Inventory Management Standard Operating Procedure (SOP)

I. Purpose

The purpose of this Inventory Management Standard Operating Procedure (SOP) is to establish guidelines and procedures for the efficient and effective management of inventory within [Your Company Name]. This SOP aims to ensure accurate inventory tracking, timely replenishment, optimal storage practices, and seamless distribution of inventory items to meet operational demands.

II. Scope

This SOP applies to all departments and personnel involved in inventory management activities within [Your Company Name]. It covers the processes of receiving, storing, tracking, and distributing inventory items across all locations and facilities of the organization.

III. Responsibilities

Inventory Manager

Oversees overall inventory management activities, including planning, monitoring, and reporting.

Warehouse Staff

Responsible for receiving, storing, and organizing inventory items in designated storage areas.

Logistics Team

Manages the transportation, distribution, and delivery of inventory items to internal departments or external customers.

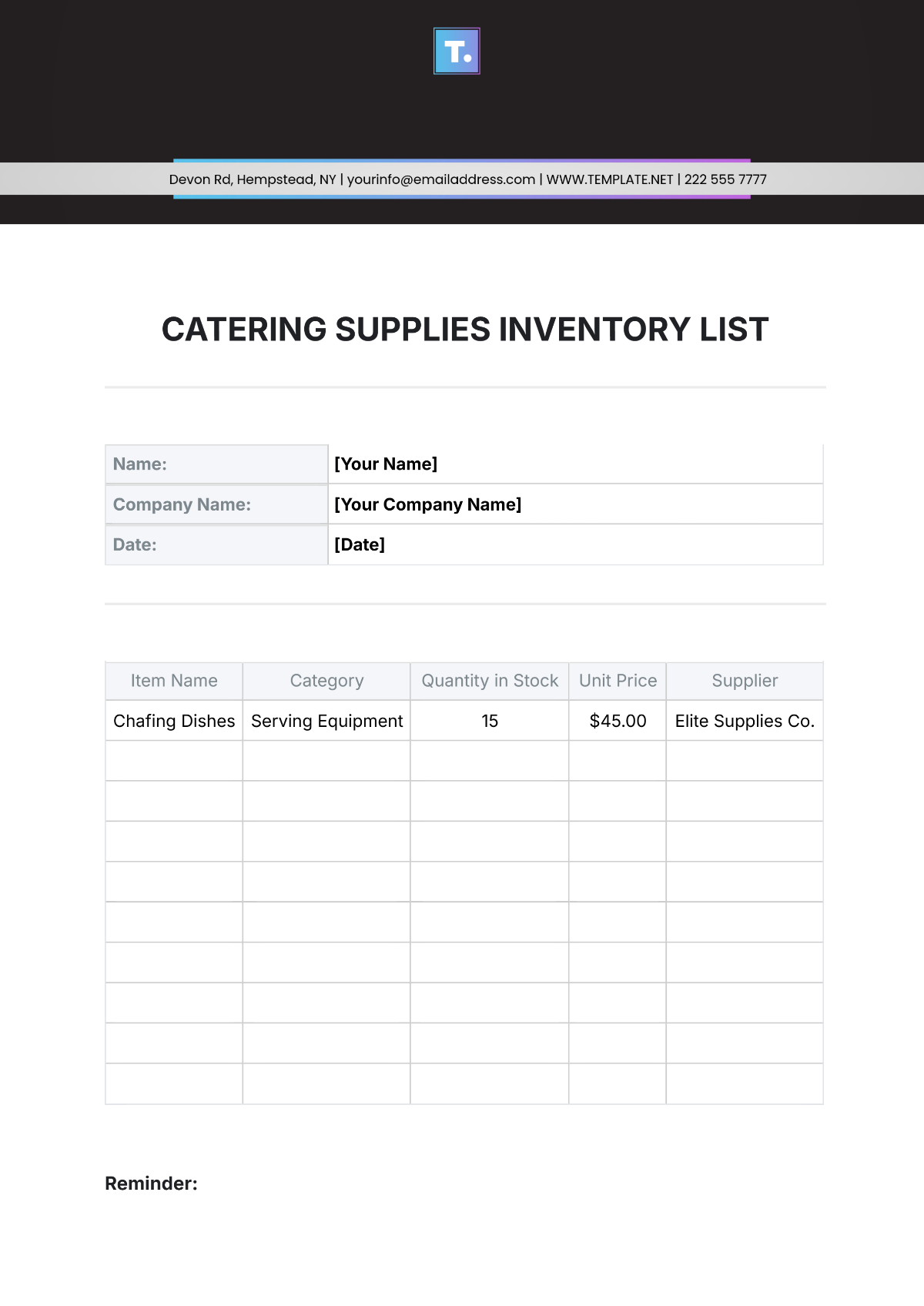

Procurement Team

Coordinates with suppliers/vendors for timely procurement and replenishment of inventory items.

