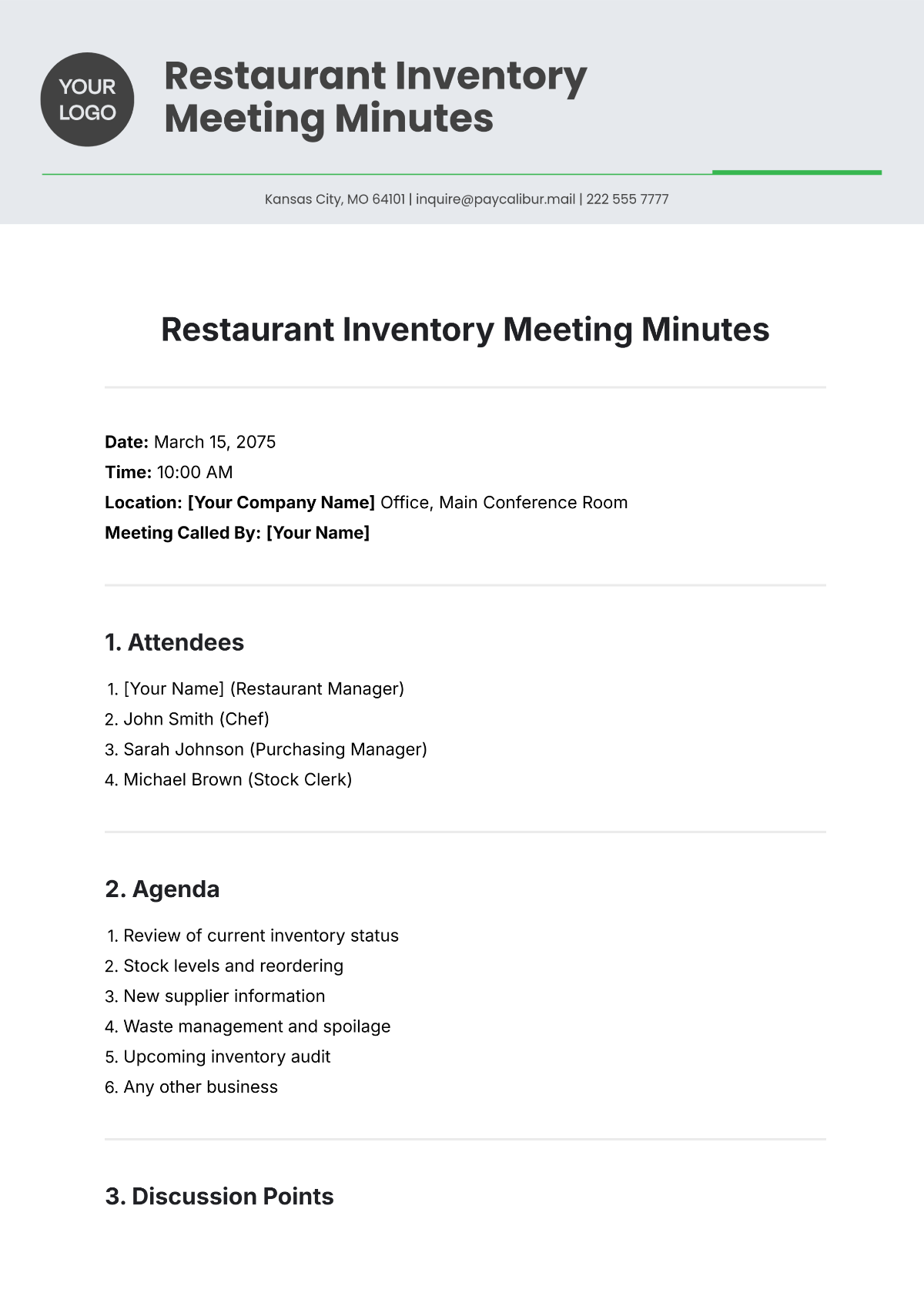

Restaurant Inventory Report

Company: [Your Company Name]

Prepared by: [Your Name]

Report Period: [Date]

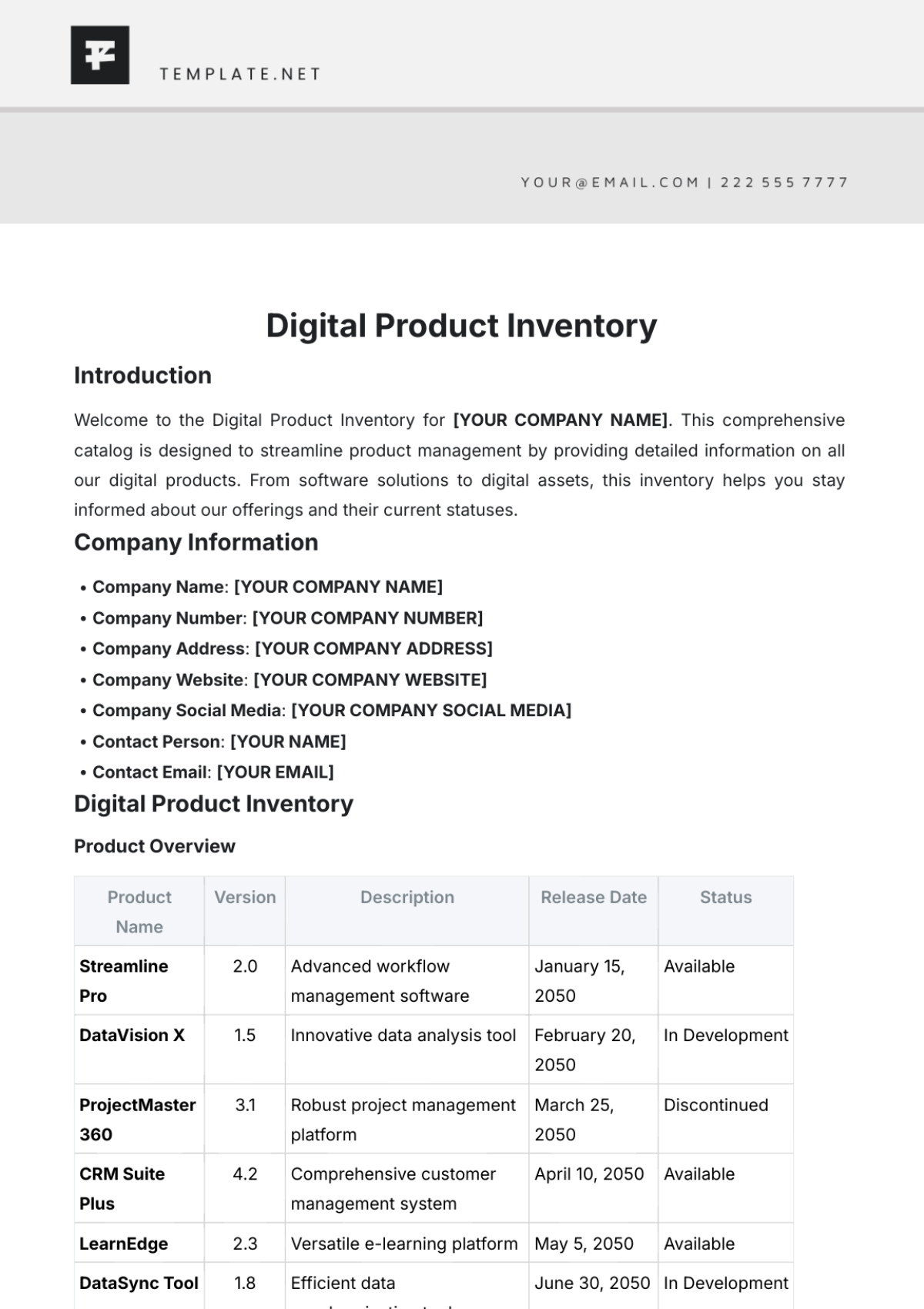

I. Introduction

The following report provides a comprehensive overview of the current inventory status at [Your Company Name]. This document is designed to facilitate inventory management, reduce waste, and ensure that critical items are adequately stocked. By regularly reviewing our inventory, we can optimize our ordering processes and enhance our service delivery.

