Architecture Inventory Report

I. Executive Summary

This inventory report provides an analysis of the current architectural supplies and materials for [Your Company Name]. Effective inventory management is crucial for maintaining the efficiency and profitability of the company. This report focuses on the current stock levels, monthly trends, usage patterns, and financial valuation of the inventory for the fiscal year ending [Month Day, Year].

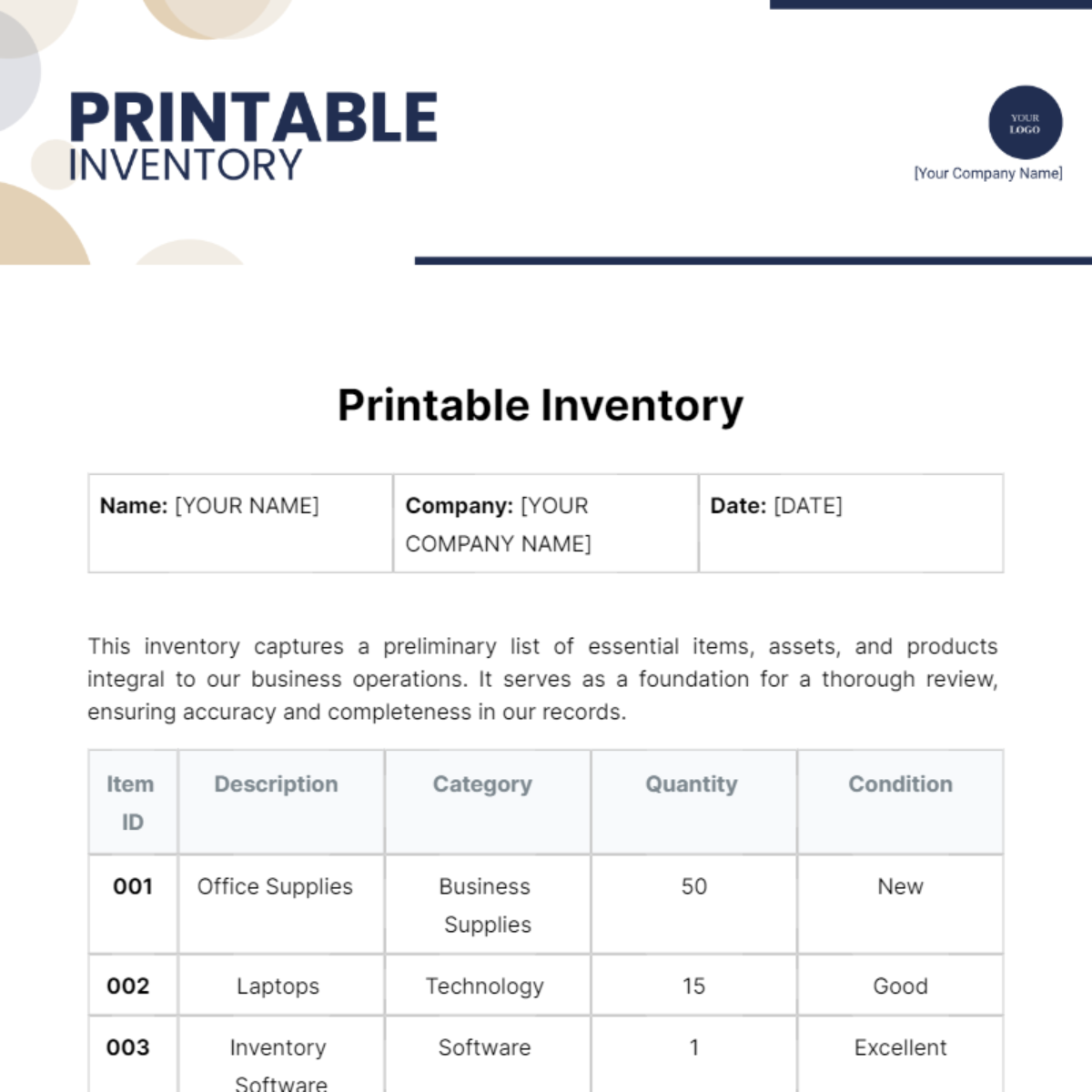

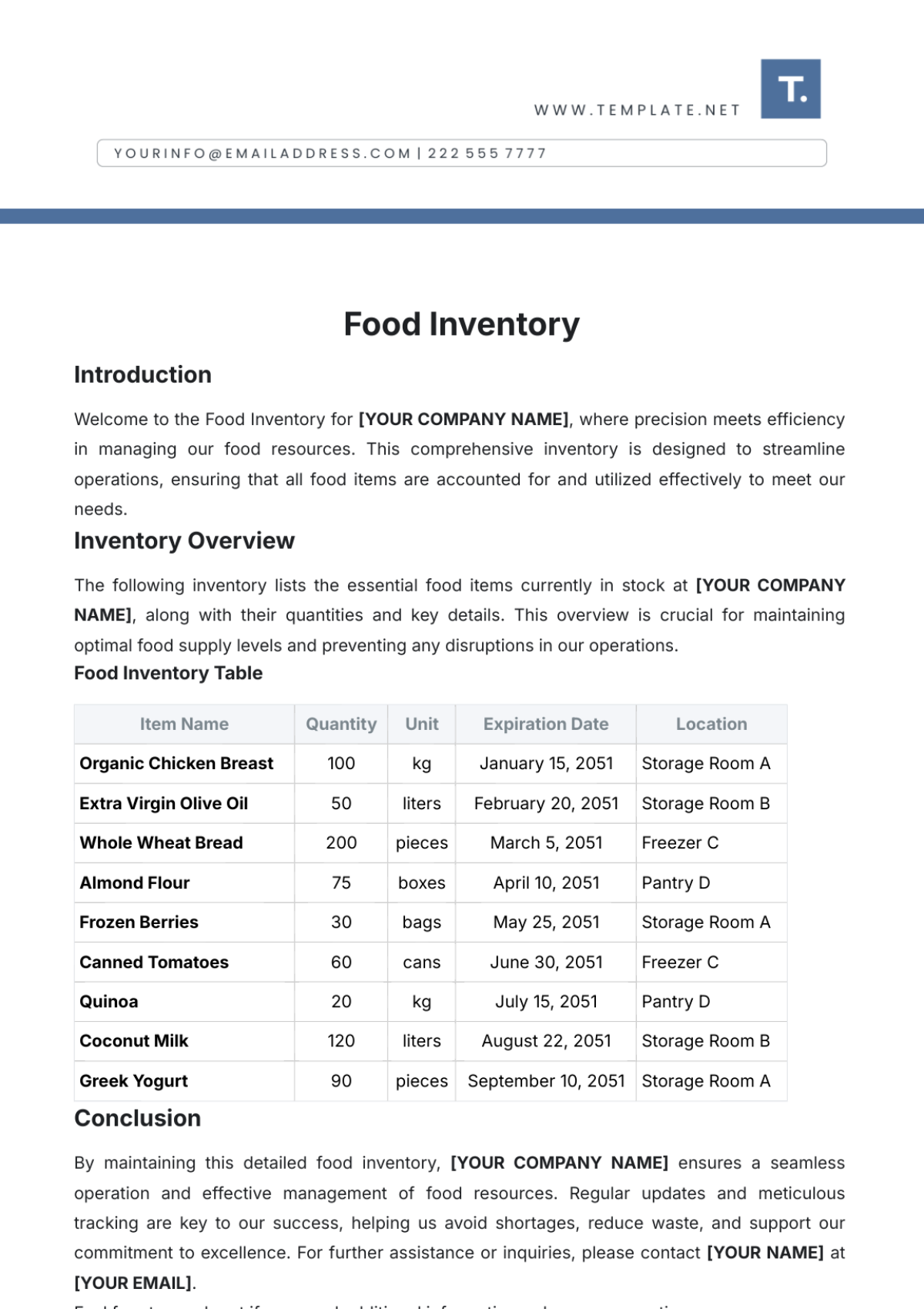

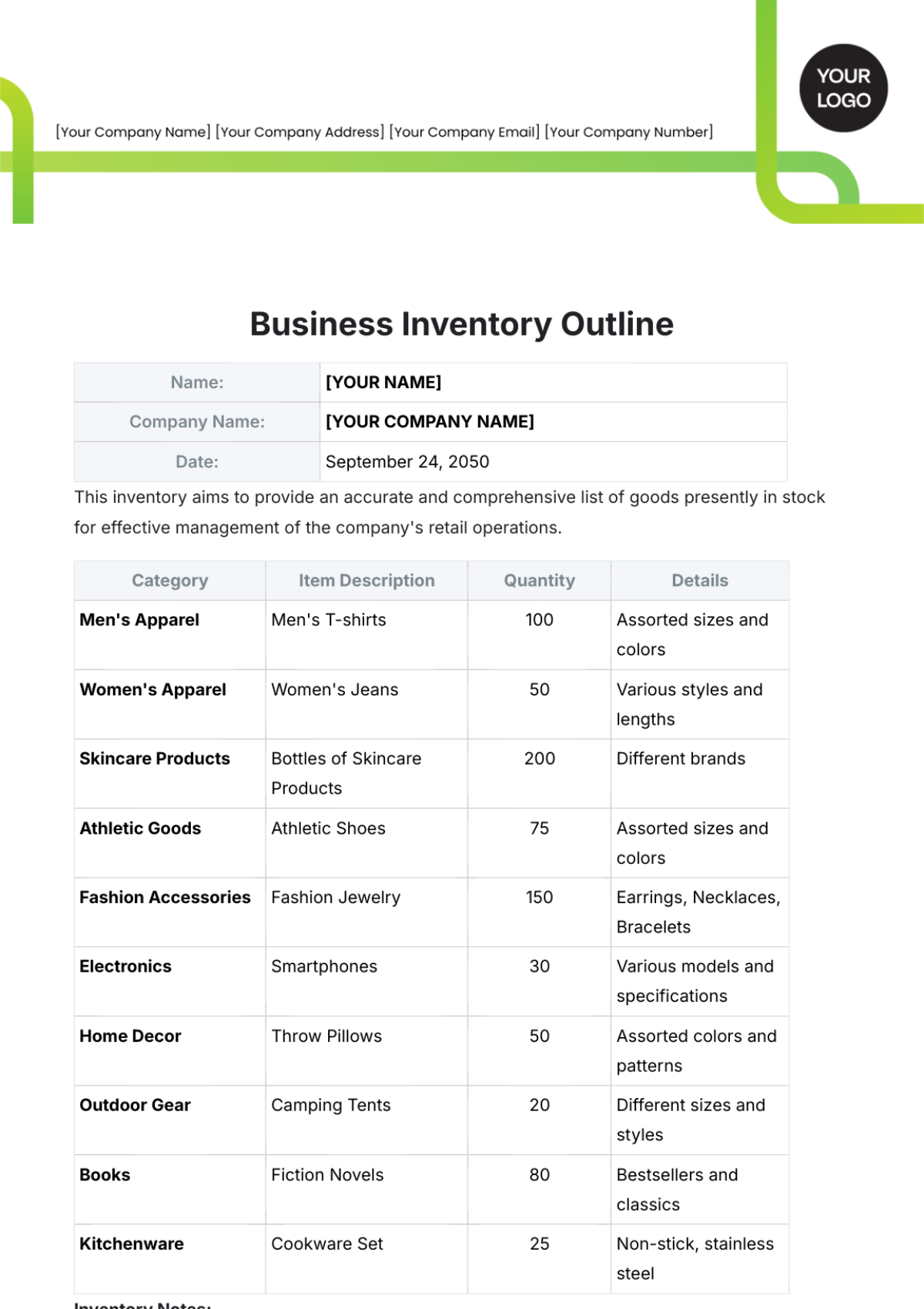

