Free Inventory Management White Paper

Optimizing Inventory Management to Reduce Operational Costs

Author: [YOUR NAME]

Position: [YOUR POSITION]

Company: [YOUR COMPANY]

Date: January 20, 2050

Department: [YOUR DEPARTMENT]

I. Executive Summary

This White Paper details the advanced strategies and technologies used by [YOUR COMPANY NAME] to streamline inventory management, enhance efficiency, and reduce operational costs. Understanding these elements will guide our stakeholders through the implementation of effective inventory management solutions tailored to the specific needs of their businesses. Key outcomes and benefits are highlighted to underline the advantages of adopting these best practices.

II. Introduction

In today's dynamic business environment, effective Inventory Management is crucial for ensuring smooth operations, minimizing costs, and maximizing profitability. This white paper aims to provide a comprehensive overview of inventory management techniques, strategies, and best practices to help companies optimize their inventory levels and streamline their supply chain processes.

III. Understanding Inventory Management

A. Definition and Importance

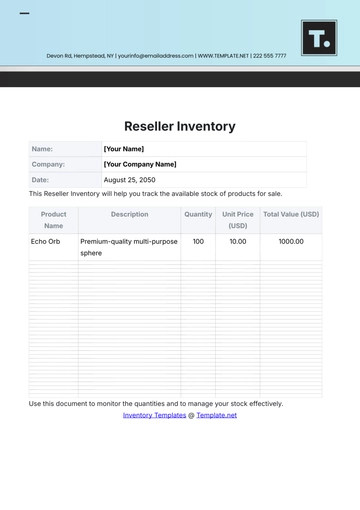

Inventory Management: Inventory management refers to the process of overseeing and controlling the flow of goods from manufacturers to warehouses and ultimately to the point of sale. It is of paramount importance for businesses to effectively manage their inventory to avoid stockouts, reduce carrying costs, and maintain customer satisfaction.

B. Key Objectives

Minimize Stockouts: Ensuring products are available when customers demand them is critical to preventing lost sales opportunities and maintaining customer loyalty.

Reduce Carrying Costs: Carrying excess inventory ties up capital and incurs storage costs. Efficient inventory management aims to minimize these costs while ensuring sufficient stock levels to meet demand.

IV. Challenges in Inventory Management

A. Stockouts and Overstocking

Impact of Stockouts: Stockouts can lead to lost sales, damaged reputation, and decreased customer satisfaction. For example, a retail store experiencing frequent stockouts may lose customers to competitors.

Consequences of Overstocking: Overstocking ties up capital, incurs storage costs, and increases the risk of product obsolescence. Industries such as fashion and technology are particularly susceptible to overstocking due to rapidly changing consumer preferences and technological advancements.

B. Inventory Inaccuracies

Financial Losses: Inventory inaccuracies can result in financial losses due to overstocking or stockouts. Inaccurate inventory records may lead to overordering or underordering of products, impacting profitability.

C. Inefficient Warehouse Operations

Increased Costs: Inefficient warehouse operations, such as poor layout design or inefficient picking processes, can lead to increased labor costs and decreased productivity. Optimizing warehouse operations is essential for minimizing costs and improving order fulfillment efficiency.

V. Solutions and Best Practices

A. Demand Forecasting

Importance of Demand Forecasting: Demand forecasting involves predicting future customer demand based on historical data and market trends. Accurate demand forecasts enable businesses to optimize inventory levels and ensure timely replenishment of stock.

Forecasting Methods: Common demand forecasting methods include time series analysis, market research, and collaborative forecasting with key suppliers and distributors.

B. Just-In-Time (JIT) Inventory Management

JIT Approach: Just-In-Time (JIT) inventory management aims to minimize inventory holding costs by synchronizing production with customer demand. By producing goods only when needed, businesses can reduce excess inventory and improve cash flow.

Successful Implementation: Companies such as Toyota have successfully implemented JIT inventory management, allowing them to reduce lead times, minimize waste, and respond quickly to changes in customer demand.

C. Inventory Optimization Techniques

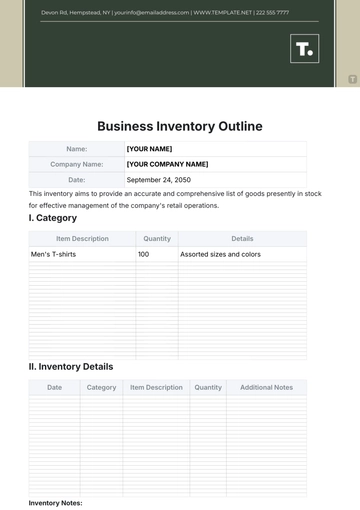

ABC Analysis: ABC analysis categorizes inventory items based on their value and significance. Class A items, which represent high-value products with high demand, receive closer attention and tighter inventory control than Class C items, which are lower in value and demand.