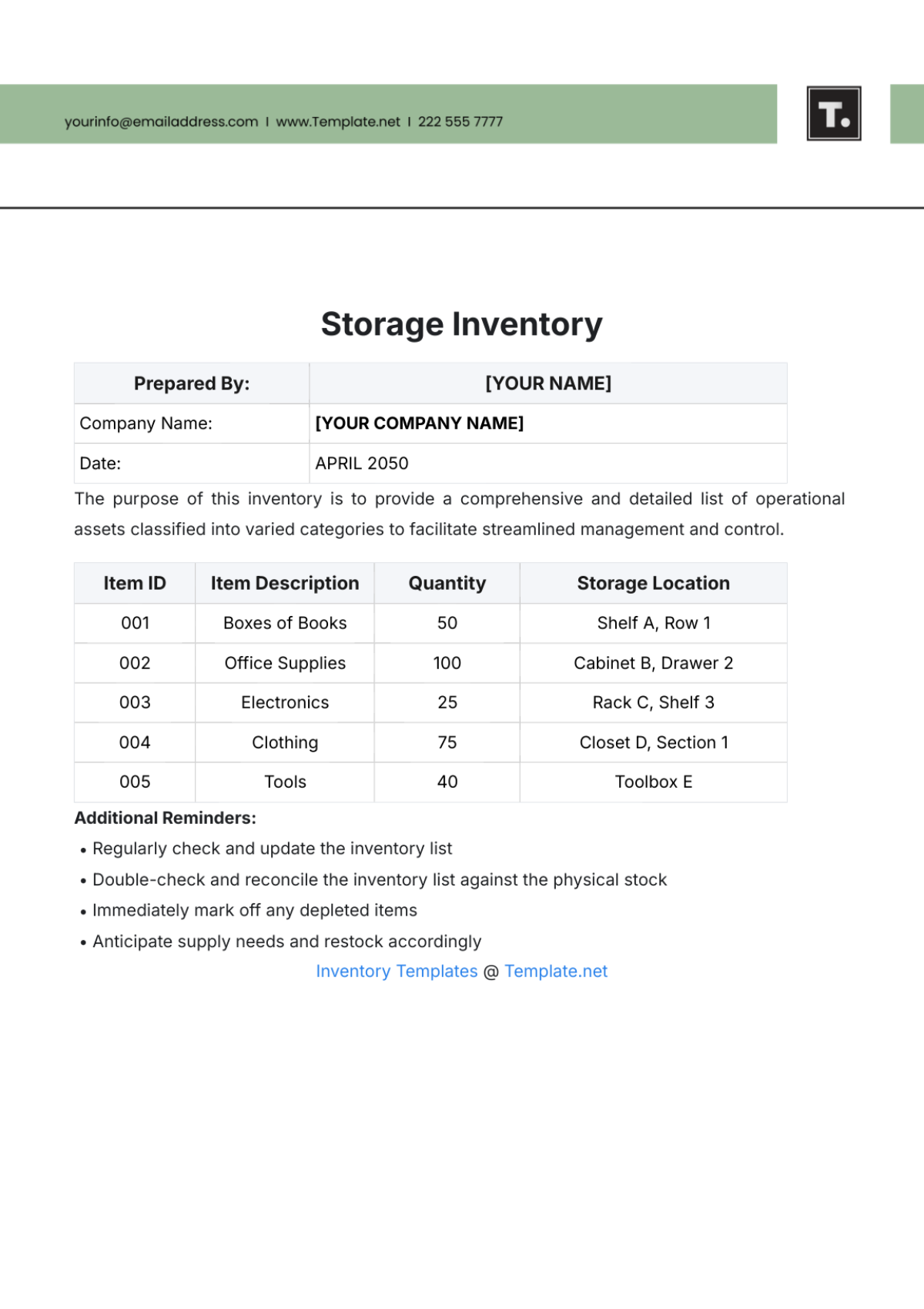

II. Current Inventory Status

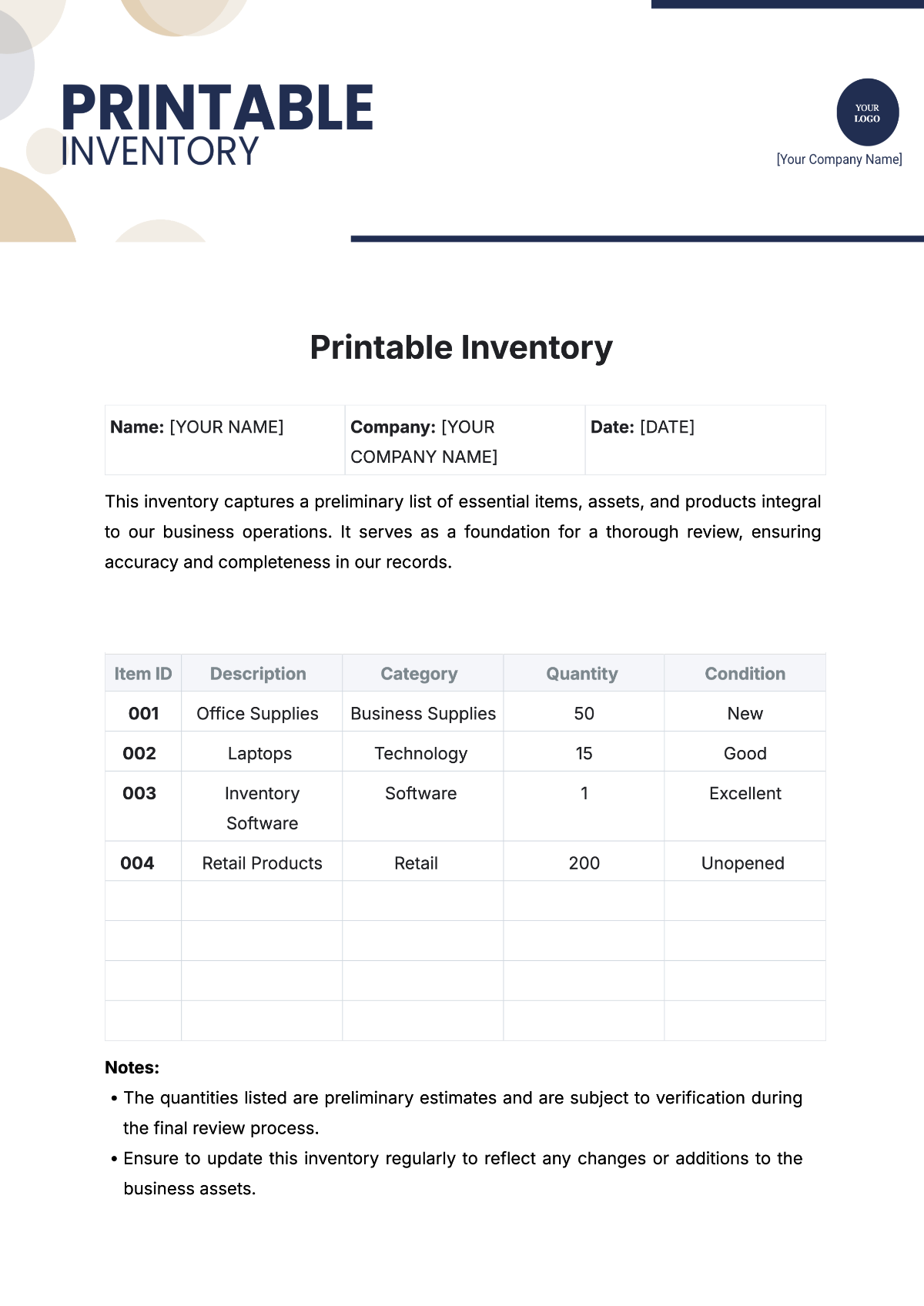

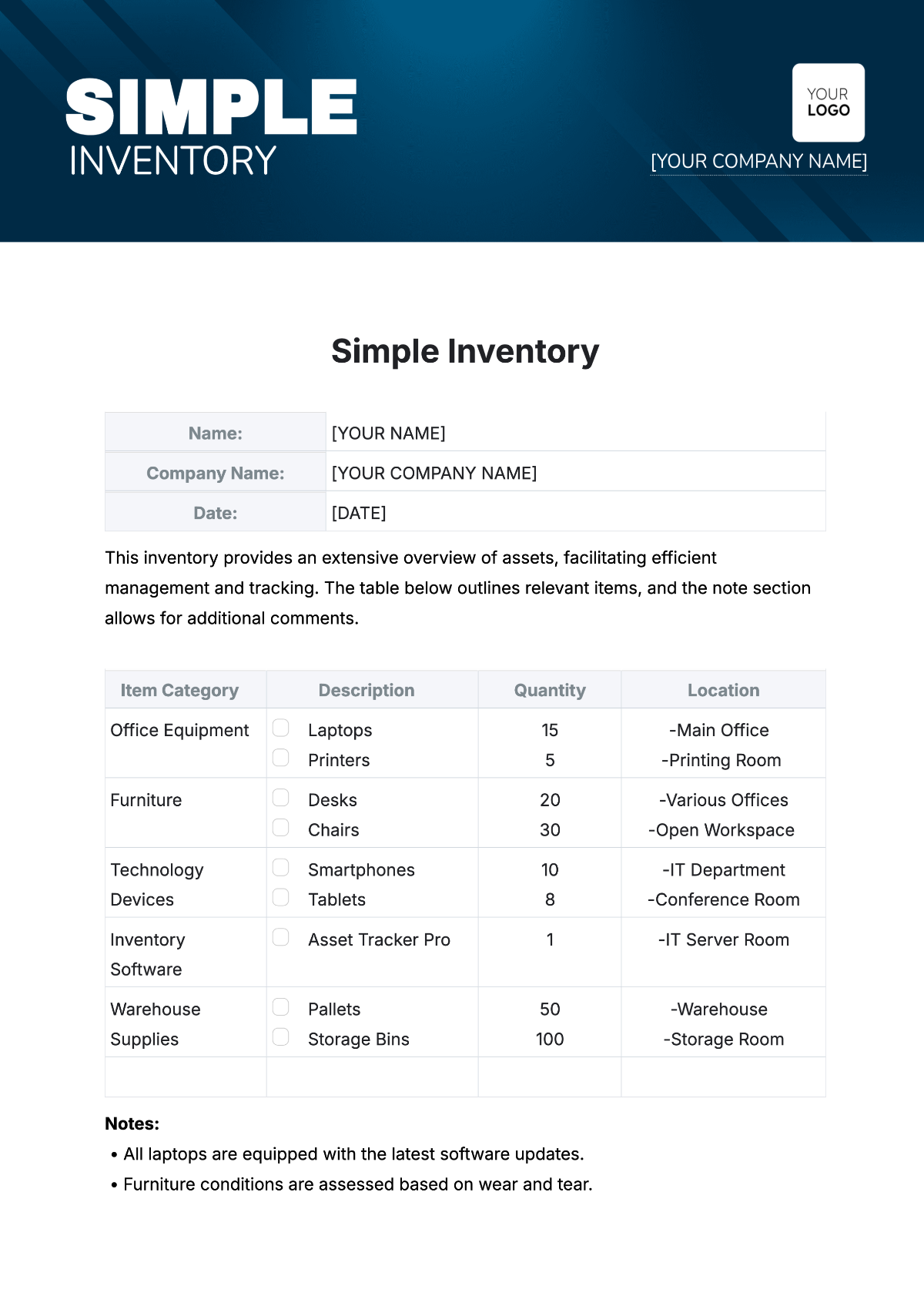

