Piping Scope Of Work

Project Overview:

The Piping Scope of Work outlines the requirements for the installation of piping systems for the new industrial facility at [LOCATION]. The project aims to provide reliable and efficient piping infrastructure to support various industrial processes and operations.

Project Objectives:

Design and install piping systems to convey fluids, gases, and other substances throughout the industrial facility.

Ensure compliance with industry standards, codes, and regulations governing piping design and installation.

Optimize piping layouts to minimize material costs, energy consumption, and operational risks.

Coordinate with other disciplines and trades to integrate piping systems seamlessly into the facility's overall infrastructure.

Complete the piping installation within the specified timeline and budget constraints.

Scope Details:

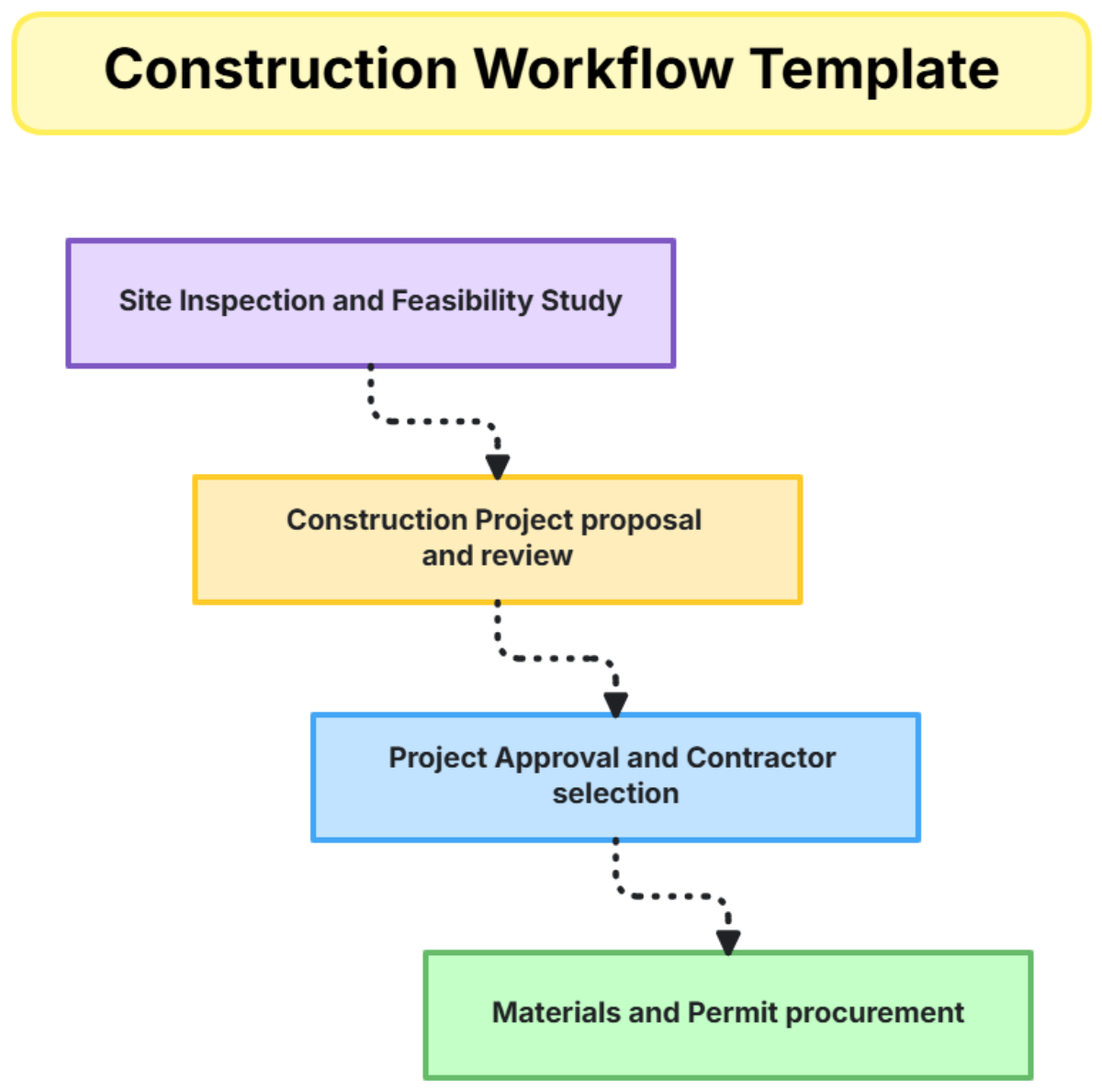

Preliminary Design:

Review process flow diagrams (PFDs) and piping and instrumentation diagrams (P&IDs) to understand piping requirements.