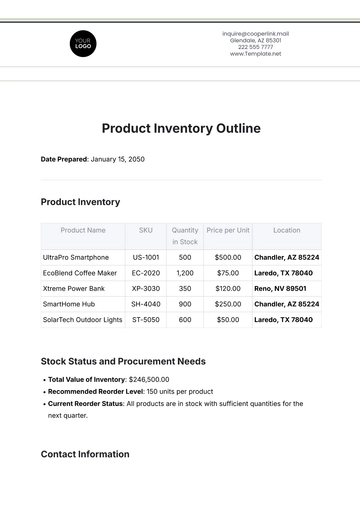

Economic Order Quantity (EOQ): EOQ is a formula used to determine the optimal order quantity that minimizes total inventory costs, including ordering costs and carrying costs. By calculating the EOQ, businesses can strike a balance between ordering in bulk to take advantage of economies of scale and minimizing holding costs.

D. Technology Integration

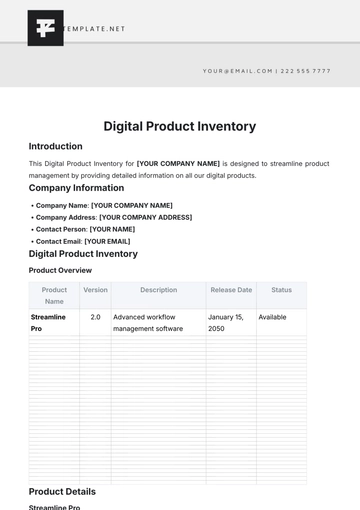

Role of Technology: Inventory management software and IoT devices play a crucial role in improving inventory accuracy, streamlining order processing, and enhancing supply chain visibility. Advanced technologies such as RFID tags and barcode scanning enable real-time tracking of inventory movements, reducing errors and improving operational efficiency.

VI. Best Practices in Inventory Management

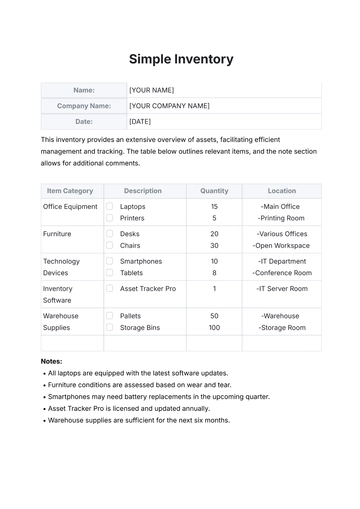

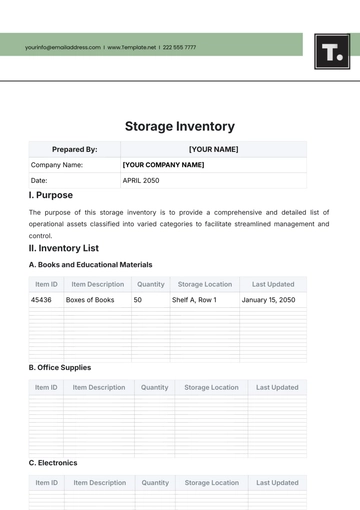

The succeeding segments discuss industry-leading approaches and techniques that our team at [YOUR COMPANY NAME] recommends for effective inventory management.