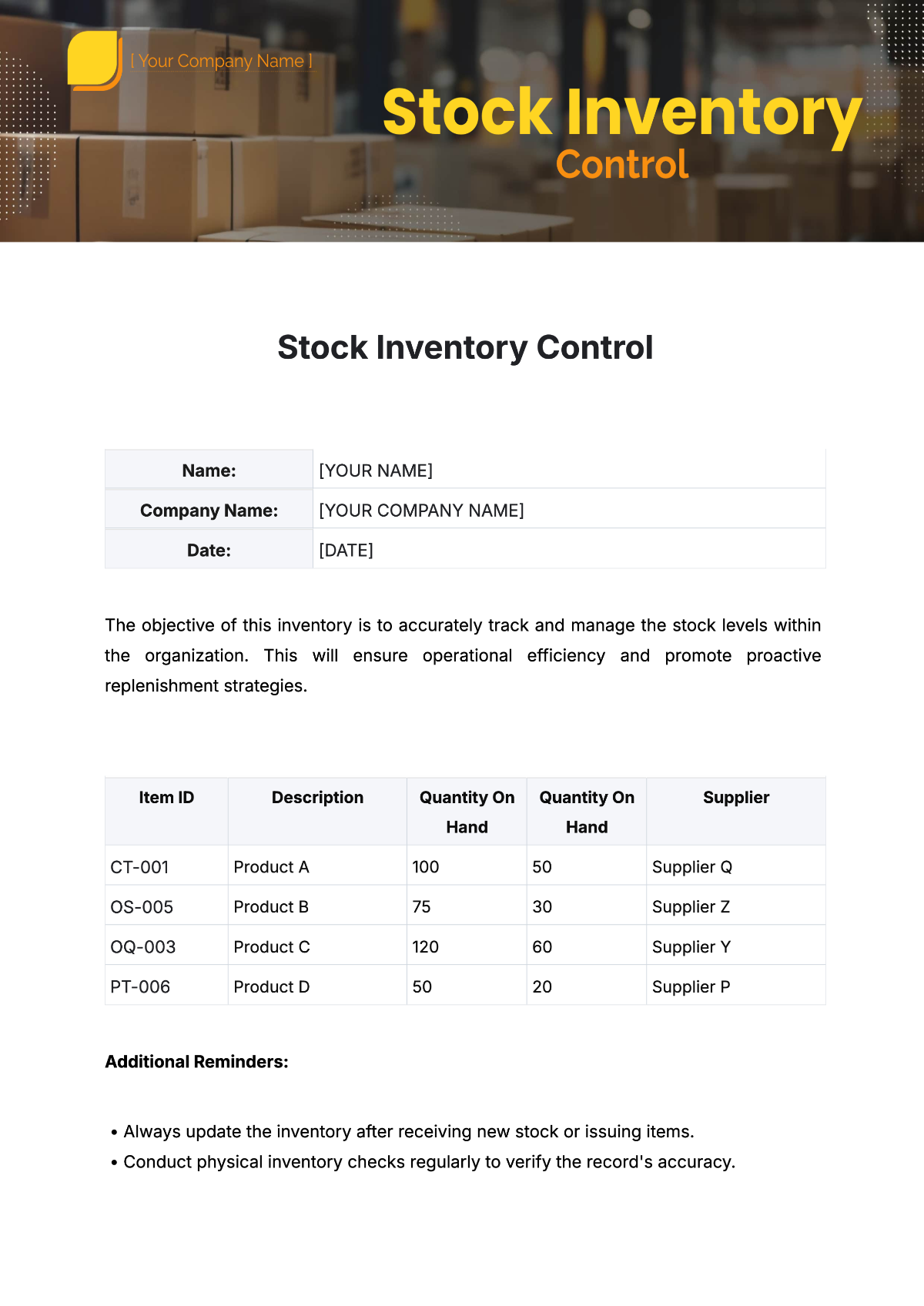

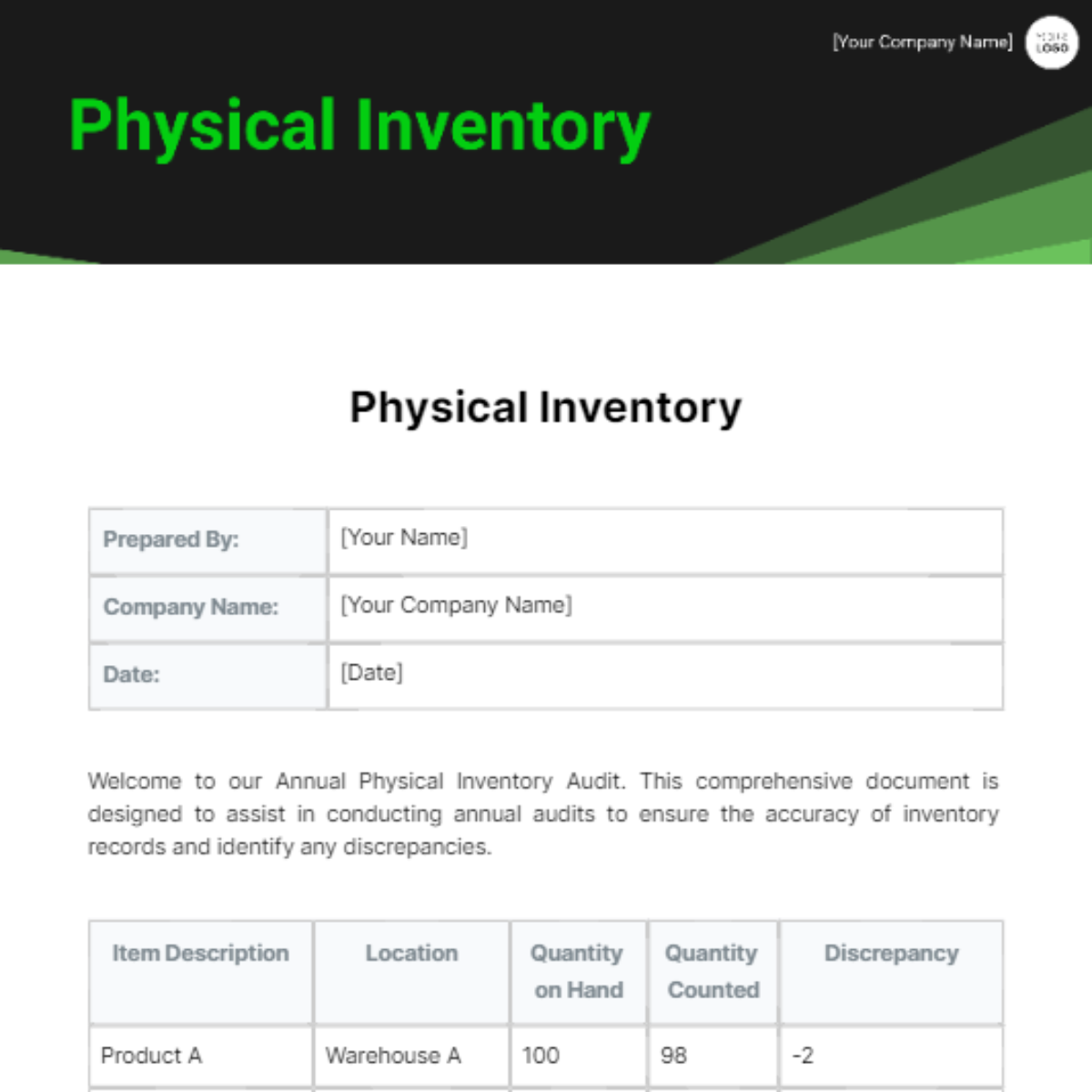

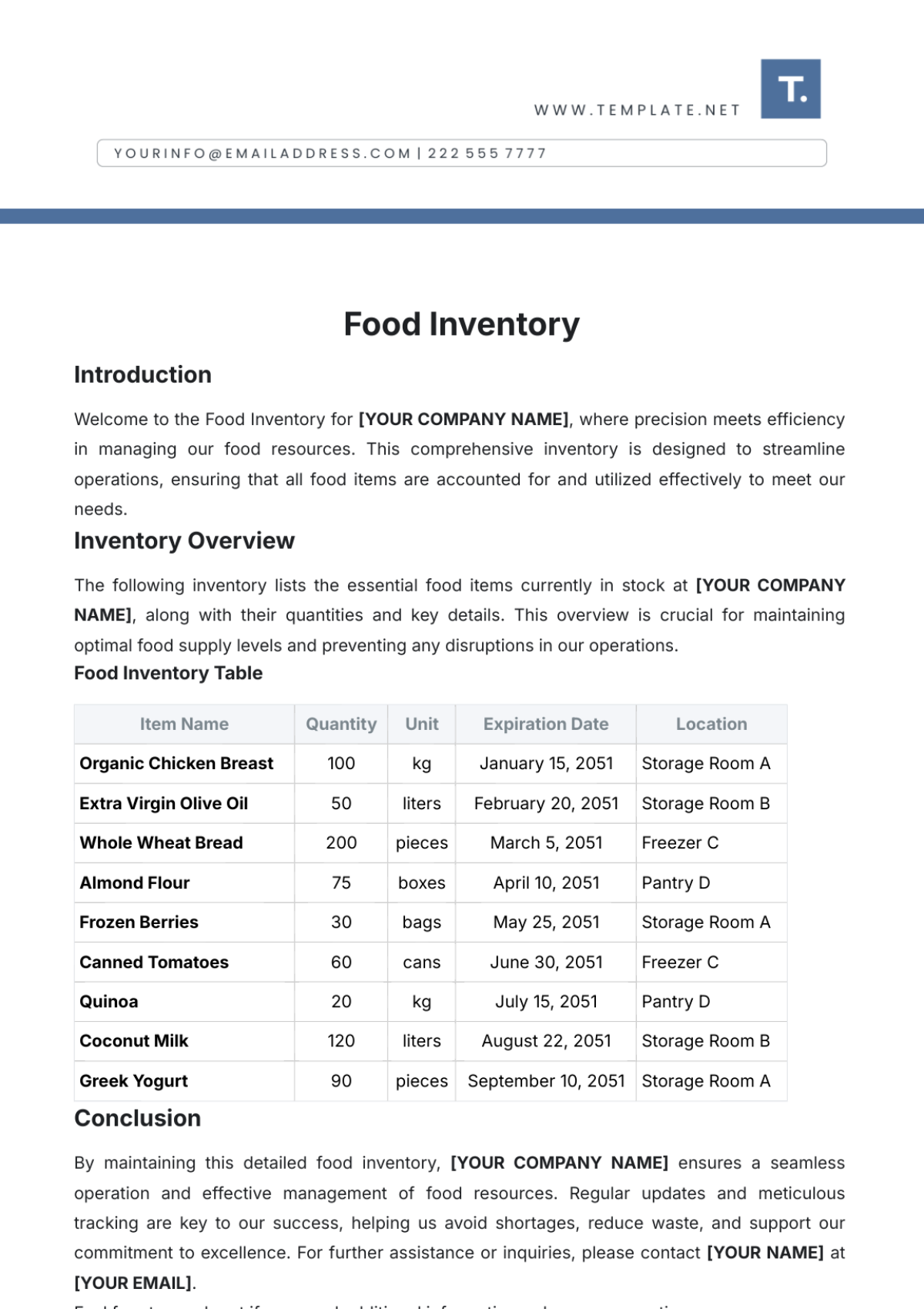

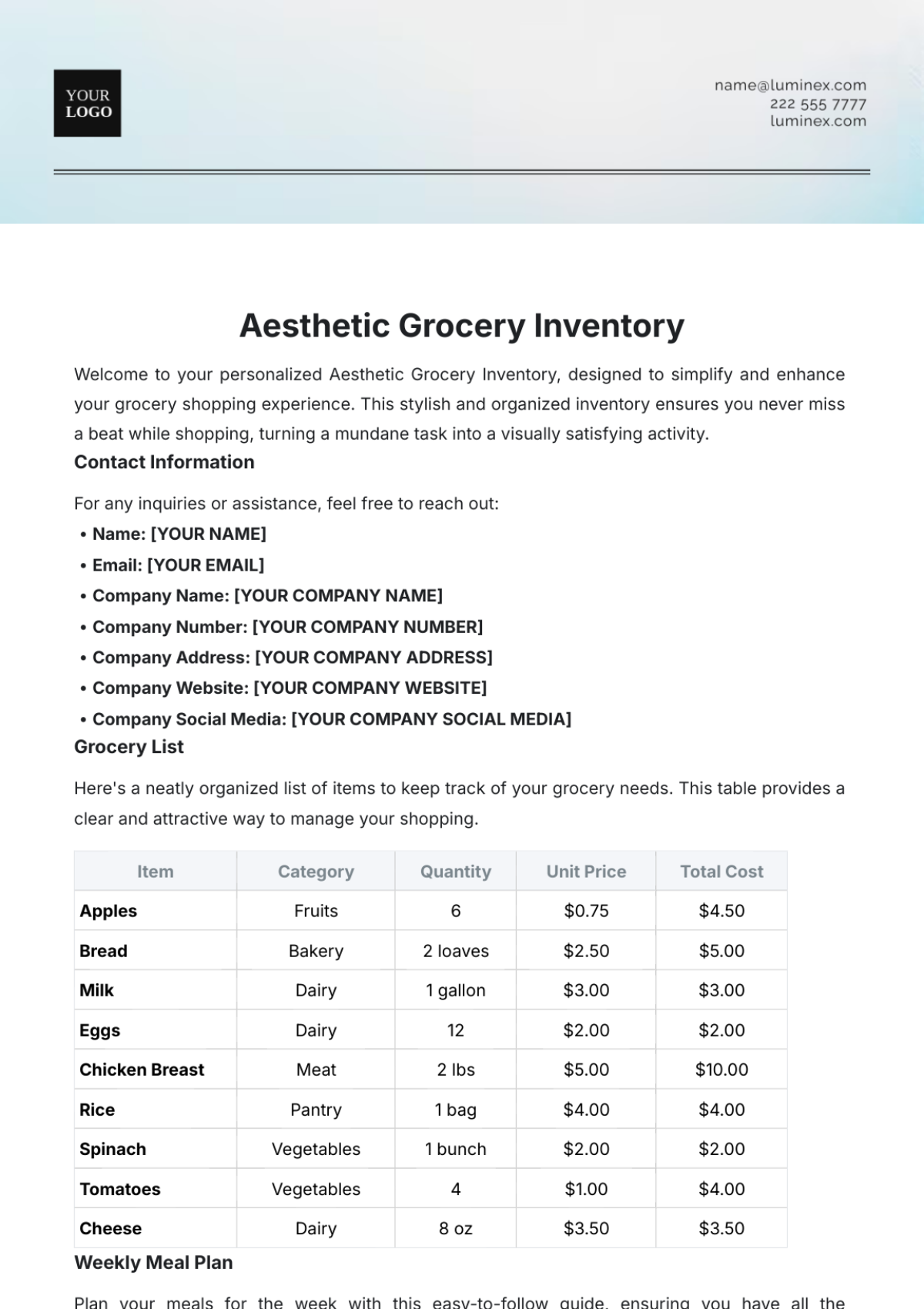