IV. Procedure

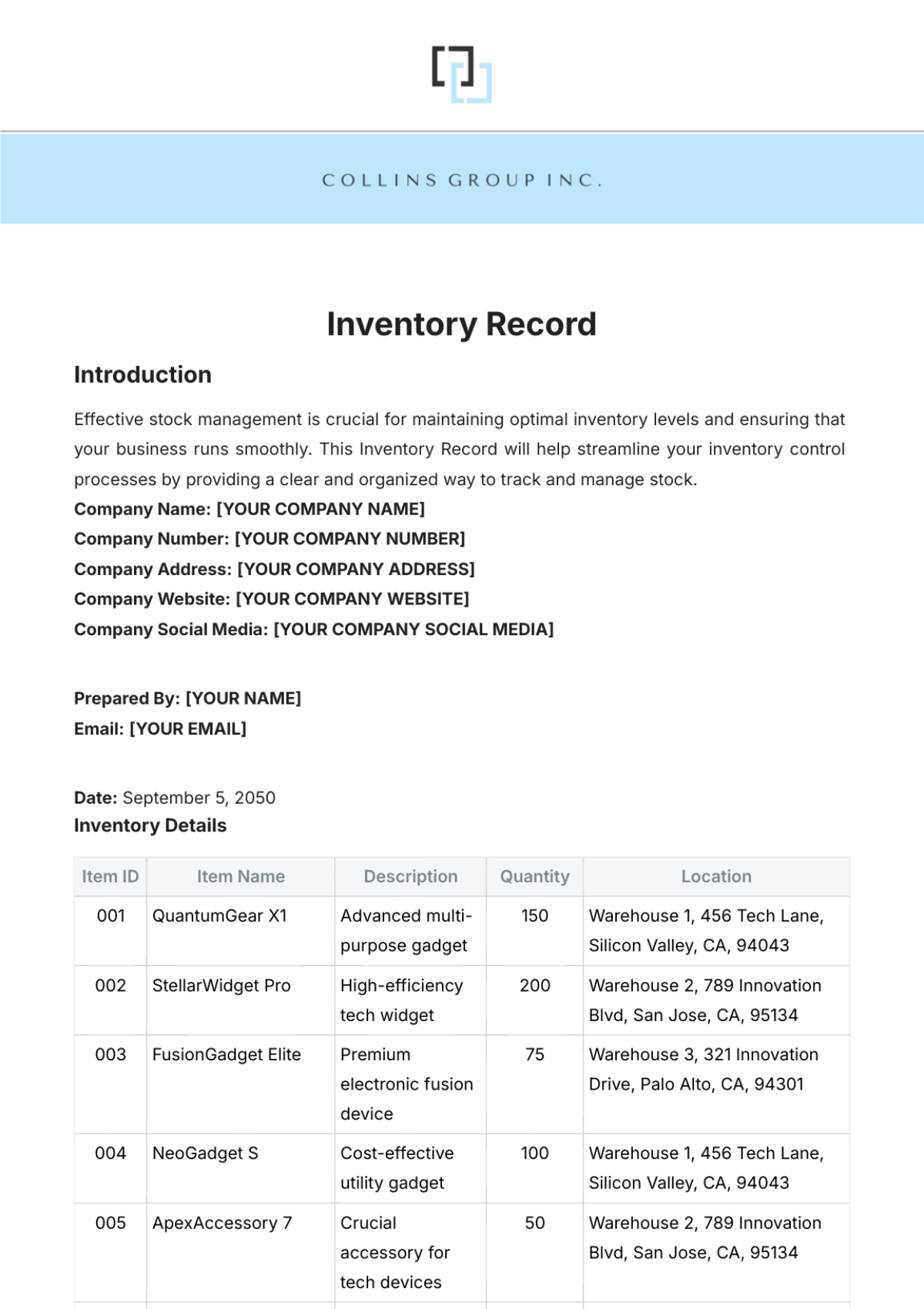

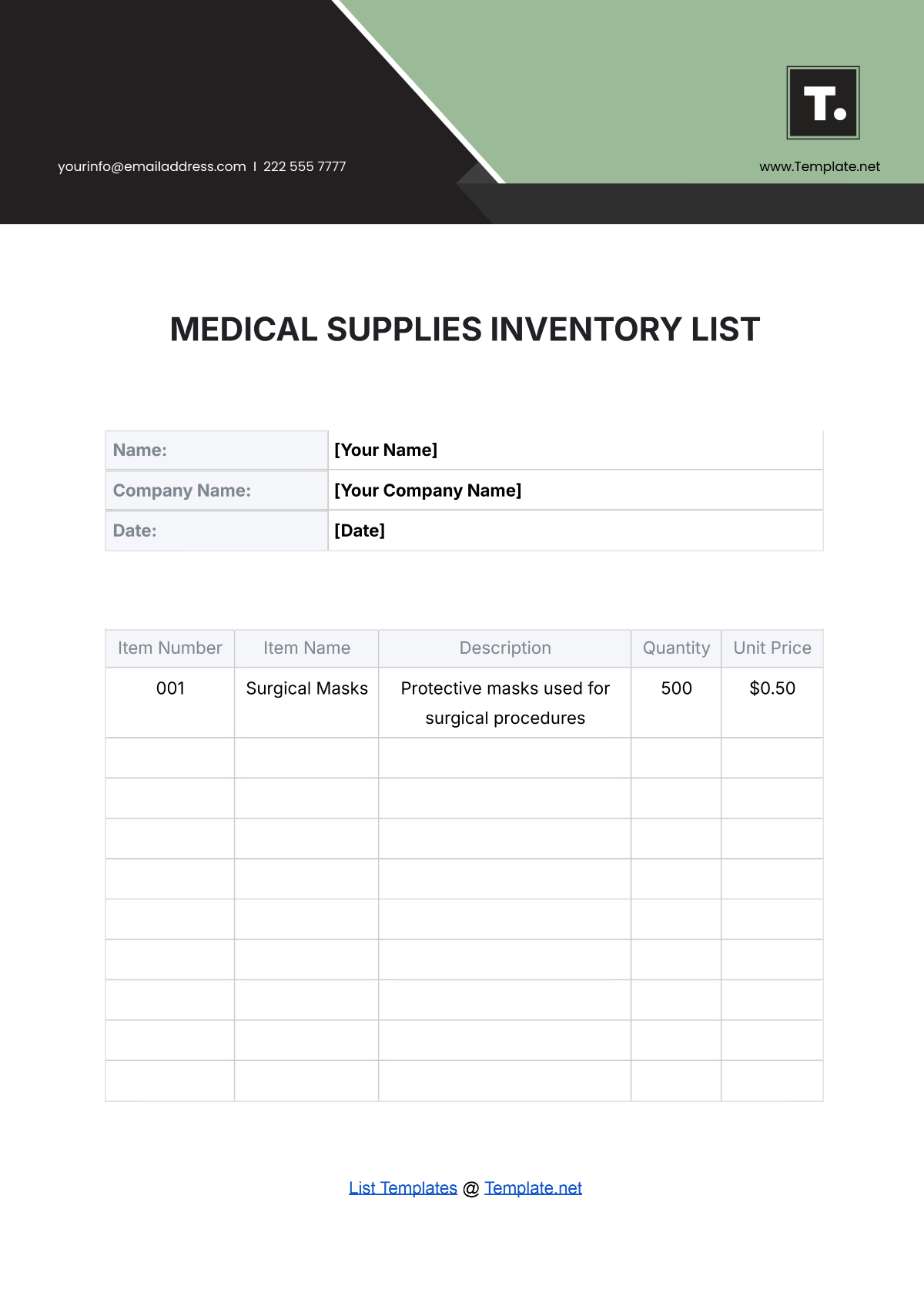

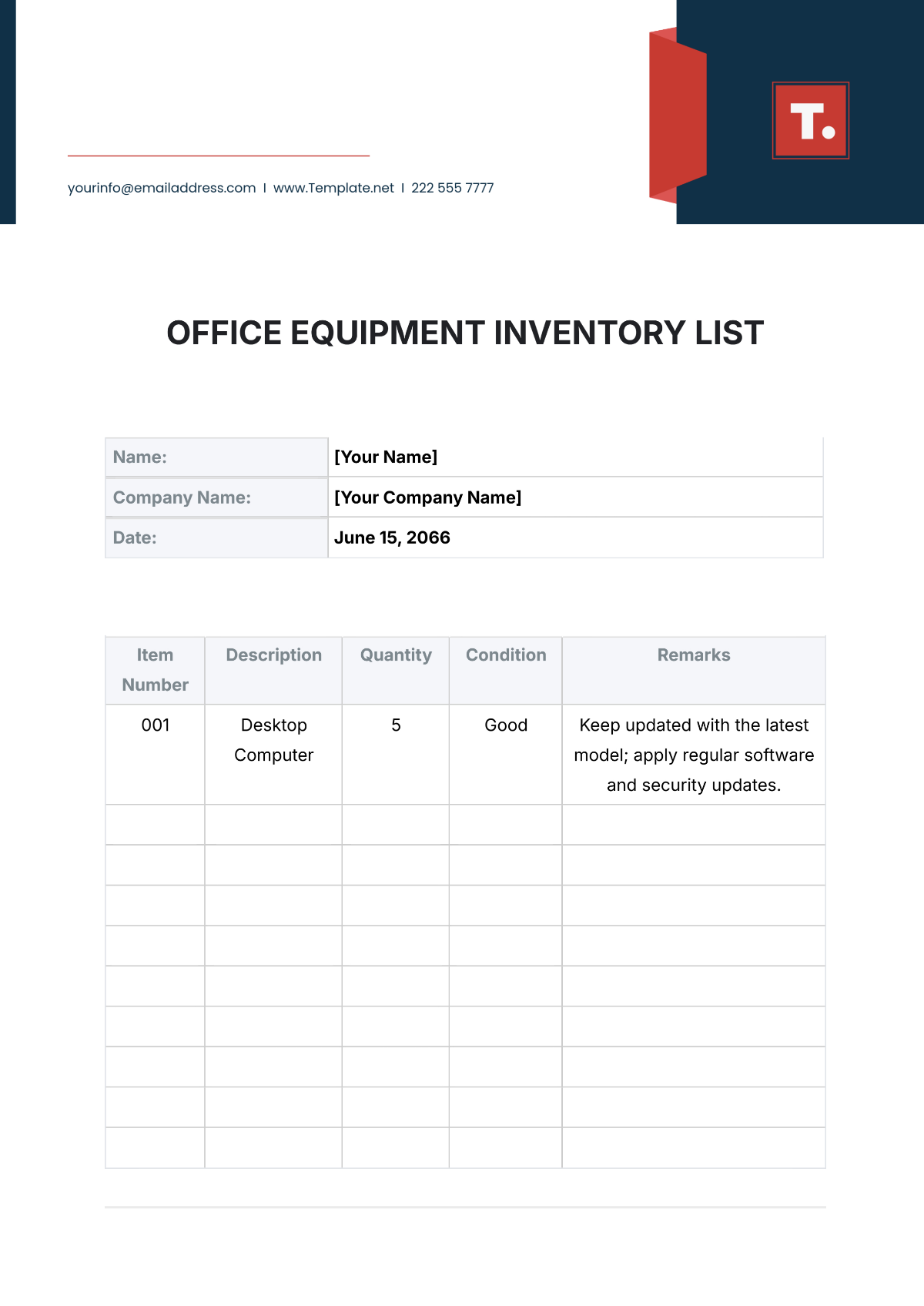

4.1 Receiving Inventory

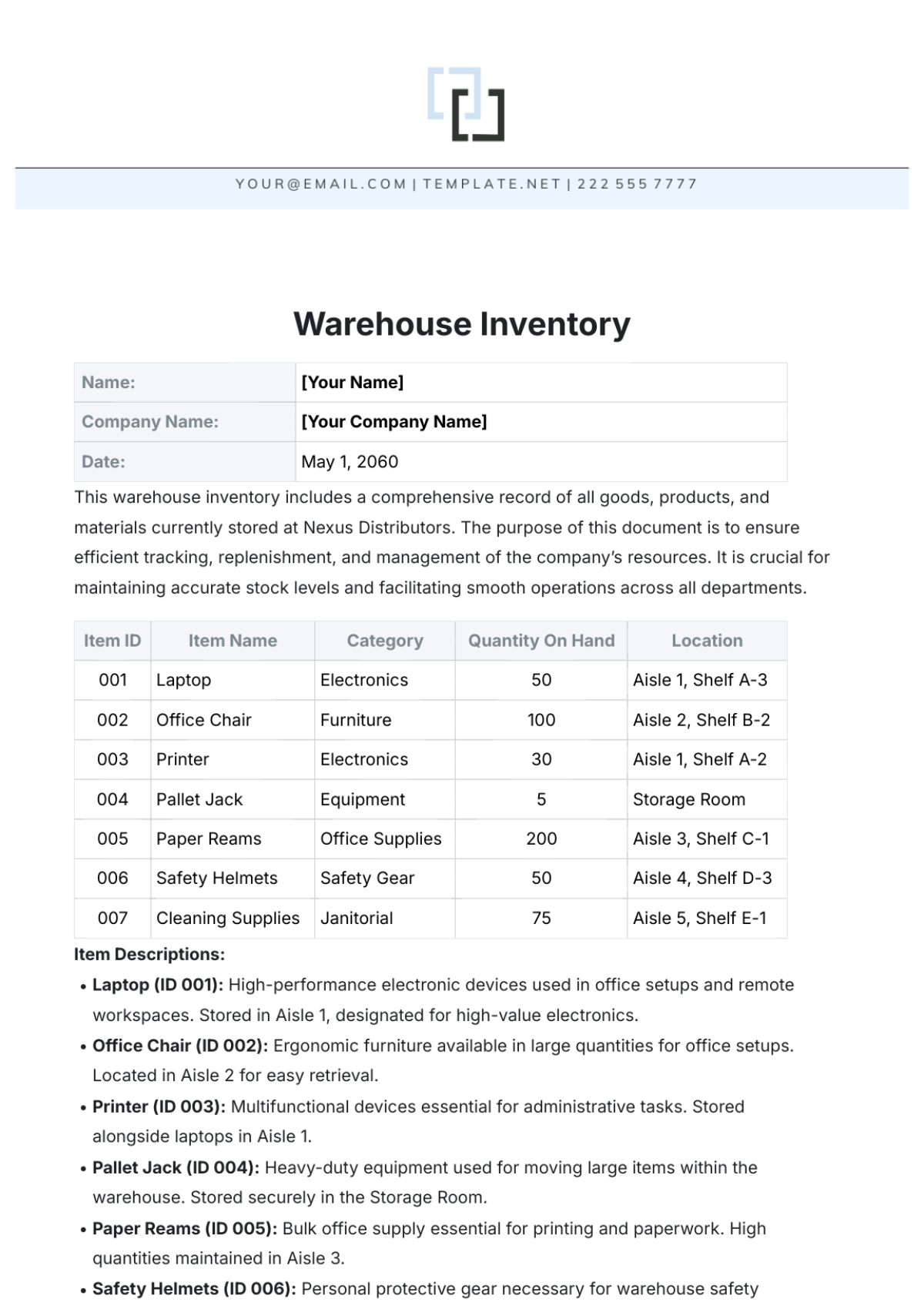

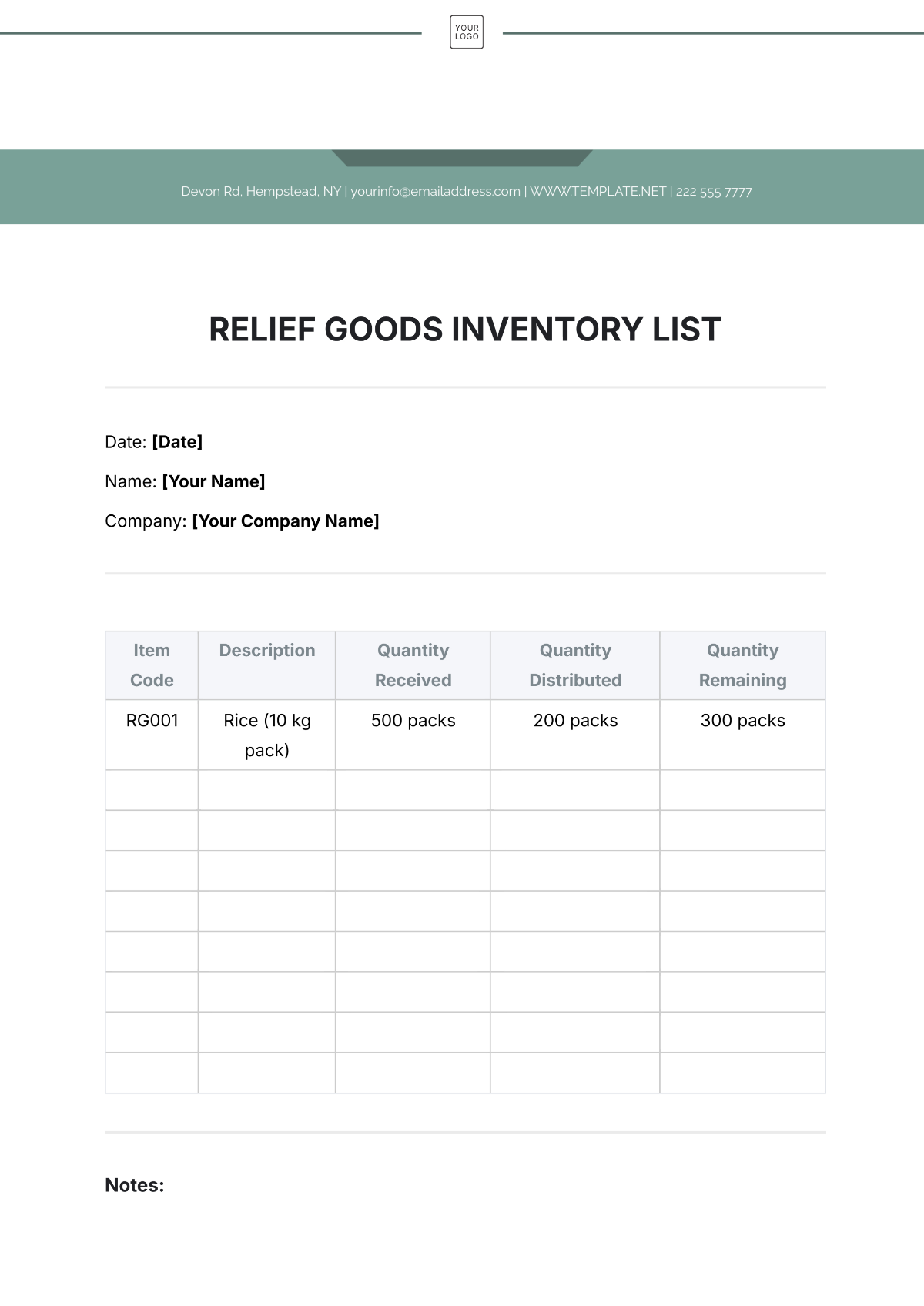

Upon receipt of inventory items, the receiving team verifies the received quantities against purchase orders and inspects for any damages or discrepancies.

Accepted items are labeled, categorized, and assigned unique identification codes before being transferred to designated storage locations.

Any discrepancies or damages are reported to the procurement team for resolution.

