PPE Program Feasibility Study

I. Introduction

The Personal Protective Equipment (PPE) Program at [Your Company Name] is a comprehensive initiative designed to significantly enhance workplace safety across all departments. This feasibility study aims to assess the practicality, costs, and benefits of implementing a robust PPE program tailored to the specific needs of our workforce. Given the diverse range of operational environments within [Your Company Name], including warehousing, laboratory work, and construction, the necessity for an effective PPE program is paramount to ensure compliance with safety regulations and to safeguard employee well-being.

The objective of this study is to evaluate current PPE usage, identify gaps in safety practices, explore market options for PPE procurement, and develop a strategy for the effective implementation and management of a company-wide PPE program. This will include an analysis of legal requirements, training needs, program implementation, and monitoring and evaluation mechanisms.

II. Analysis of Current PPE Usage and Requirements

Current PPE Policies

The current PPE policies at [Your Company Name] are outlined in the table below:

Job Role | Required PPE | Compliance Rate | Comments |

Warehouse Worker | Safety helmets, Gloves | 85 | Non-compliance during rush hours |

Laboratory Technician | Lab coats, Eye protection | 95 | High compliance, minor issues with eye protection fit |

Construction Worker | High-visibility vests, Steel-toe boots | 90 | Occasional non-compliance in summer due to heat |

Needs Assessment

A comprehensive assessment of the current PPE usage indicates a generally satisfactory compliance rate, with a few areas needing improvement. However, with the introduction of a new construction wing and an expansion in the laboratory department, there is a projected increase in the demand for PPE.

Specifically, enhanced respiratory protection for lab technicians working with volatile chemicals and improved ergonomic safety wear for construction workers are required. Additionally, there is a need for better quality PPE to ensure higher durability and user comfort, particularly for warehouse workers who have reported discomfort with the current gloves provided.

III. Market Analysis for PPE Supplies

Available PPE Providers

The market analysis for potential PPE suppliers is summarized in the table below:

Supplier Name | Product Range | Unit Cost | Quality Rating | Delivery Reliability |

[Company A] | Wide (All job roles) | Medium | High | High |

ProShield Solutions | Limited (Lab and Construction) | Low | Medium | Medium |

[Company B] | Medium (Most job roles) | High | Very High | High |

Cost-Benefit Analysis

Upon analyzing the potential suppliers, [Company A] emerges as a favorable option for a comprehensive range of PPE, balancing cost and quality effectively. However, for specialized PPE, such as advanced respiratory masks for lab technicians, [Company B] offers superior quality, albeit at a higher cost.

It is proposed to primarily source standard PPE from [Company A] while obtaining specialized equipment from [Company B] to ensure both quality and cost-effectiveness. The initial investment might be higher with this approach, but the long-term benefits of durability and enhanced safety are expected to offset the initial costs. Furthermore, the high reliability in delivery from these suppliers ensures that PPE needs will be consistently met, reducing the risk of shortages.

IV. Compliance and Regulatory Requirements

Legal Obligations

The table below summarizes the key legal and regulatory requirements for PPE at [Your Company Name]:

Regulation Title | Applicable Area | Key Requirements |

Occupational Safety and Health Act (OSHA) | General Safety | Provision of adequate PPE, training on usage |

Construction Safety Standards | Construction Sites | Specific PPE for high-risk areas |

Laboratory Safety Regulations | Laboratory Settings | Chemical-resistant clothing, eye and face protection |

Compliance Strategies

To ensure adherence to these regulations, a compliance strategy is proposed. For the general workforce, including warehouse and administrative staff, regular audits will be conducted to assess PPE usage and compliance.

Additionally, a digital tracking system will be implemented to log PPE distribution and usage, ensuring that all employees have the necessary equipment and are using it correctly.