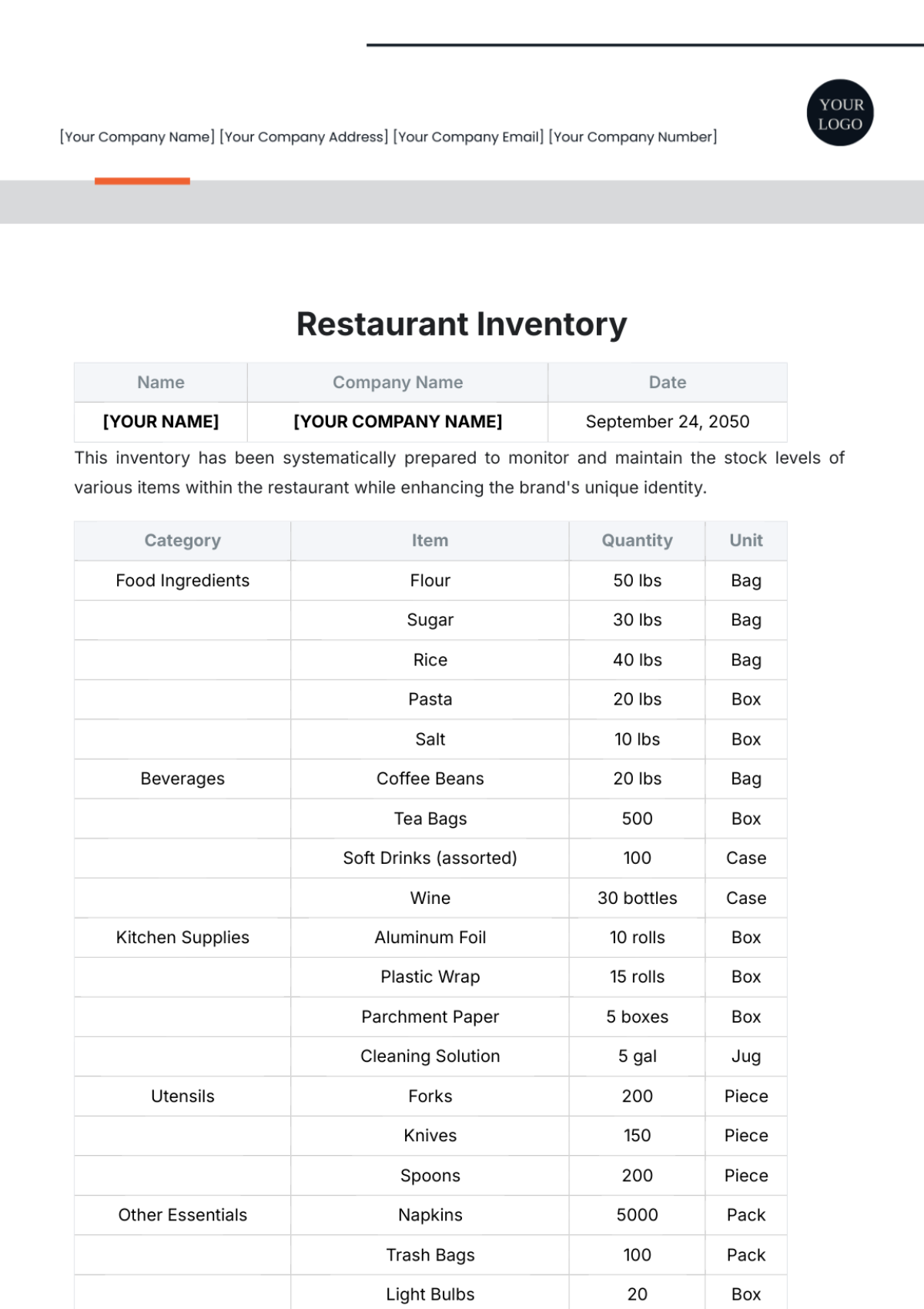

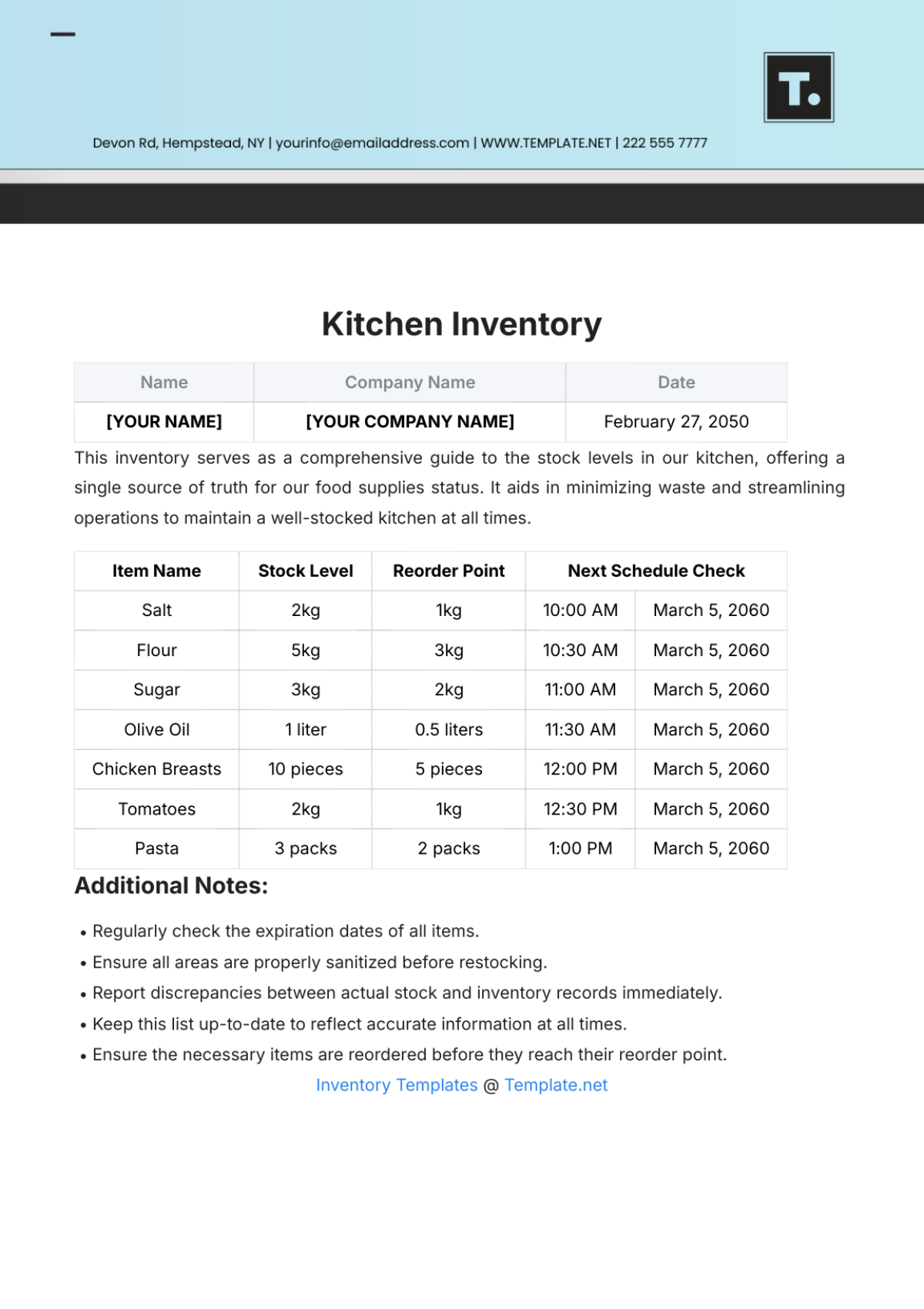

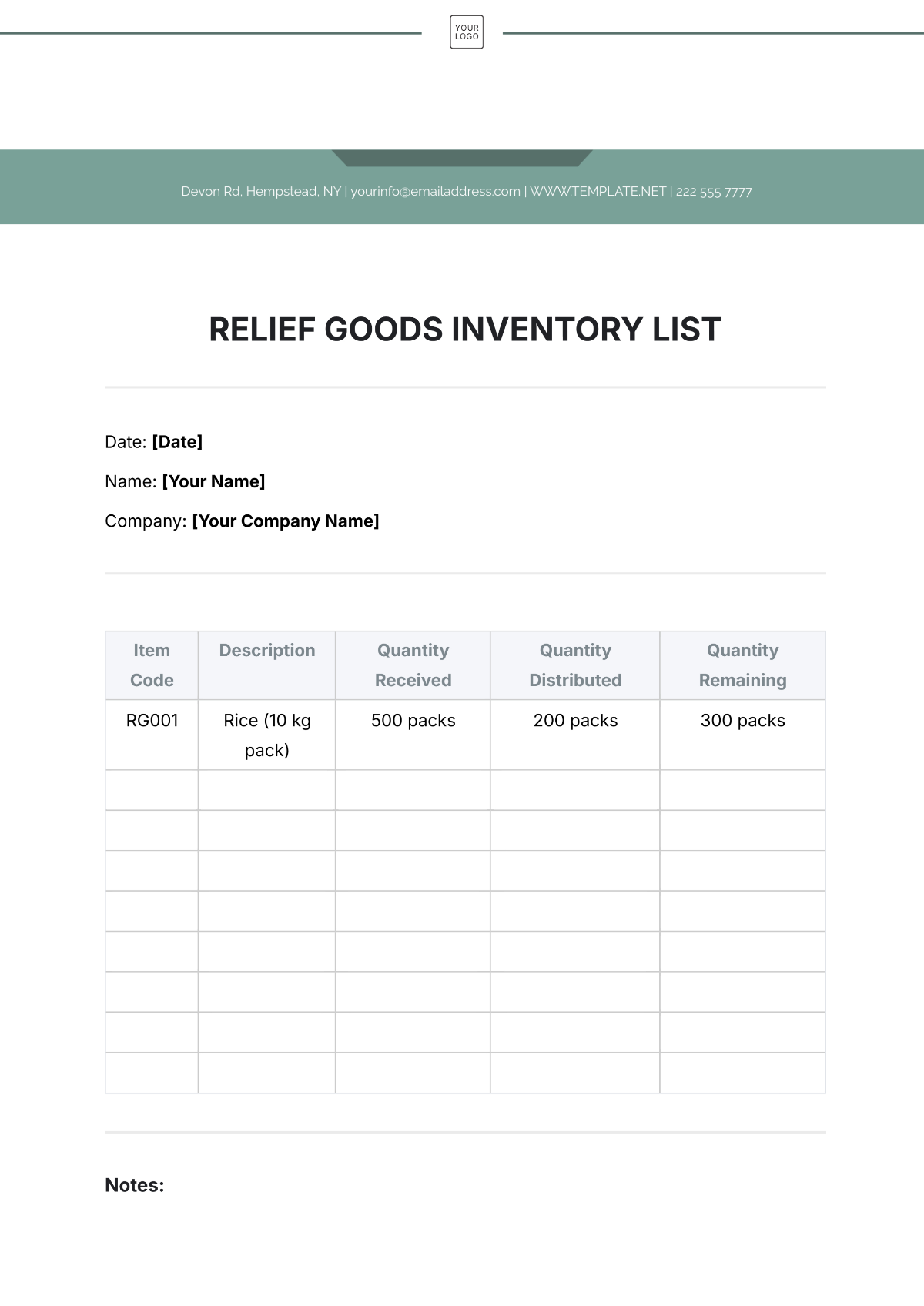