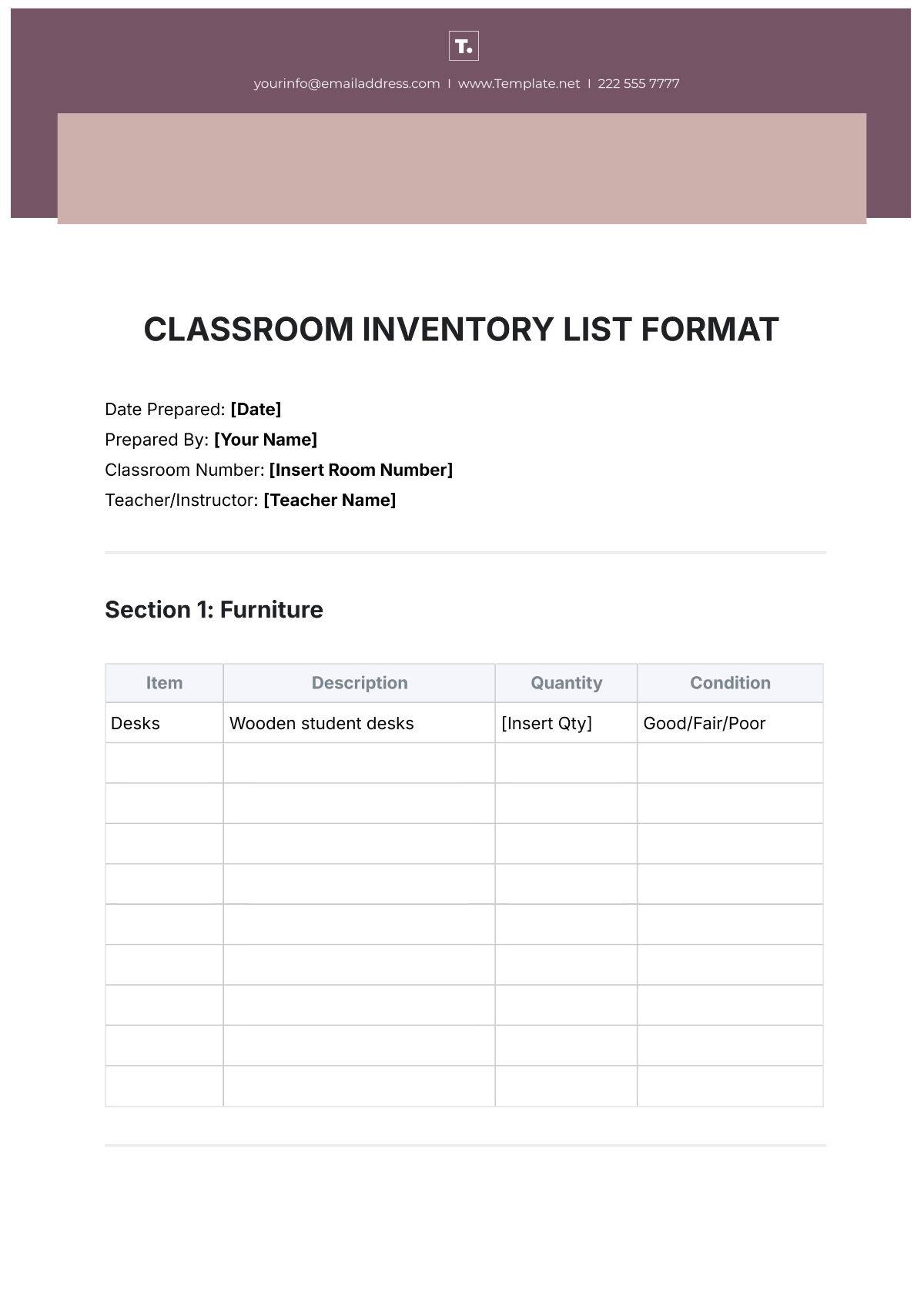

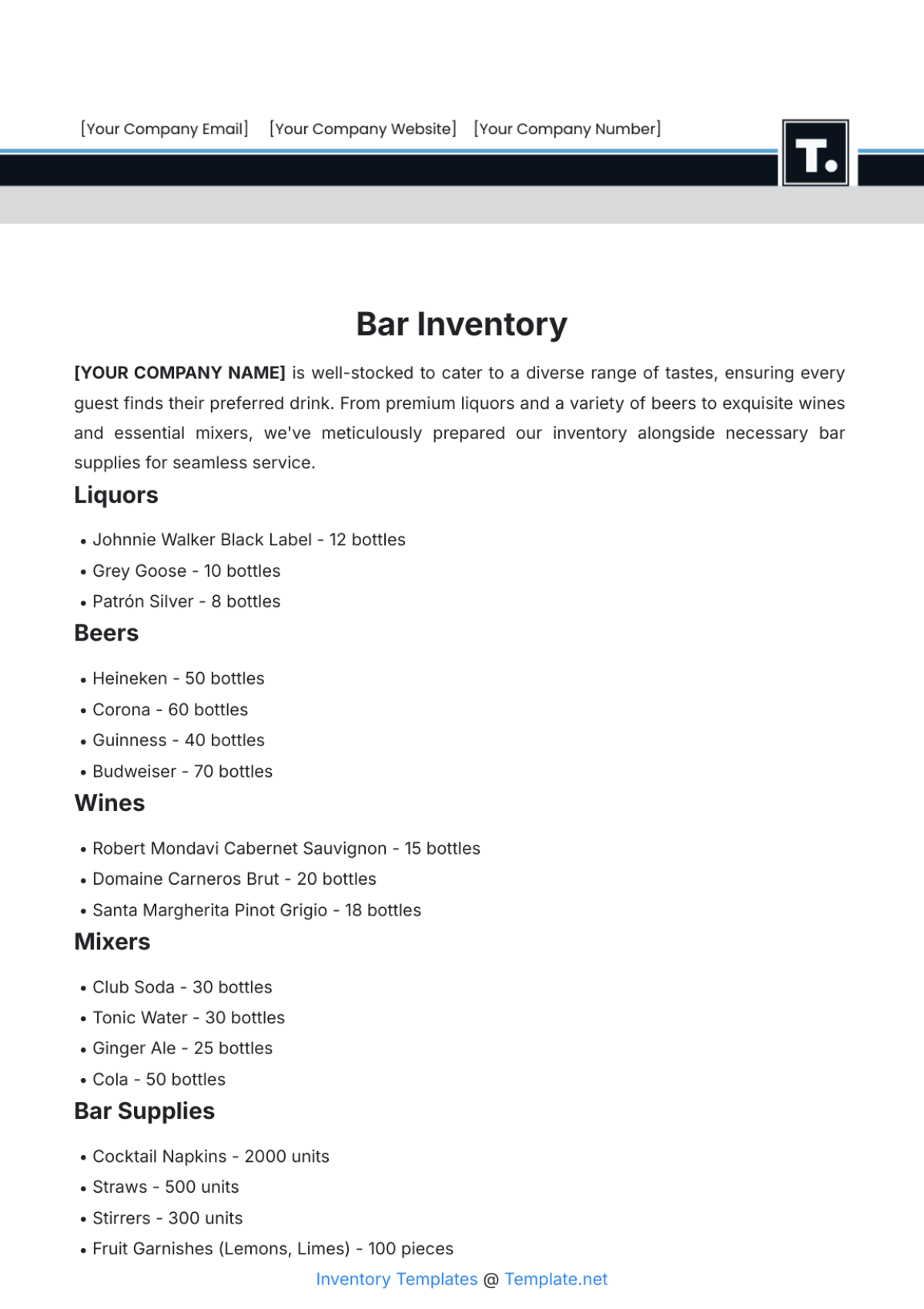

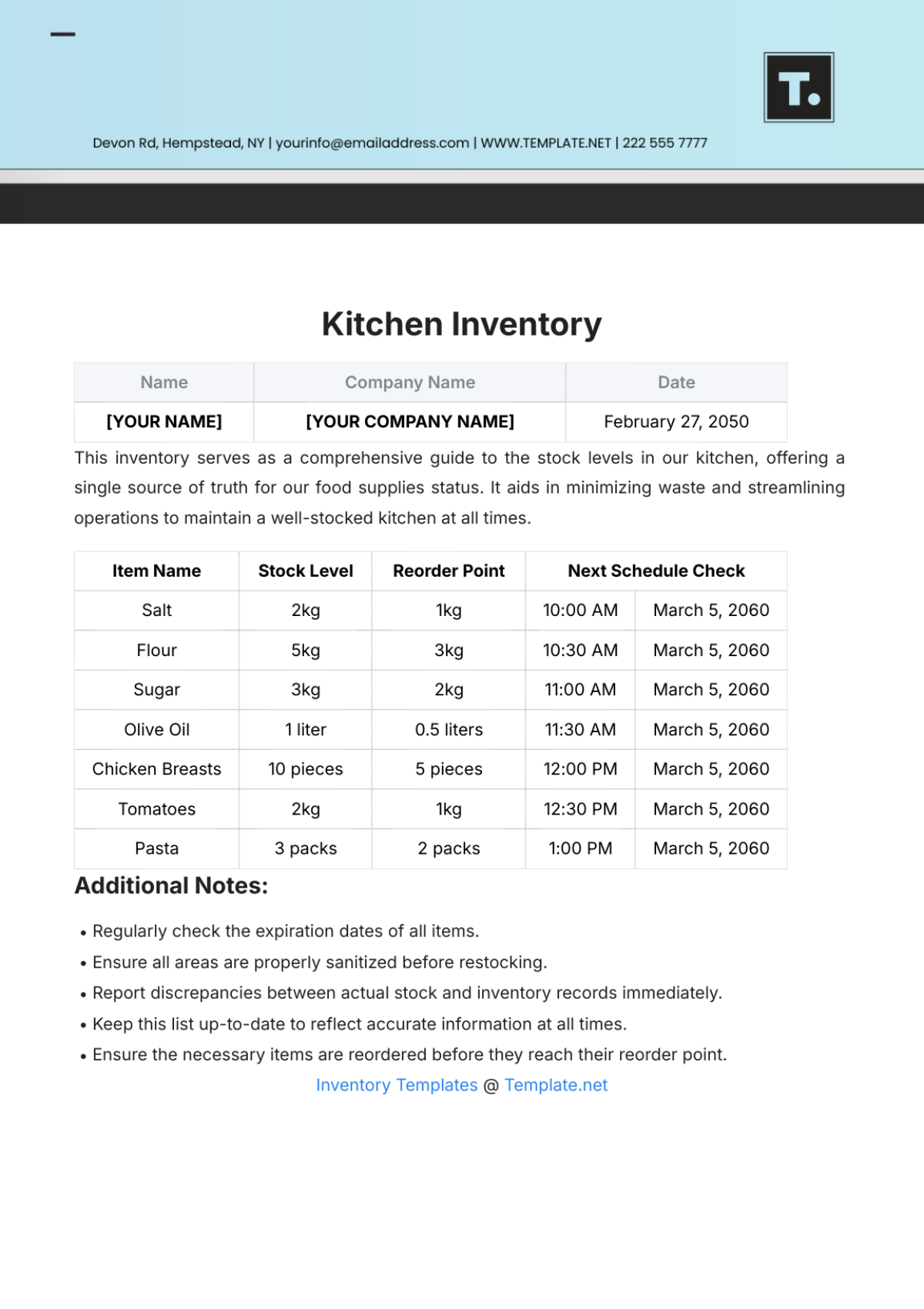

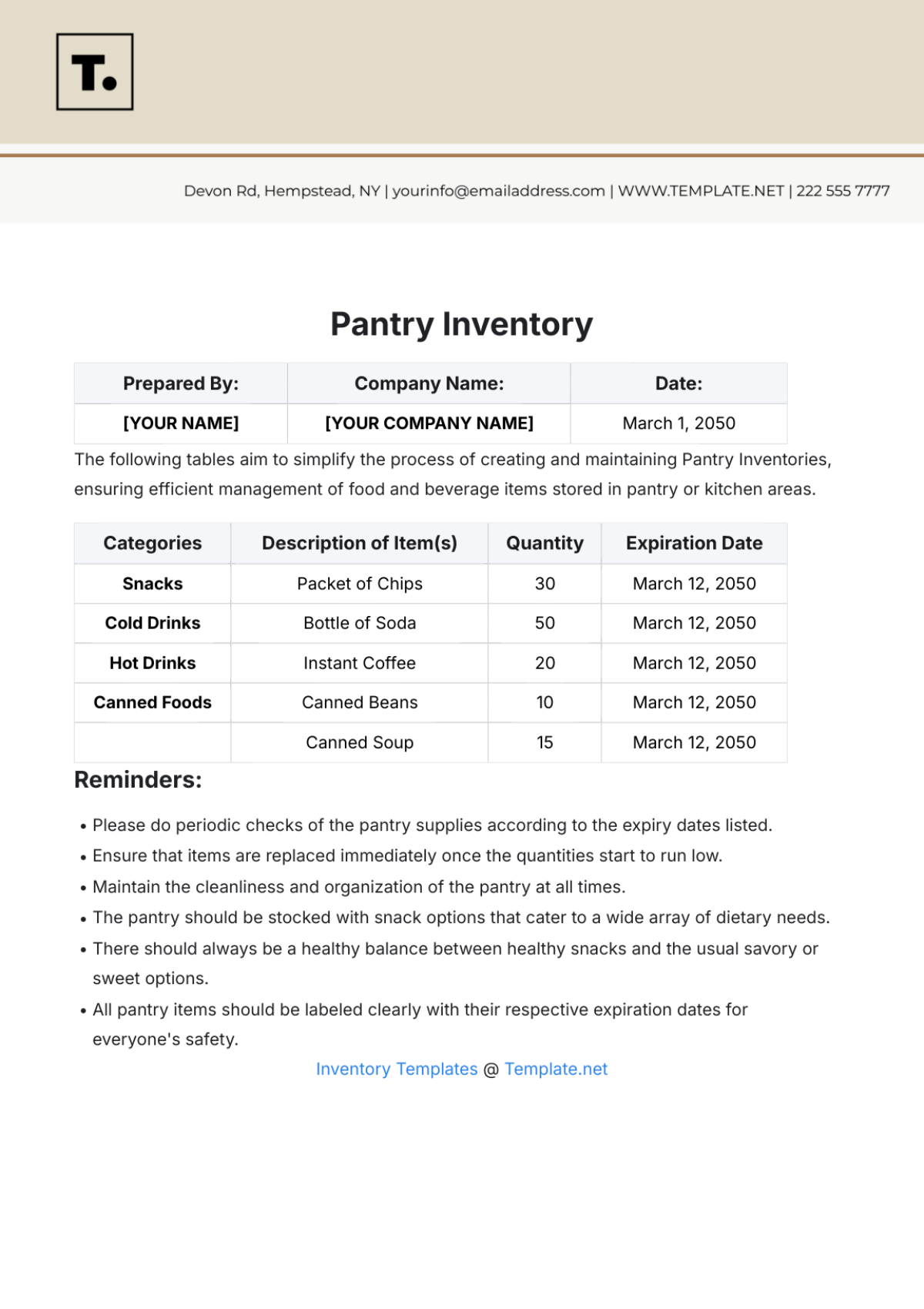

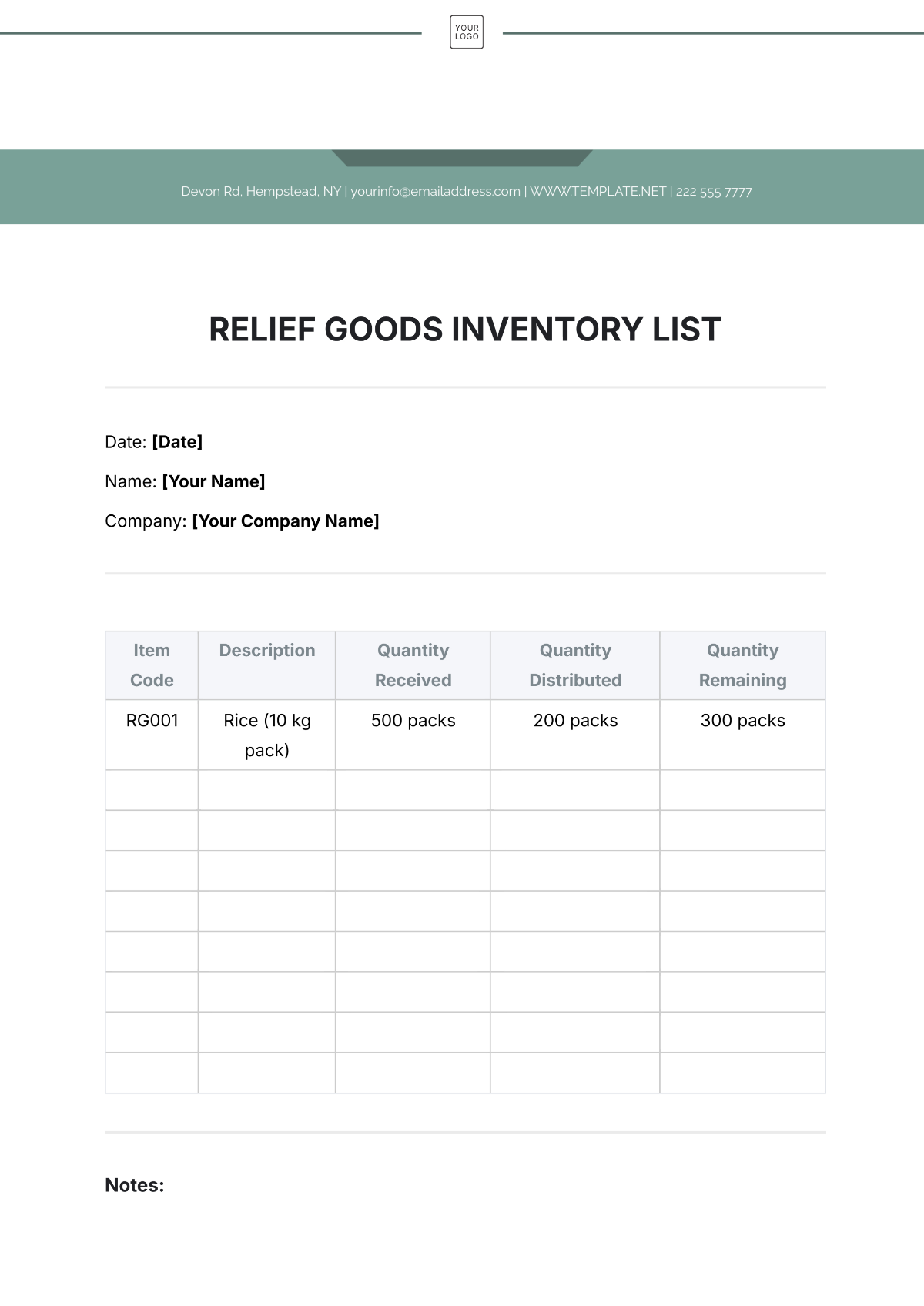

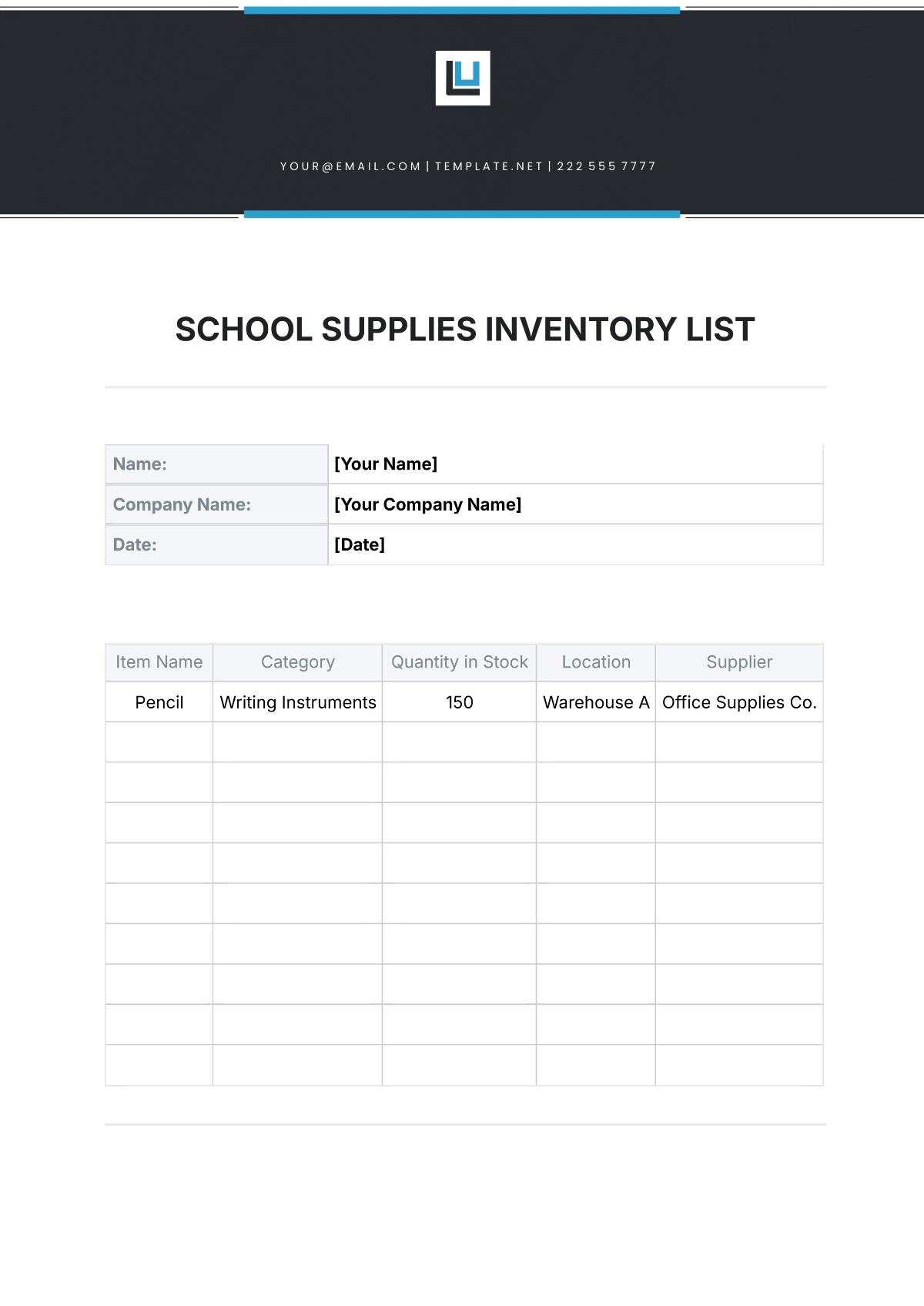

II. Inventory Overview

[Your Company Name] maintains a comprehensive and various range of architectural supplies to support both ongoing and upcoming projects. The inventory encompasses essential construction materials, drafting supplies, and advanced technological tools, ensuring that the firm is well-equipped to handle various project requirements efficiently.