Develop preliminary piping layouts and routing plans in coordination with process engineers and facility designers.

Identify equipment connections, pipe sizes, materials, and specifications based on process requirements.

Detailed Engineering:

Perform hydraulic calculations to determine pipe sizes, flow rates, and pressure drops.

Prepare detailed piping isometric drawings, including dimensions, elevations, and support requirements.

Specify piping materials, fittings, valves, and accessories based on project specifications and standards.

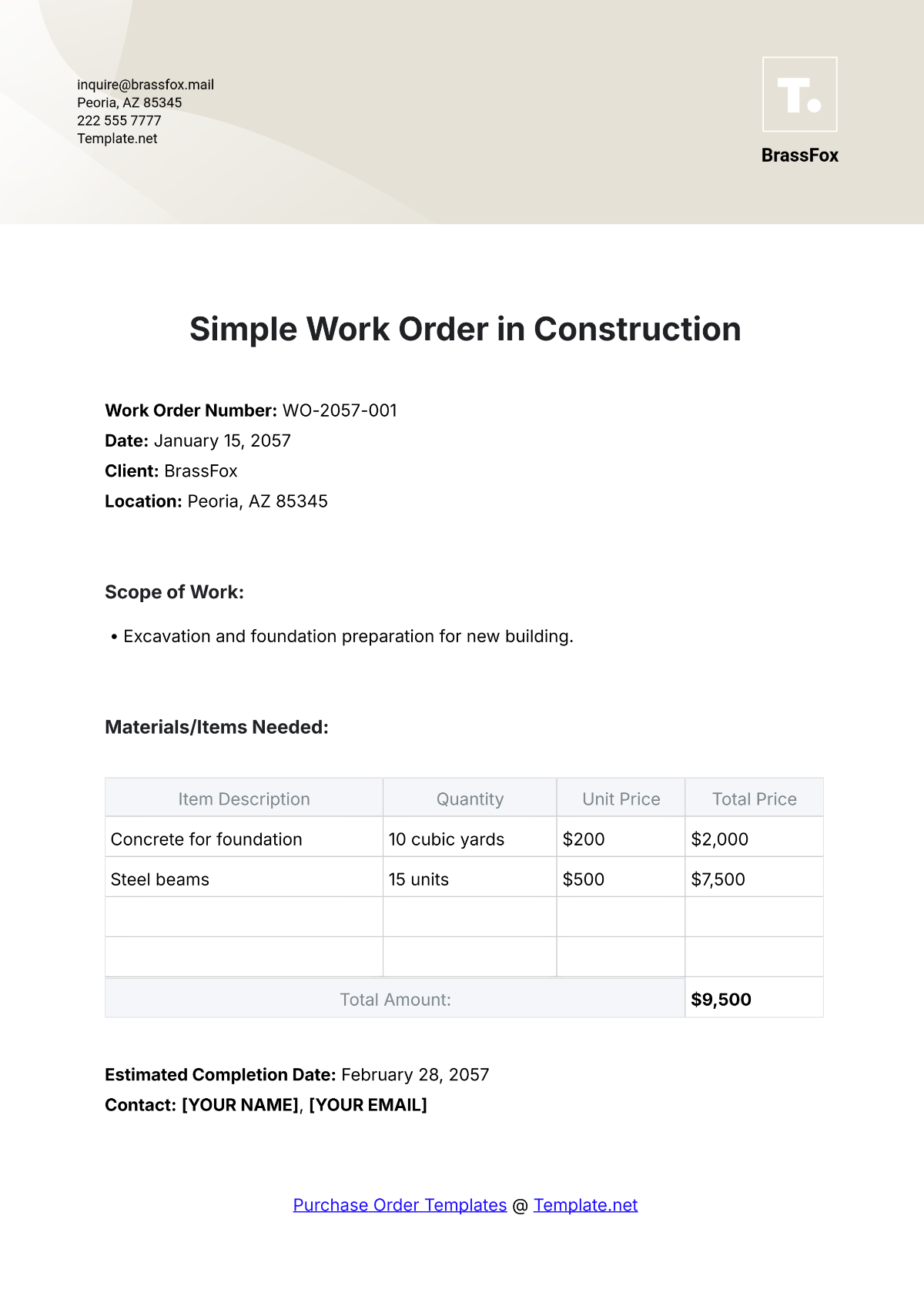

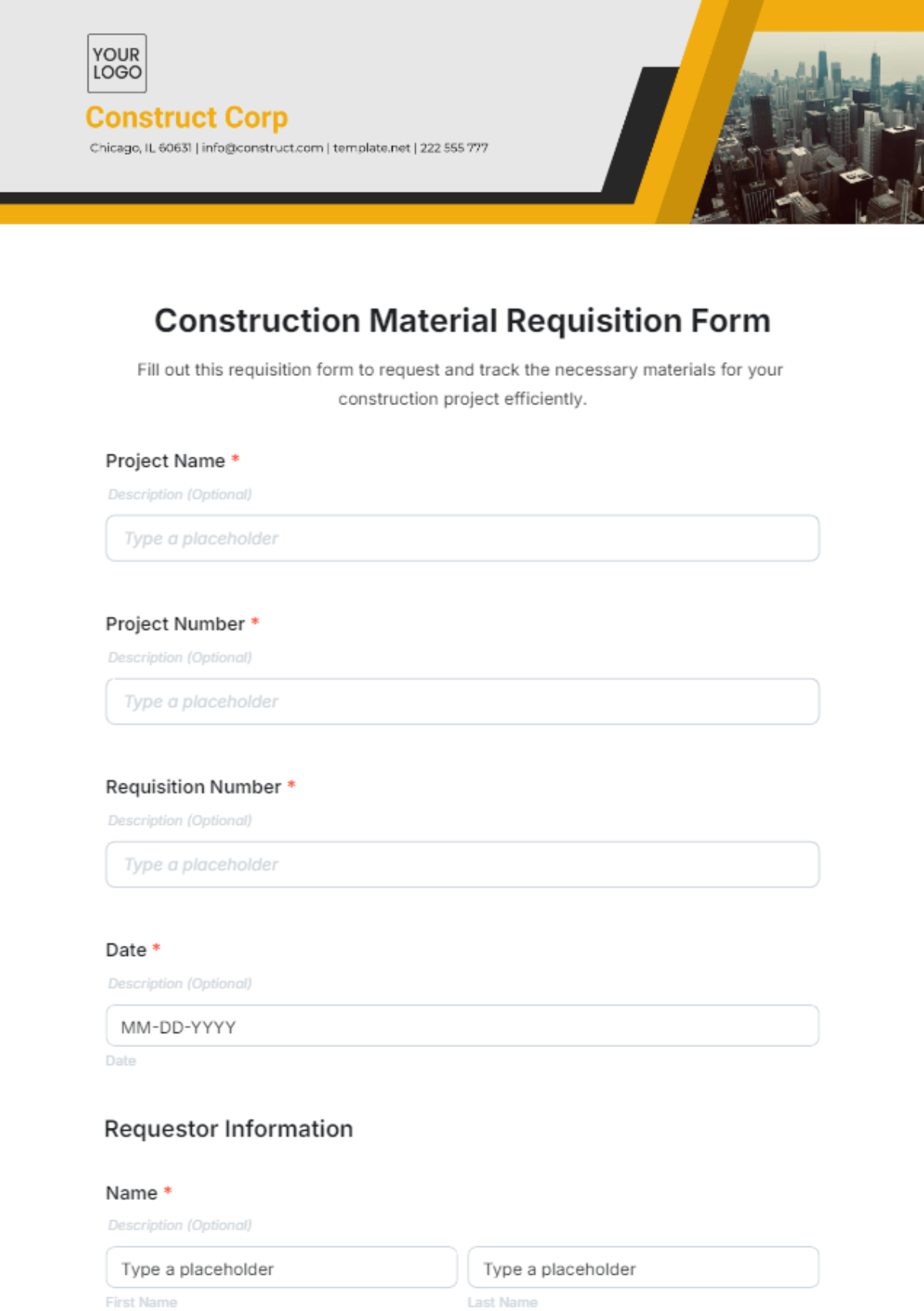

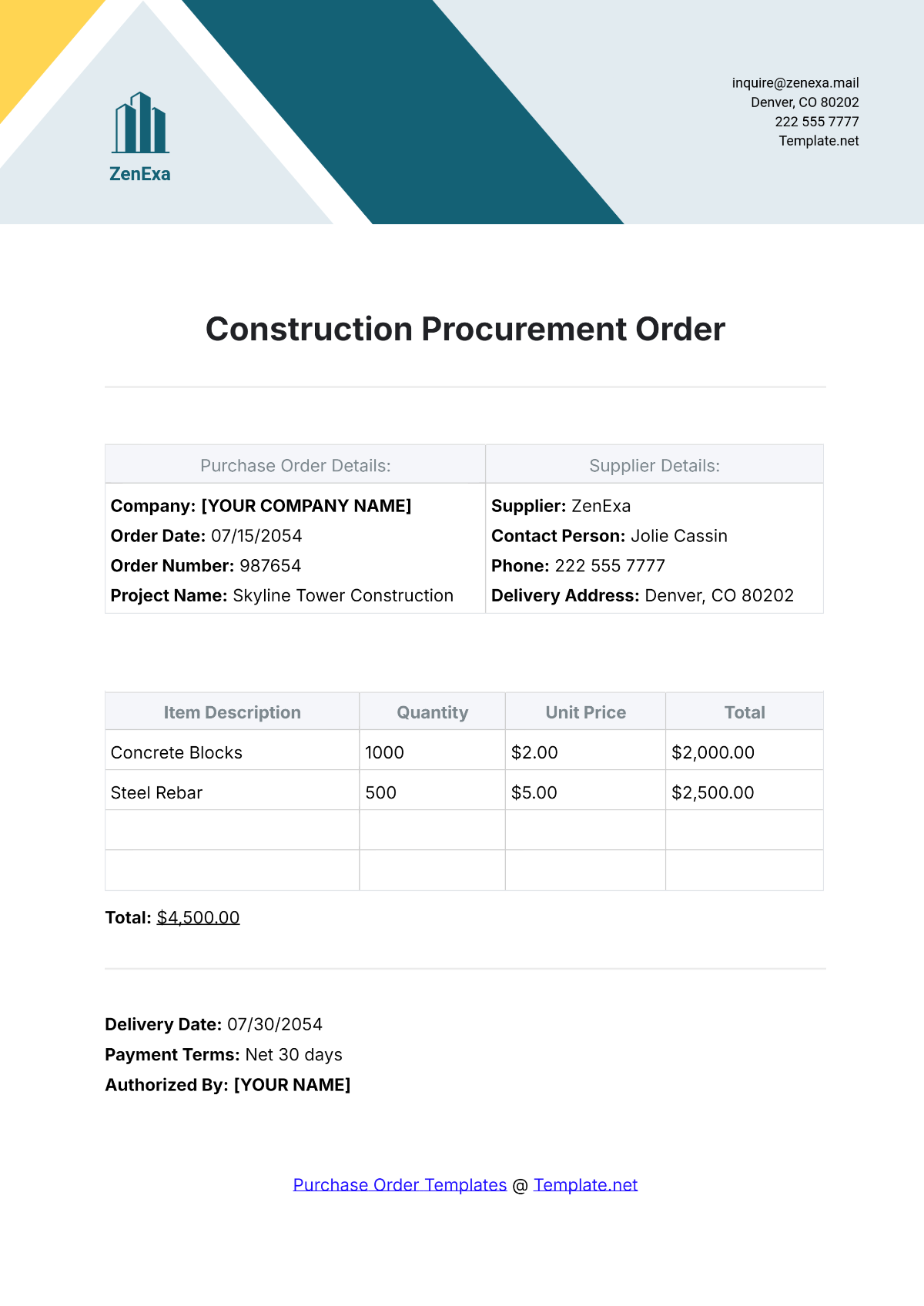

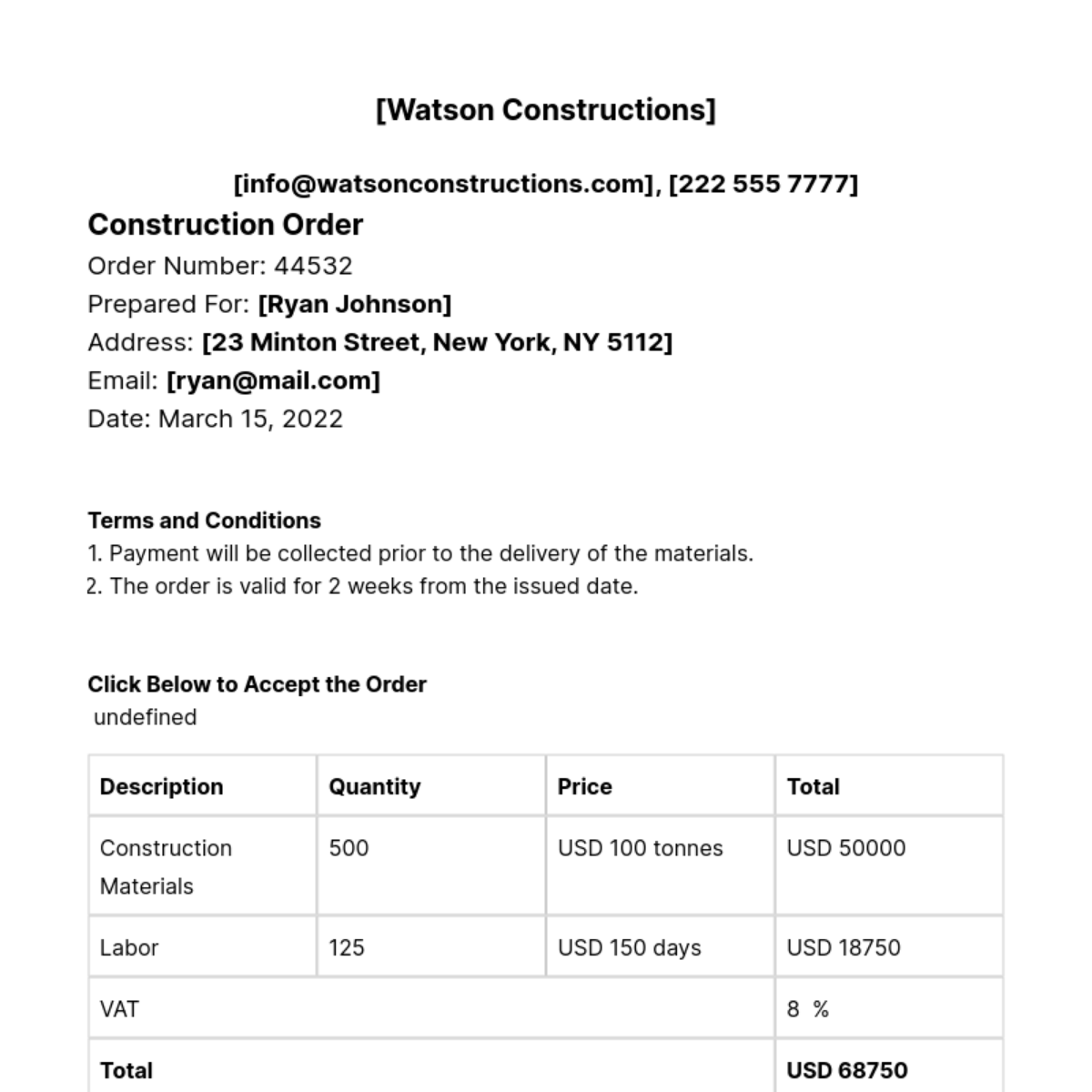

Procurement and Material Management:

Prepare material take-offs and generate procurement requisitions for piping components.

Coordinate with vendors and suppliers to ensure timely delivery of piping materials and equipment.

Verify material compliance with project specifications and quality standards upon receipt.

Piping Installation:

Mobilize construction crews and equipment to the project site.

Excavate trenches, install pipe supports, and lay piping according to approved drawings and specifications.

Weld, thread, or join pipes using appropriate techniques and procedures.

Conduct hydrostatic testing and leak detection to ensure the integrity of installed piping systems.

Quality Assurance and Control:

Implement inspection and testing protocols to verify the quality and performance of installed piping systems.

Conduct visual inspections, non-destructive testing (NDT), and pressure testing as per industry standards.

Document inspection results, deviations, and corrective actions for record-keeping and compliance purposes.

Project Timeline:

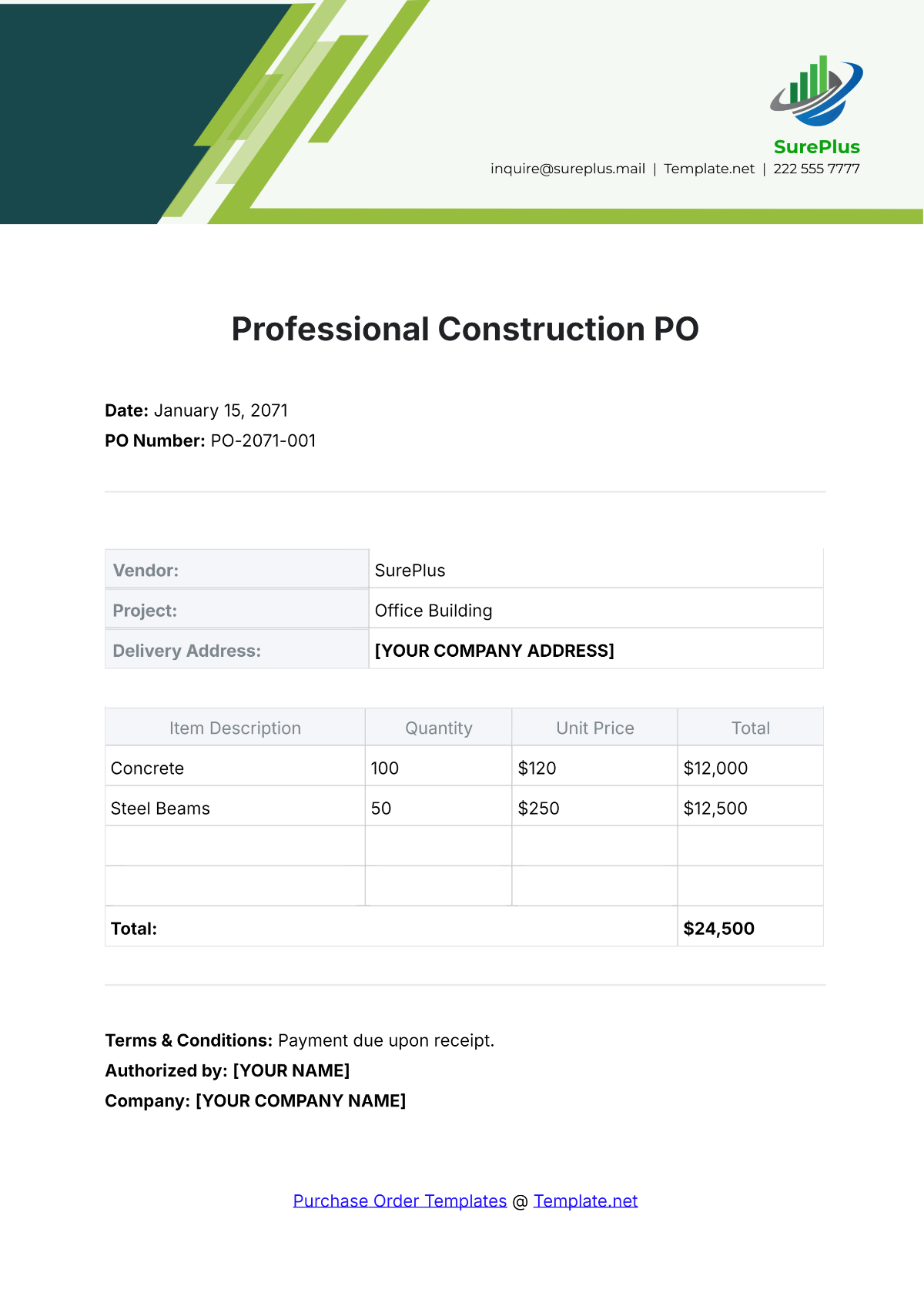

Task | Duration | Start Date | End Date |

|---|---|---|---|

Preliminary Design | 4 weeks | 04/01/2050 | 04/28/2050 |

Detailed Engineering | 6 weeks | 04/29/2050 | 06/10/2050 |

Procurement and Material Mgmt | 8 weeks | 06/11/2050 | 08/05/2050 |

Piping Installation | 12 weeks | 08/06/2050 | 10/28/2050 |

Quality Assurance and Control | 4 weeks | 10/29/2050 | 11/25/2050 |

Deliverables:

Preliminary piping layout and routing plans.

Detailed piping isometric drawings and specifications.

Material procurement requisitions and documentation.

Completed piping installation as per approved drawings and specifications.

Quality assurance and control reports and documentation.

Budget Allocation:

Task | Estimated Cost ($) |

|---|---|

Preliminary Design | $20,000 |

Detailed Engineering | $30,000 |

Procurement and Material Mgmt | $40,000 |

Piping Installation | $150,000 |

Quality Assurance and Control | $20,000 |

Contingency | $20,000 |

Total Project Budget | $280,000 |

Project Team:

Role | Name(s) |

|---|---|

Piping Engineer | [NAME] |

Design Drafters | [NAME] |

Procurement Specialist | [NAME] |

Construction Supervisor | [NAME] |

Quality Control Inspector | [NAME] |

Communication Plan:

Regular progress meetings, site visits, and weekly reports will facilitate communication among project team members and stakeholders, ensuring alignment with project goals and timelines.

Signature:

Date:[DATE]