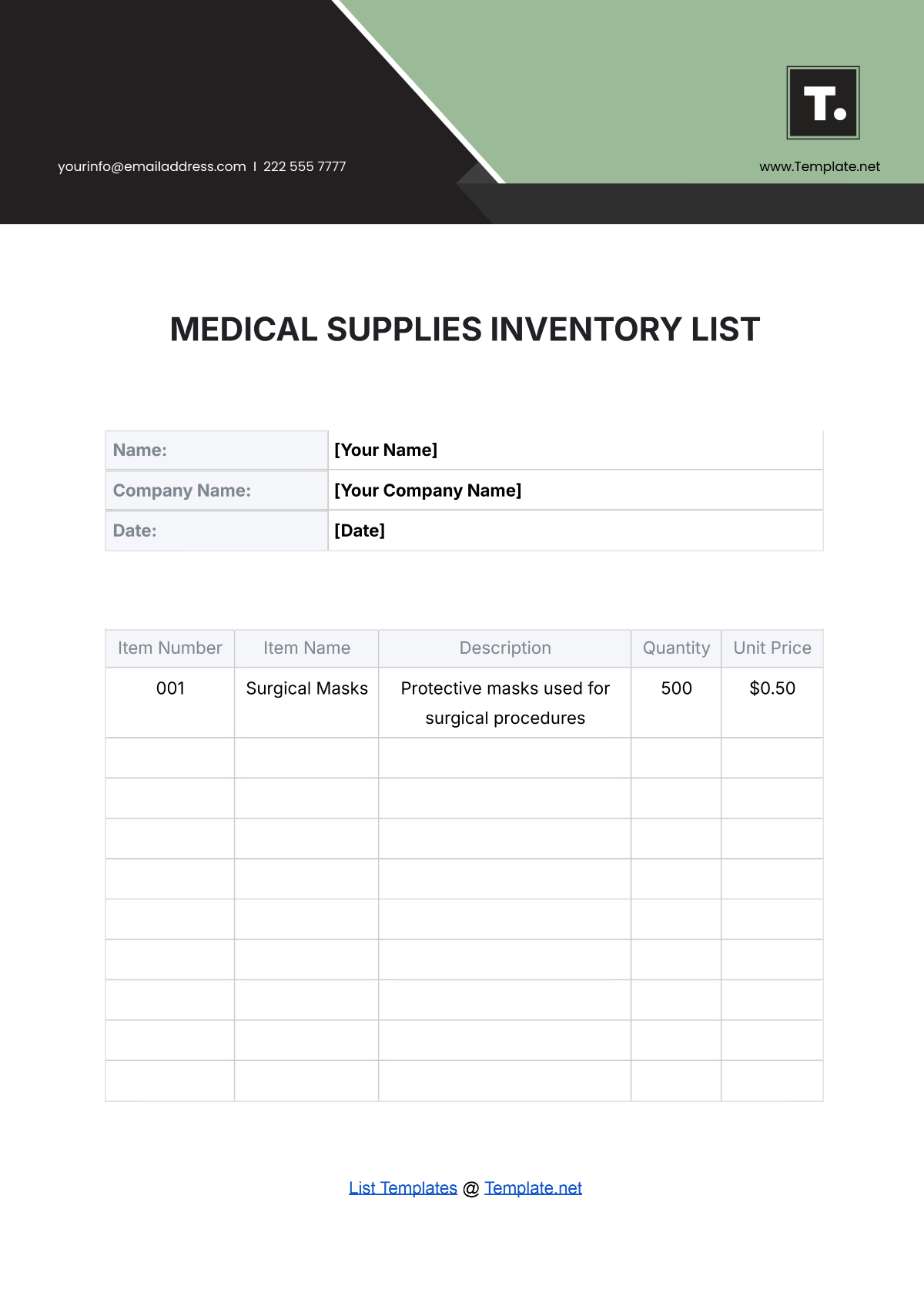

A. Perishable Goods

Perishable goods require constant monitoring due to their limited shelf life. The key perishable items include:

Item | Quantity | Unit | Shelf Life |

|---|---|---|---|

Milk | 20 | Liters | 2 weeks |

Chicken Breast | 15 | Kilograms | 1 week |

Fresh Vegetables | 30 | Kilograms | 1 week |

Fish Fillet | 10 | Kilograms | 5 days |

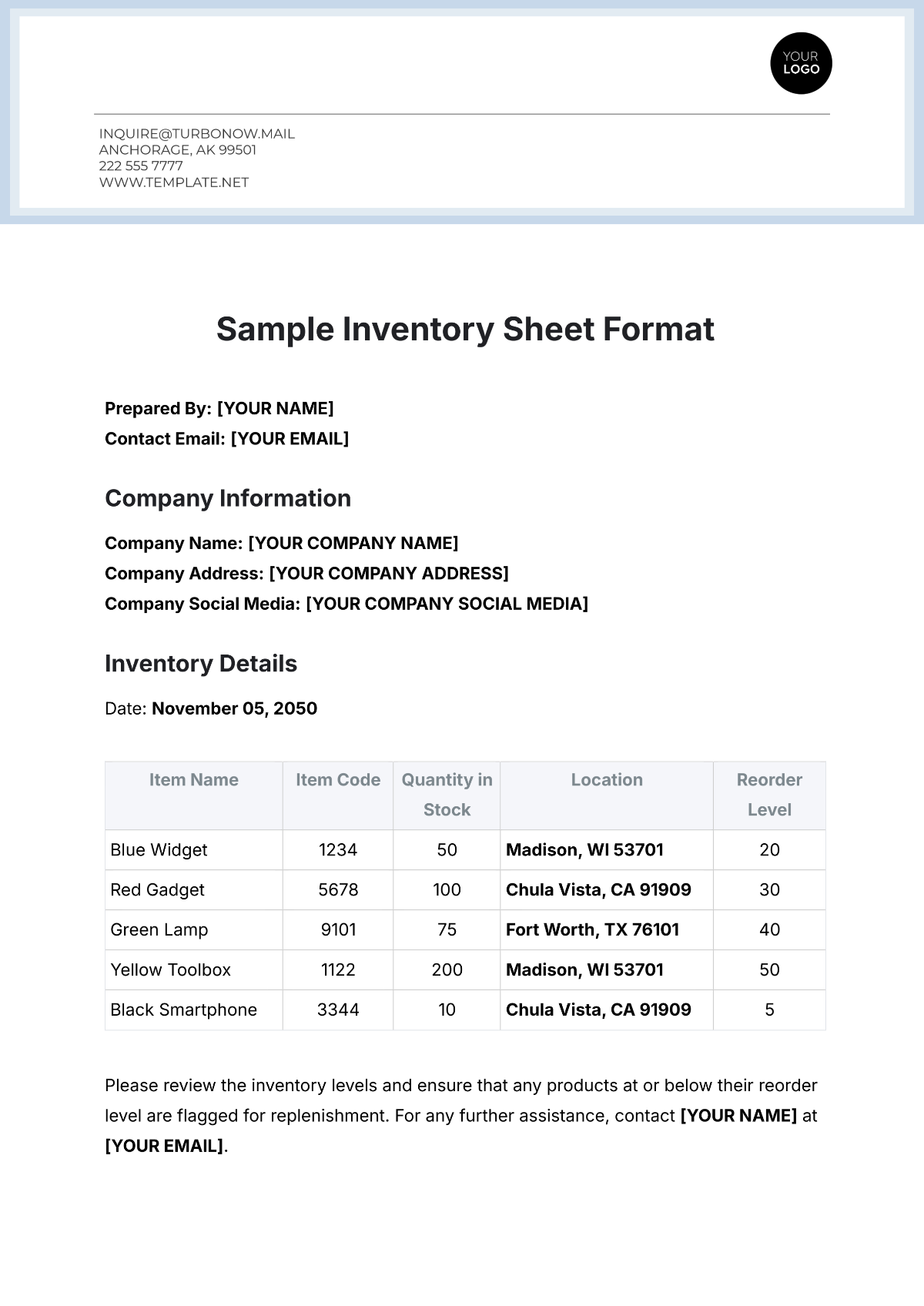