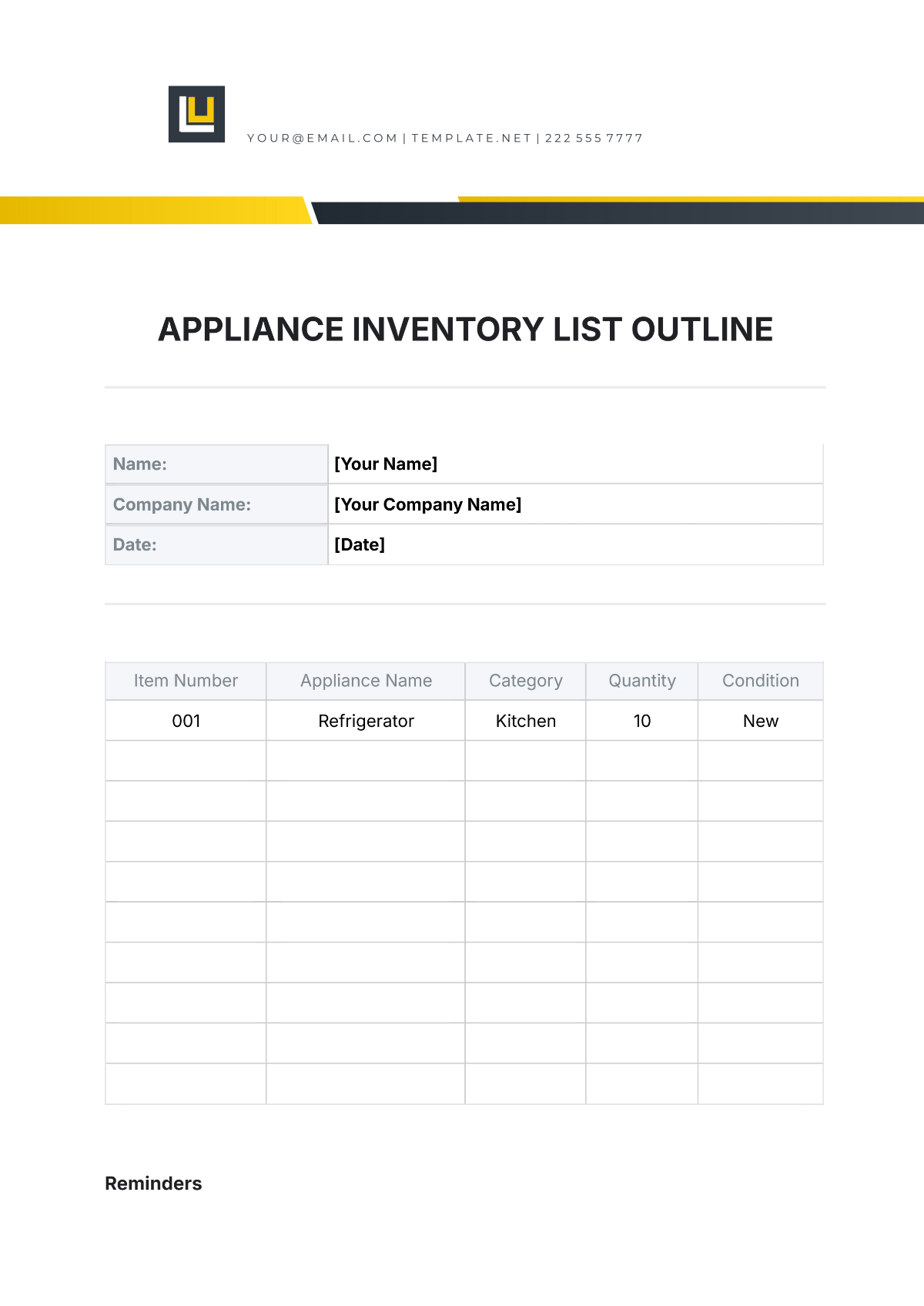

4.2 Storing Inventory

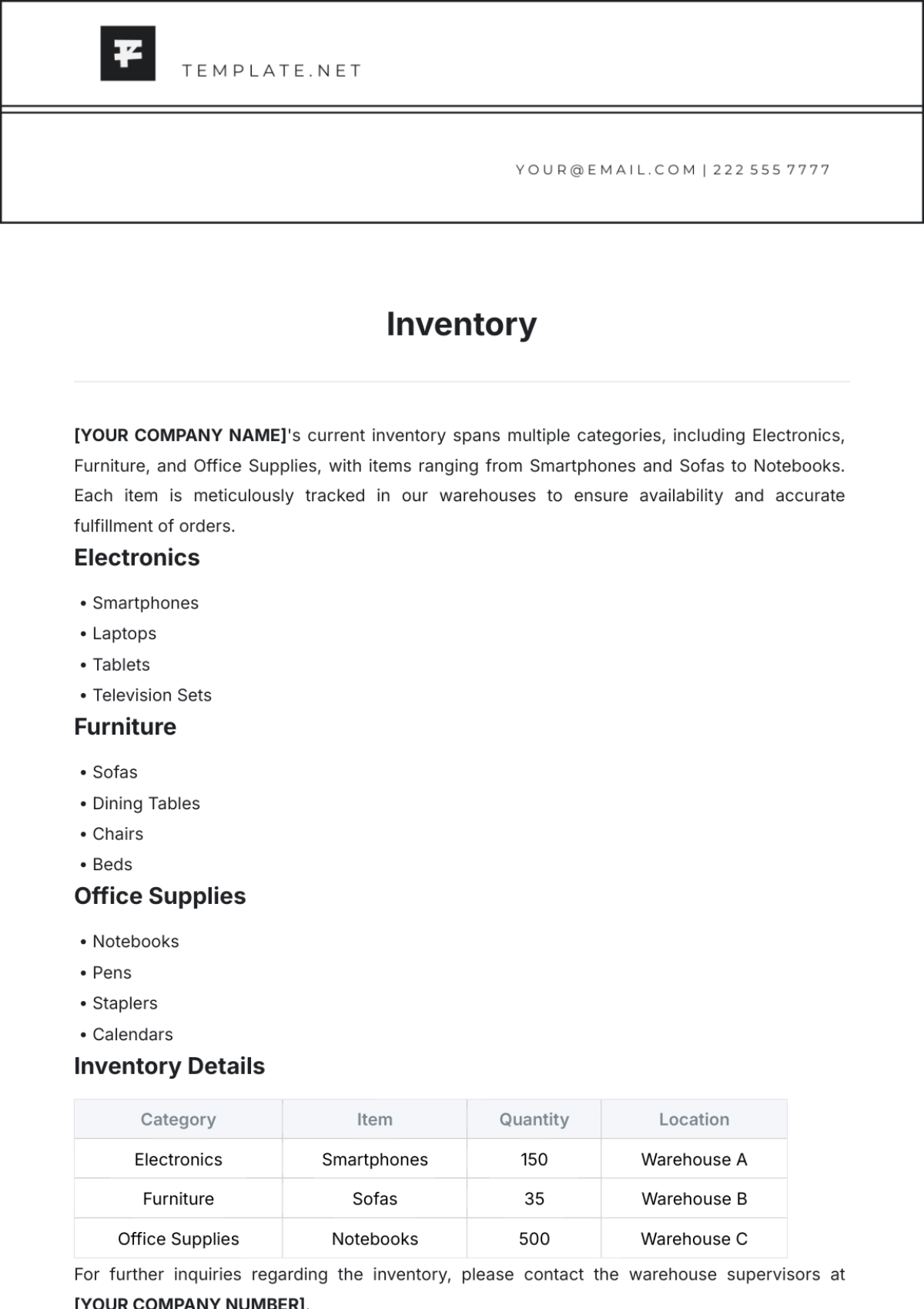

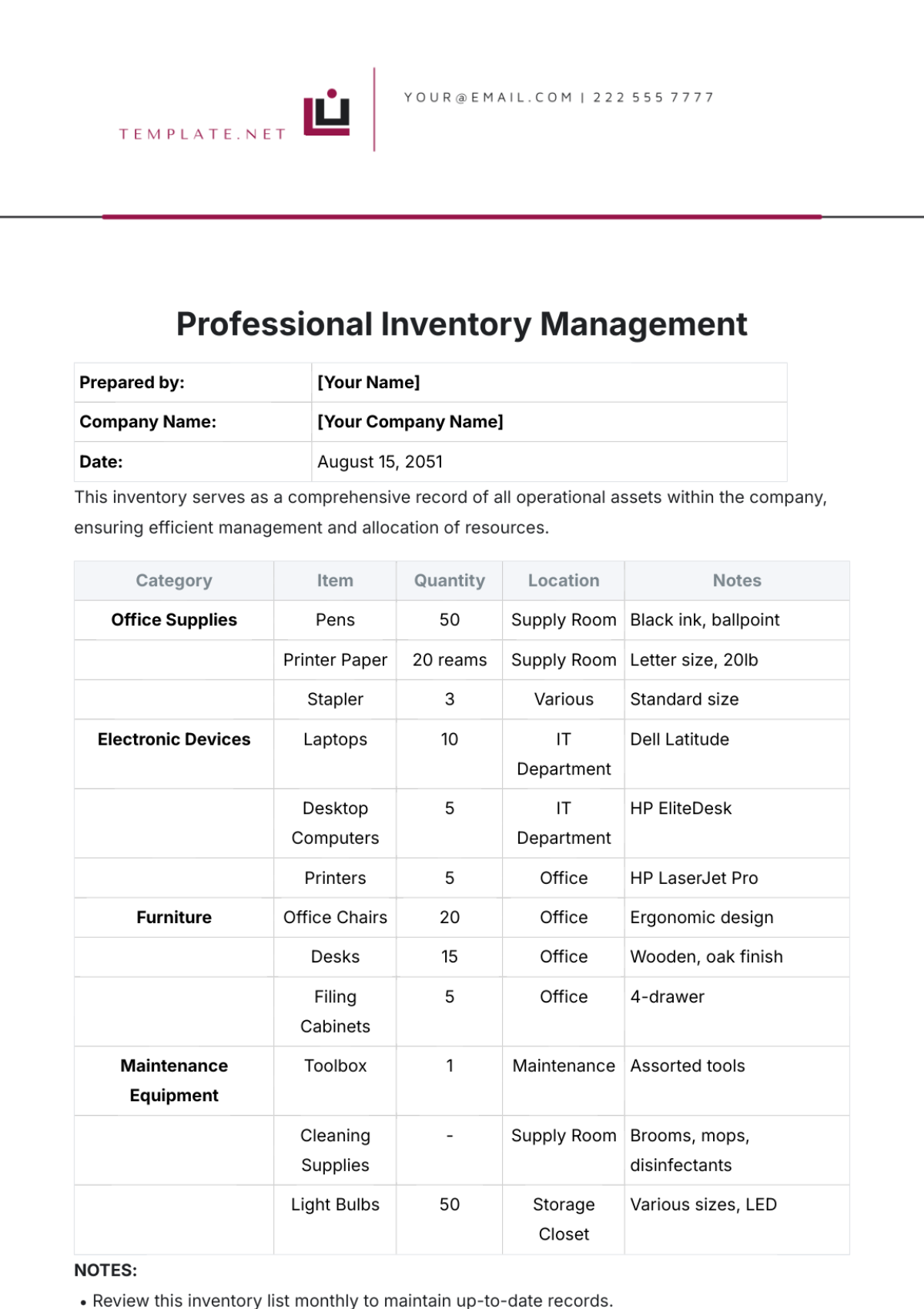

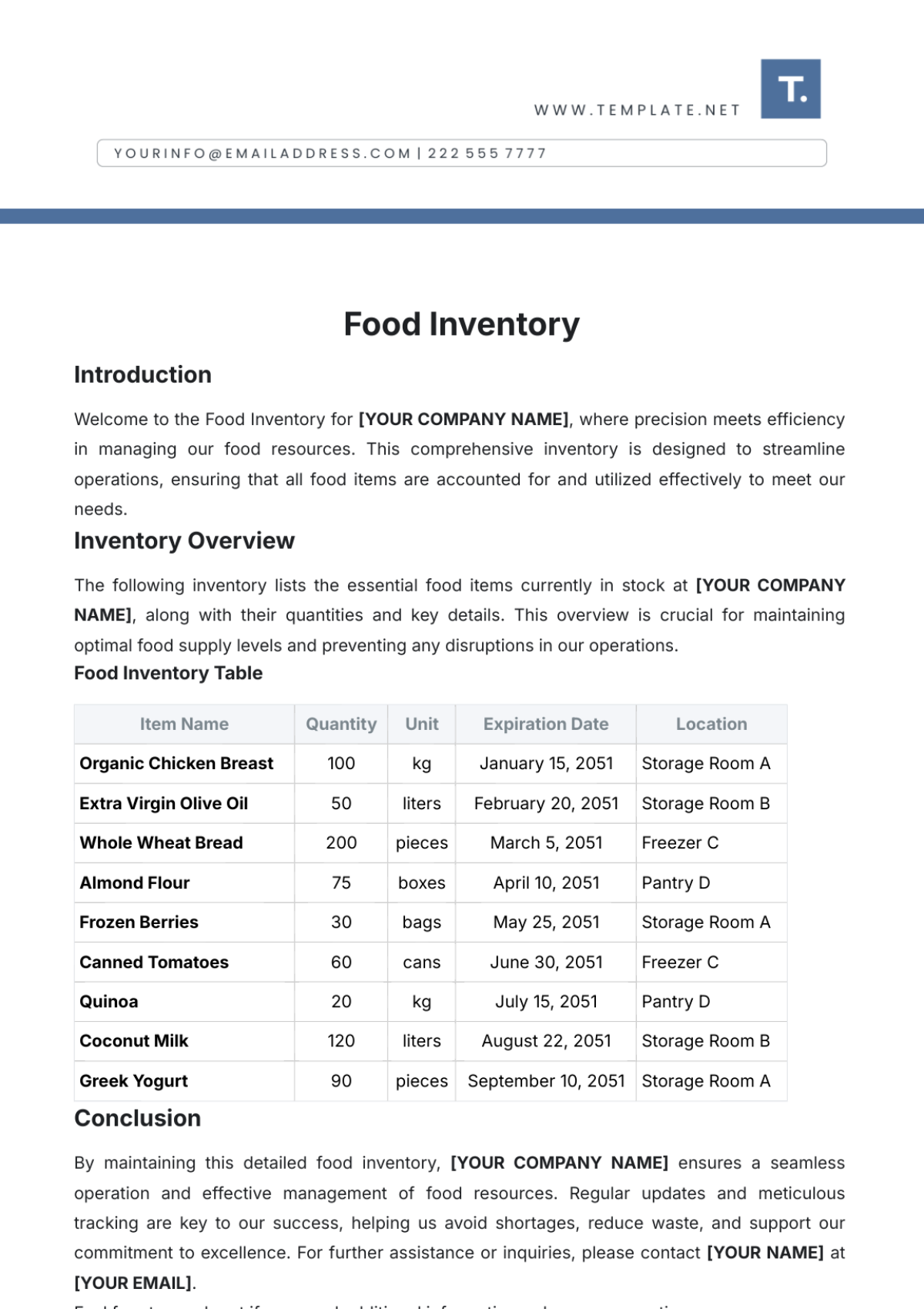

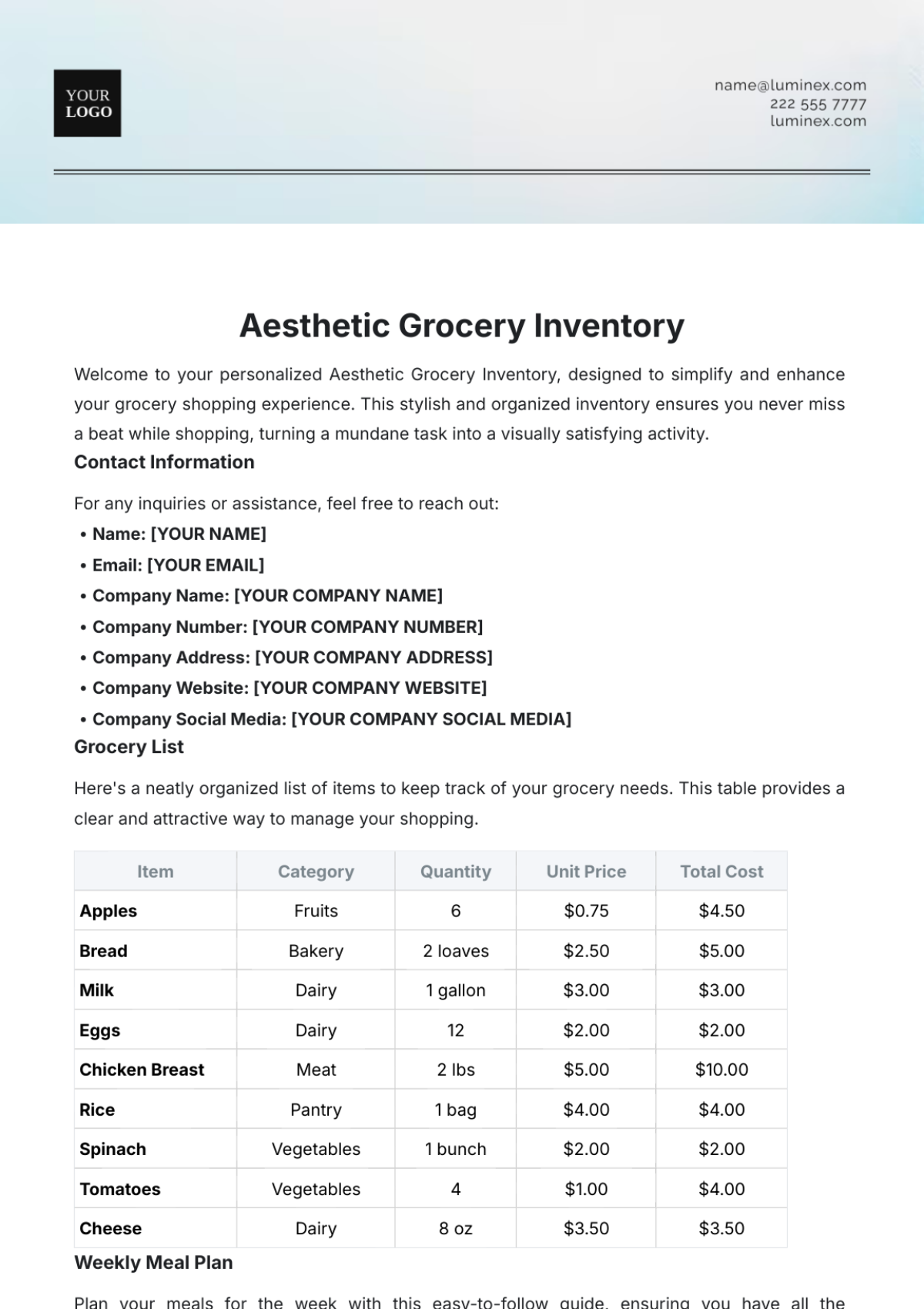

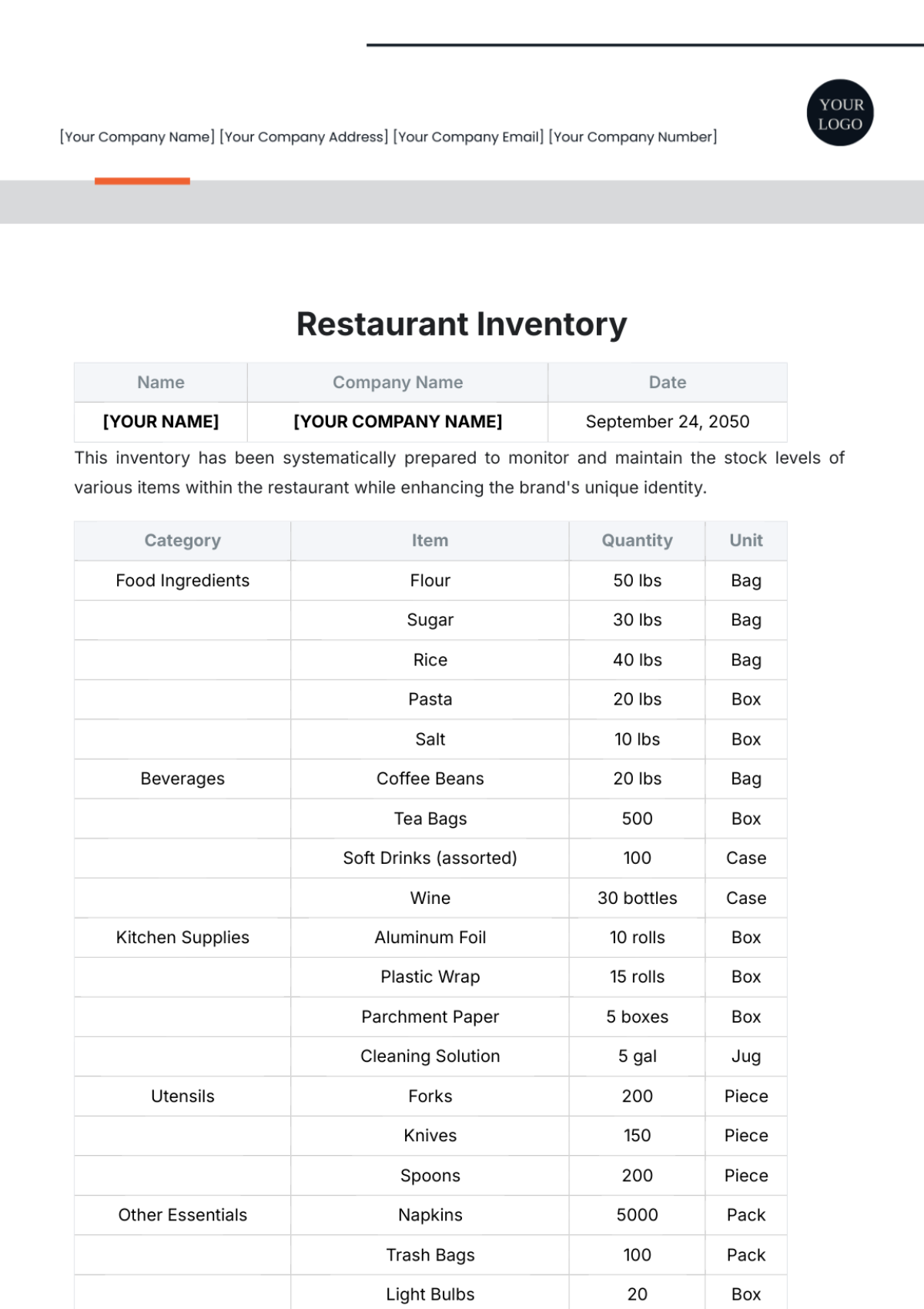