Item Category | Total Stock | Unit Price | Total Value |

|---|---|---|---|

Construction Materials | 50,000 units | $10 per unit | $500,000 |

Drafting Supplies | 30,000 units | $2 per unit | $60,000 |

Technological Tools | 10,000 units | $50 per unit | $500,000 |

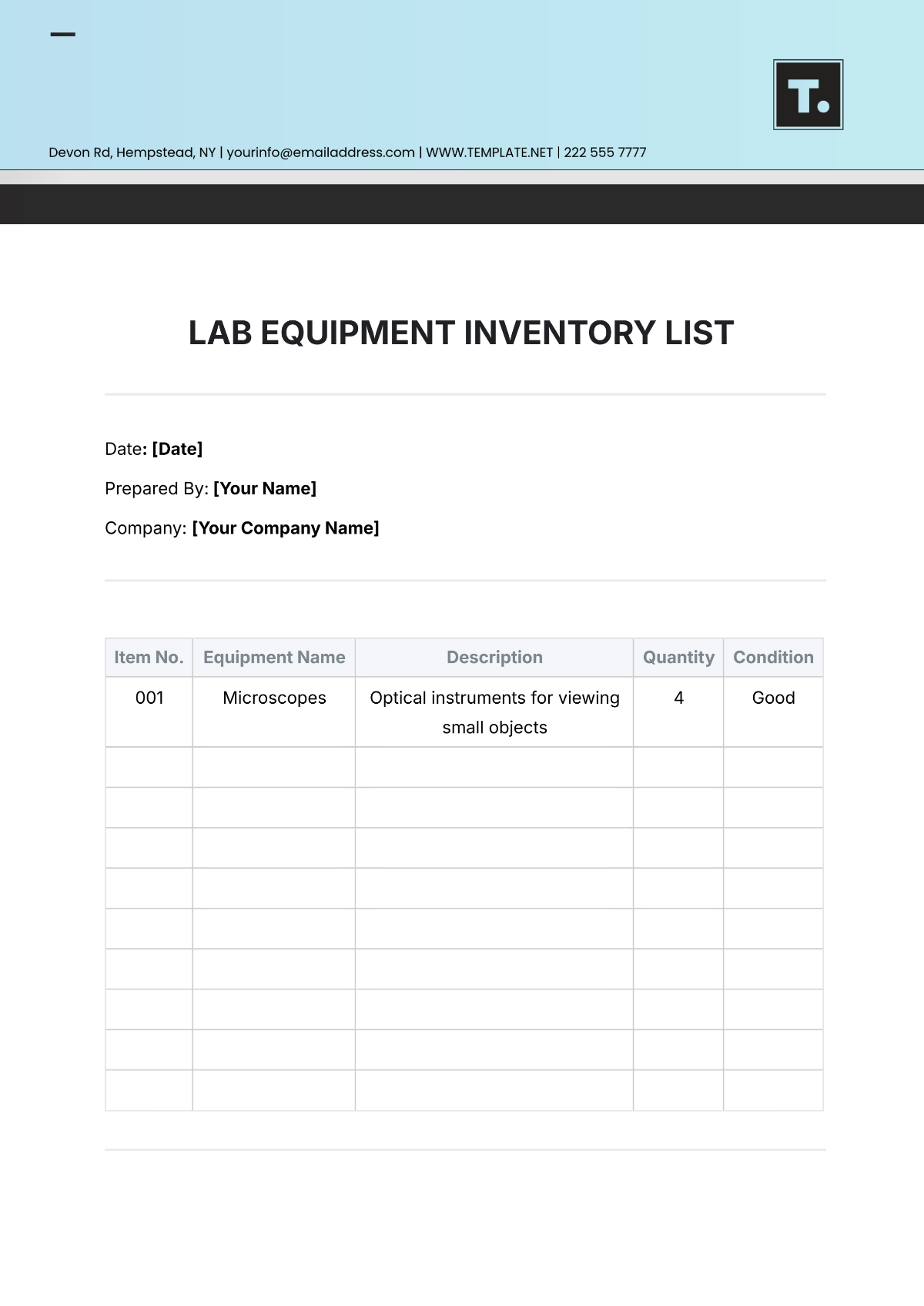

A. Inventory Breakdown

Construction Materials: The construction materials category includes items such as cement, steel, timber, and other essential building supplies. These materials are crucial for the foundational and structural aspects of architectural projects.