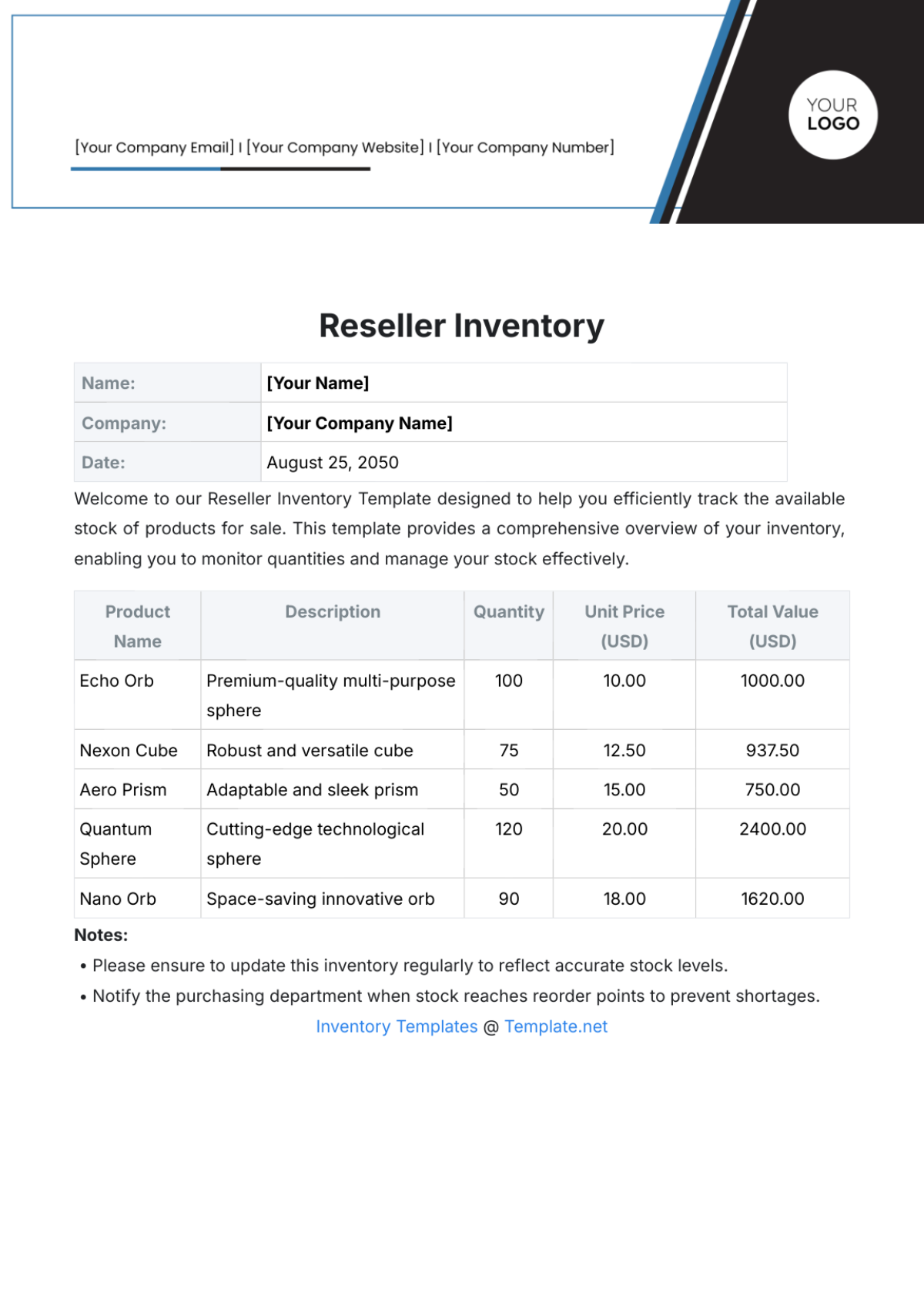

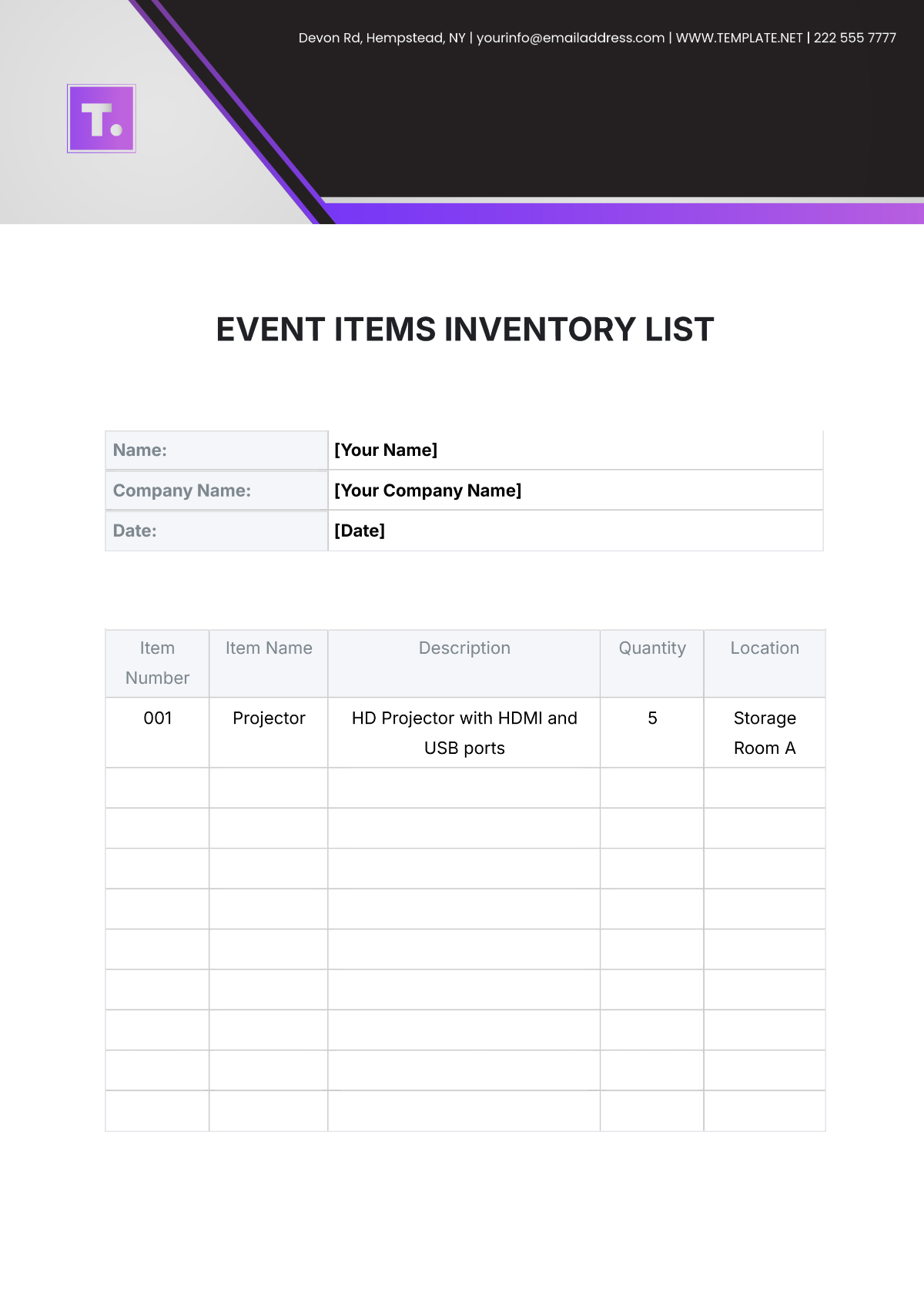

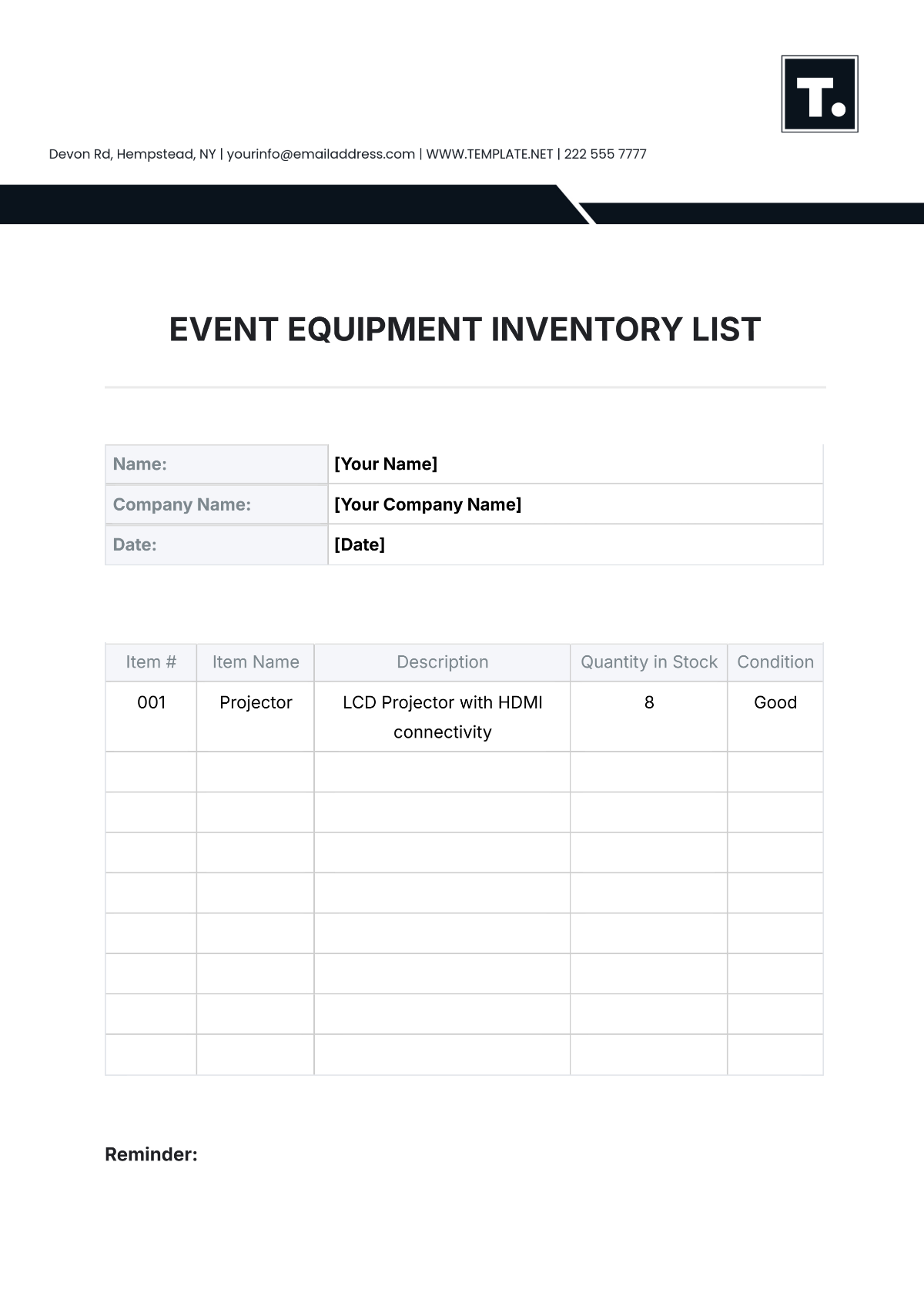

B. Non-Perishable Goods

Non-perishable goods, while not as urgent as perishables, still require regular stock checks. The main non-perishable items include:

Item | Quantity | Unit | Restock Threshold |

|---|---|---|---|

Olive Oil | 50 | Liters | 20 Liters |

Pasta | 100 | Kilograms | 25 Kilograms |

Canned Beans | 200 | Cans | 50 Cans |

Sugar | 80 | Kilograms | 30 Kilograms |

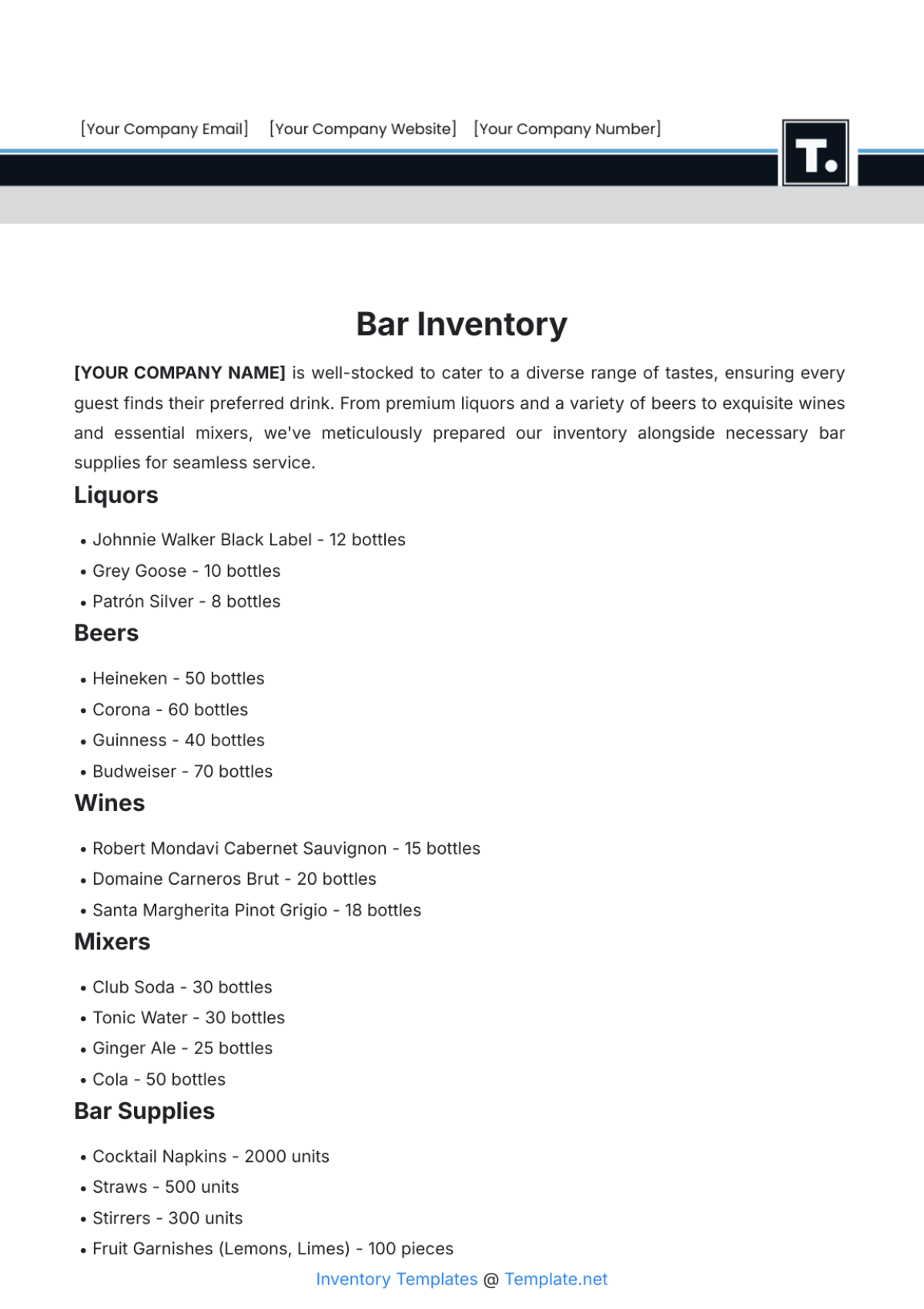

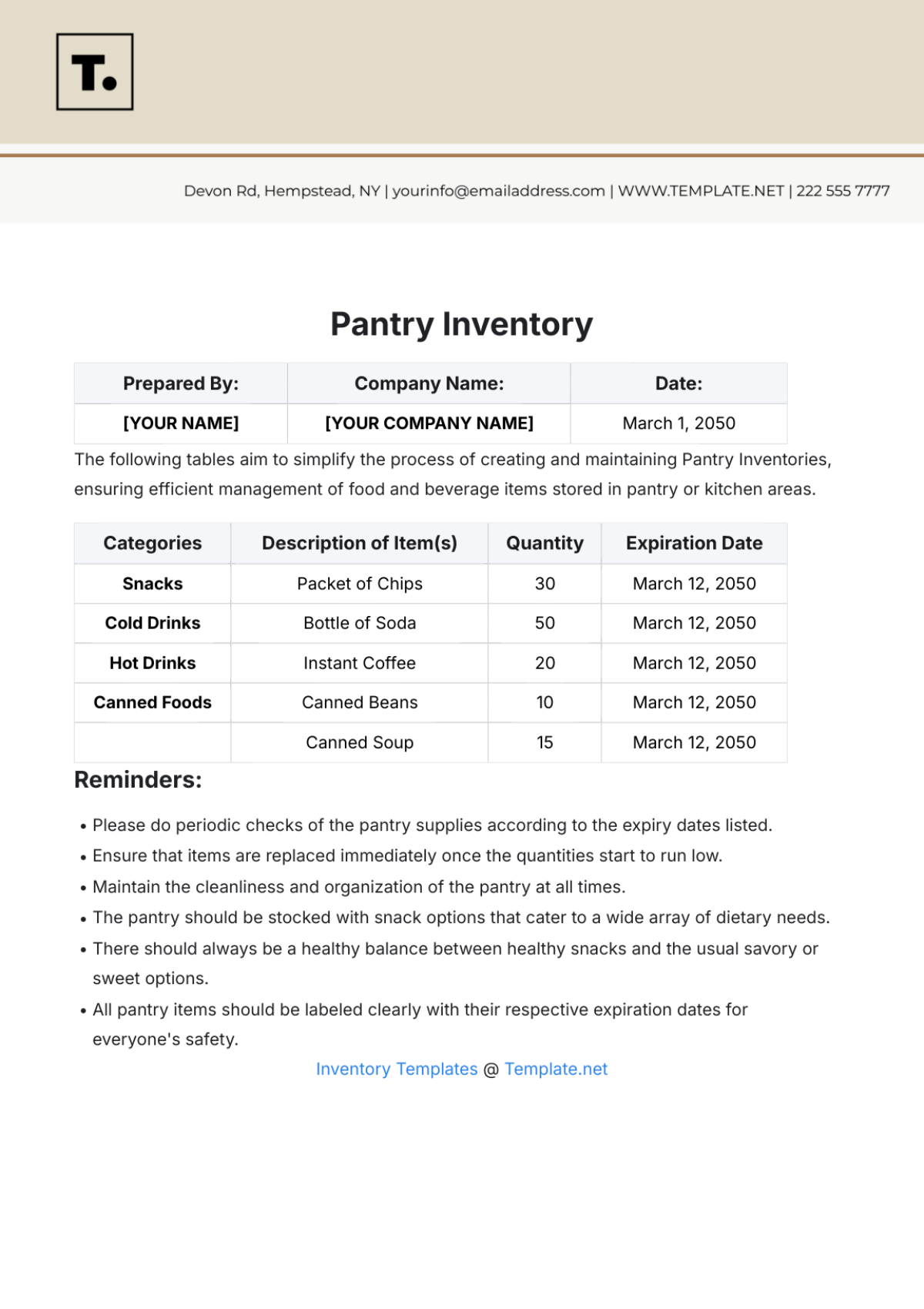

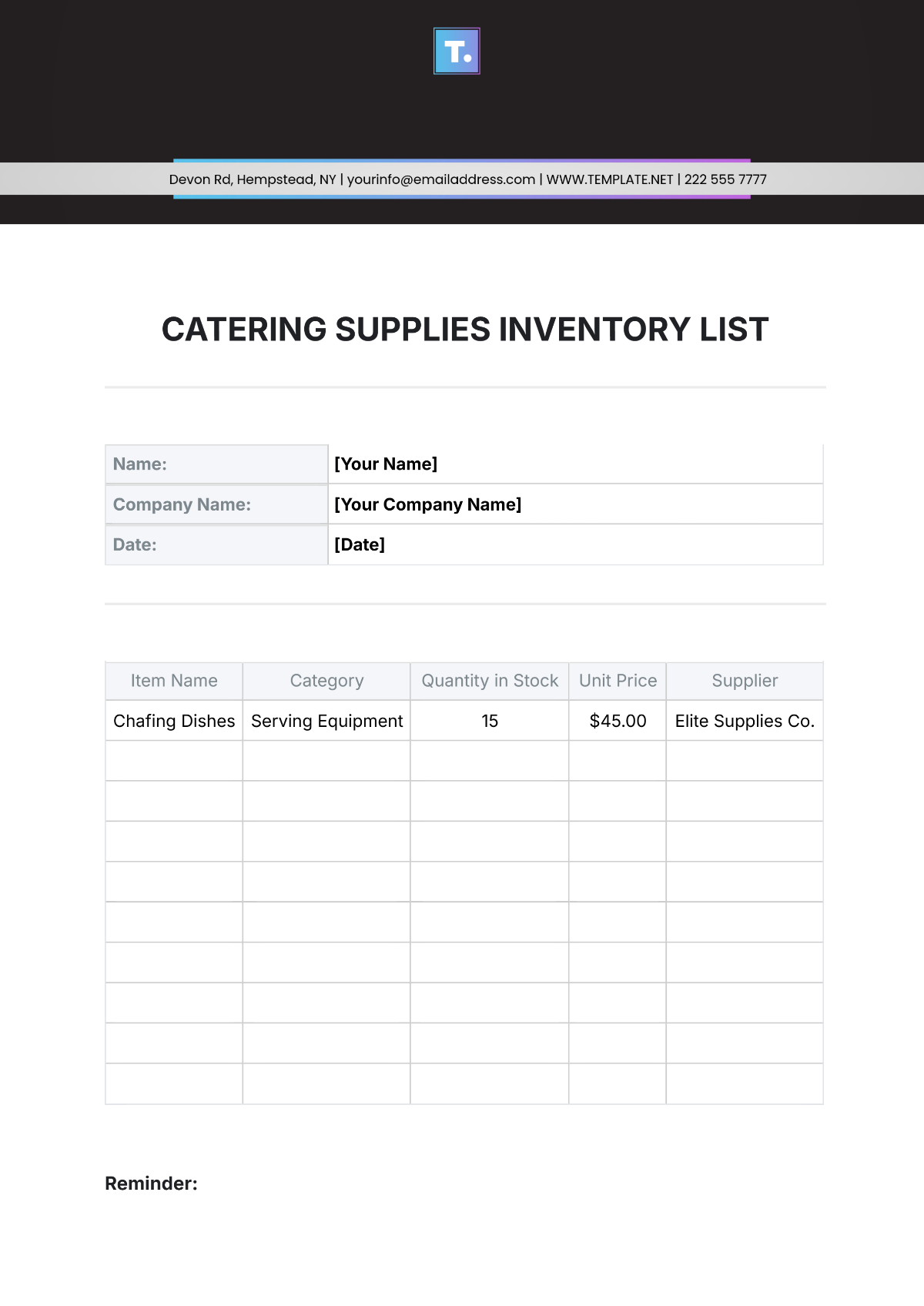

C. Beverages

Beverage inventory is crucial for customer satisfaction. The beverage stock includes both alcoholic and non-alcoholic options:

Item | Quantity | Unit | Restock Point |

|---|---|---|---|

Red Wine | 60 | Bottles | 20 Bottles |

Beer | 200 | Bottles | 50 Bottles |

Orange Juice | 150 | Liters | 50 Liters |

Sparkling Water | 100 | Bottles | 30 Bottles |

III. Inventory Analysis

A. Stock Turnover Rates

Stock turnover rates provide insight into how frequently inventory is used and how often it needs to be replenished. High turnover in items like fresh produce indicates efficient use, while low turnover might suggest overstocking or slow-moving items.

B. Current Challenges

Wastage: There is a need to reduce the wastage of perishable items to ensure cost-efficiency.

Supplier Delays: Occasional delays from suppliers can lead to shortages in critical stock.

Storage Constraints: Limited storage space necessitates frequent inventory checks and efficient use of available space.

IV. Recommendations

Based on the current inventory status and analysis, the following recommendations are made:

Implement a First-In, First-Out (FIFO) policy to minimize waste, especially for perishable goods.

Establish stronger relationships with suppliers to ensure timely deliveries and negotiate better terms.

Optimize stock levels by analyzing historical sales data to predict future inventory needs more accurately.

V.Conclusion

The inventory management at [Your Company Name] can be significantly improved by implementing the recommendations above. This will ensure that the establishment operates efficiently, reduces waste, enhances customer satisfaction, and ultimately improves profitability.