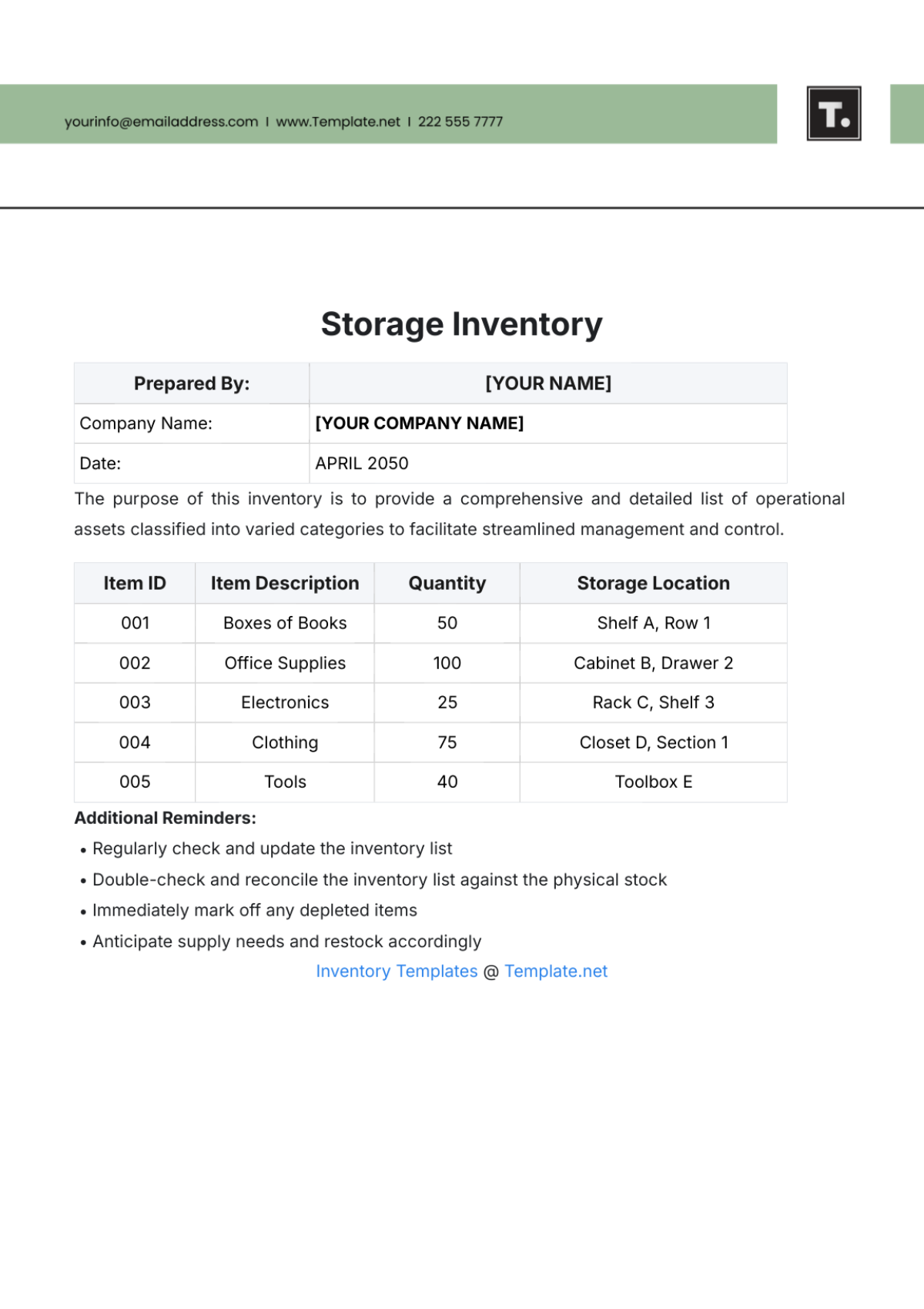

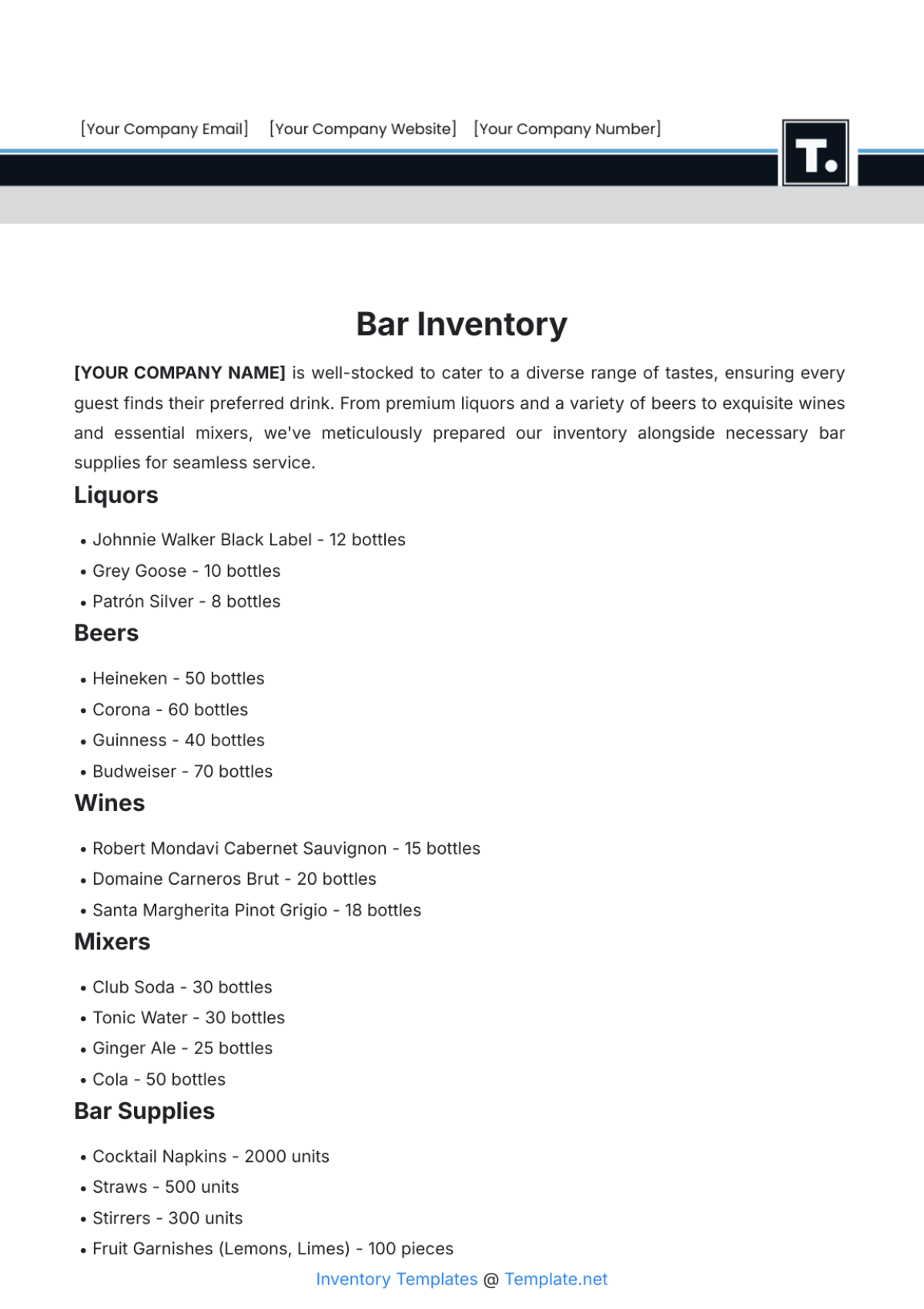

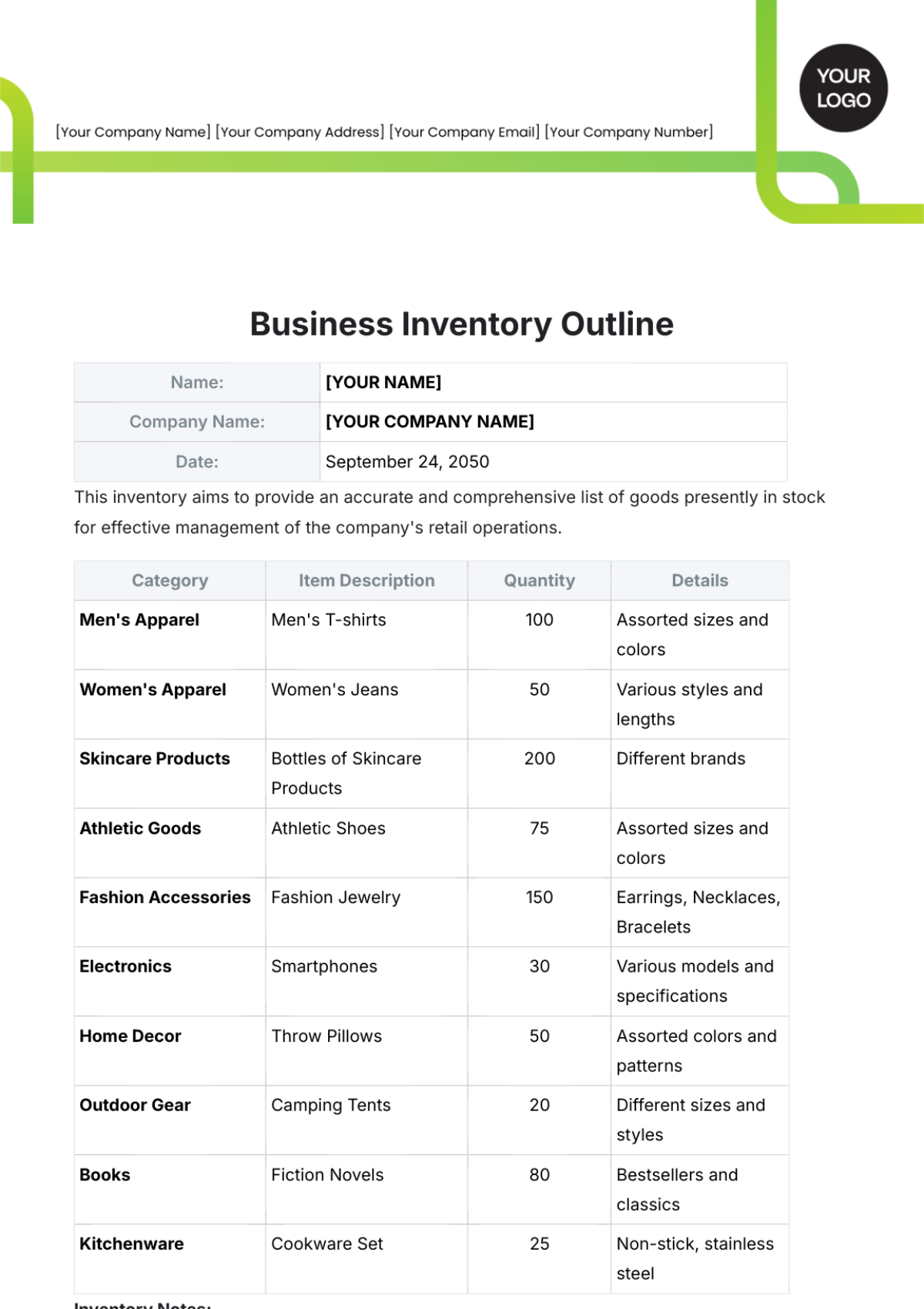

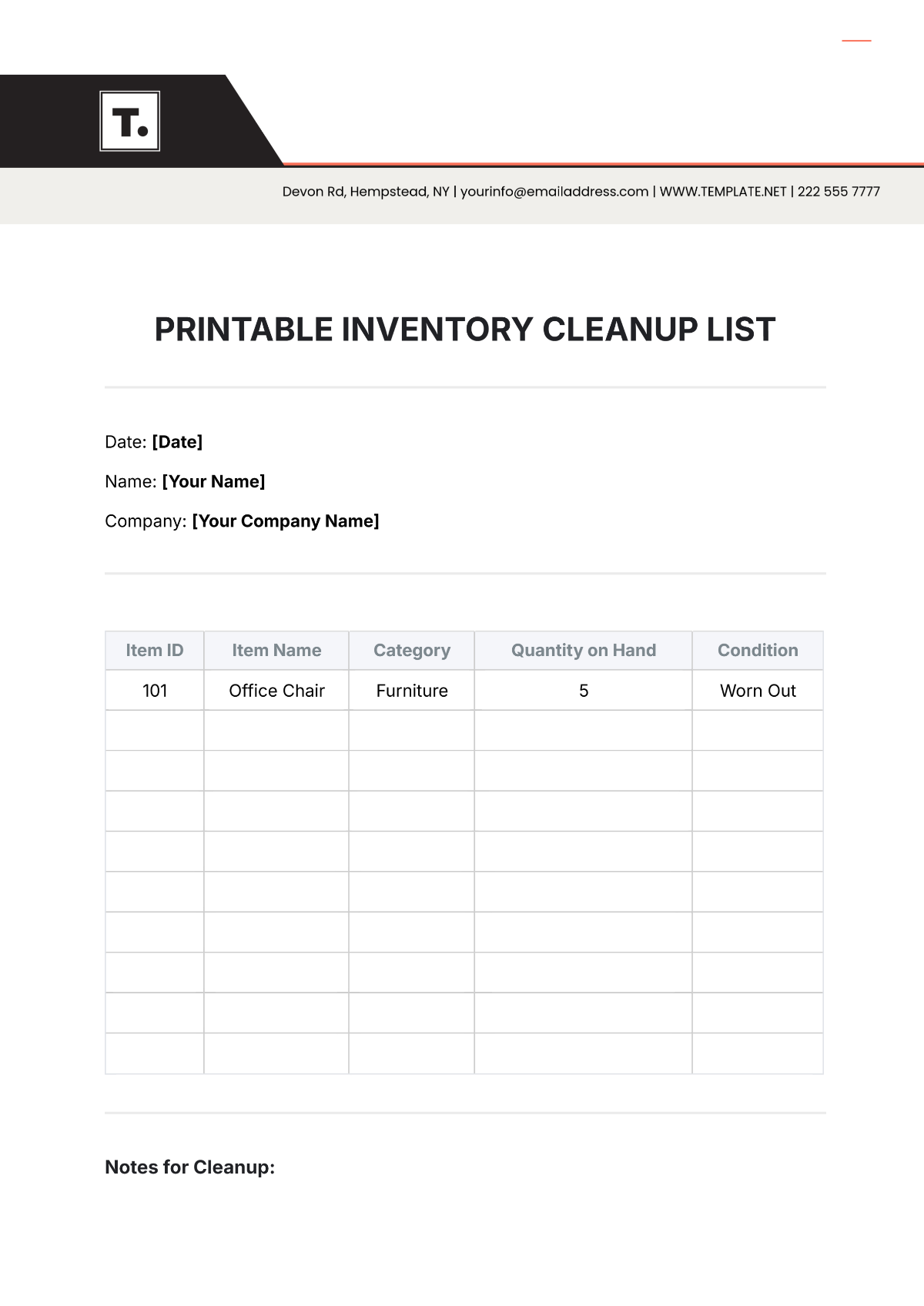

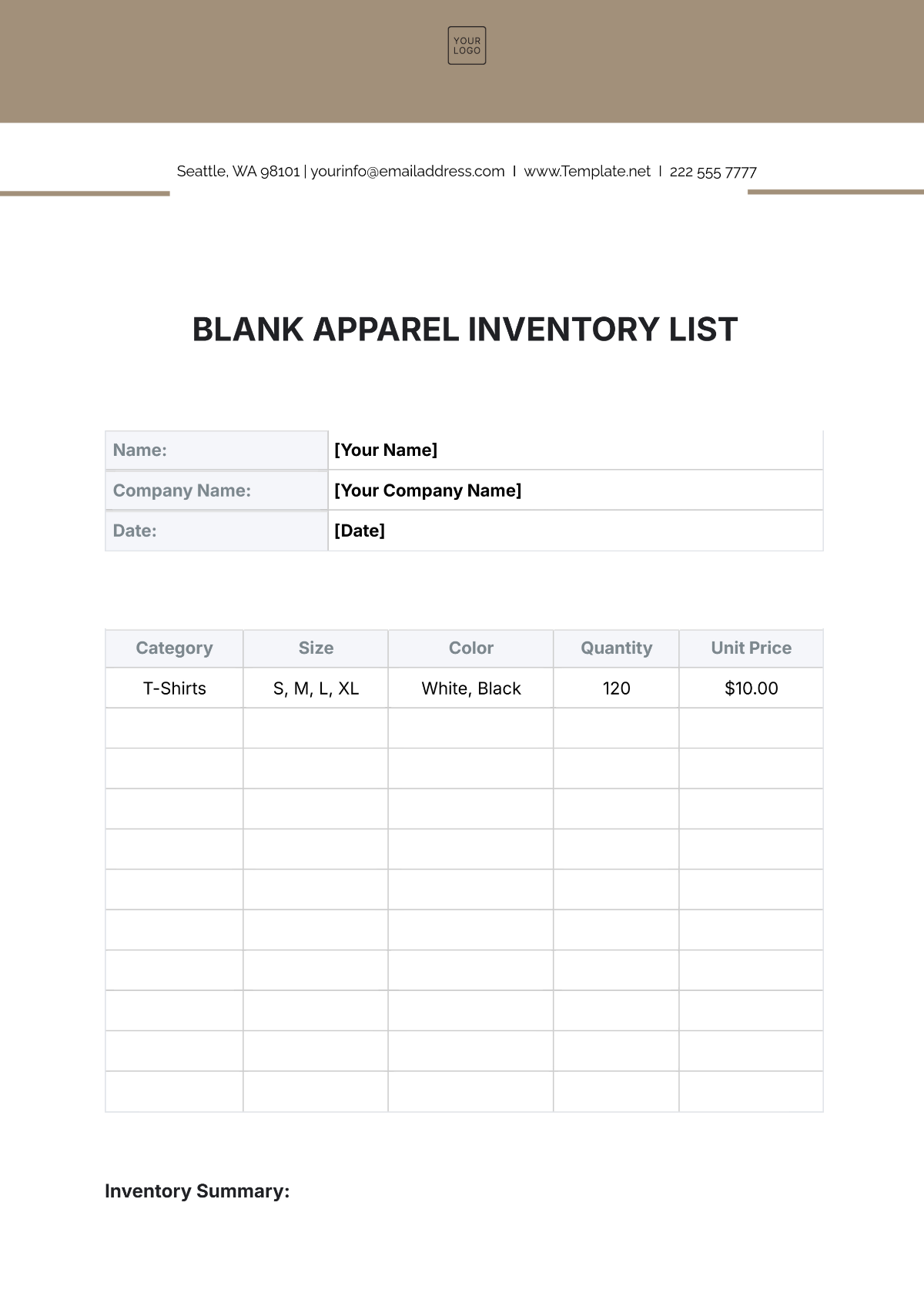

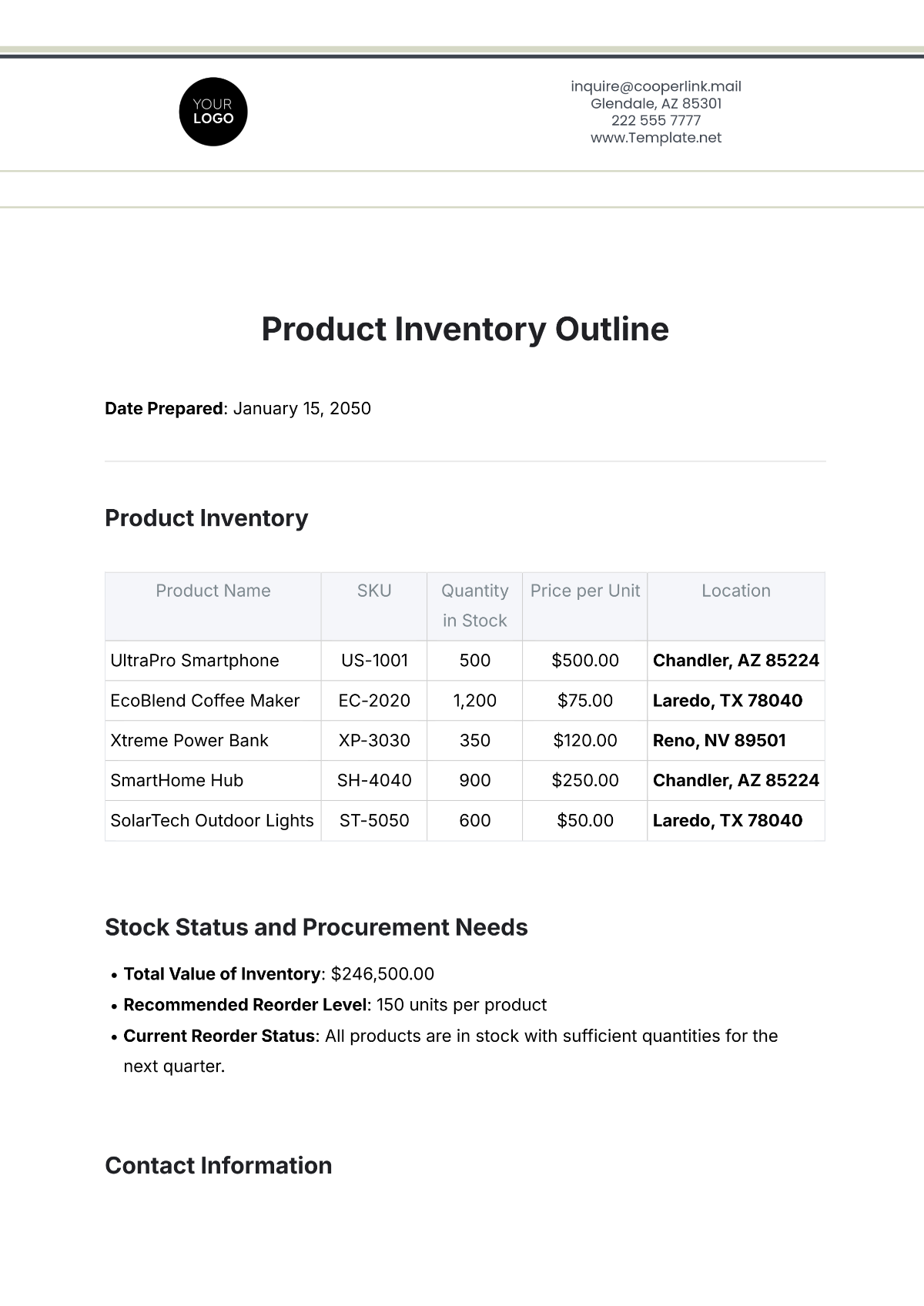

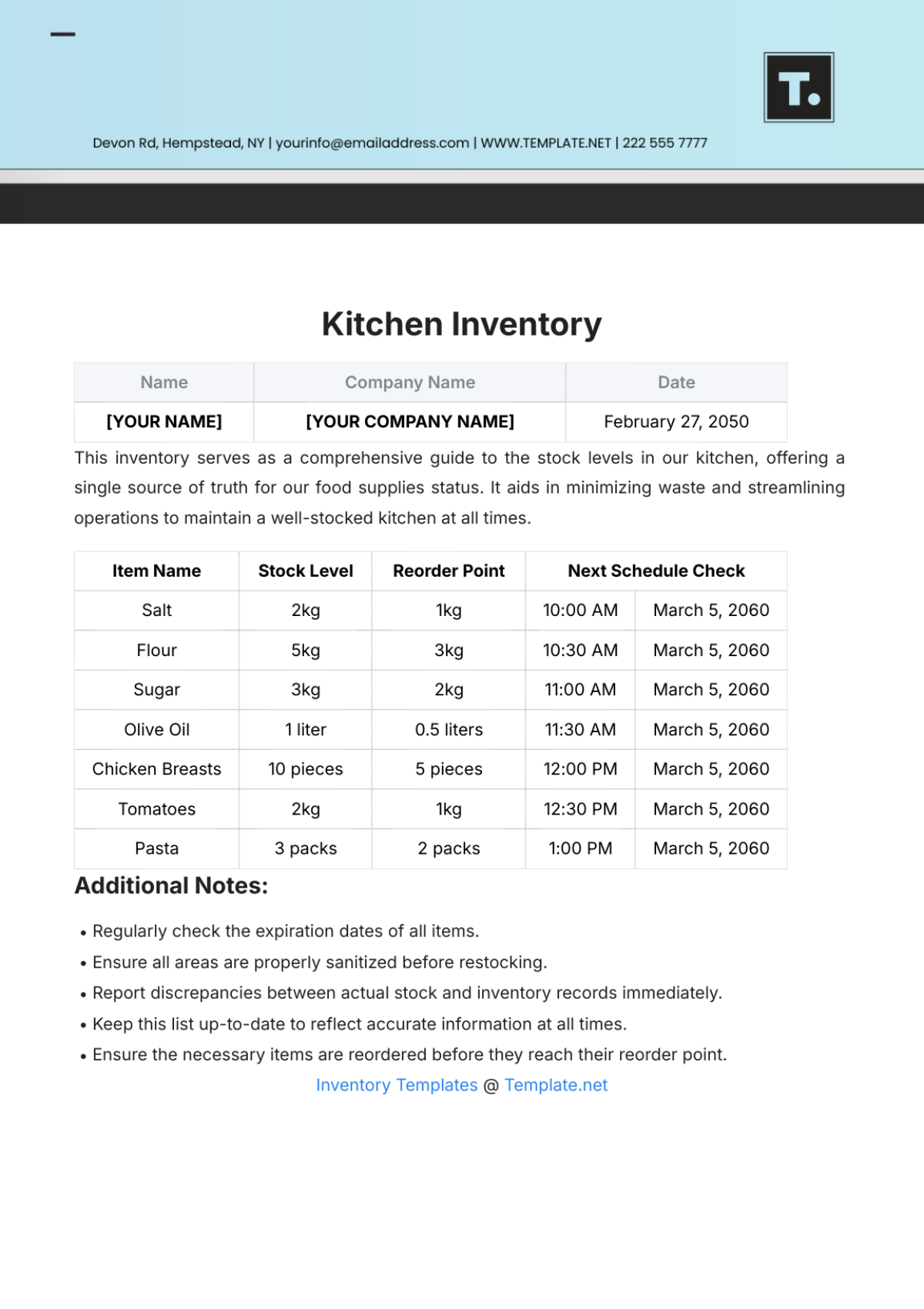

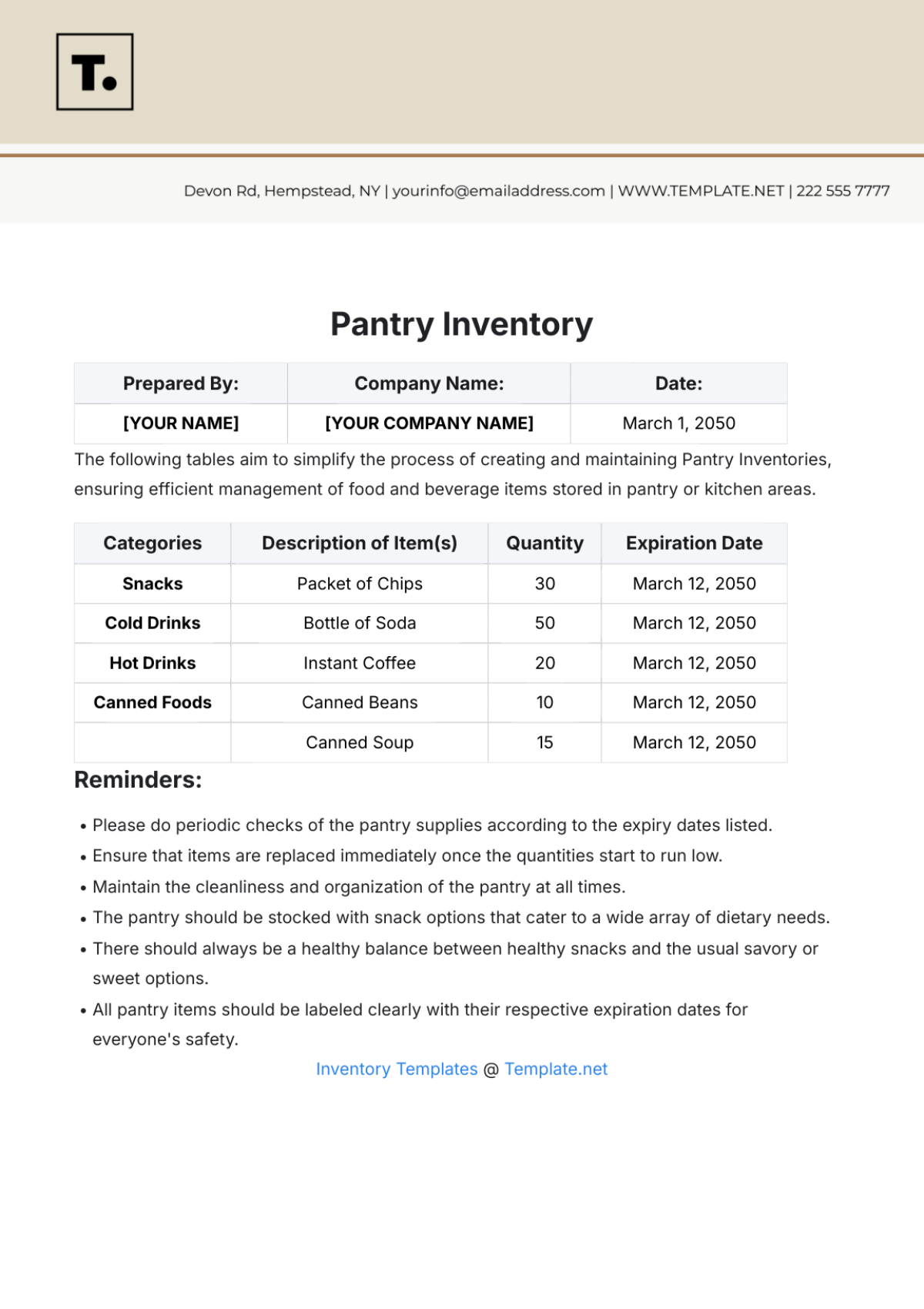

