Free Manufacturing Engineering Datasheet

Prepared By: | [Your Name] |

Company: | [Your Company Name] |

Department: | Department of Manufacturing Engineering and Management |

Date: | [Date] |

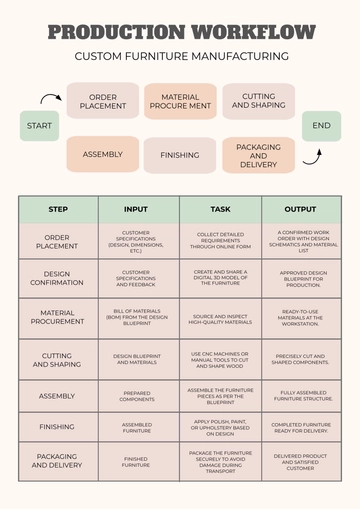

I. Process Description and Purpose

The Process Description and Purpose section of the Manufacturing Engineering Datasheet provides an overview of the specific manufacturing process being documented. This section should outline the objectives, goals, and key steps involved in the process. It serves as a roadmap for understanding the purpose and importance of the manufacturing process.

[Your Company Name] utilizes this Manufacturing Engineering Datasheet template to document various manufacturing processes, ensuring consistency and clarity across operations. The Process Description and Purpose section typically includes:

A summary of the process and its importance in production.

Key objectives and goals that the process aims to achieve.

Description of the desired outcome or product resulting from the process.

Any safety considerations or regulatory requirements associated with the process.

II. Equipment and Tools Required

In this section, the necessary equipment and tools for executing the manufacturing process are listed in detail. [Your Company Name] emphasizes the importance of identifying and maintaining appropriate tools and equipment to ensure the smooth operation of the process. This section helps streamline procurement efforts and facilitates proper resource allocation.

[Your Name], the Manufacturing Engineer, is responsible for compiling accurate information regarding equipment and tools required for each process. The Equipment and Tools Required section typically includes:

List of machinery, tools, and instruments needed for the process.

Safety precautions related to the operation of equipment.

Maintenance requirements and schedules to ensure optimal performance.

Specifications for each piece of equipment, covering model numbers, capacity, and special features.

III. Operating Procedures

Operating Procedures detail the step-by-step instructions for executing the manufacturing process efficiently and safely. [Your Company Name] prioritizes clear and concise documentation of procedures to minimize errors and ensure consistency in production. This section serves as a guide for operators and technicians involved in carrying out the process.

Under the guidance of [Your Name], Manufacturing Engineers collaborate with production teams to develop comprehensive operating procedures. The Operating Procedures section typically includes:

A clear and easy-to-follow sequence of steps.

Parameters such as temperature, pressure, and timing for each step.

Troubleshooting guidelines to address common issues or challenges.

Quality control checkpoints to ensure product integrity throughout the process.

IV. Quality Control Measures

Quality Control Measures are essential for maintaining product quality and meeting customer specifications. This section outlines the inspection and testing protocols implemented during the manufacturing process. [Your Company Name] places great emphasis on quality assurance to uphold its reputation for excellence.

[Your Name], in collaboration with Quality Assurance teams, defines and documents robust quality control measures. The Quality Control Measures section typically includes:

Inspection criteria for all production stages.

Documentation needs, including records and reports.

Actions to correct quality deviations and prevent their recurrence.

Validation of product effectiveness and compliance through testing protocols and standards.

This Manufacturing Engineering Datasheet template provides a structured framework for documenting and communicating essential information related to manufacturing processes at [Your Company Name]. By adhering to this template, [Your Company Name] ensures consistency, efficiency, and quality in its manufacturing operations.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Enhance your engineering reports with Template.net's Manufacturing Engineering Datasheet Template. Fully customizable and editable, this template is designed to meet your specific needs. Easily editable in our AI Editor Tool, it allows you to create precise, professional datasheets quickly. Ideal for manufacturing engineers seeking to improve their documentation and workflow efficiency.

