PPE maintenance manual.

XI. Emergency Procedures

A. Protocols for Emergencies While Wearing PPE

In the event of an emergency, employees must follow evacuation procedures while wearing their PPE. Emergency response teams will be equipped with additional PPE as needed.

B. Evacuation Procedures

Evacuation routes and assembly points are posted throughout the facility. Employees must evacuate to the designated assembly points while wearing appropriate PPE.

C. Decontamination Processes

Procedures for decontamination, if applicable to specific hazards, are outlined in the organization's emergency response plan.

XII. Communication and Signage

A. Communication Strategies for PPE Requirements

PPE requirements will be communicated through employee handbooks, training sessions, and posted signage in relevant work areas.

B. Use of Visual Aids and Signage

Visual aids and signage will be strategically placed to remind employees of PPE requirements and locations.