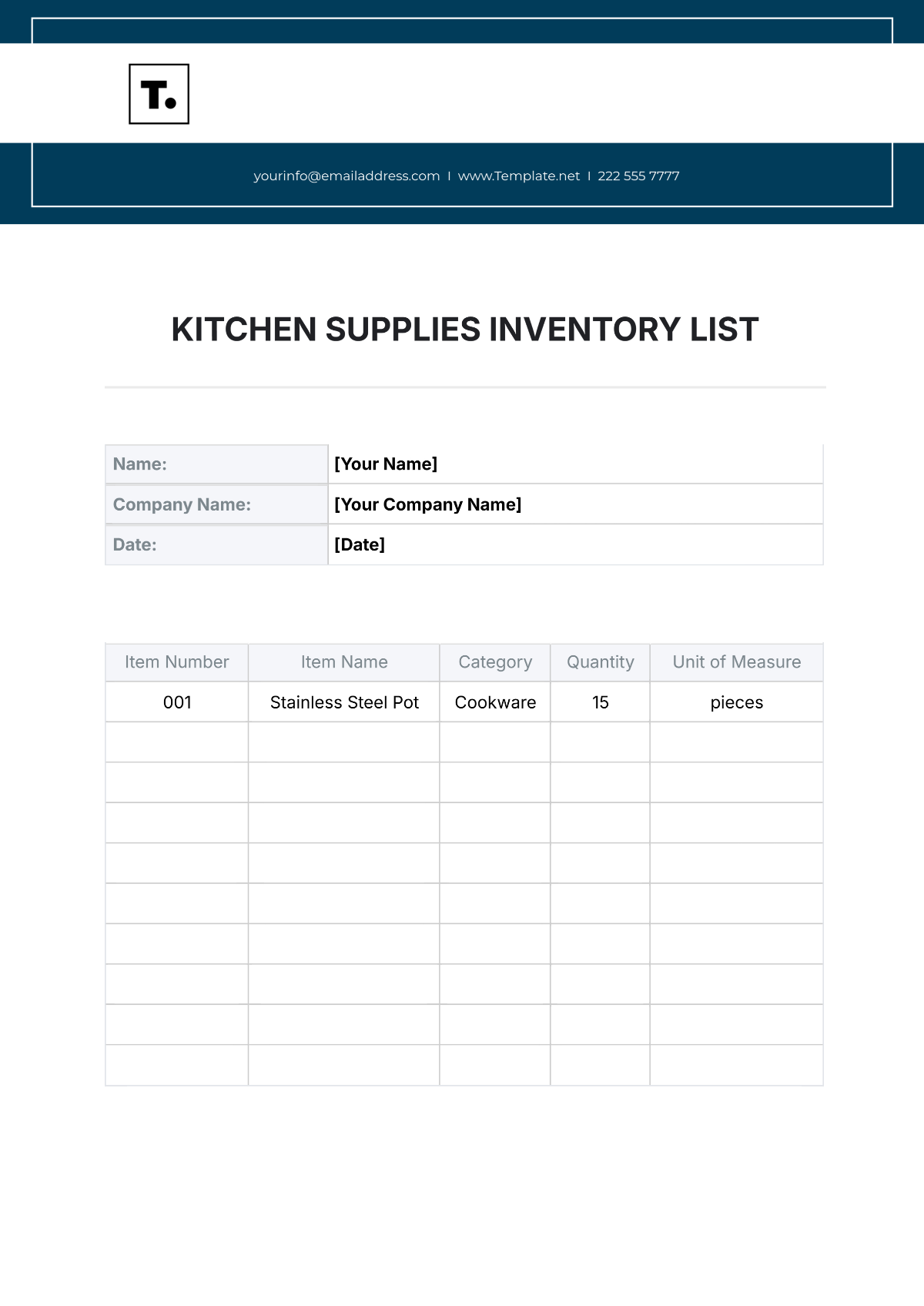

Inventory items are stored in designated storage areas based on factors such as item type, size, weight, and shelf life.

Storage areas are organized logically, with clear labeling and signage for easy identification and retrieval.