Drafting Supplies: This category comprises various tools and materials used in the design and drafting stages of projects. Items include paper, pencils, rulers, compasses, and other essential drafting instruments.

Technological Tools: Technological tools encompass advanced equipment such as computers, software licenses, 3D printers, and other digital tools that aid in design, simulation, and project management. These tools are integral for modern architectural practices, enabling precise and efficient project execution.

By maintaining a well-stocked inventory across these categories, [Your Company Name] ensures readiness and reliability in delivering high-quality architectural solutions.

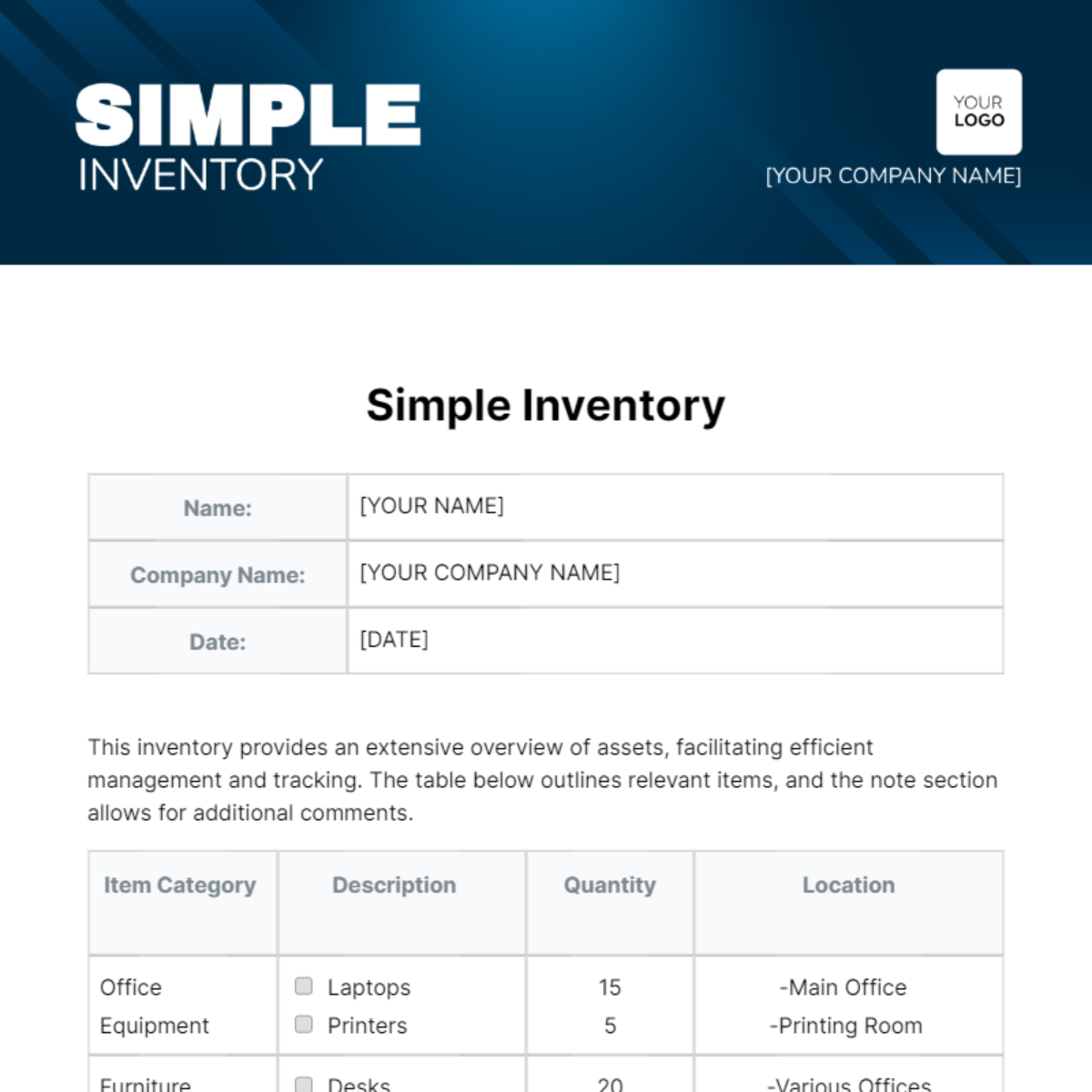

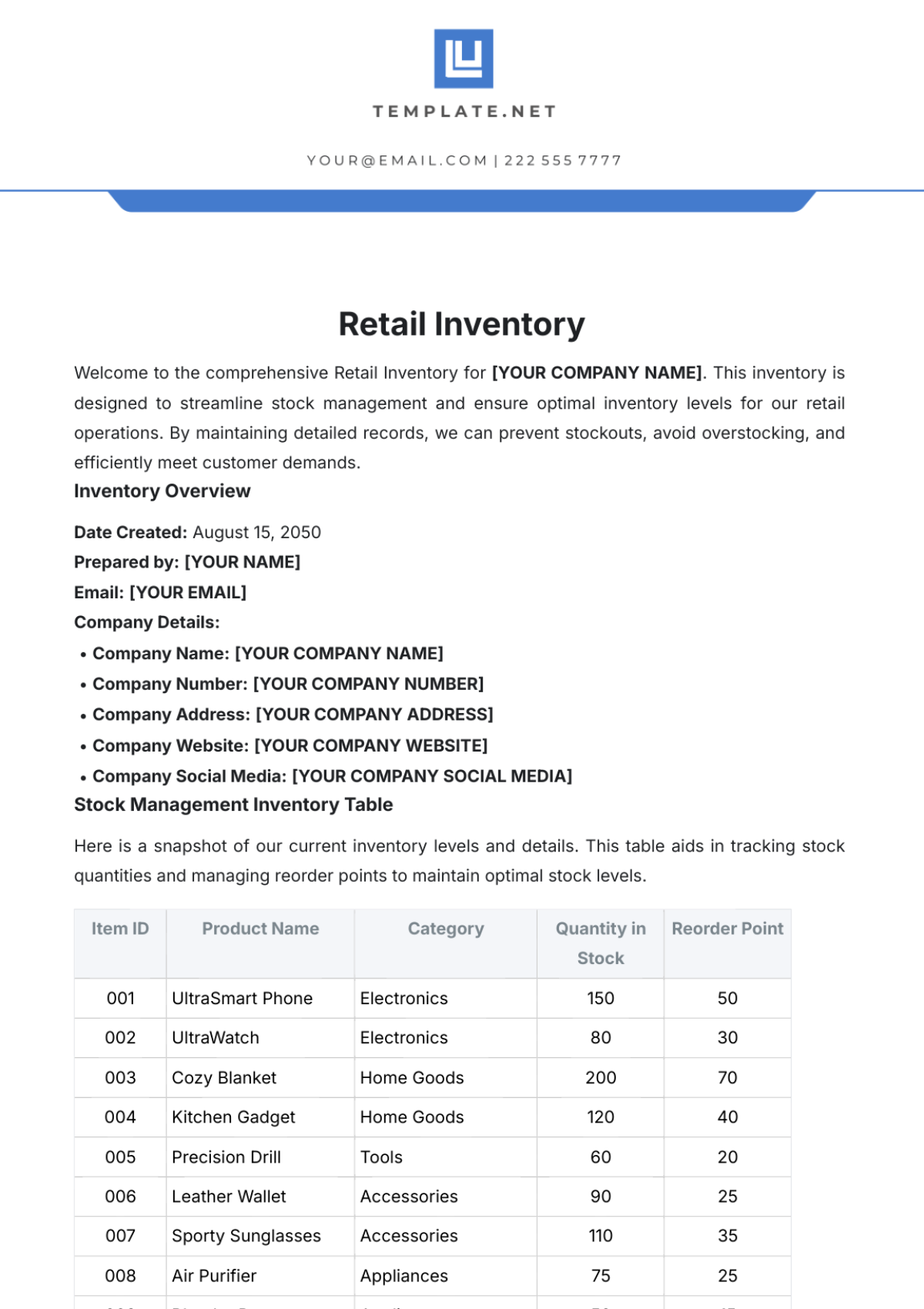

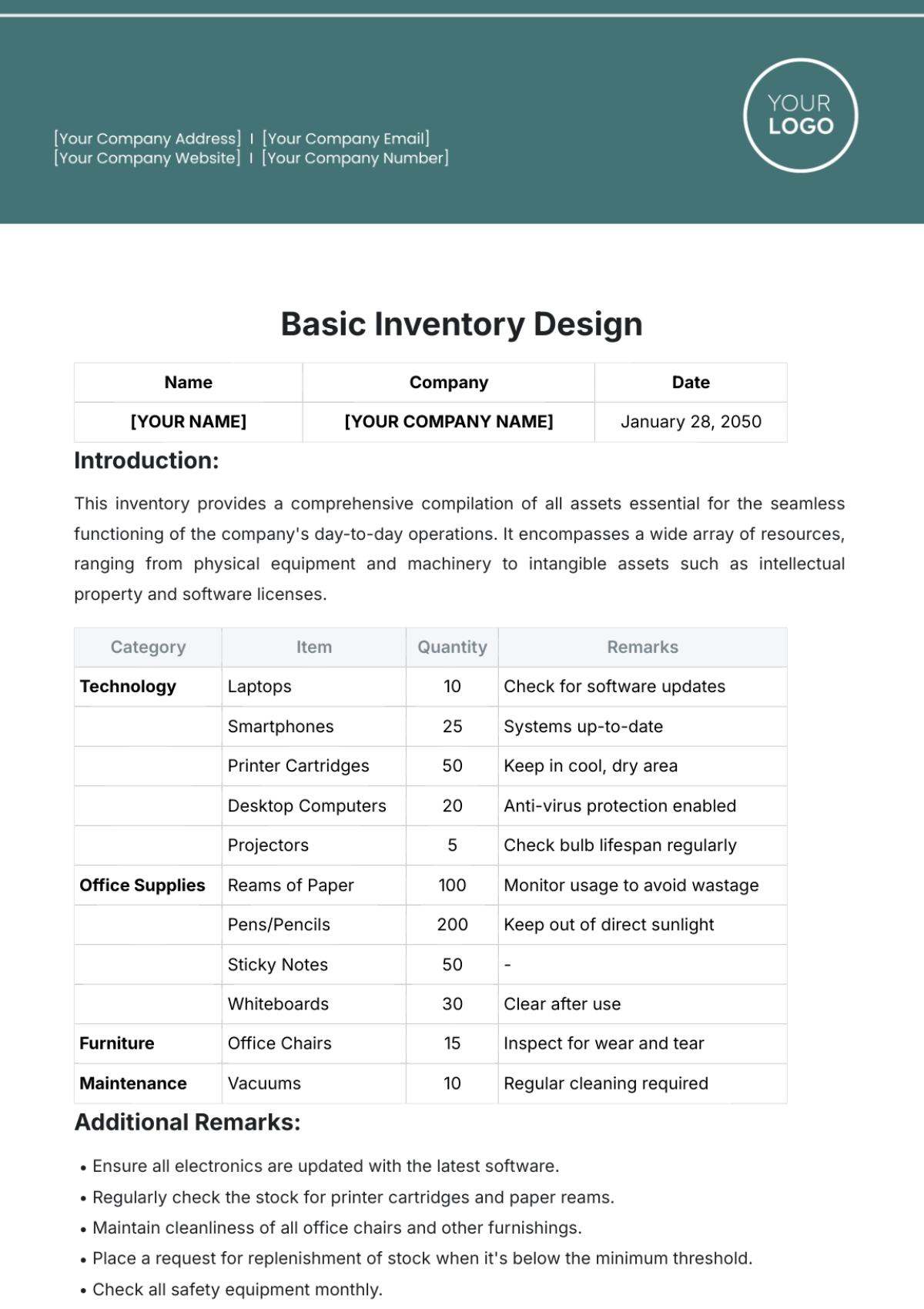

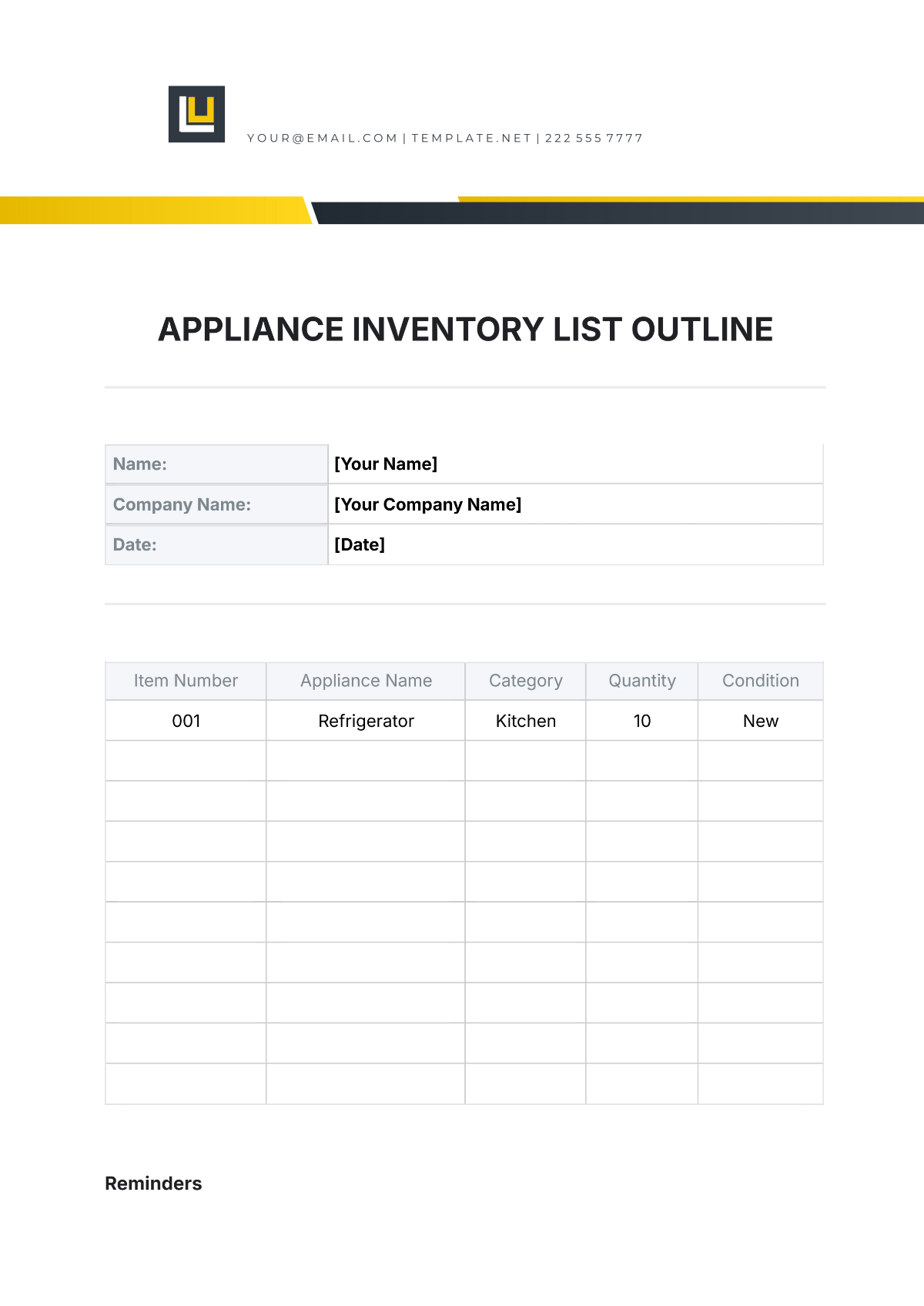

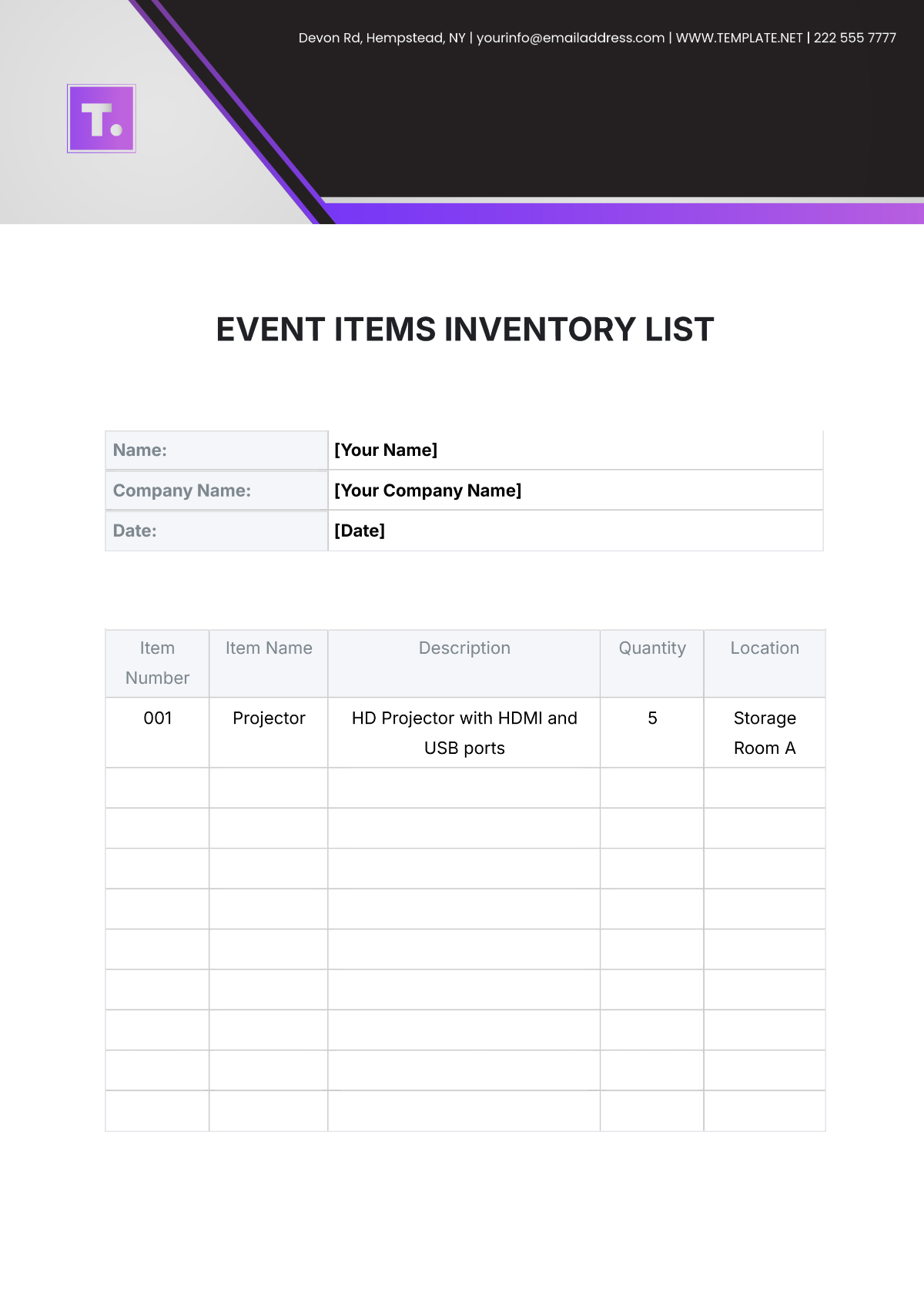

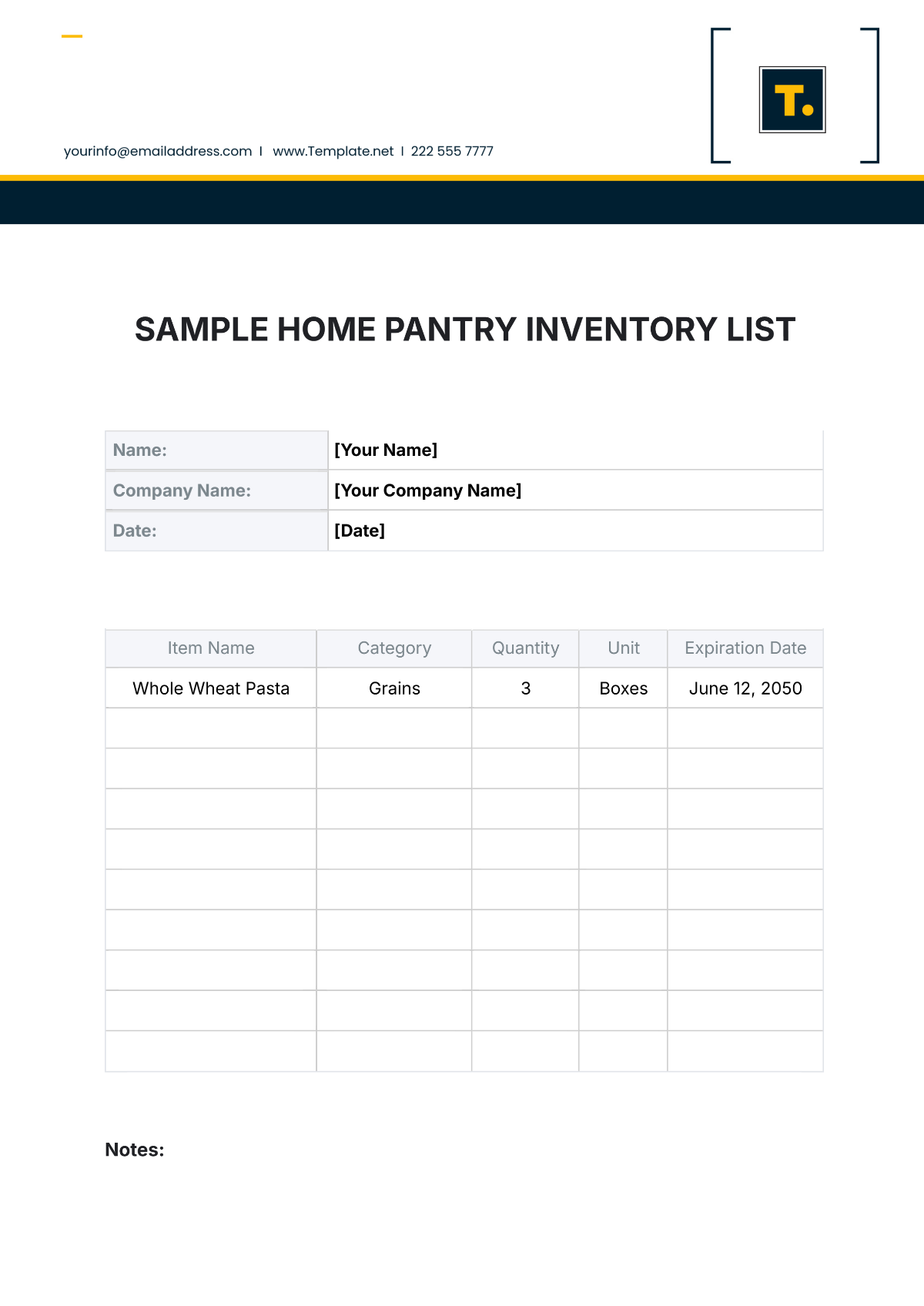

III. Monthly Inventory Levels

The table below details the monthly inventory levels for the year [2050], providing an overview of stock variations throughout the year. This data is crucial for understanding supply trends, managing procurement schedules, and ensuring that inventory levels meet project demands without overstocking or shortages.

Month | Construction Materials | Drafting Supplies | Technological Tools |

|---|---|---|---|