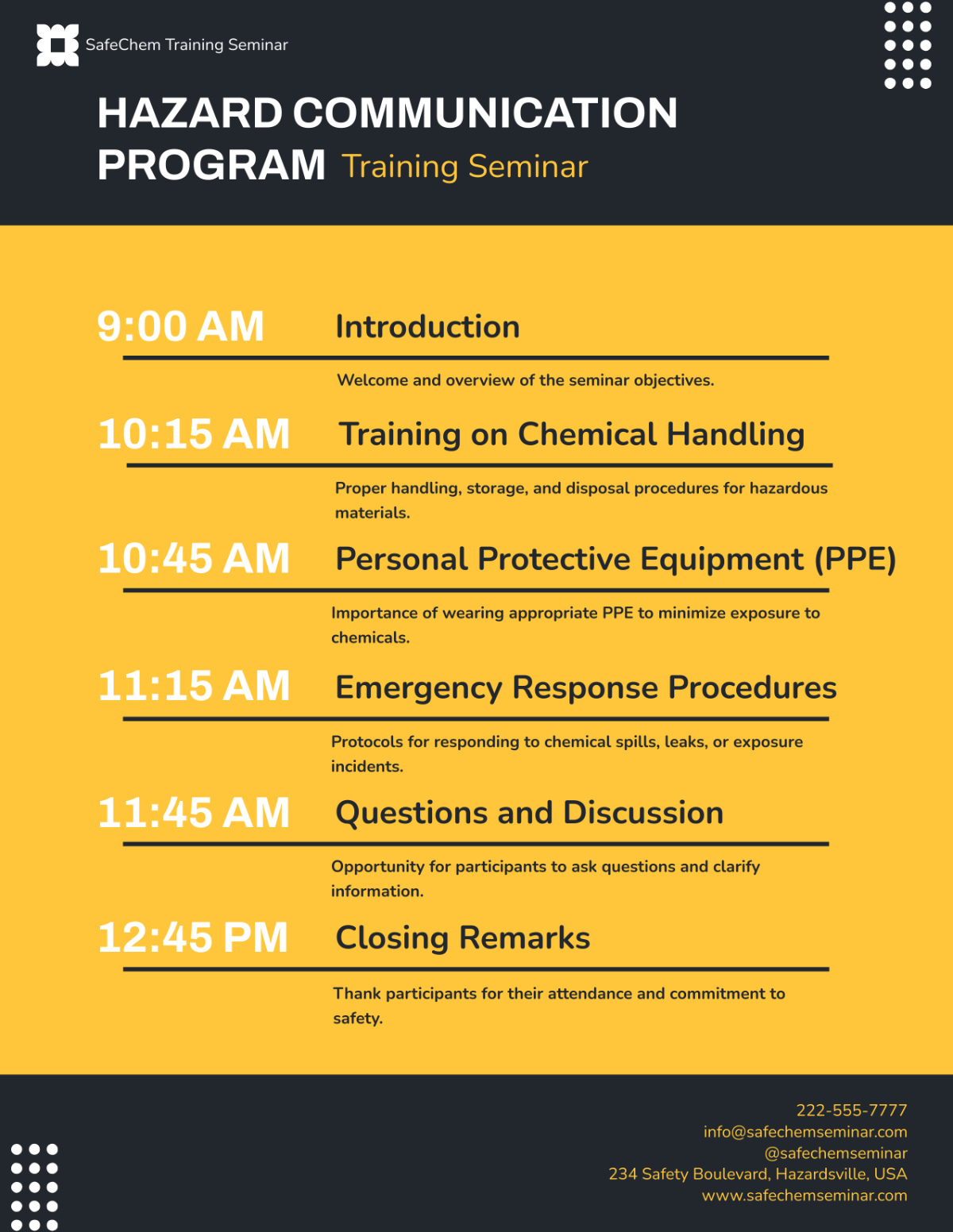

V. Training and Awareness Programs

Training Needs

The identified training needs for different employee groups are outlined in the table below:

Employee Group | Training Needs | Frequency |

Warehouse Worker | Proper use of gloves, helmets | Bi-annually |

Laboratory Technician | Handling and maintenance of PPE, Emergency response | Annually |

Construction Worker | Use of safety harnesses, Risk-awareness in construction sites | Annually |

Program Development

For the effective implementation of the PPE program, a structured training and awareness plan is essential. Tailored training modules will be developed for each employee group, focusing on the correct usage, maintenance, and storage of PPE. Interactive workshops and hands-on sessions will be conducted to ensure practical understanding.