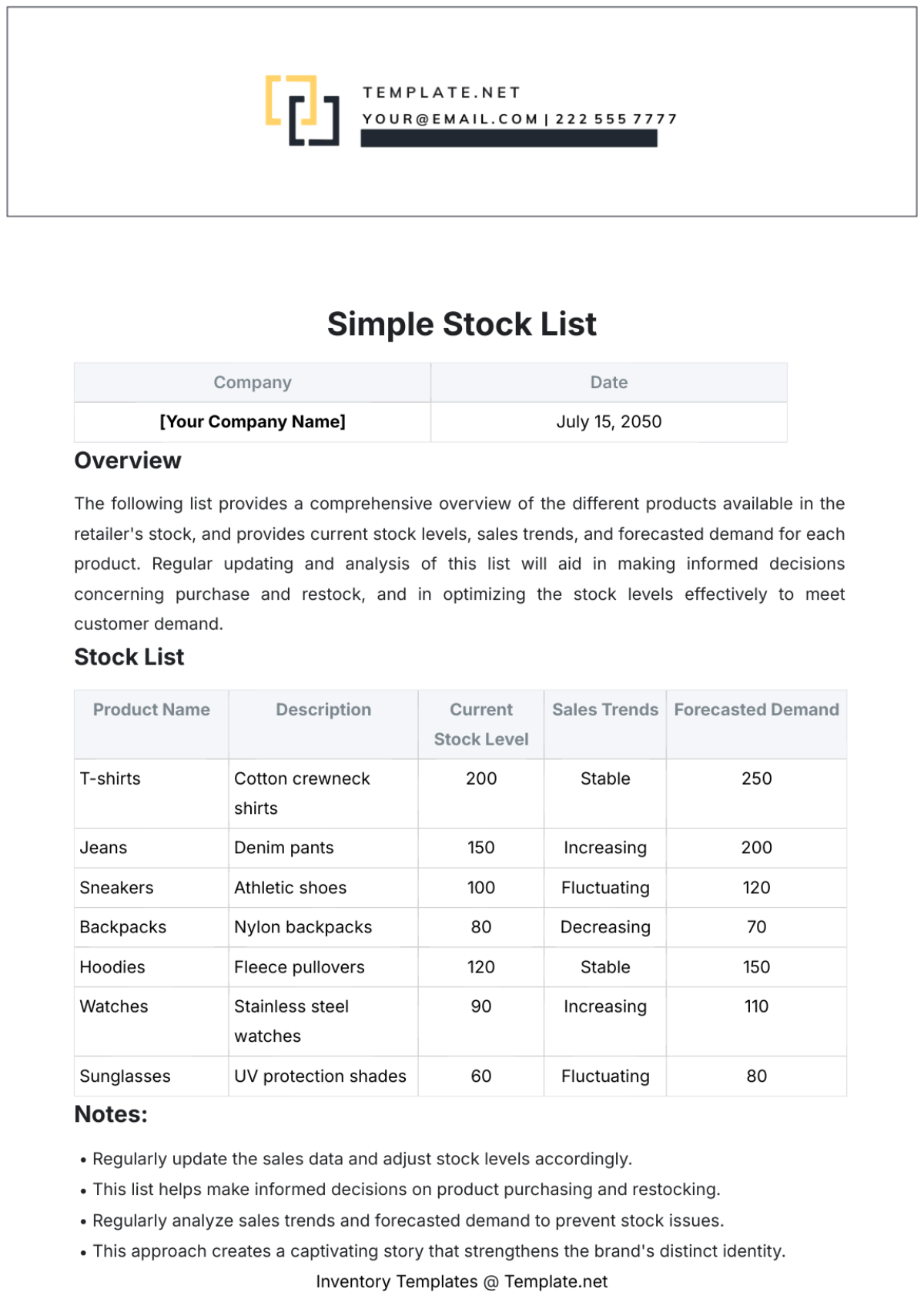

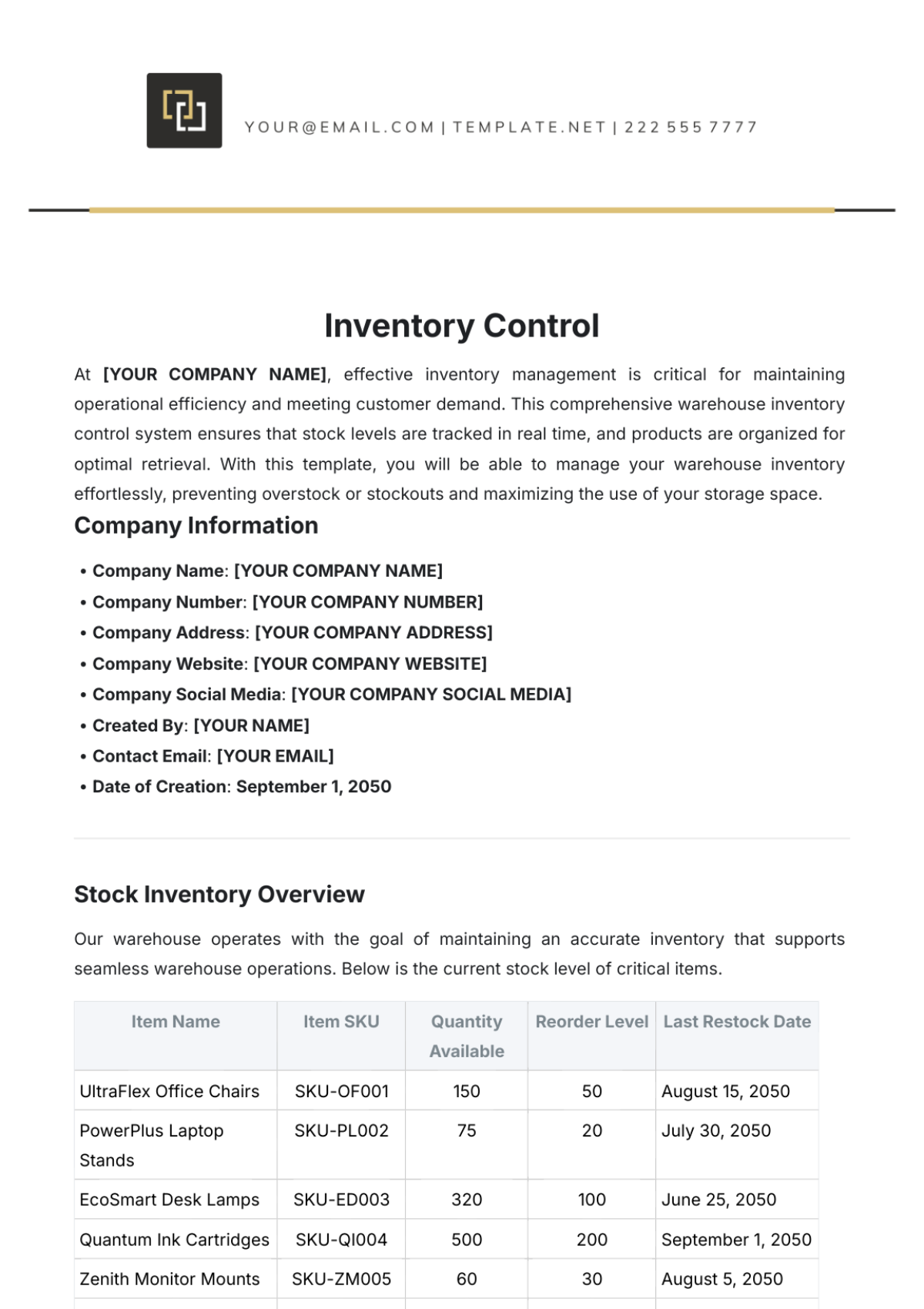

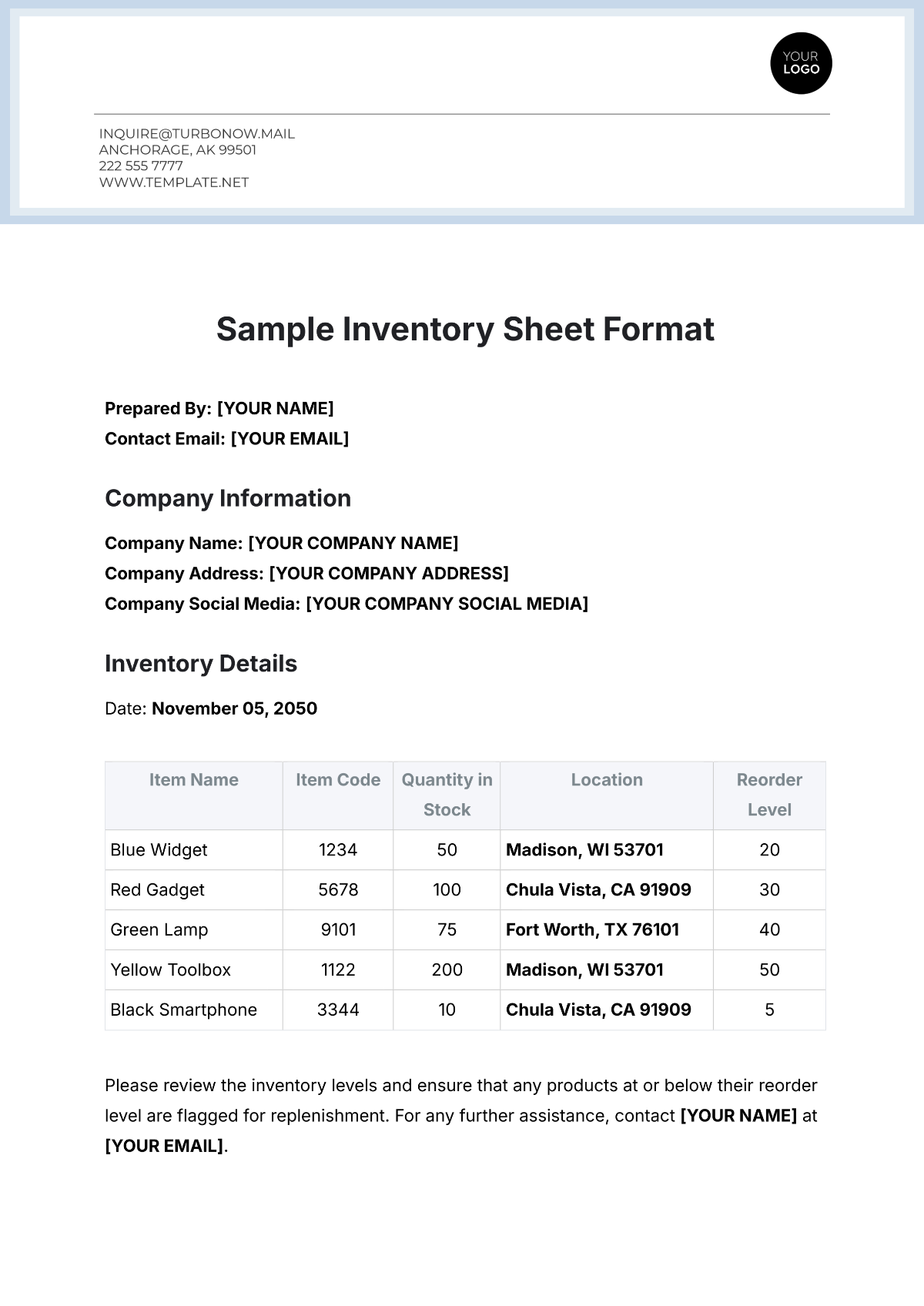

Inventory levels are regularly monitored to ensure adequate stock levels and prevent overstocking or stockouts.

