PPE Selection Guide

Introduction

Purpose of the Guide

Welcome to the Personal Protective Equipment (PPE) Selection Guide. This guide is designed to assist employers, safety officers, and employees in understanding the crucial role of PPE in maintaining workplace safety. The selection of appropriate PPE is not only a regulatory requirement but also a fundamental aspect of risk management in any work environment. This guide aims to provide clear, practical advice on choosing, using, and maintaining PPE effectively.

Scope of Application

This guide is applicable across a range of industries including manufacturing, construction, healthcare, and laboratory environments. It serves as a comprehensive resource for anyone responsible for or involved in the selection and management of PPE. Whether you're assessing hazards, selecting suitable PPE, or ensuring its proper maintenance and care, this guide offers valuable insights and structured information to enhance safety and compliance in your workplace.

Understanding PPE Categories

Types of PPE

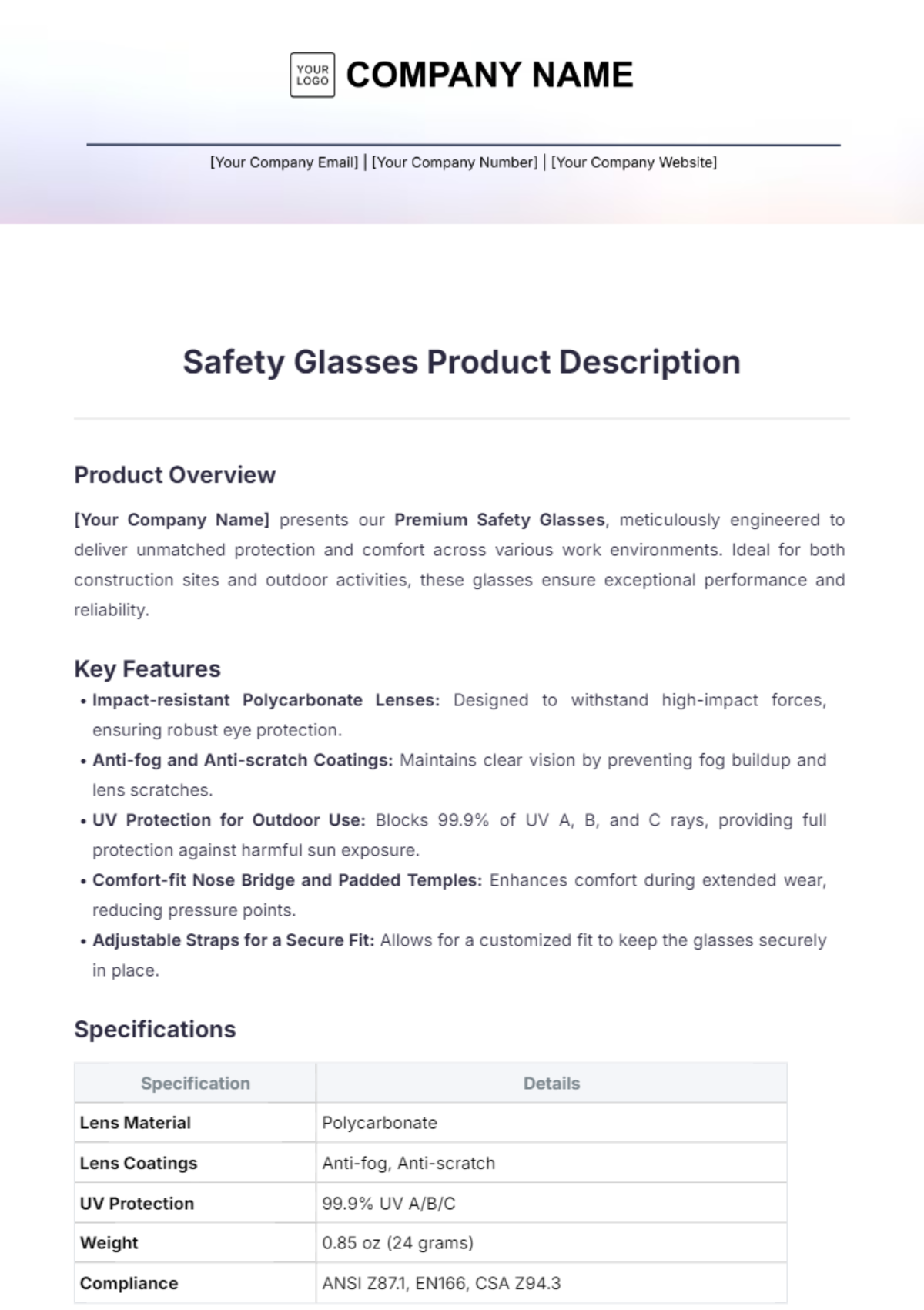

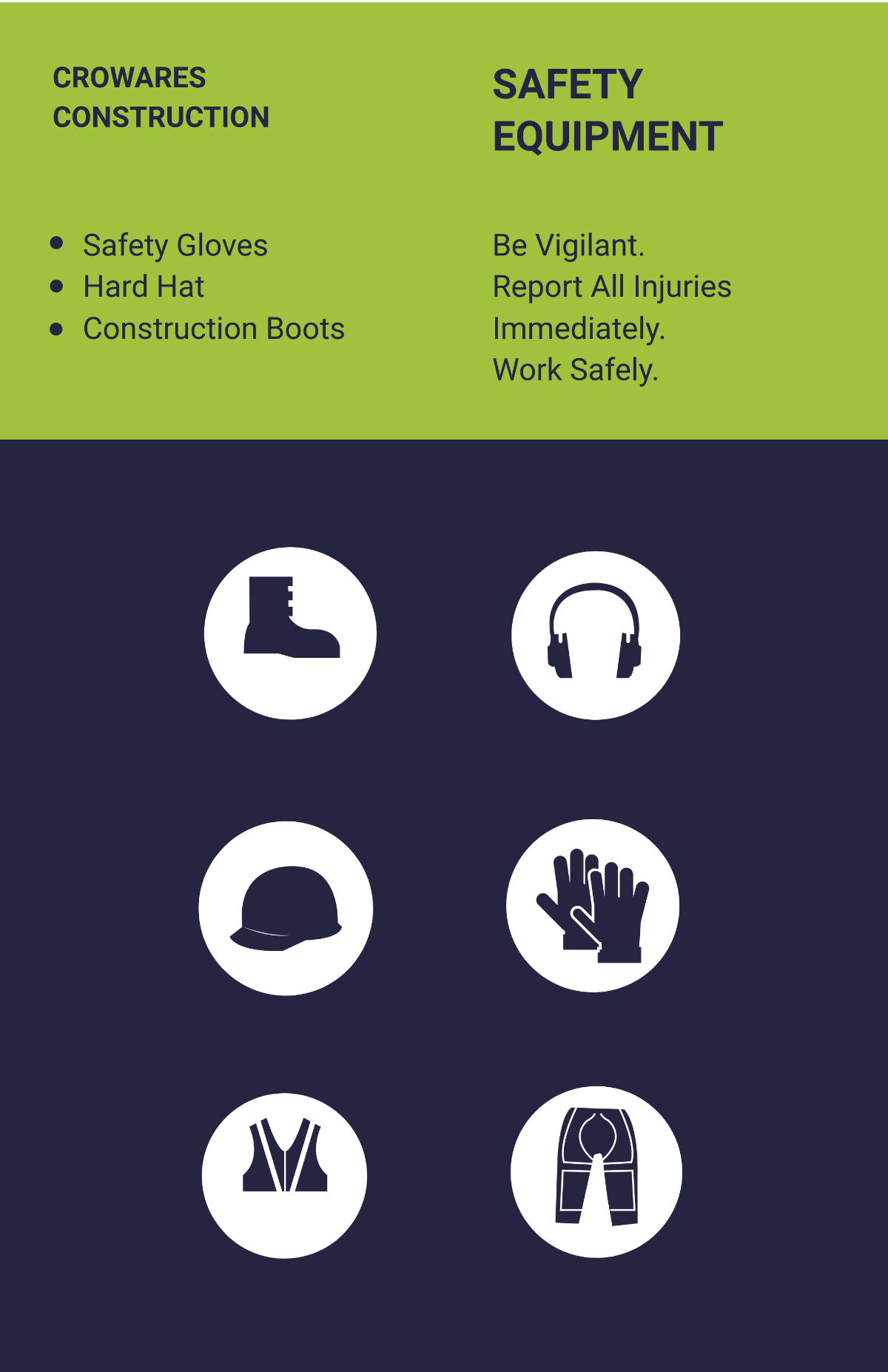

This table categorizes various types of PPE and provides a brief description of each.

PPE Type | Description |

Gloves | Protective gloves for handling hazardous materials, preventing cuts, and insulating against electrical hazards. |

Goggles | Eye protection against chemical splashes, dust, and intense light. |

Helmets | Headgear for protection against falling objects and impact hazards. |

Ear Protection | Devices to safeguard against hearing damage in noisy environments. |

Respirators | Masks for filtering airborne contaminants and providing breathable air. |