January | 45,000 units | 28,000 units | 9,500 units |

February | 47,500 units | 27,500 units | 9,800 units |

March | 50,000 units | 30,000 units | 10,000 units |

April | 48,000 units | 29,000 units | 9,700 units |

May | 46,500 units | 28,500 units | 9,900 units |

June | 49,000 units | 29,800 units | 9,850 units |

July | 50,000 units | 30,000 units | 10,000 units |

August | 48,500 units | 28,700 units | 9,600 units |

September | 47,000 units | 27,900 units | 9,700 units |

October | 46,000 units | 27,500 units | 9,850 units |

November | 48,000 units | 29,000 units | 9,950 units |

December | 50,000 units | 30,000 units | 10,000 units |

A. Analysis of Monthly Inventory Levels

Construction Materials: Inventory levels fluctuate between [45,000] and [50,000 units], reflecting periodic replenishments and usage. The peak levels are typically in [March, July, and December], aligning with project timelines and construction phases.

Drafting Supplies: Stock levels range from [27,500 to 30,000 units], indicating consistent usage and restocking practices. Notable increases occur in [March and July], suggesting heightened design activity during these months.

Technological Tools: Inventory remains relatively stable, with minor fluctuations between [9,500 and 10,000 units]. This stability is essential for maintaining continuous technological support across various projects.