Moreover, a series of awareness campaigns will be launched, including posters, newsletters, and digital reminders, to keep PPE importance and best practices at the forefront of employees' minds. The training programs will be reviewed and updated annually to incorporate any changes in regulations or PPE technology. A feedback mechanism will also be established to gather employee insights and continuously improve the training process.

VI. Program Implementation Plan

Implementation Phases

The implementation of the PPE program at [Your Company Name] will be executed in phases, as outlined in the table below:

Phase | Description | Duration | Key Activities |

Phase 1 | Preparation and Planning | [2 Months] | Finalize supplier contracts, Purchase initial PPE stock |

Phase 2 | Training and Awareness | [3 Months] | Conduct training sessions, Launch awareness campaigns |

Phase 3 | Full Implementation | [Ongoing] | Distribute PPE, Monitor usage, Continuous improvement |

Resource Allocation

The implementation plan requires careful allocation of resources to ensure its success. A budget of [$200,000] has been allocated for the first year, covering the cost of PPE purchases, training materials, and staffing for program management. An implementation team, consisting of safety officers, HR representatives, and department managers, will be formed to oversee the program's rollout.

This team will be responsible for coordinating training sessions, managing PPE distribution, and collecting feedback for ongoing improvements. Regular meetings will be held to review progress and address any challenges that arise during the implementation phases.

VII. Monitoring and Evaluation

Monitoring Framework

The effectiveness of the PPE program will be monitored using the following key performance indicators (KPIs):

KPI | Description | Target |

PPE Compliance Rate | Percentage of employees complying with PPE requirements | [≥ 95%] |

Incident Reduction | Reduction in safety incidents due to PPE usage | [≥ 30% reduction] |

Employee Satisfaction | Satisfaction level with PPE quality and training | [≥ 80% positive feedback] |

Evaluation Techniques

A comprehensive evaluation strategy will be implemented to assess the program's effectiveness. This will include regular safety audits to measure compliance rates and incident logs to track any safety incidents. Employee surveys will be conducted bi-annually to gather feedback on PPE comfort, training effectiveness, and overall satisfaction with the program.

Data collected from these evaluations will be analyzed quarterly to identify trends, areas for improvement, and to make data-driven decisions for program enhancements. The implementation team will review this data and make recommendations for any necessary changes to the program.

Conclusion

Summary of Findings

The feasibility study reveals several key findings:

The current PPE usage within [Your Company Name] shows varied compliance rates, highlighting a need for improved PPE quality and employee training.

Market analysis indicates that a combination of suppliers would best meet our needs for quality, cost-effectiveness, and reliability.

Compliance with legal and regulatory requirements can be achieved through targeted strategies, including regular audits and digital tracking systems.

A well-structured training and awareness program is essential to enhance employee knowledge and adherence to PPE protocols.

A phased implementation plan, coupled with a dedicated resource allocation, will enable a smooth rollout of the PPE program.

Monitoring and evaluation through specific KPIs will ensure continuous improvement and effectiveness of the program.

Recommendations

Based on the findings of this feasibility study, the following recommendations are proposed for the PPE program:

Procurement Strategy: Adopt a hybrid procurement strategy utilizing both [Company A] and [Company B] to balance cost and quality.

Training and Awareness: Implement comprehensive training modules specific to each employee group, supplemented by ongoing awareness campaigns.

Compliance Enhancement: Establish a digital tracking system for PPE distribution and usage, and appoint safety officers in high-risk areas.

Phased Implementation: Follow the outlined phased approach for program rollout, ensuring adequate time for preparation, training, and full-scale implementation.

Continuous Monitoring and Evaluation: Regularly monitor the program using the identified KPIs and conduct bi-annual surveys to gather employee feedback for ongoing program refinement.

With these recommendations, [Your Company Name] can expect a significant improvement in workplace safety, compliance with safety regulations, and overall employee well-being.