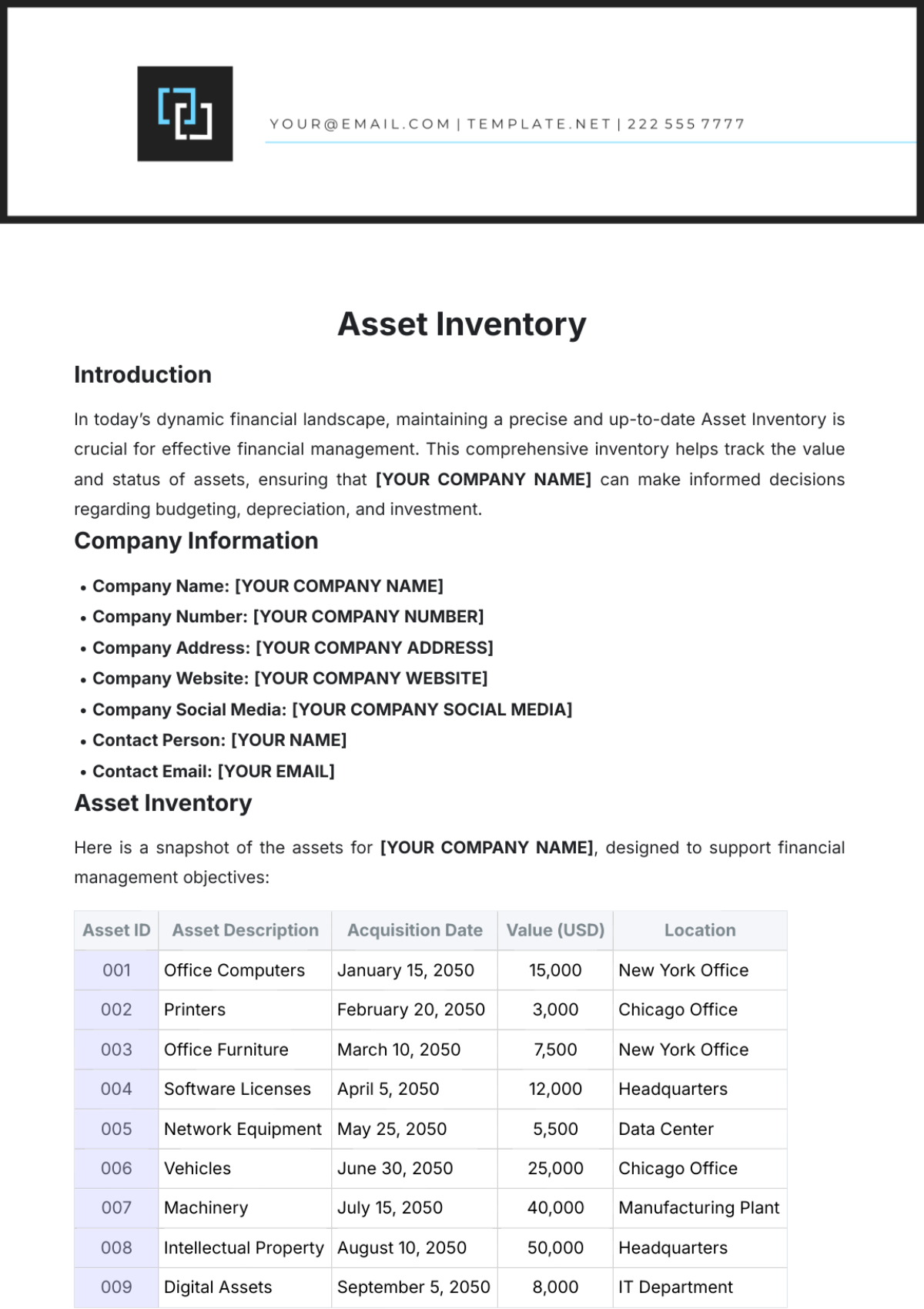

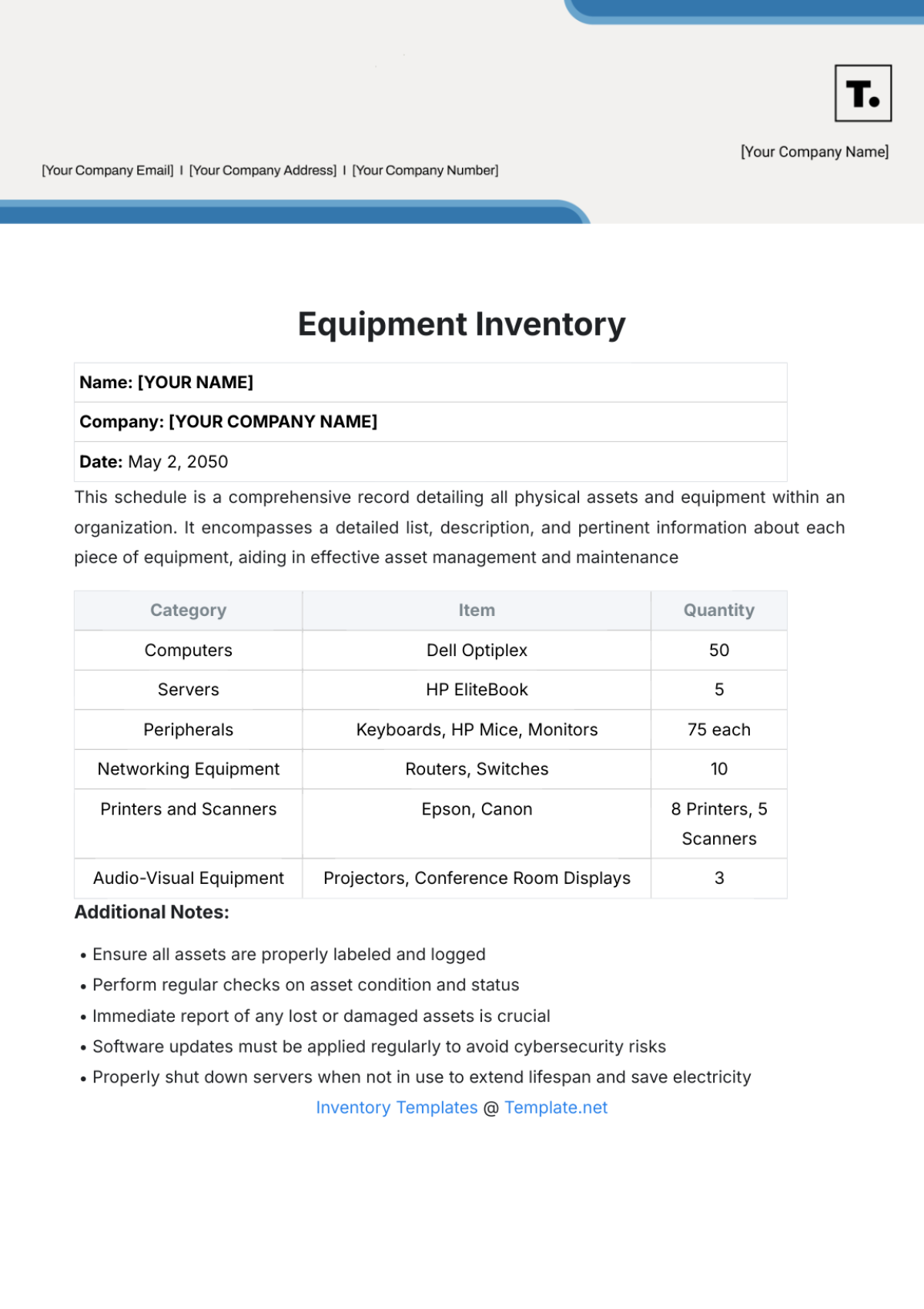

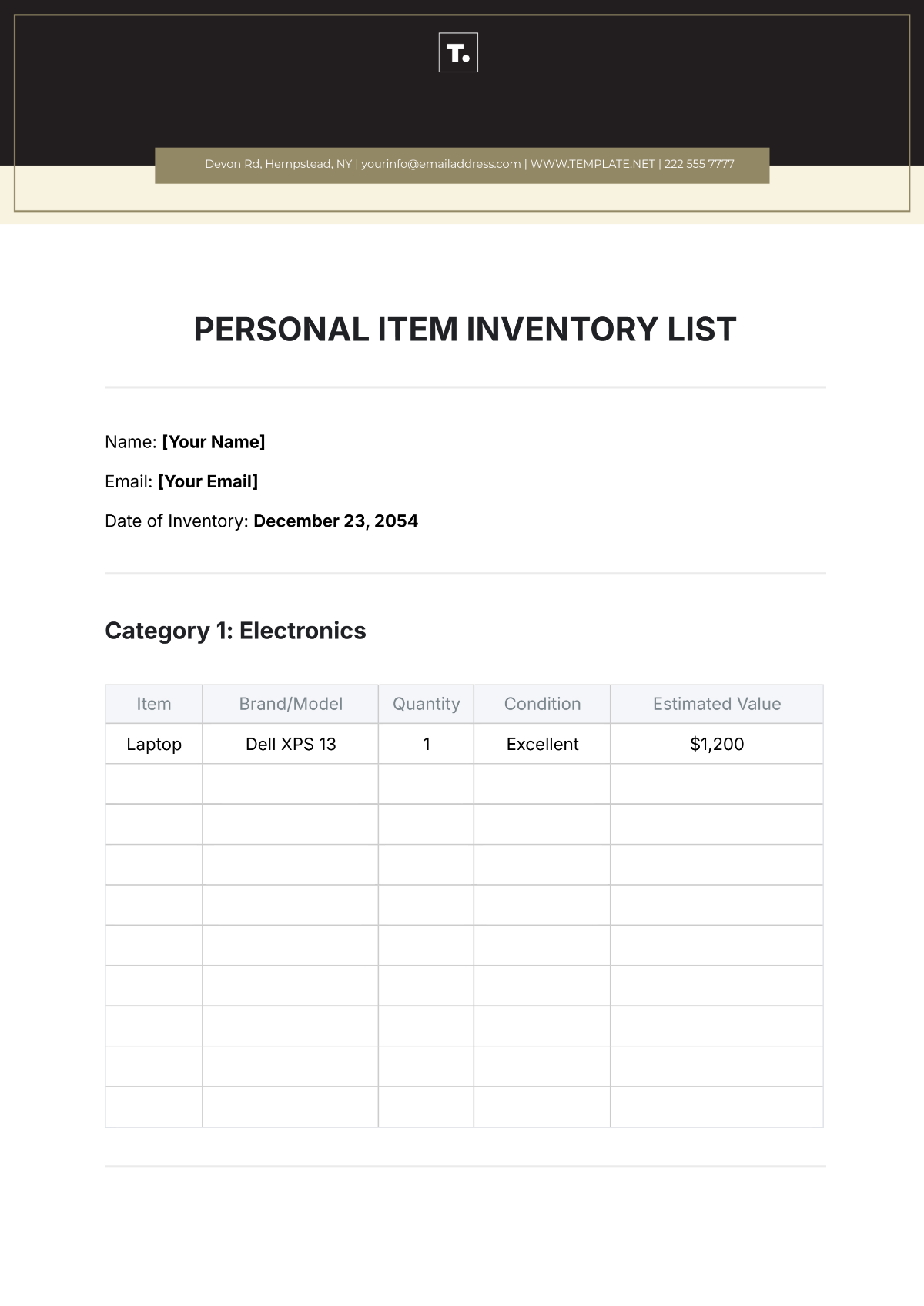

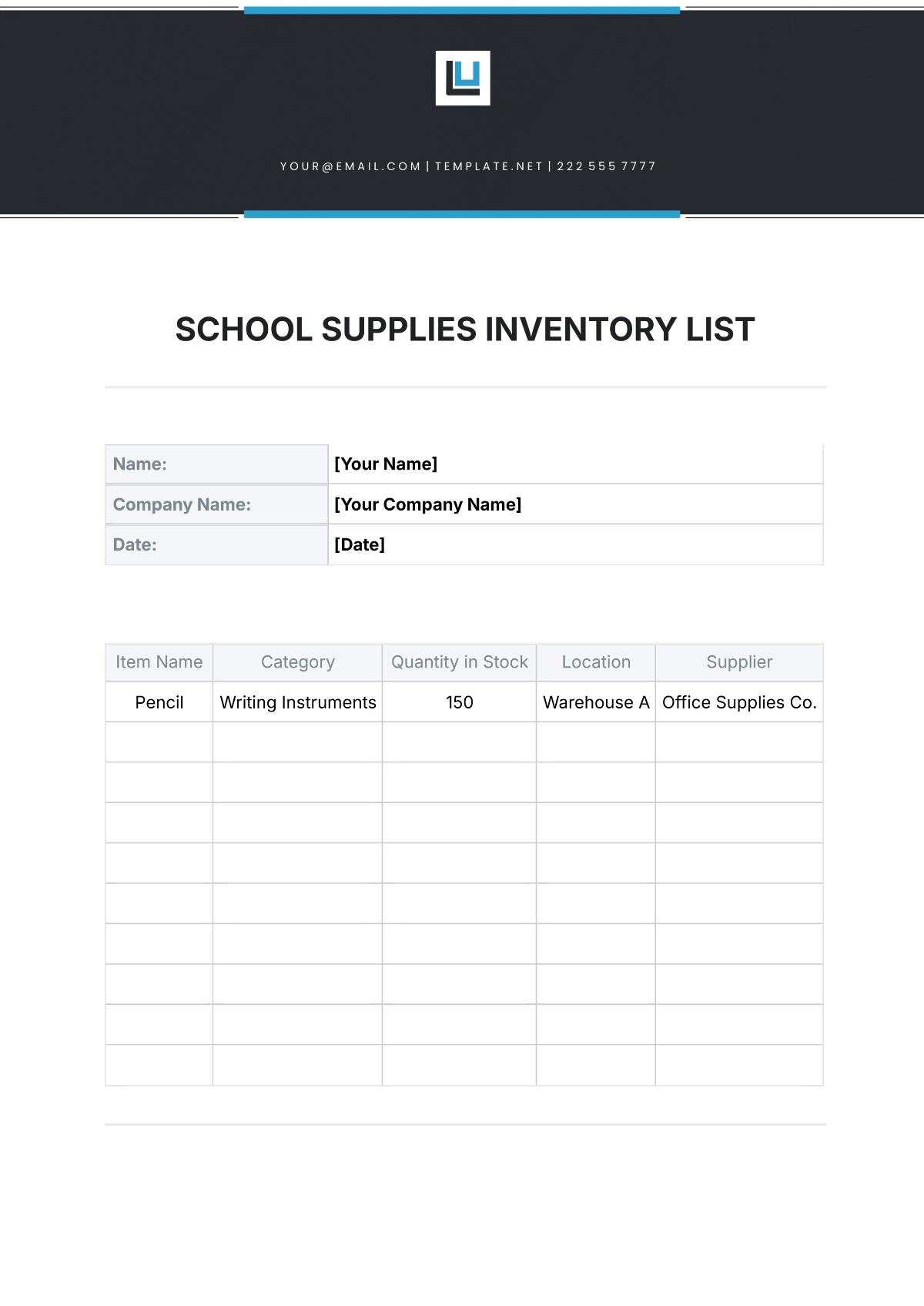

4.3 Tracking Inventory

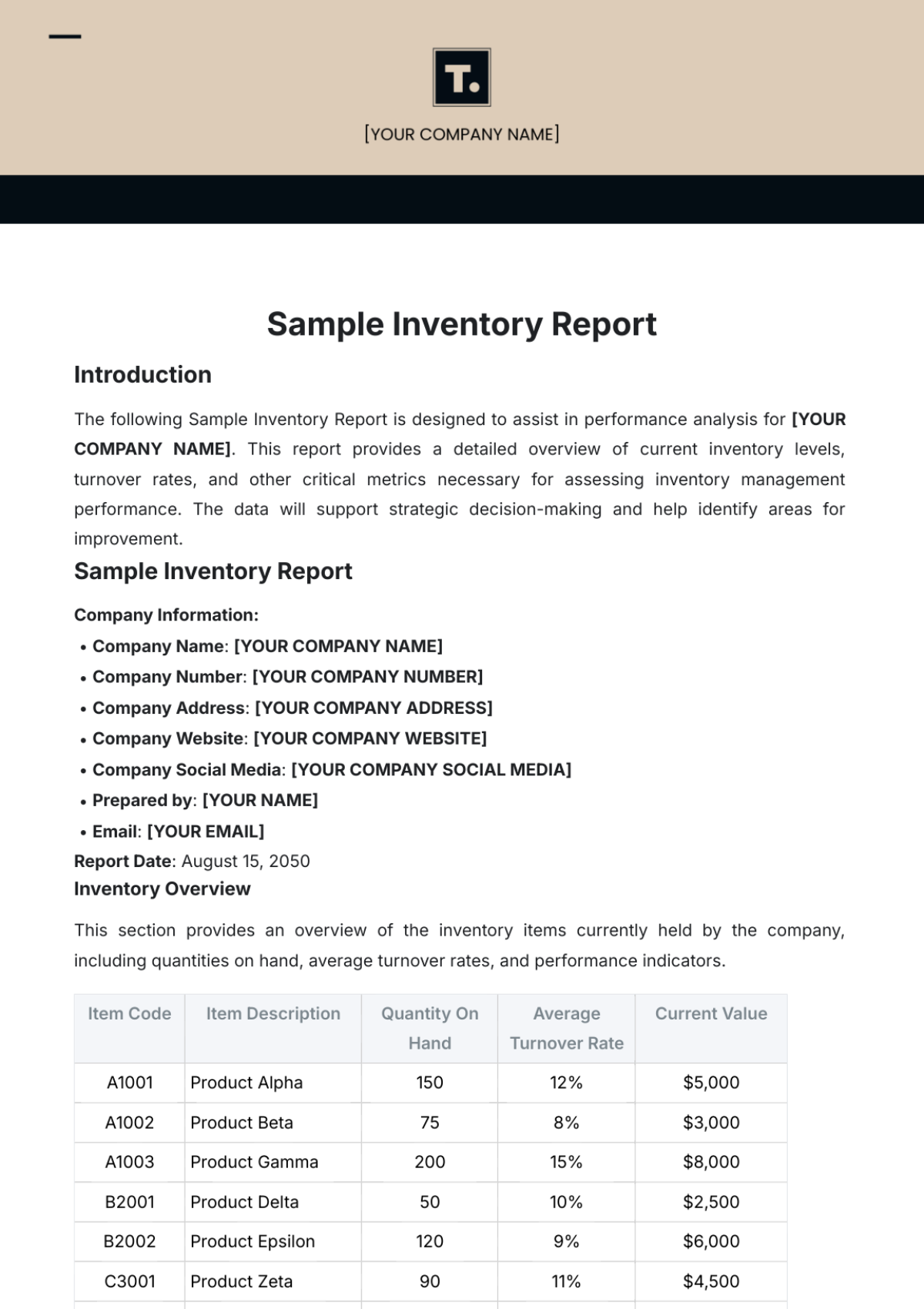

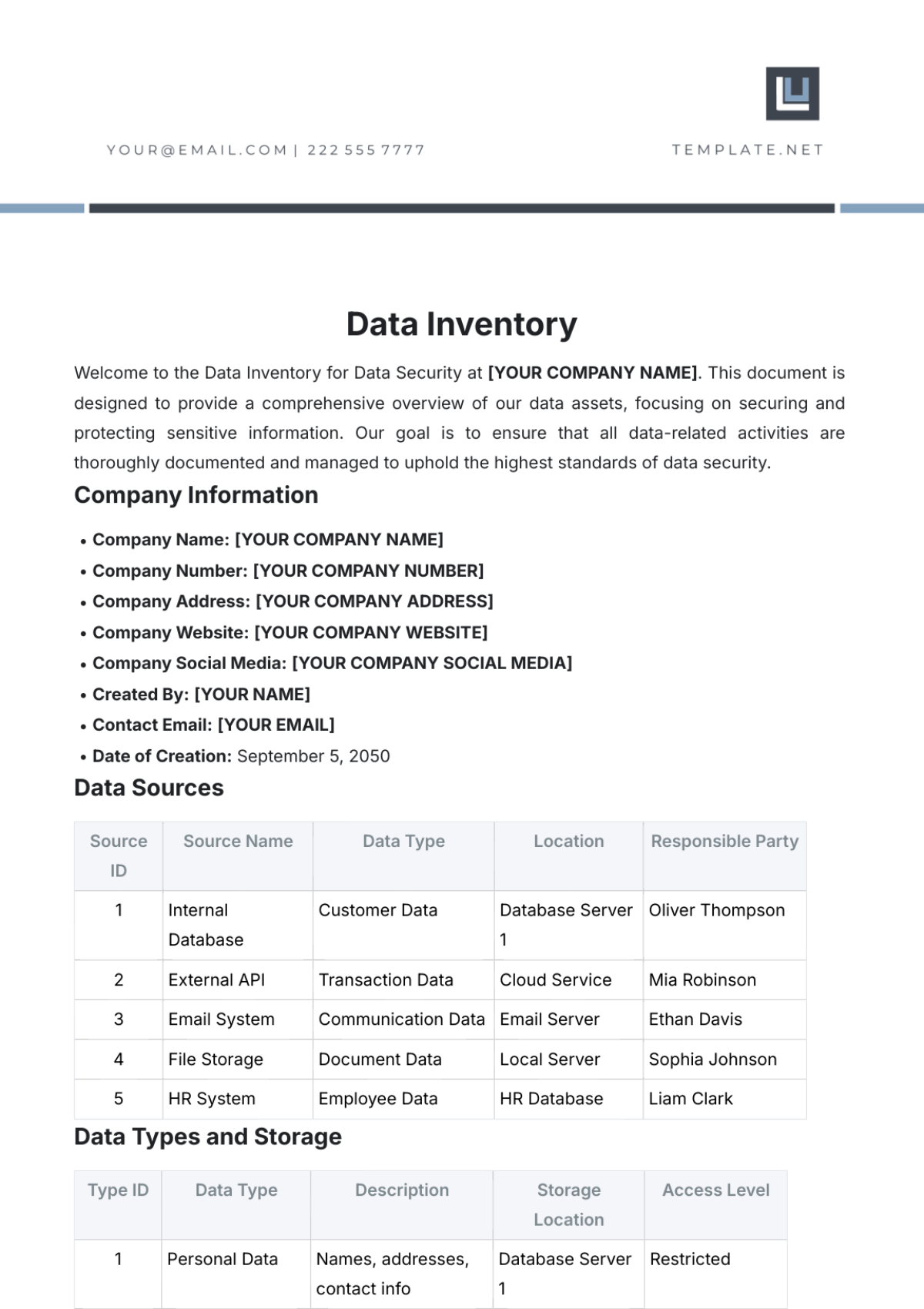

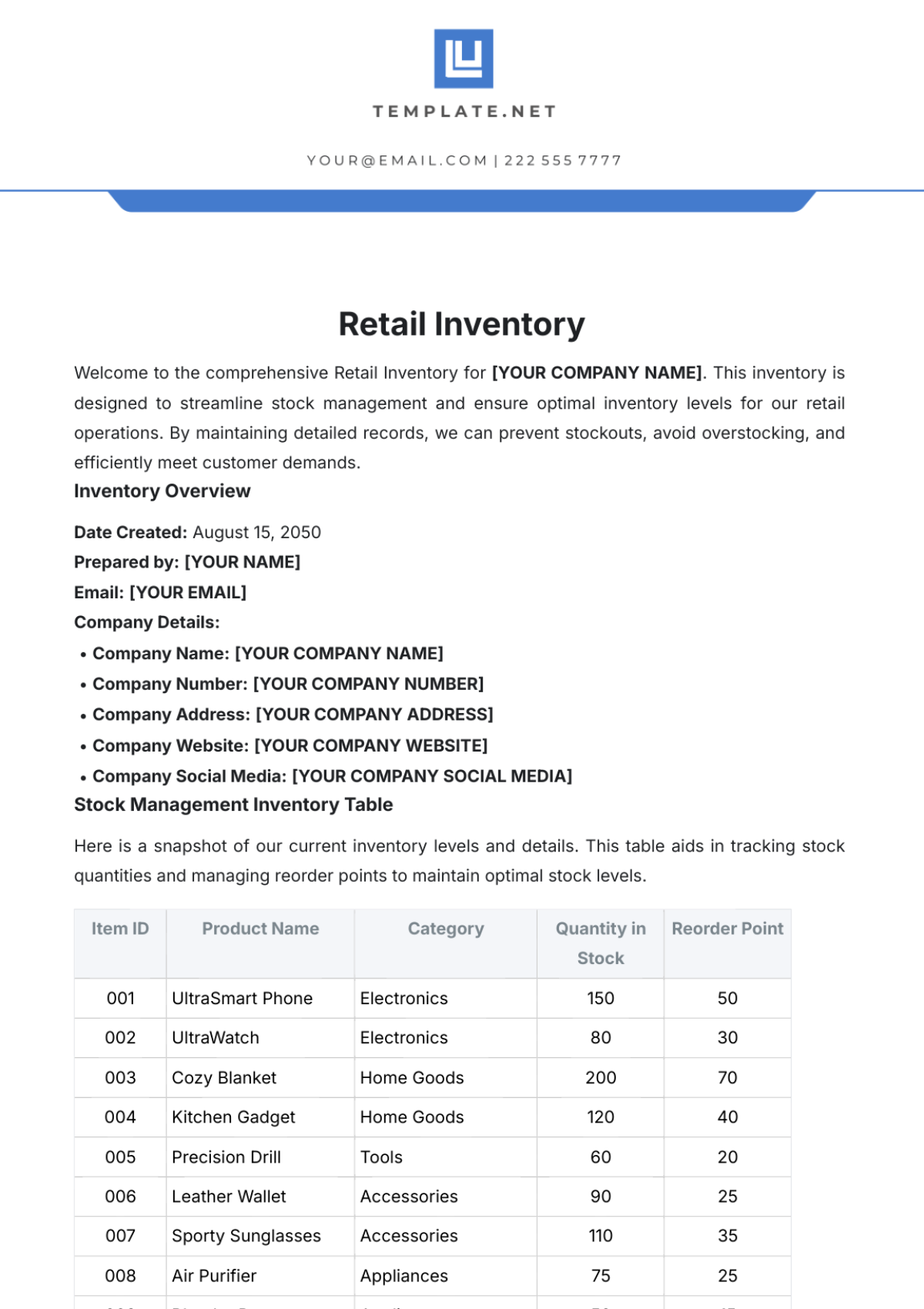

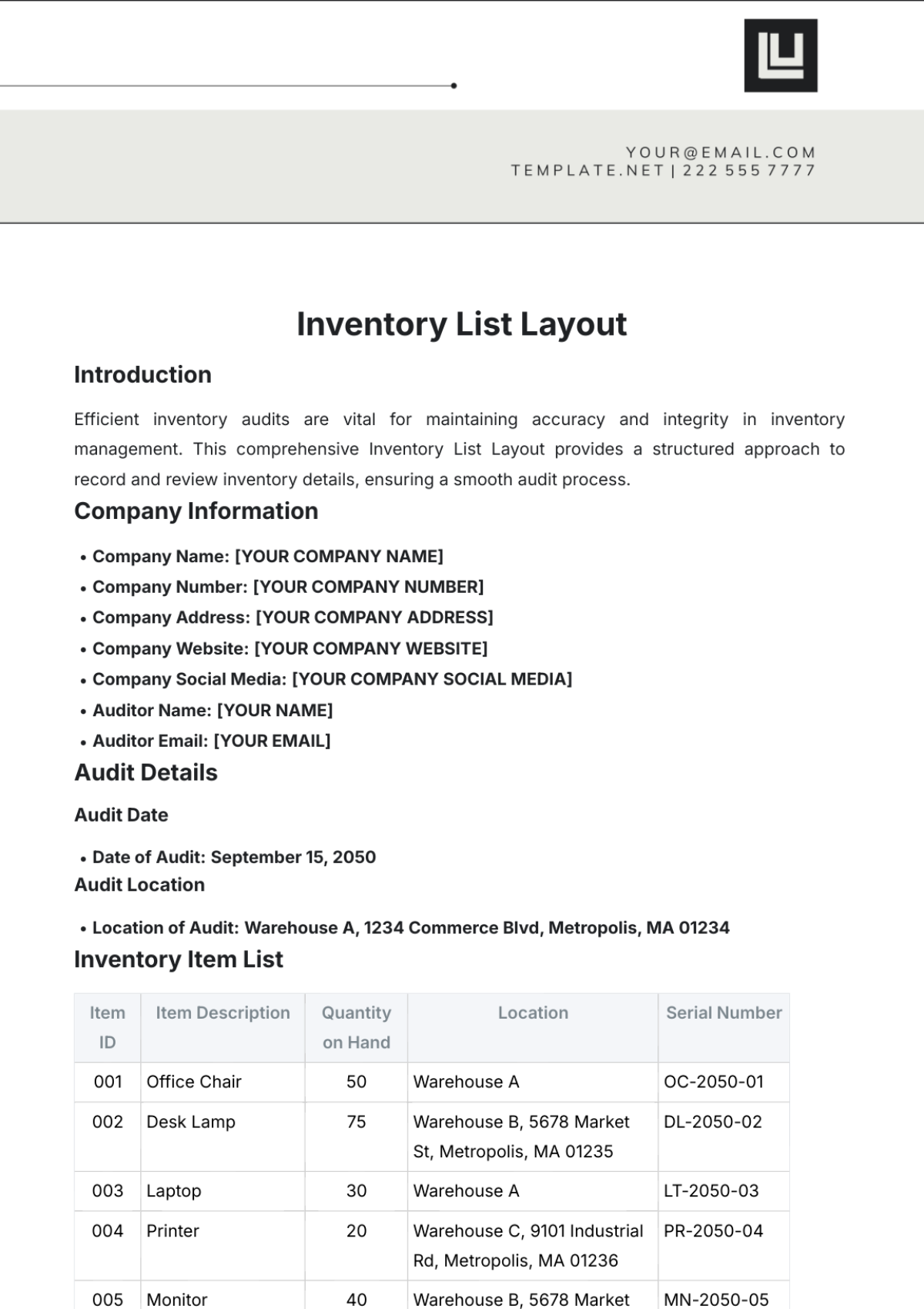

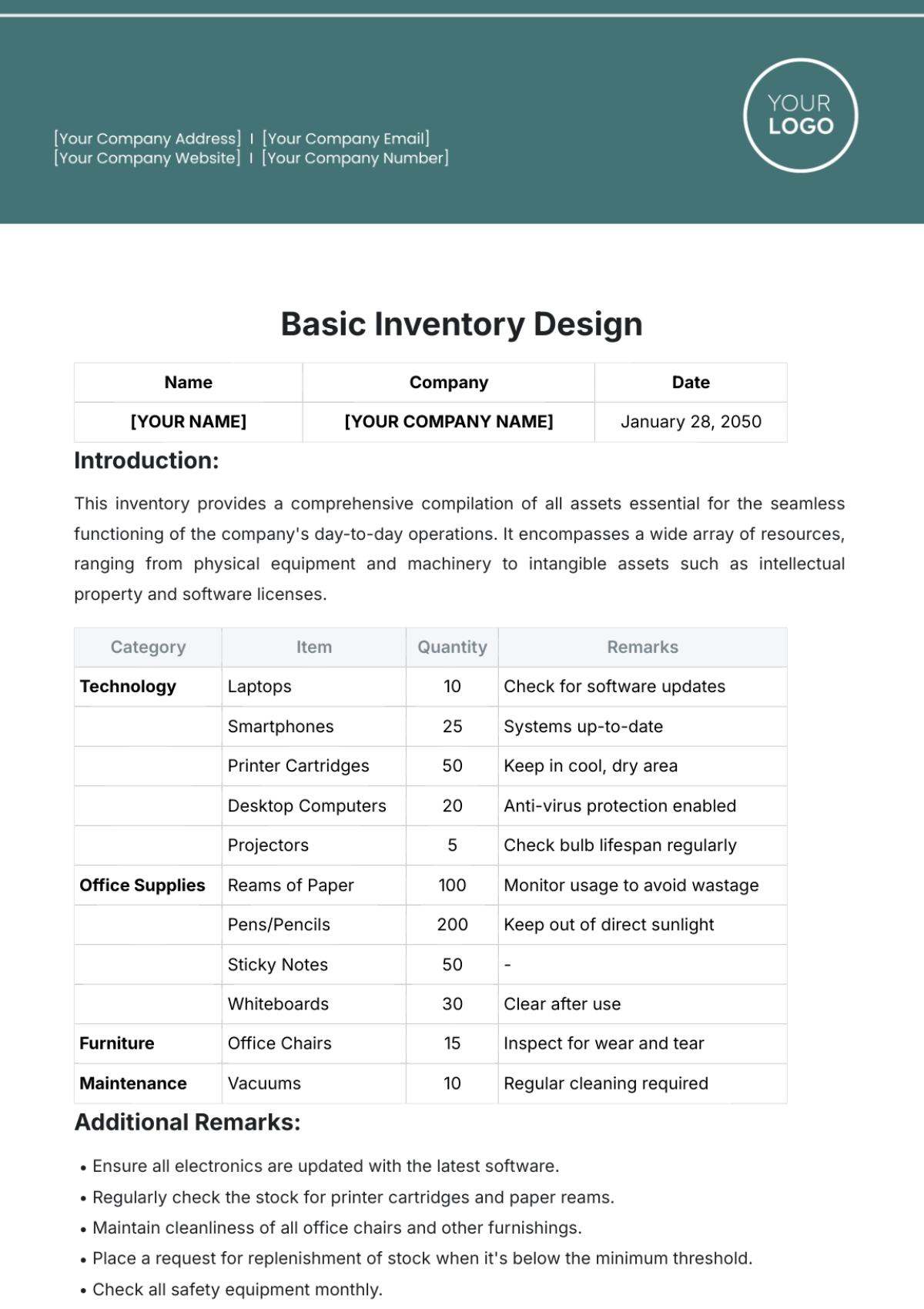

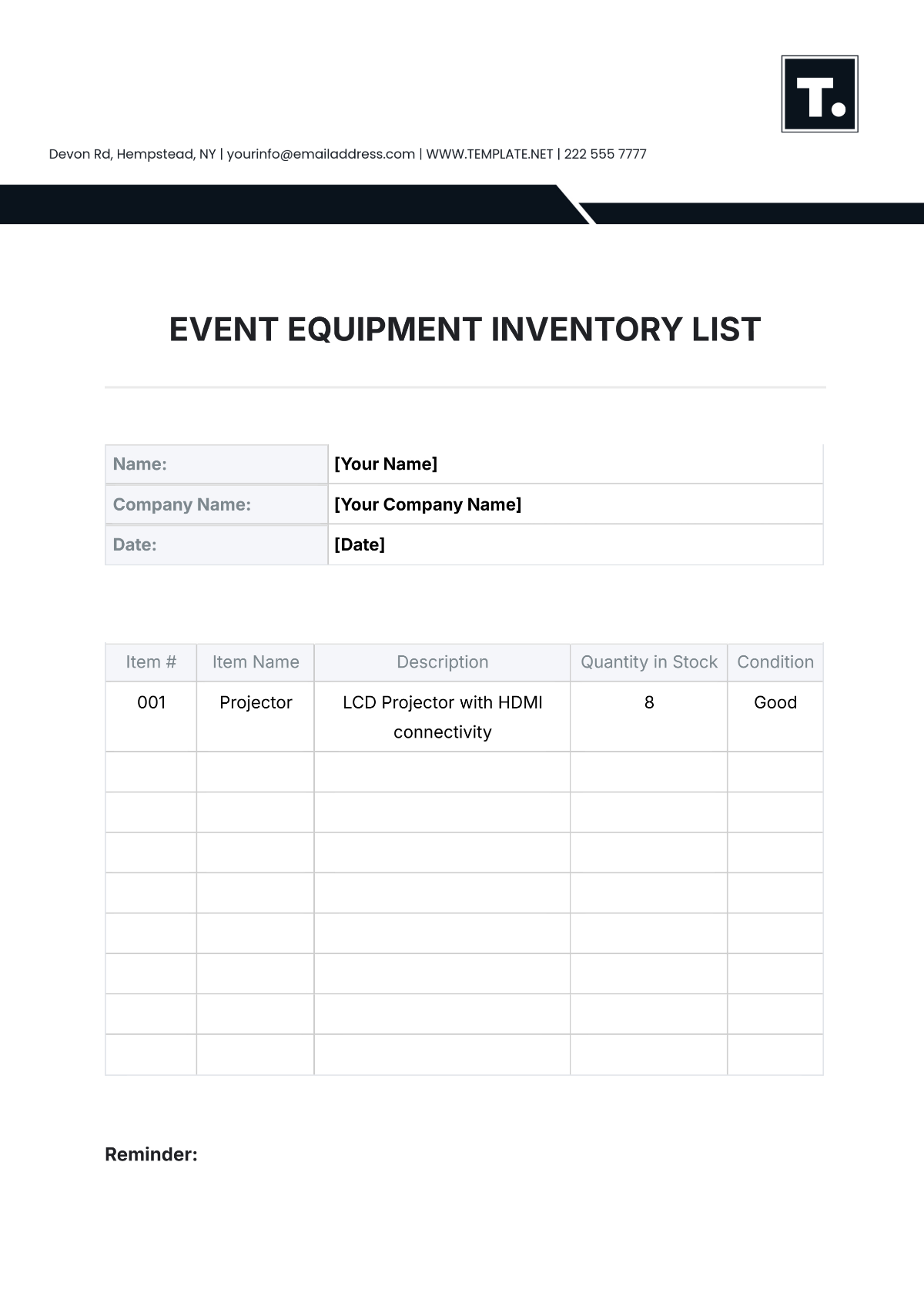

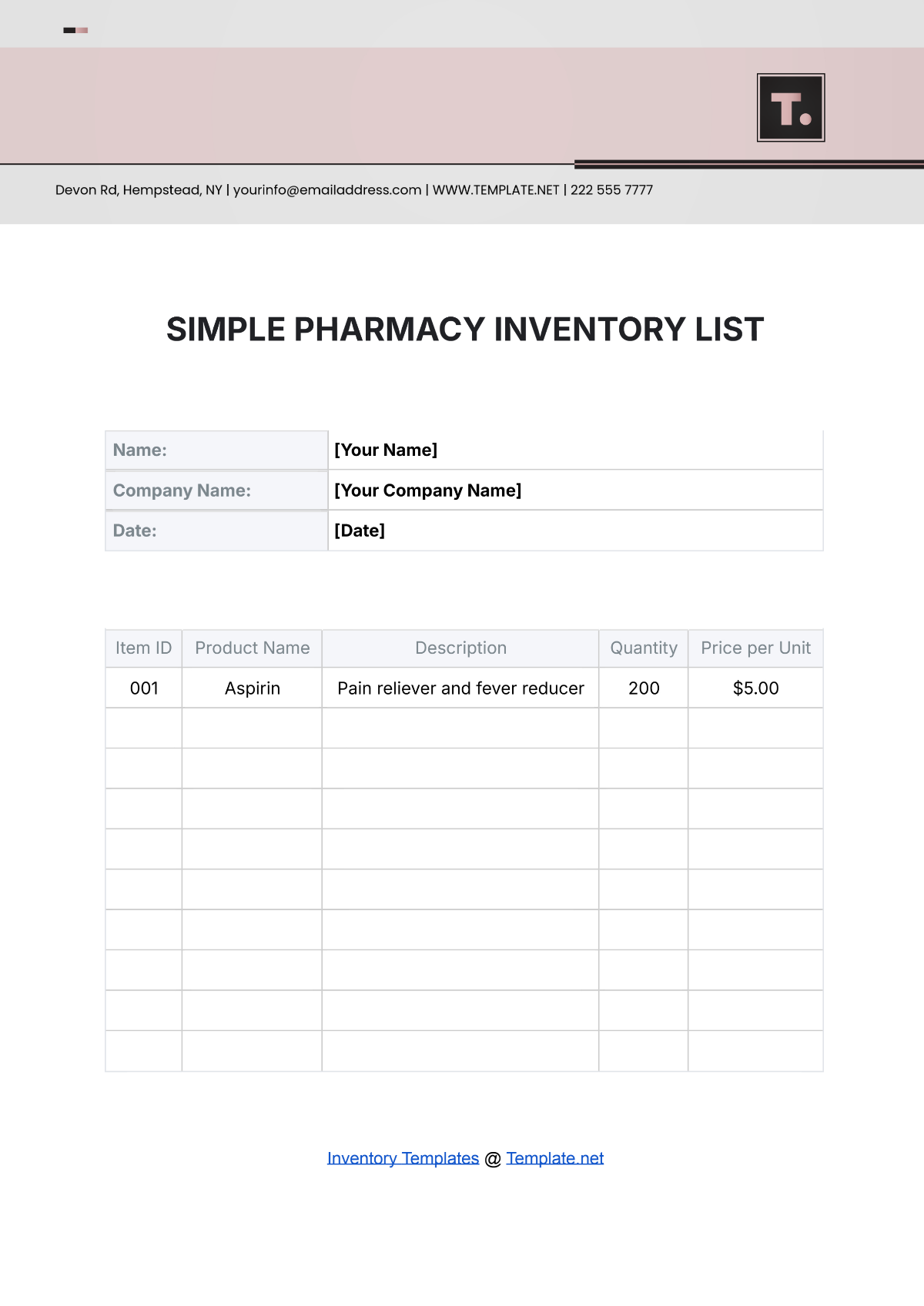

Inventory transactions (receipts, transfers, withdrawals) are accurately recorded in the inventory management system in real time.

Regular physical inventory counts and reconciliations are conducted to validate system accuracy and identify discrepancies.

Barcoding or RFID technology may be utilized for efficient tracking and inventory visibility.

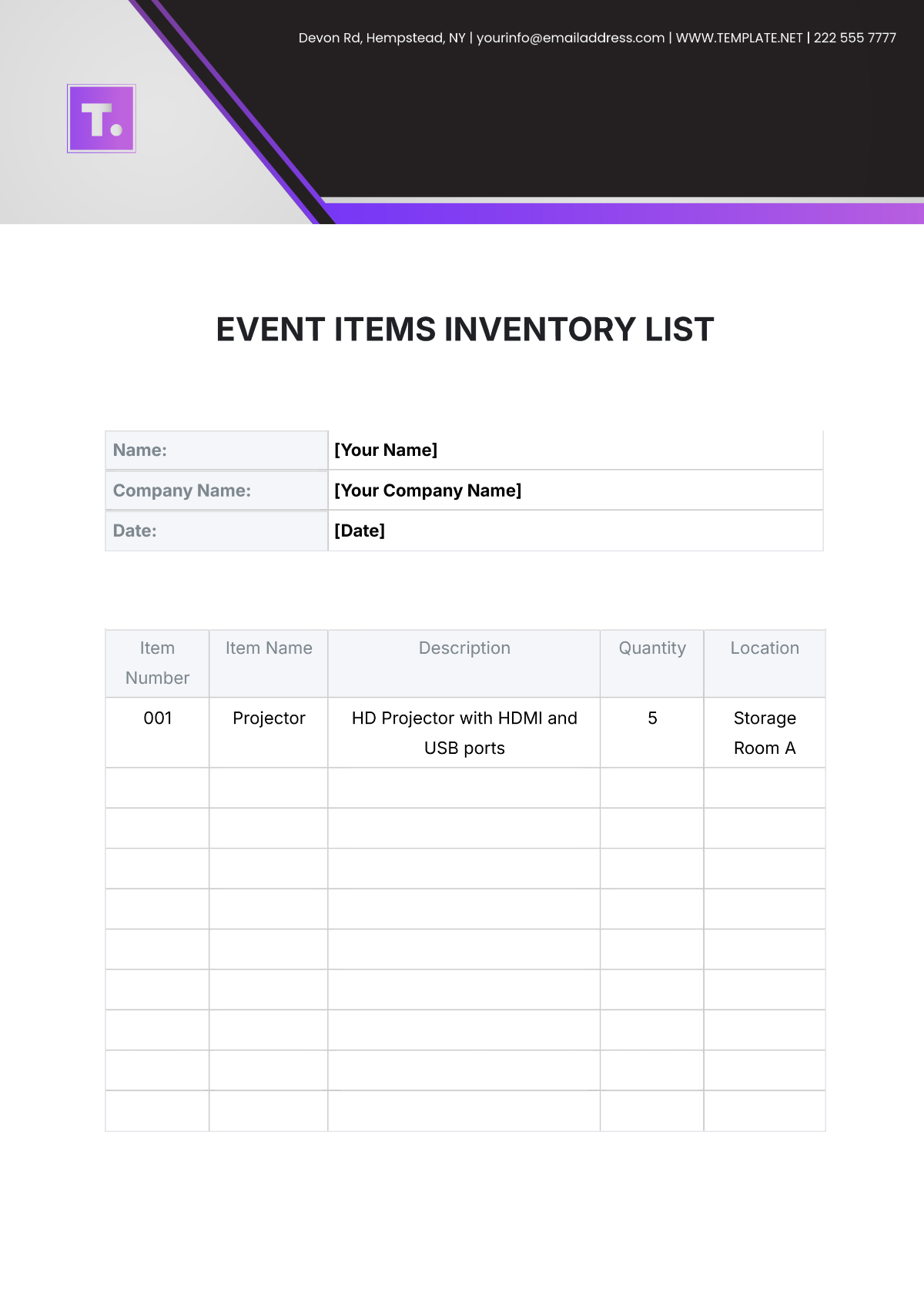

4.4 Distributing Inventory

Requests for inventory items from internal departments or external customers are processed through an authorized request system.

The logistics team schedules and coordinates the transportation and delivery of inventory items based on priority, location, and delivery requirements.

Delivery receipts are verified against order details to ensure completeness and accuracy of deliveries.

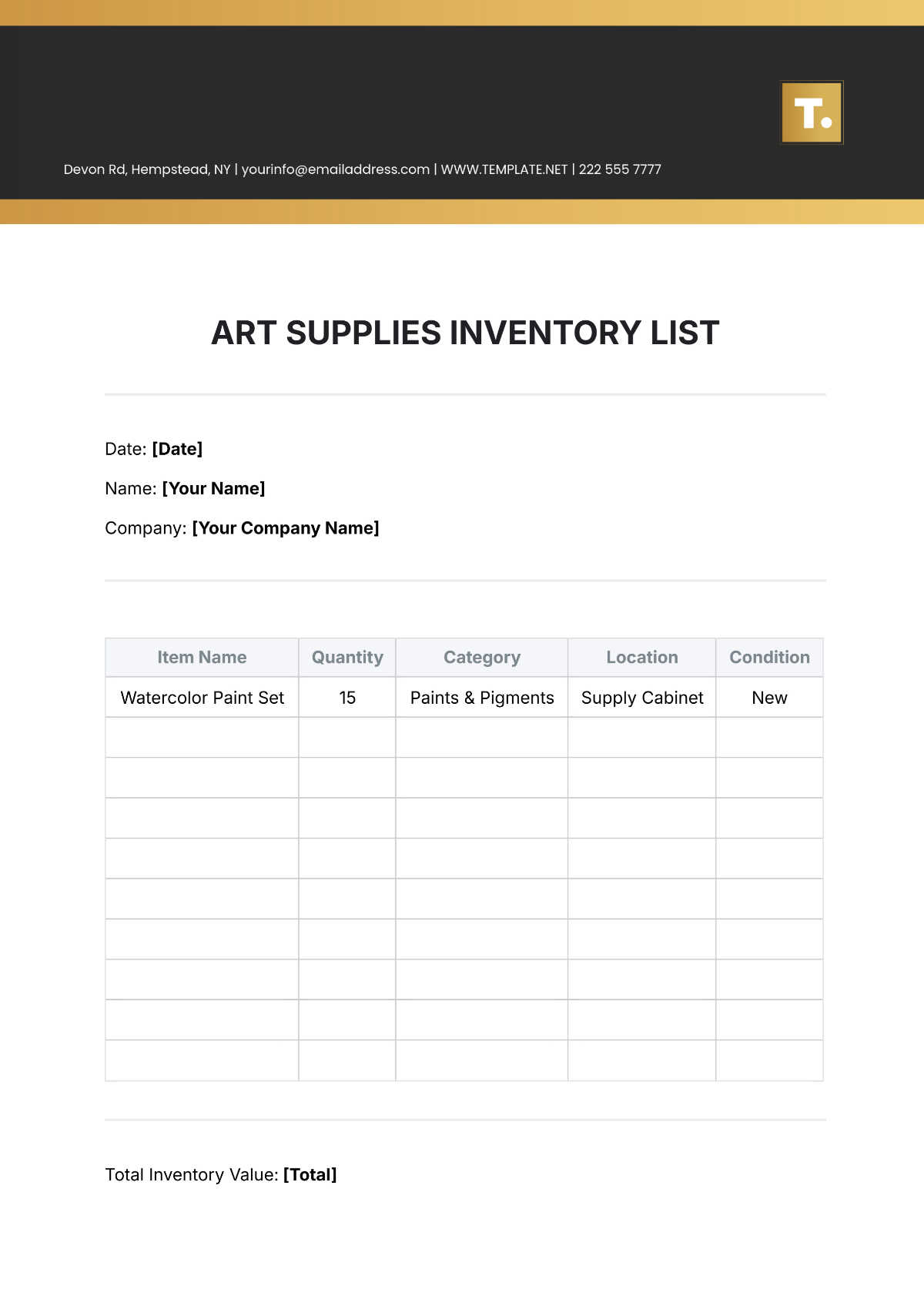

V. Documentation

In the inventory management system, every transaction that is related to inventory is documented with complete accuracy. This includes all actions concerning receipts, in addition to any transfers, adjustments, and even disposals of inventory.

Physical inventory count reports reconciliation reports, and inventory movement reports are generated and reviewed periodically for management visibility and decision-making.

VI. Training

New employees involved in inventory management undergo comprehensive training on this SOP, inventory management software/systems, and proper handling/storage procedures.

To maintain the competence of the staff and to ensure they adhere strictly to the Standard Operating Procedures guidelines, continuous training, and regular refresher courses are provided.

VII. Compliance

This SOP complies with relevant regulatory requirements, industry standards, and internal policies related to inventory management, safety, and security.

Frequent audits and compliance assessments are conducted regularly to guarantee every department, operation, and procedure adheres strictly to the Standard Operating Procedures (SOP) guidelines. These examinations also serve as a significant tool to identify and evaluate areas requiring improvements, which ultimately enables the entire organization to operate more smoothly, efficiently, and fruitfully.

VIII. Approval

This SOP is hereby approved on the date specified below

[Approver's Name]

[Approver's Role]

[Approval Date]