By closely monitoring these monthly inventory levels, [Your Company Name] can optimize resource allocation, improve project planning, and ensure timely procurement of necessary supplies. This proactive approach helps maintain operational efficiency and project continuity throughout the year.

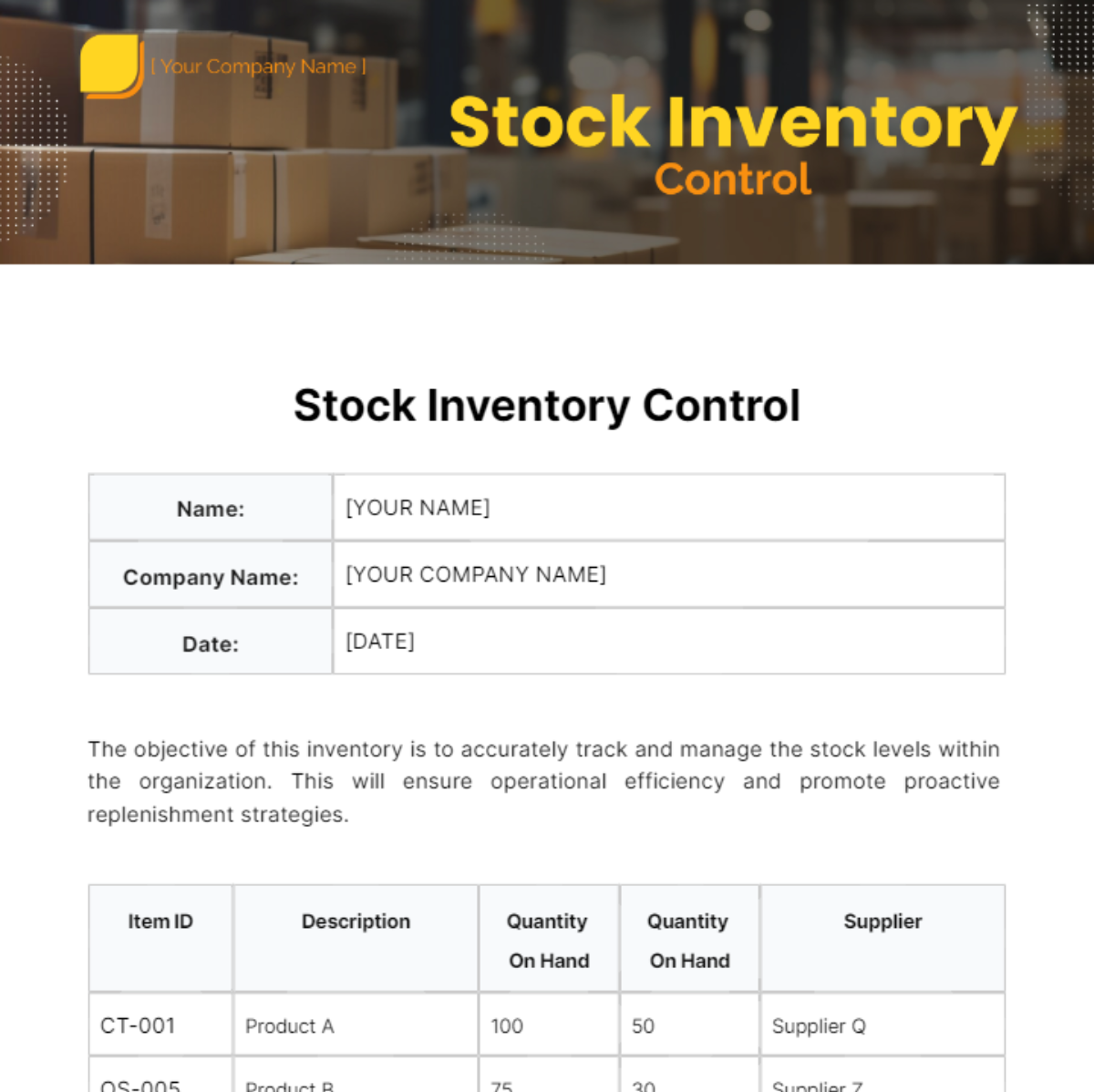

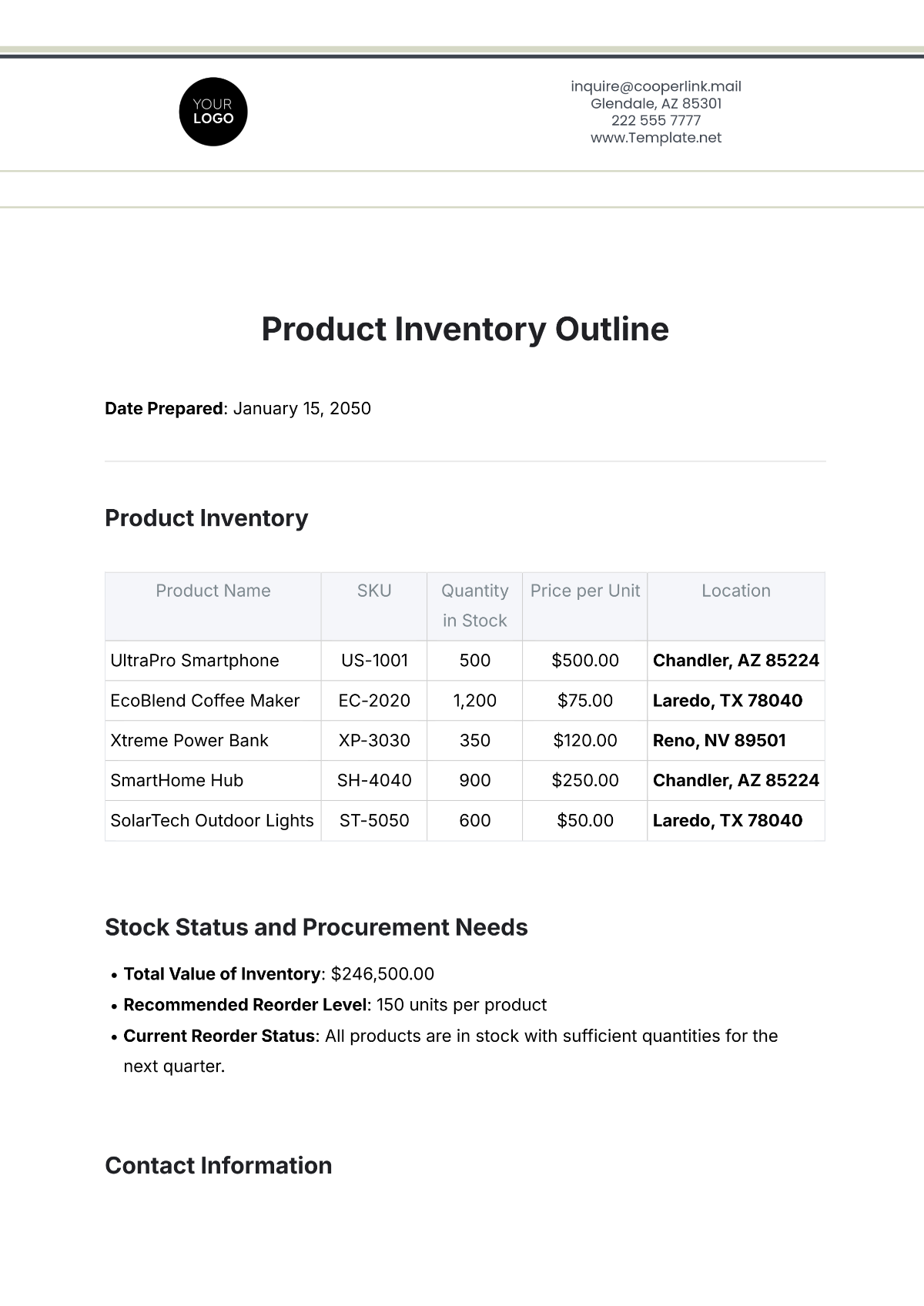

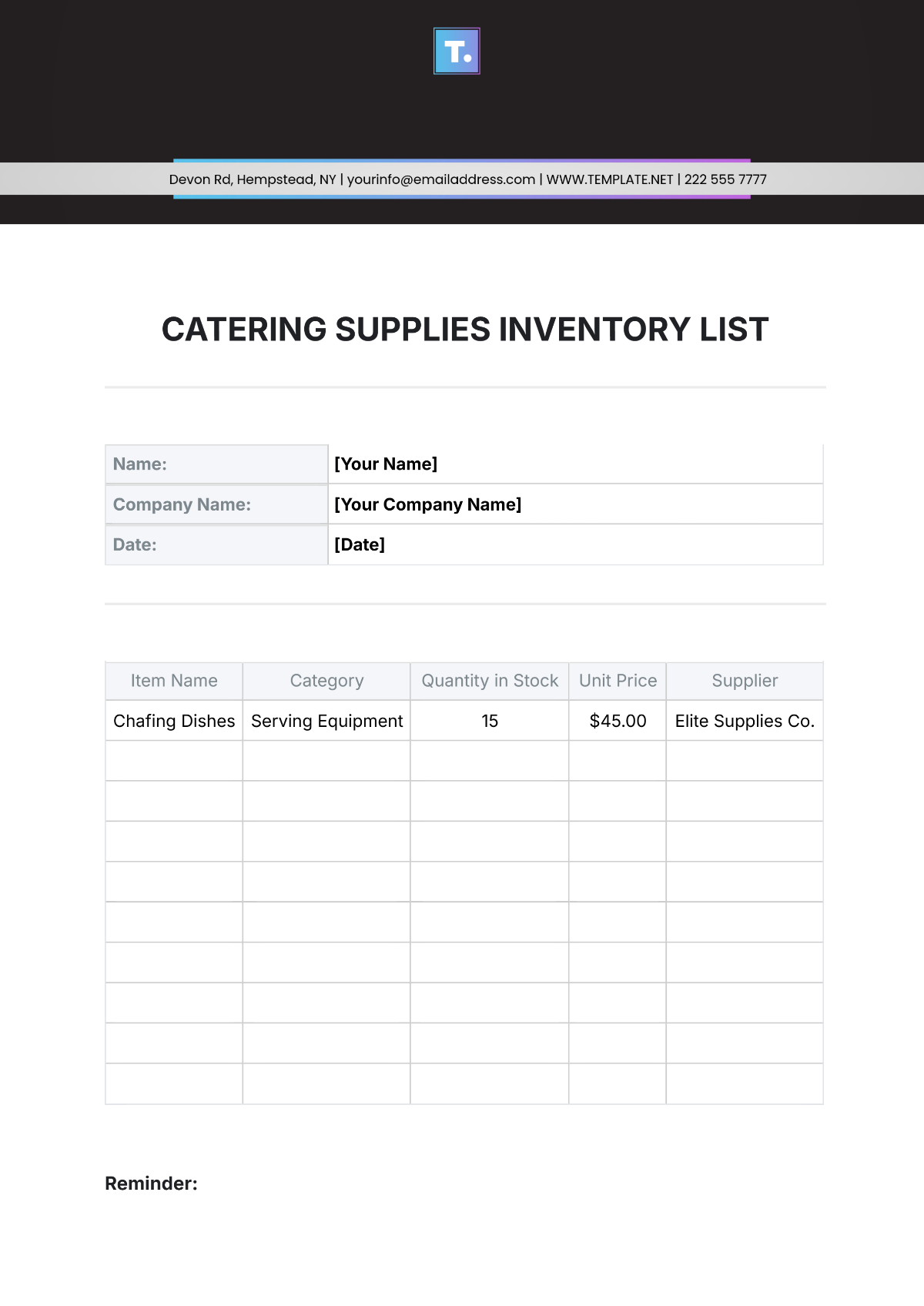

IV. Usage Analysis

A comprehensive analysis of inventory usage patterns offers valuable insights into consumption trends and future needs. The following key points summarize the findings:

Construction Materials:

High Initial Usage: The usage of construction materials was significantly higher in the initial months of the year. This increase was due to the commencement of several major projects, which required substantial amounts of materials for foundational and structural work.

Stabilization: After the initial surge, the usage levels stabilized, reflecting the progression of these projects into less material-intensive phases.

Drafting Supplies:

Consistent Usage: Drafting supplies exhibited a steady usage pattern throughout the year. This consistency indicates ongoing design and planning activities that are crucial at all stages of project development.

Predictable Demand: The steady consumption suggests a predictable demand, making it easier to maintain optimal stock levels without significant fluctuations.

Technological Tools:

Stable Demand: The technological tools category showed minimal fluctuations in usage. This stability underscores the continuous and essential need for digital and technological support across all projects.

Long-term Investment: The stable demand highlights the importance of long-term investment in technological tools to support ongoing and future projects.

