Free Strategic Sourcing Plan

Name | Company | Date |

|---|---|---|

[YOUR NAME] | [YOUR COMPANY NAME] | [DATE] |

I. Executive Summary

The Strategic Sourcing Plan for [YOUR COMPANY NAME] aims to enhance the overall quality of goods produced or services delivered by the organization. By implementing strategic sourcing practices, we will optimize supplier selection, improve collaboration, and mitigate risks, thereby driving quality improvements across the supply chain.

II. Introduction

A. Background

[YOUR COMPANY NAME] is a leading provider of industrial machinery with a commitment to delivering high-quality products to our customers. However, recent quality issues in our supply chain have highlighted the need for a more strategic approach to sourcing.

B. Objectives

Identify areas for quality improvement within the supply chain.

Develop strategic partnerships with suppliers to enhance product quality.

Implement robust quality assurance measures to ensure consistent standards.

III. Analysis

A. Supplier Evaluation

Supplier Quality Performance Assessment:

Supplier

On-time delivery rate

Defective product rate

Customer satisfaction rating

A

98%

0.5%

4.5/5

B

95%

1%

4/5

Key Criteria for Evaluating Potential Suppliers:

Quality Standards: ISO 9001 certification or equivalent

Reliability: Consistent track record of meeting delivery deadlines

Compliance: Adherence to relevant industry regulations and standards

Supplier Scorecards:

Supplier Scorecard Template:

Quality Performance: 25%

Reliability: 30%

Compliance: 20%

Cost-effectiveness: 25%

Example Scorecard Ratings:

Supplier A: 85/100

Supplier B: 75/100

B. Market Research

Market Trends and Industry Benchmarks:

Quality Standards: ISO 9001:2015 has become the standard for quality management systems in the industry.

Industry Benchmarks: Average defective product rate in the industry is 1.2%.

Emerging Technologies and Best Practices:

Emerging Technologies: Introduction of AI-based quality control systems for real-time defect detection.

Best Practices: Just-in-time inventory management to minimize inventory holding costs while ensuring timely deliveries.

Competitors' Sourcing Strategies:

Competitor A

Emphasizes long-term partnerships with suppliers to ensure consistent quality.

Competitor B

Focuses on diversifying supplier base to mitigate risks associated with single sourcing.

C. Risk Assessment

Identified Risks:

Supply Chain Disruptions: Potential disruptions due to natural disasters, geopolitical tensions, or transportation delays.

Regulatory Changes: Changes in environmental regulations impacting raw material sourcing or manufacturing processes.

Risk Mitigation Strategies:

Supply Chain Disruptions: Implementing dual sourcing strategies to have alternative suppliers for critical components.

Regulatory Changes: Regular monitoring of regulatory updates and proactive adjustments to ensure compliance.

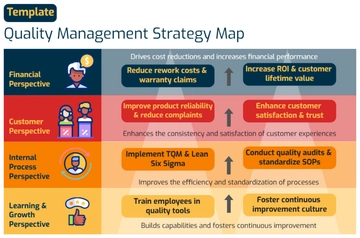

IV. Strategy Development

A. Supplier Selection

Define clear selection criteria based on quality, reliability, and cost-effectiveness.

Establish a structured evaluation process for assessing potential suppliers.

Develop a shortlist of preferred suppliers based on evaluation results and strategic fit.

B. Collaboration and Communication

Foster open communication channels with selected suppliers to align on quality expectations.

Establish collaborative initiatives, such as joint product development or continuous improvement programs.

Implement regular performance reviews and feedback mechanisms to monitor supplier performance.

C. Quality Assurance

Implement quality control measures at key stages of the procurement process.

Conduct regular audits and inspections to ensure compliance with quality standards.

Provide training and support to suppliers to improve quality management capabilities.

V. Implementation Plan

A. Timeline

Q3 | Supplier evaluation and selection process |

|---|---|

Q4 | Implementation of quality assurance measures |

Ongoing | Continuous improvement initiatives |

B. Resource Allocation

Dedicated quality assurance team

Investment in technology for monitoring and tracking supplier performance

Budget allocation for training and development programs

C. Stakeholder Engagement

Regular communication with senior management on sourcing strategy

Collaboration with procurement teams to implement sourcing initiatives

Engagement with suppliers to align on quality goals and objectives

VI. Monitoring and Evaluation

A. Key Performance Indicators (KPIs)

Percentage of suppliers meeting quality standards.

Number of quality-related incidents or defects.

Cost savings are achieved through quality improvements.

B. Review Mechanisms

Conduct regular reviews of supplier performance against agreed-upon quality metrics.