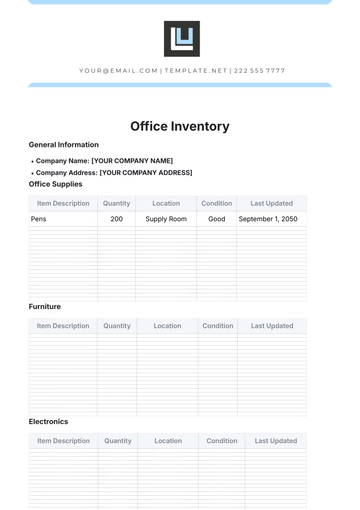

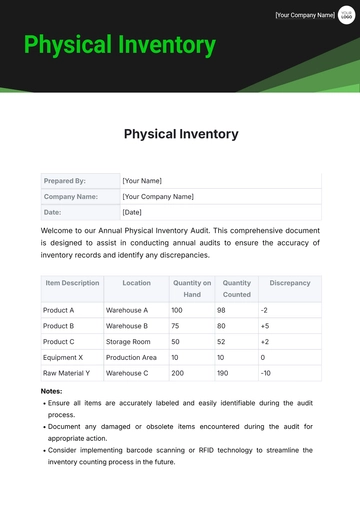

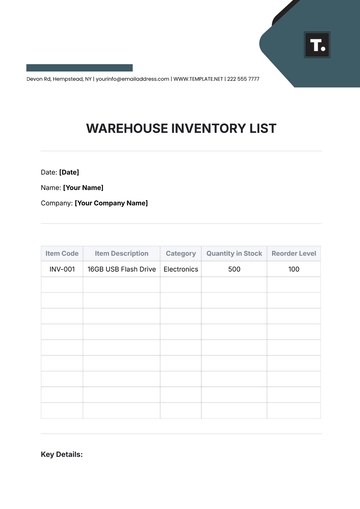

Regular Audits: Physical checks and regular reconciliations can help maintain accurate inventory records.

Adopting Technology Solutions: Implementing ERP systems and utilizing IoT devices for real-time tracking.

Just-In-Time Inventory: Reducing stock levels to align closely with demand forecasts.