General Trends:

Peak and Trough Patterns: Usage patterns typically exhibit peaks and troughs corresponding to project phases. Initial phases tend to consume more materials, while later stages require fewer resources.

Impact of Major Projects: The initiation of major projects has a pronounced impact on inventory usage, necessitating careful planning and monitoring to ensure timely replenishment.

By understanding these usage trends, [Your Company Name] can better forecast future needs, optimize inventory levels, and ensure efficient resource allocation throughout the year.

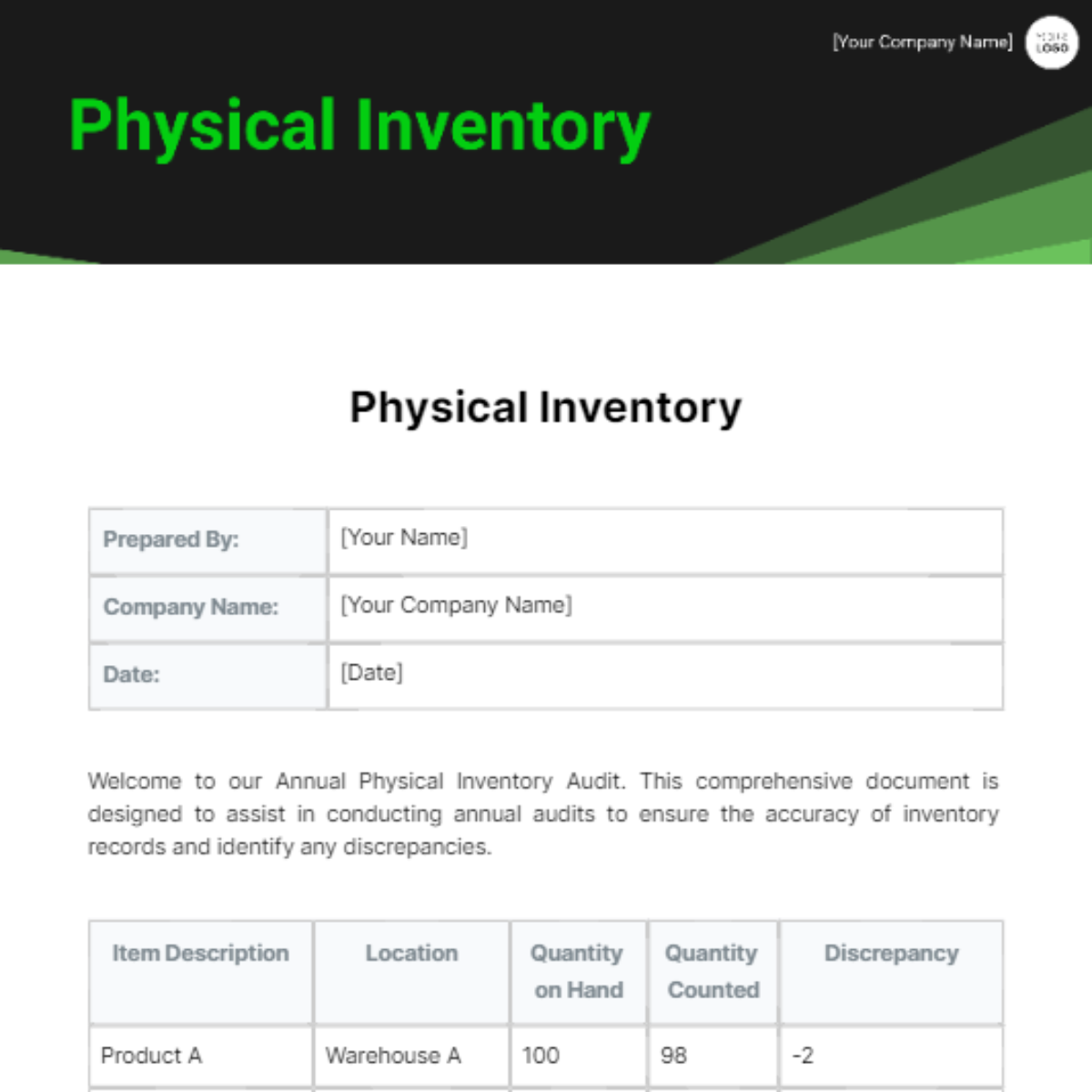

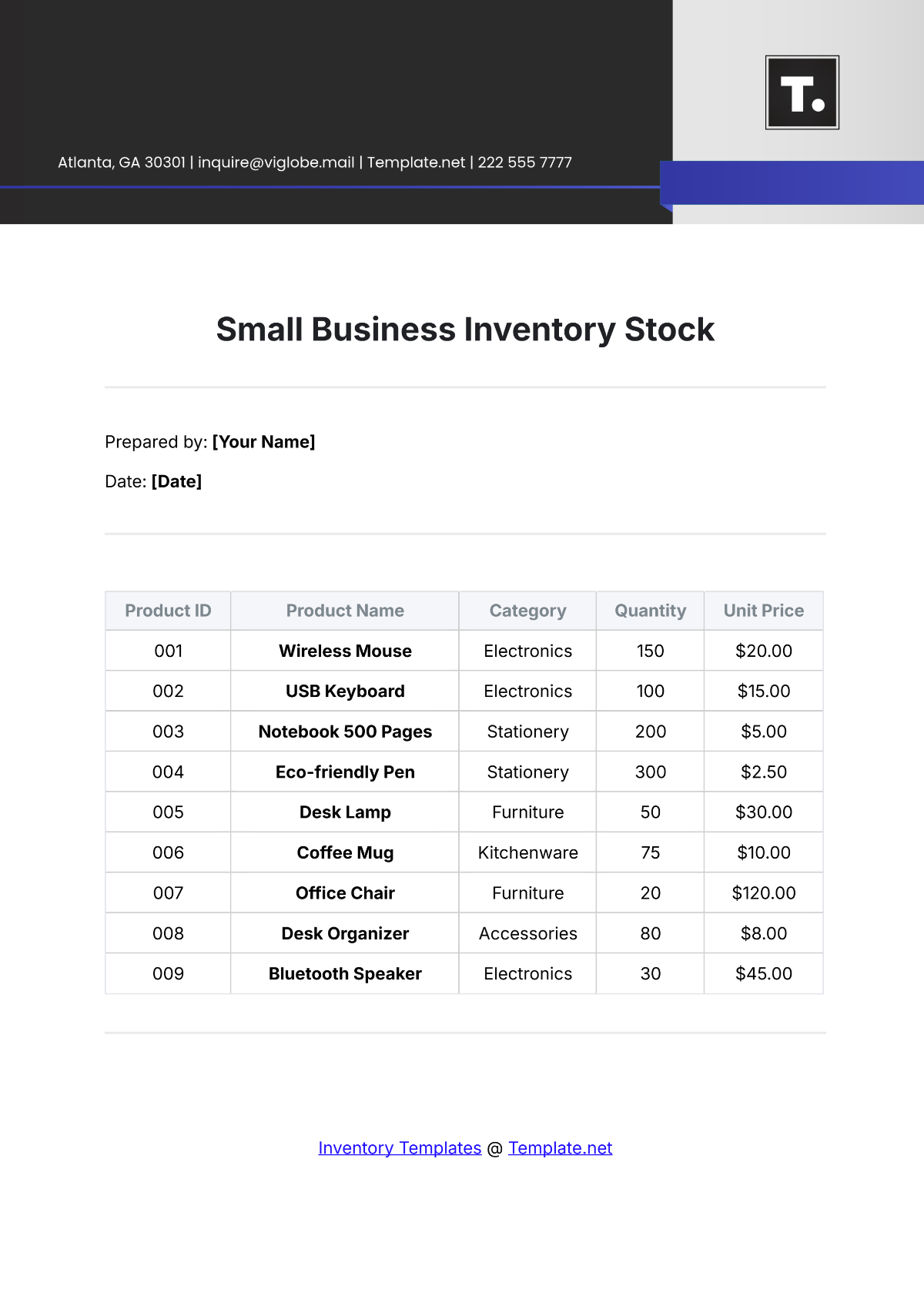

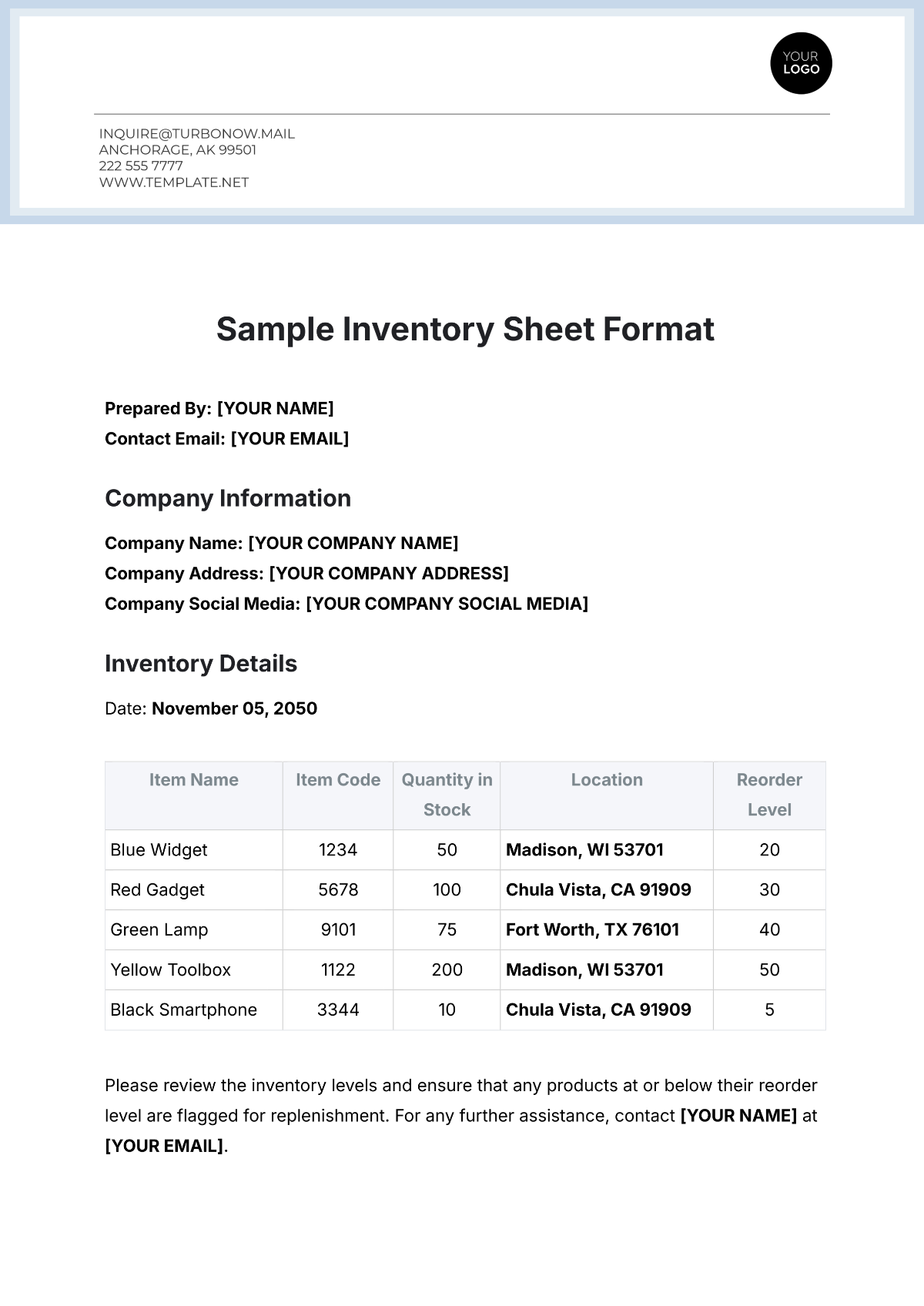

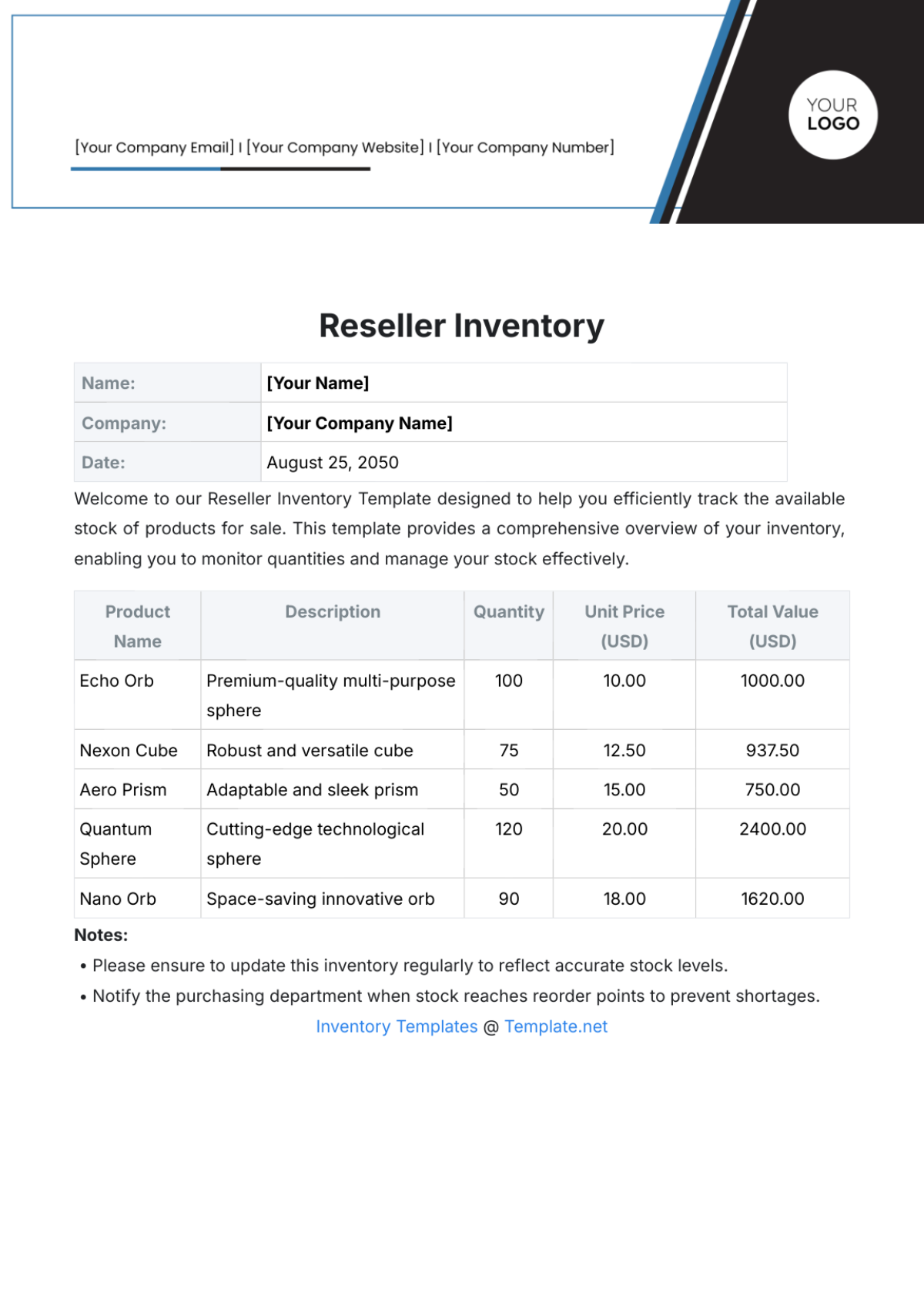

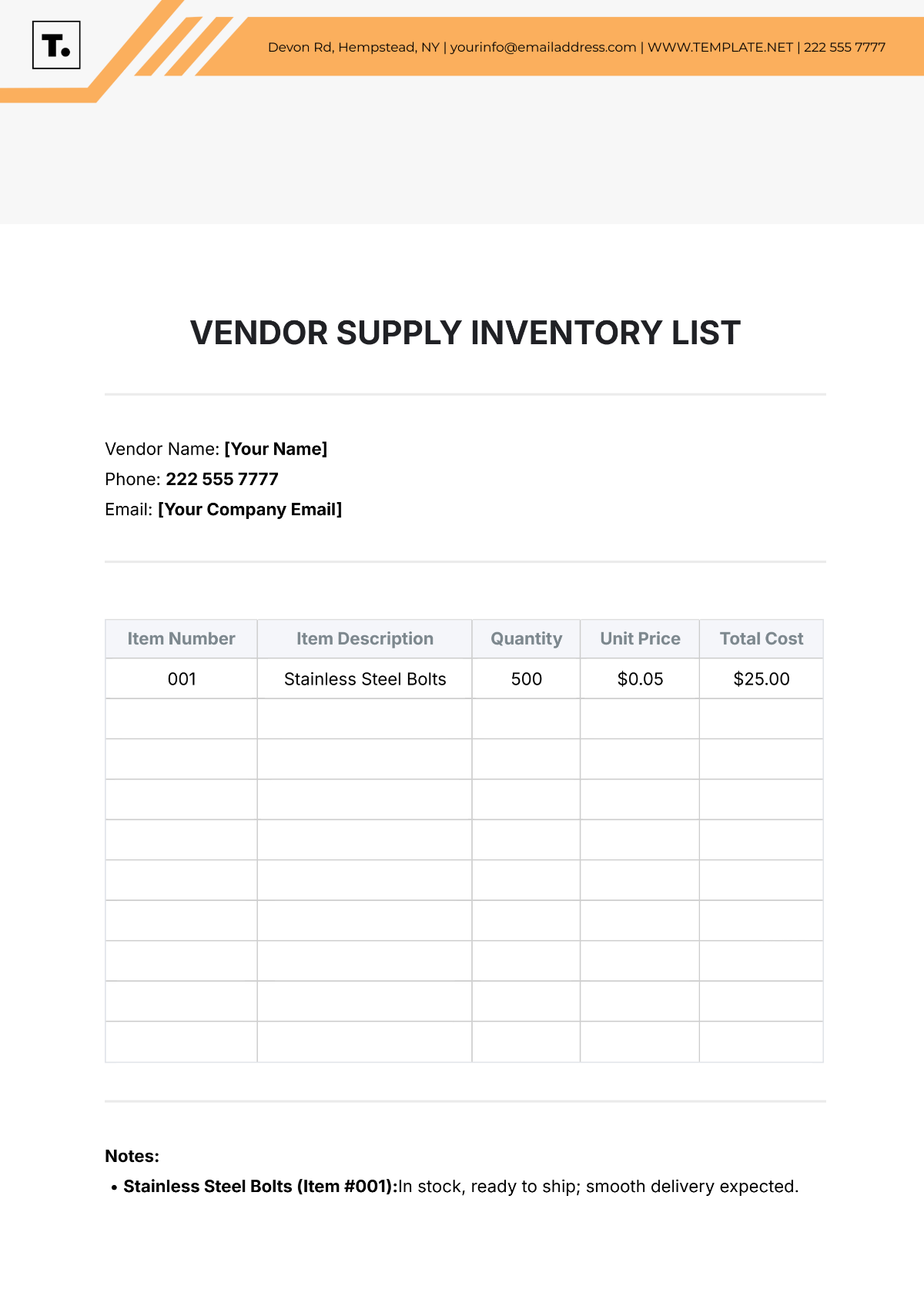

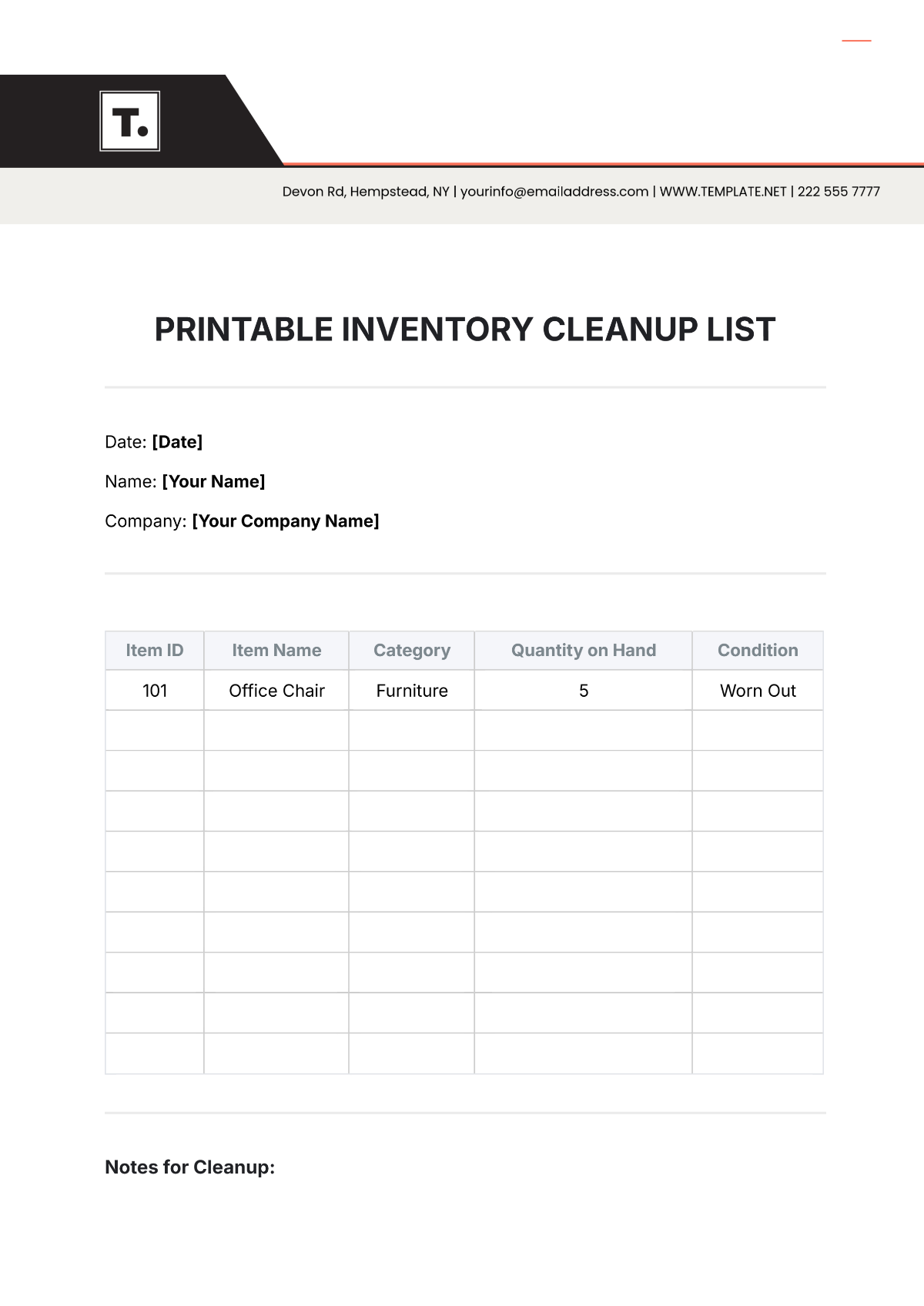

V. Stock Value

At the end of the fiscal year [2050], the total value of [Your Company Name]'s inventory stood at [$1,060,000]. This valuation is a comprehensive consolidation of the three main inventory categories, reflecting the firm’s diverse range of architectural supplies.

Item Category | Total Value |

|---|---|

Construction Materials | $500,000 |

Drafting Supplies | $60,000 |

Technological Tools | $500,000 |

A. Construction Materials

High Investment: The substantial investment in construction materials underscores their importance in the firm's operations.

Project Readiness: Ensures a continuous supply for large-scale and high-demand projects, preventing delays due to material shortages.

Versatility: Covers a wide range of materials essential for different stages of construction, from foundational work to finishing touches.

B. Drafting Supplies

Steady Demand: Reflects the consistent need for drafting supplies throughout the year.

Critical Role: Essential for the design and planning stages, supporting architects and designers in creating detailed project plans.