You may also like

- Attendance Sheet

- Work Sheet

- Sheet Cost

- Expense Sheet

- Tracker Sheet

- Student Sheet

- Tracking Sheet

- Blank Sheet

- Information Sheet

- Sales Sheet

- Record Sheet

- Price Sheet

- Plan Sheet

- Score Sheet

- Estimate Sheet

- Evaluation Sheet

- Checklist Sheet

- Bid Sheet

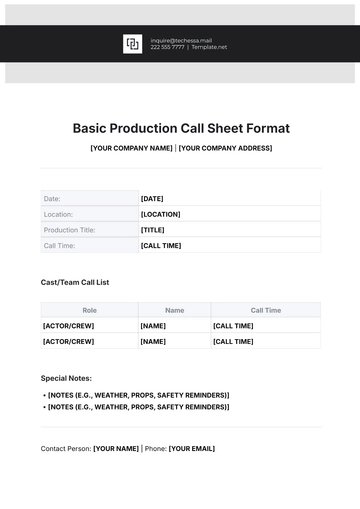

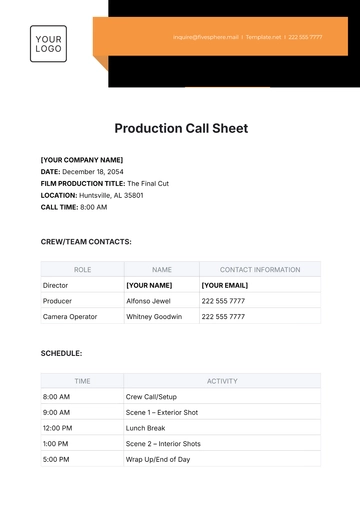

- Call Log Sheet

- Bill Sheet

- Assessment Sheet

- Task Sheet

- School Sheet

- Work From Home Sheet

- Summary Sheet

- Construction Sheet

- Cover Sheet

- Debt Spreadsheet

- Debt Sheet

- Client Information Sheet

- University Sheet

- Freelancer Sheet