Safety Harness | Equipment for fall protection in elevated work areas. |

Protective Suits | Full-body suits designed for environments with chemical or biological hazards. |

When to Use Each Type

When selecting PPE, it's crucial to consider the nature of the task and the environment. Here's guidance on when to use each type of PPE:

Gloves: Essential for tasks involving the handling of sharp objects, chemicals, or electrical components.

Goggles: Mandatory in areas with airborne particles, chemical risks, or intense light (e.g., welding).

Helmets: Required in construction zones, warehouses, and areas where head injuries are a risk.

Ear Protection: Needed in environments with decibel levels exceeding safe thresholds, such as manufacturing plants.

Respirators: Used in situations with poor air quality or the presence of toxic substances.

Safety Harness: Necessary for work at heights, such as building maintenance or construction.

Protective Suits: Vital in environments with high risk of contamination, such as laboratories handling hazardous materials.

Hazard Assessment

Identifying Workplace Hazards

Identifying potential hazards is the first step in ensuring a safe work environment. This involves a thorough assessment of the workplace to pinpoint areas and activities that pose risks. Key aspects to consider include:

Physical Hazards: Machinery, heights, noise, and temperature extremes.

Chemical Hazards: Exposure to harmful substances, including gases, liquids, and solids.

Biological Hazards: Risks from bacteria, viruses, and other biological agents.

Ergonomic Hazards: Issues arising from poor workstation design, repetitive motion, and manual handling.