Cost Management: Represents a relatively small portion of the total inventory value, indicating efficient cost management for these supplies.

C. Technological Tools

Advanced Equipment: Significant investment in high-value items such as computers, software licenses, and 3D printers.

Innovation and Efficiency: Supports modern architectural practices by enhancing project management, design precision, and overall efficiency.

Long-term Utility: Ensures that the firm remains at the forefront of technological advancements, providing long-term benefits and improved project outcomes.

The total inventory value of [$1,060,000] demonstrates [Your Company Name]'s commitment to maintaining a well-rounded and adequately stocked inventory, ensuring readiness and flexibility to meet the diverse needs of various projects.

VI. Recommendations

Based on the detailed inventory analysis, the following recommendations are proposed to optimize inventory management and operational efficiency:

Frequent Monitoring of High-Demand Items: Enhance the frequency of monitoring for high-demand items such as construction materials. This proactive approach will help in identifying any potential shortages early and enable timely restocking to avoid project delays.

Optimization of Low-Demand Stock Levels: Review and optimize the stock levels of low-demand items, particularly in the drafting supplies category. This adjustment will help reduce holding costs and free up capital for other operational needs.

Investment in Technology: Invest in advanced inventory management systems and forecasting tools. Implementing such technology will improve accuracy in tracking inventory levels, predict future demand more effectively, and streamline the procurement process.

VII. Conclusion

This inventory report for [Your Company Name] highlights key areas of focus in inventory management. By continually monitoring and optimizing inventory levels, the company can improve operational efficiency and reduce costs, ensuring a robust supply chain that supports its architectural projects.