Solicit feedback from internal stakeholders to assess the effectiveness of sourcing strategies.

Adjust sourcing strategies as needed based on performance evaluations and market dynamics.

VII. Conclusion

The Strategic Sourcing Plan outlined above provides a comprehensive framework for enhancing the overall quality of goods produced or services delivered by [YOUR COMPANY NAME]. By leveraging strategic sourcing practices, we aim to optimize supplier relationships, mitigate risks, and drive continuous quality improvements across the supply chain.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Unlock the potential of your procurement process with Template.net's Strategic Sourcing PlanTemplate. This customizable and editable template empowers you to optimize your strategic sourcing efforts effortlessly. Seamlessly tailor your strategies with our AI Editor Tool, ensuring precision and efficiency. Elevate your sourcing game with a comprehensive plan that streamlines operations and maximizes savings.

You may also like

- Finance Plan

- Construction Plan

- Sales Plan

- Development Plan

- Career Plan

- Budget Plan

- HR Plan

- Education Plan

- Transition Plan

- Work Plan

- Training Plan

- Communication Plan

- Operation Plan

- Health And Safety Plan

- Strategy Plan

- Professional Development Plan

- Advertising Plan

- Risk Management Plan

- Restaurant Plan

- School Plan

- Nursing Home Patient Care Plan

- Nursing Care Plan

- Plan Event

- Startup Plan

- Social Media Plan

- Staffing Plan

- Annual Plan

- Content Plan

- Payment Plan

- Implementation Plan

- Hotel Plan

- Workout Plan

- Accounting Plan

- Campaign Plan

- Essay Plan

- 30 60 90 Day Plan

- Research Plan

- Recruitment Plan

- 90 Day Plan

- Quarterly Plan

- Emergency Plan

- 5 Year Plan

- Gym Plan

- Personal Plan

- IT and Software Plan

- Treatment Plan

- Real Estate Plan

- Law Firm Plan

- Healthcare Plan

- Improvement Plan

- Media Plan

- 5 Year Business Plan

- Learning Plan

- Marketing Campaign Plan

- Travel Agency Plan

- Cleaning Services Plan

- Interior Design Plan

- Performance Plan

- PR Plan

- Birth Plan

- Life Plan

- SEO Plan

- Disaster Recovery Plan

- Continuity Plan

- Launch Plan

- Legal Plan

- Behavior Plan

- Performance Improvement Plan

- Salon Plan

- Security Plan

- Security Management Plan

- Employee Development Plan

- Quality Plan

- Service Improvement Plan

- Growth Plan

- Incident Response Plan

- Basketball Plan

- Emergency Action Plan

- Product Launch Plan

- Spa Plan

- Employee Training Plan

- Data Analysis Plan

- Employee Action Plan

- Territory Plan

- Audit Plan

- Classroom Plan

- Activity Plan

- Parenting Plan

- Care Plan

- Project Execution Plan

- Exercise Plan

- Internship Plan

- Software Development Plan

- Continuous Improvement Plan

- Leave Plan

- 90 Day Sales Plan

- Advertising Agency Plan

- Employee Transition Plan

- Smart Action Plan

- Workplace Safety Plan

- Behavior Change Plan

- Contingency Plan

- Continuity of Operations Plan

- Health Plan

- Quality Control Plan

- Self Plan

- Sports Development Plan

- Change Management Plan

- Ecommerce Plan

- Personal Financial Plan

- Process Improvement Plan

- 30-60-90 Day Sales Plan

- Crisis Management Plan

- Engagement Plan

- Execution Plan

- Pandemic Plan

- Quality Assurance Plan

- Service Continuity Plan

- Agile Project Plan

- Fundraising Plan

- Job Transition Plan

- Asset Maintenance Plan

- Maintenance Plan

- Software Test Plan

- Staff Training and Development Plan

- 3 Year Plan

- Brand Activation Plan

- Release Plan

- Resource Plan

- Risk Mitigation Plan

- Teacher Plan

- 30 60 90 Day Plan for New Manager

- Food Safety Plan

- Food Truck Plan

- Hiring Plan

- Quality Management Plan

- Wellness Plan

- Behavior Intervention Plan

- Bonus Plan

- Investment Plan

- Maternity Leave Plan

- Pandemic Response Plan

- Succession Planning

- Coaching Plan

- Configuration Management Plan

- Remote Work Plan

- Self Care Plan

- Teaching Plan

- 100-Day Plan

- HACCP Plan

- Student Plan

- Sustainability Plan

- 30 60 90 Day Plan for Interview

- Access Plan

- Site Specific Safety Plan