Matching PPE to Hazards

This table shows how to match PPE to specific types of hazards identified in the workplace.

Hazard Type | Recommended PPE |

Physical | Helmets, safety shoes, gloves, eye protection |

Chemical | Gloves, respirators, protective suits, goggles |

Biological | Respirators, protective suits, gloves, face shields |

Ergonomic | Support braces, ergonomic tools, anti-fatigue mats |

Effective hazard assessment is critical for the correct selection of PPE. It ensures that employees are adequately protected against the specific risks present in their work environment.

PPE Maintenance and Care

Cleaning and Storage

Proper maintenance of PPE is crucial to ensure its effectiveness and longevity. Here are guidelines for cleaning and storing different types of PPE:

Gloves: Wash with mild soap and water after each use. Store in a dry, cool place away from direct sunlight.

Goggles: Clean lenses with a soft cloth and disinfectant. Store in a protective case to avoid scratches.

Helmets: Wipe with a damp cloth and mild detergent. Inspect for cracks or wear and store in a room-temperature environment.

Ear Protection: Disinfect ear muffs or plugs regularly. Keep in a clean, dust-free container.

Respirators: Wash facepieces in warm water with mild detergent. Replace filters as per manufacturer's guidelines.

Safety Harness: Inspect for fraying or damage after use. Store hung up in a dry, cool area.

Protective Suits: Clean according to the type of material and contamination. Dry completely before storage.

Inspection and Replacement

Regular inspection and timely replacement of PPE are essential. The table below outlines a suggested schedule and criteria for replacing PPE.