- Bookkeeping Sheet

- Itinerary Spreadsheet

- Scorecard Sheet

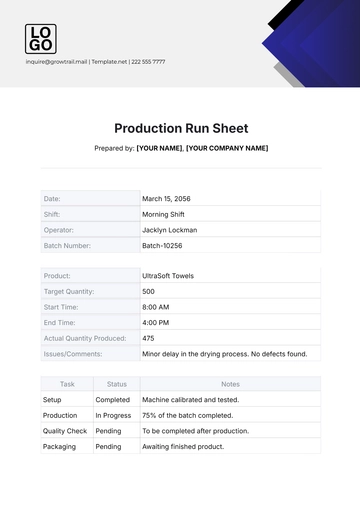

- Run Sheet

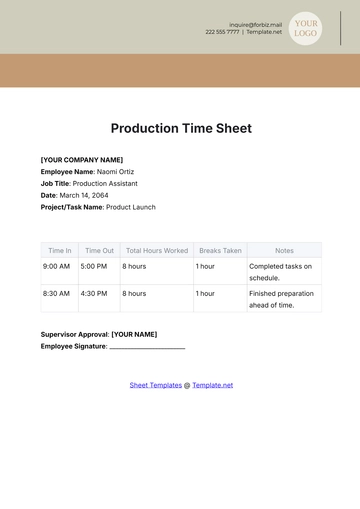

- Monthly Timesheet

- Event Sheet

- Advertising Agency Sheet

- Missing Numbers Worksheet

- Training Sheet

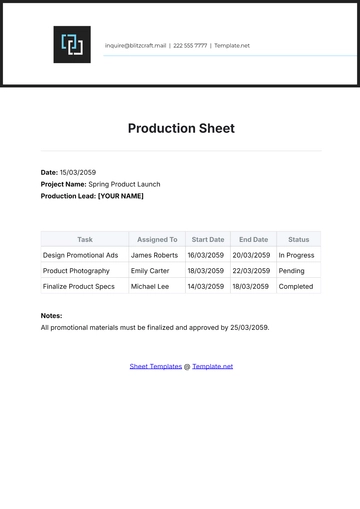

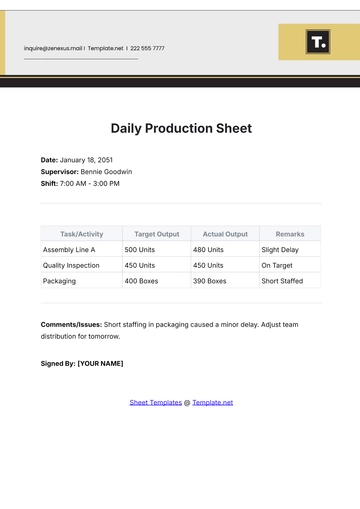

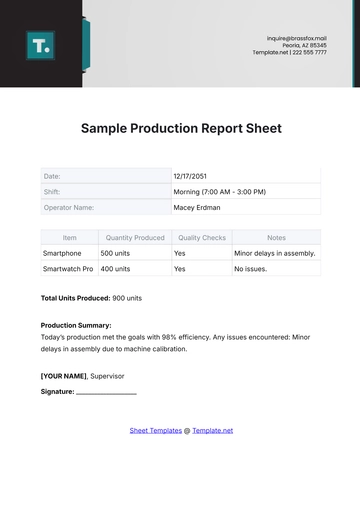

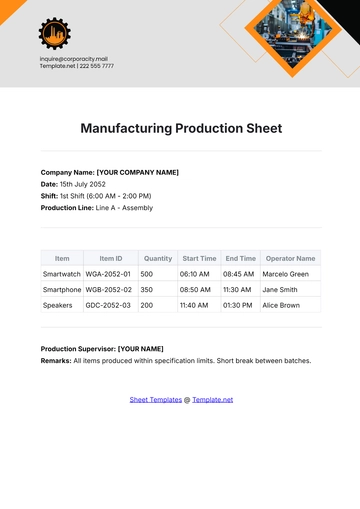

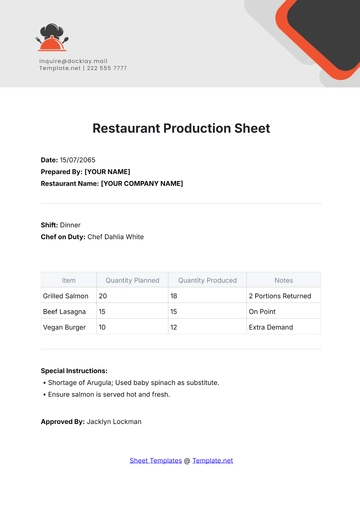

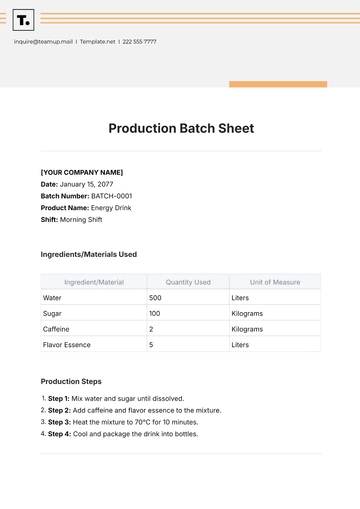

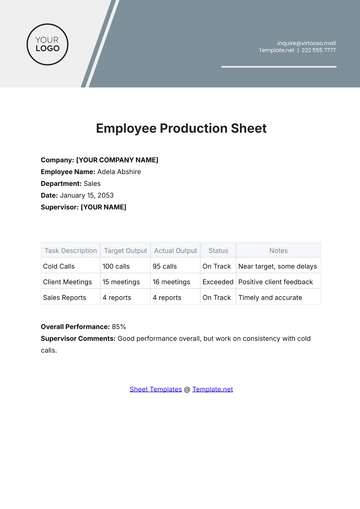

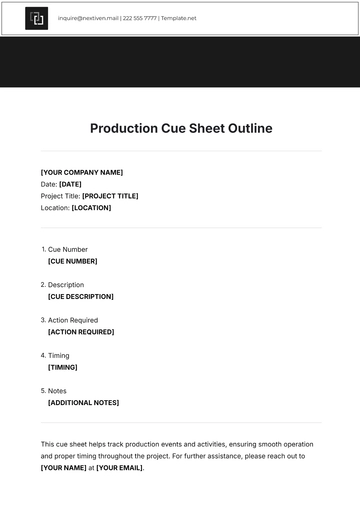

- Production Sheet

- Mortgage Sheet

- Answer Sheet

- Excel Sheet