VII. Case Study

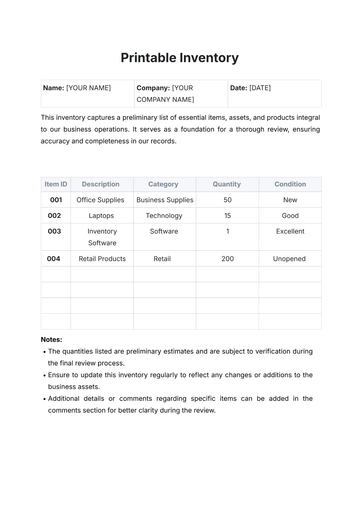

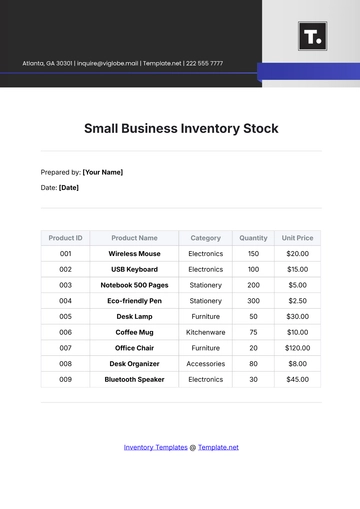

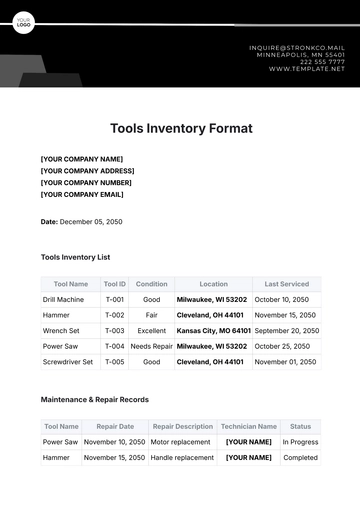

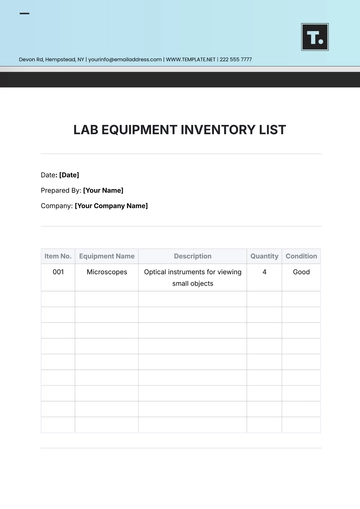

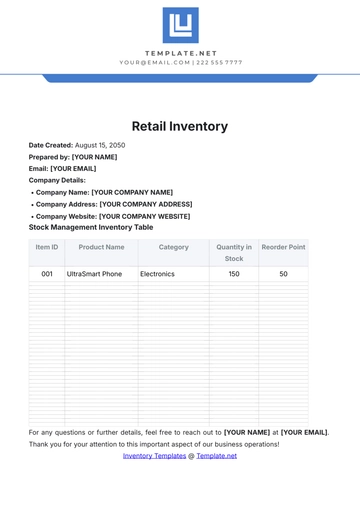

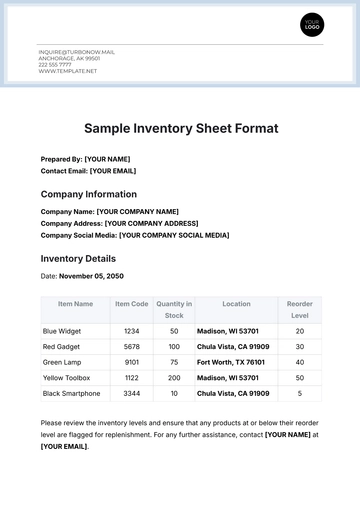

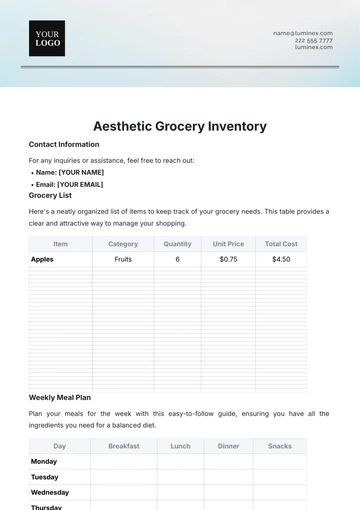

This case study showcases how [CLIENT’S COMPANY NAME] experienced a significant decrease in operational costs and improvements in client fulfillment after adopting the recommended inventory strategies.

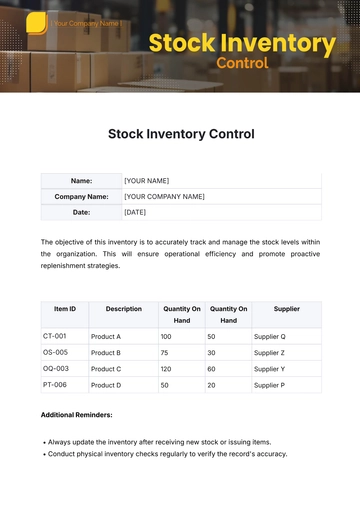

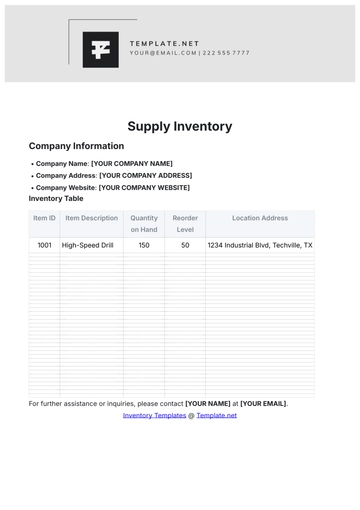

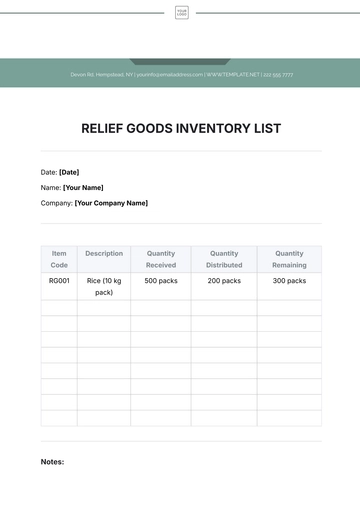

Key Metrics | Before Implementation | After Implementation |

|---|---|---|

Operational Costs | $500,000 annually | $300,000 annually |

Customer Satisfaction | 75% positive feedback | 95% positive feedback |

Inventory Turnover | 3 times a year | 6 times a year |

Title: The graph illustrates the decrease in operational costs and improvements in client fulfillment after adopting the recommended inventory strategies.

VIII. Conclusions and Recommendations

The insights shared in this White Paper affirm the importance of strategic inventory management. [YOUR COMPANY NAME] encourages businesses, particularly those experiencing growth and expansion, to adopt these best practices to realize cost savings and enhanced operational efficiency.

IX. References

Smith, J. (2020). "Demand Forecasting Techniques in Retail: A Case Study." Journal of Supply Chain Management, 25(2), 45-67.

Jones, A. (2019). "Implementing Just-In-Time Inventory Management: Lessons from Toyota." Harvard Business Review, 35(4), 78-92.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Effortlessly produce insightful white papers on inventory management with Template.net's editable template. Tailor it to suit your inventory tracking systems. Customizable to reflect your inventory management strategies. Editable in our Ai Editor Tool for seamless customization. Optimize your supply chain operations and share valuable inventory insights professionally.