PPE Type | Inspection Frequency | Replacement Criteria |

Gloves | Before each use | Tears, punctures, loss of elasticity |

Goggles | Monthly | Scratches, cracks, compromised seal |

Helmets | Every 6 months | Cracks, dents, interior degradation |

Ear Protection | Before each use | Loss of shape, reduced effectiveness |

Respirators | After each use | Wear and tear, expiration of filters |

Safety Harness | Before each use | Signs of wear, fraying, damaged buckles |

Protective Suits | After each use | Tears, permeation, loss of integrity |

Training and Proper Usage

Training Programs

Effective training is vital for the proper use of PPE. It should cover:

Correct Use: Teach how to wear, adjust, and remove PPE correctly.

Limitations: Educate about the limitations of each PPE type.

Care Instructions: Provide detailed instructions on cleaning, inspection, and storage.

Emergency Procedures: Train on how to respond in case of PPE failure or other emergencies.

Training should be conducted by qualified professionals and include practical demonstrations.

Demonstrations and Drills

Hands-on exercises enhance the understanding of PPE usage. Consider incorporating:

Fitting Workshops: Sessions where employees can learn how to correctly fit and wear various PPE.

Mock Drills: Simulate emergency situations to practice the use of PPE under pressure.

Inspection Exercises: Teach employees how to inspect their PPE for signs of wear or damage.

Scenario-Based Training: Create real-life scenarios specific to your workplace for practical learning.

Regular maintenance and care, combined with thorough training and practical usage exercises, are key to ensuring the effectiveness of PPE in safeguarding employees. This holistic approach not only enhances safety but also fosters a culture of responsibility and awareness regarding workplace hazards.

Record Keeping and Monitoring

Documentation

Effective record-keeping is fundamental in managing PPE effectively. It ensures accountability and compliance with safety regulations. Key aspects to document include:

PPE Issuance Records: Maintain a log of PPE issued to each employee, including the type of PPE, date of issuance, and employee acknowledgment.

Inspection Logs: Document regular inspections of PPE, noting the condition and any actions taken (such as repair or replacement).

Training Records: Keep detailed records of all training sessions attended by employees, including the date, content covered, and attendees' names.

Incident Reports: In case of any workplace incident involving PPE, document the specifics, including the type of PPE used and its condition at the time of the incident.

Ongoing Evaluation

Regular evaluation of PPE effectiveness and compliance is crucial. This table outlines steps and frequency for evaluations:

Evaluation Aspect | Frequency | Details |

PPE Effectiveness Assessment | Bi-annually | Evaluate the adequacy of current PPE in protecting against identified hazards. |

Compliance Audits | Annually | Conduct audits to ensure adherence to safety regulations and internal guidelines. |

Employee Feedback | Quarterly | Gather feedback from employees about PPE comfort, fit, and any concerns. |

Training Program Review | Annually | Review and update training programs to reflect any changes in PPE technology or workplace hazards. |

Consistent and meticulous record-keeping, coupled with regular monitoring and evaluation, ensures that the PPE program remains effective, up-to-date, and compliant with safety regulations. This proactive approach not only enhances employee safety but also contributes to the overall culture of safety within the organization.

Conclusion

Summary of Best Practices

Throughout this guide, we've explored various aspects of PPE management, from understanding different categories of PPE and assessing workplace hazards to ensuring proper maintenance, care, and training in PPE usage. We've emphasized the importance of regular inspections, record-keeping, and ongoing monitoring to ensure the effectiveness and compliance of your PPE program.

Continuous Improvement

The world of workplace safety is always evolving, with new challenges and solutions emerging. It's important to stay informed about the latest developments in PPE technology and safety standards. We encourage a culture of continuous improvement, where feedback from employees is valued, and safety procedures are regularly reviewed and updated. Remember, effective PPE management is a collaborative effort that enhances the overall safety and well-being of all employees.

In closing, we hope this guide serves as a valuable tool in your efforts to maintain a safe and compliant work environment. Your commitment to PPE management is not only a legal obligation but a testament to your dedication to the health and safety of your workforce.