Spa Inventory Report

I. Executive Summary

This Spa Inventory Report provides a comprehensive analysis of the current inventory status at [Your Company Name]. The purpose of this report is to ensure optimal inventory levels, improve inventory management processes, and identify areas where cost savings can be achieved. The key findings reveal areas for improvement in stock control, inventory turnover rates, and cost efficiency. By implementing the recommendations provided, [Your Company Name] can enhance its inventory management practices, reduce costs, and maintain a high level of service for its customers.

II. Inventory Overview

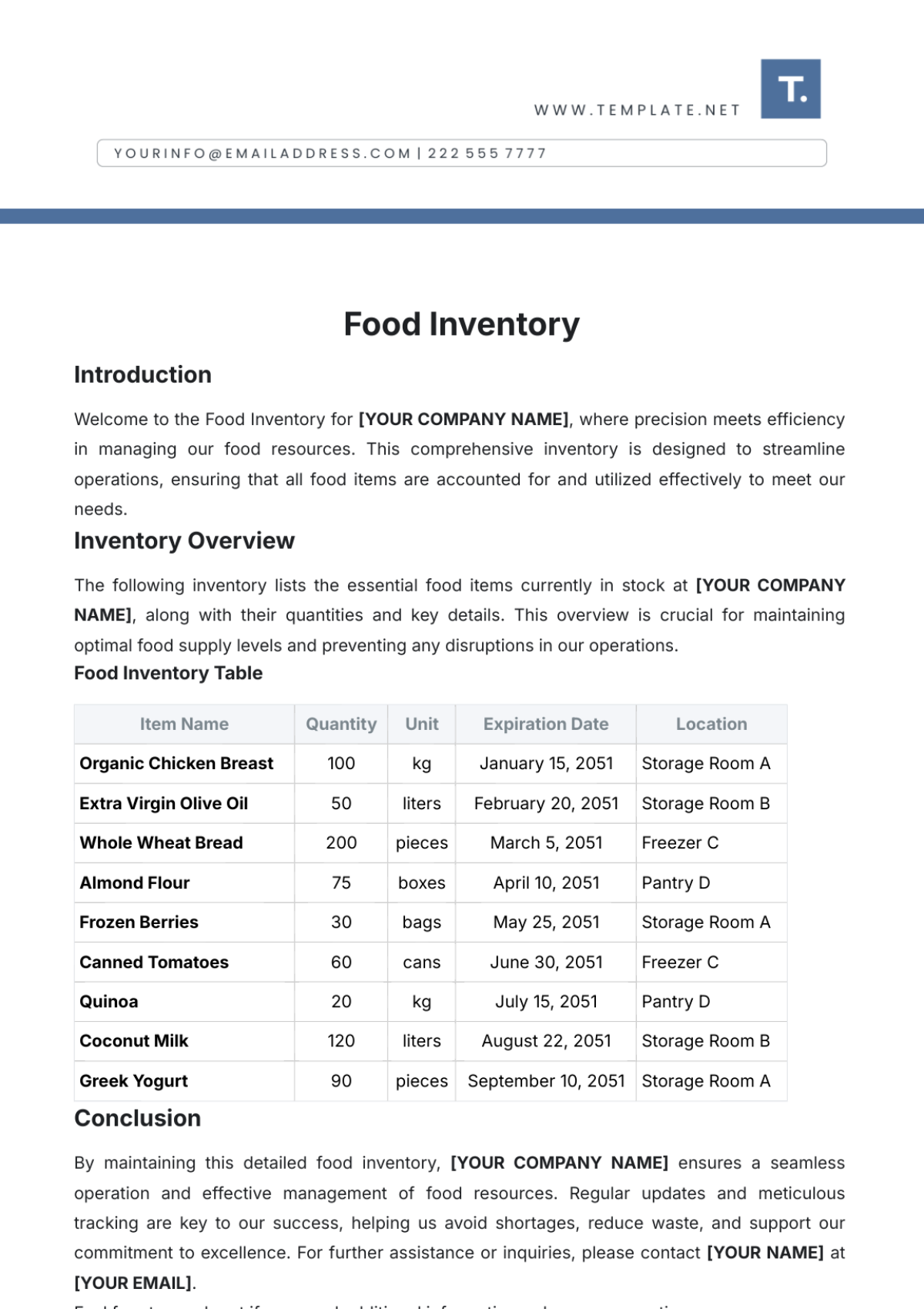

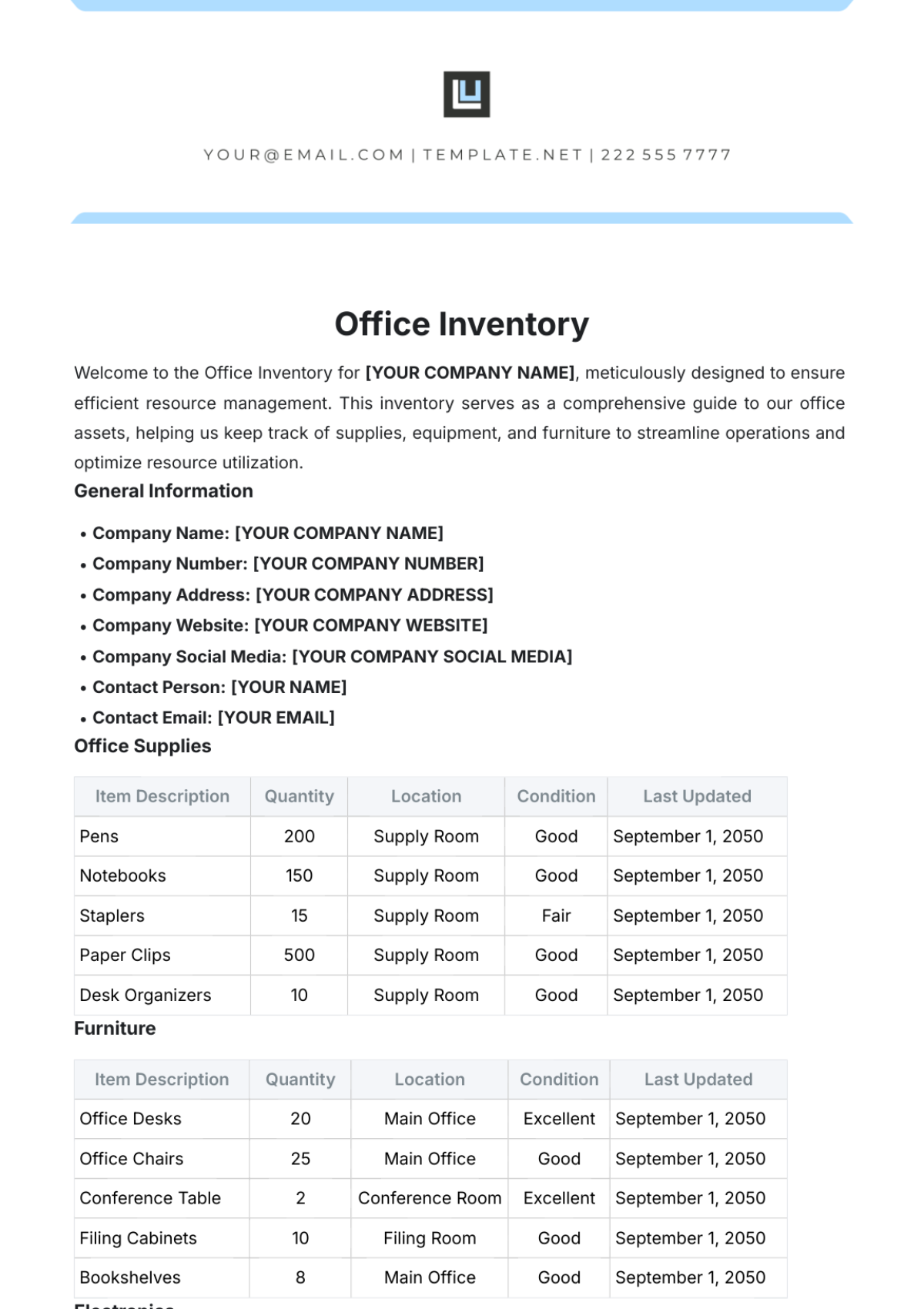

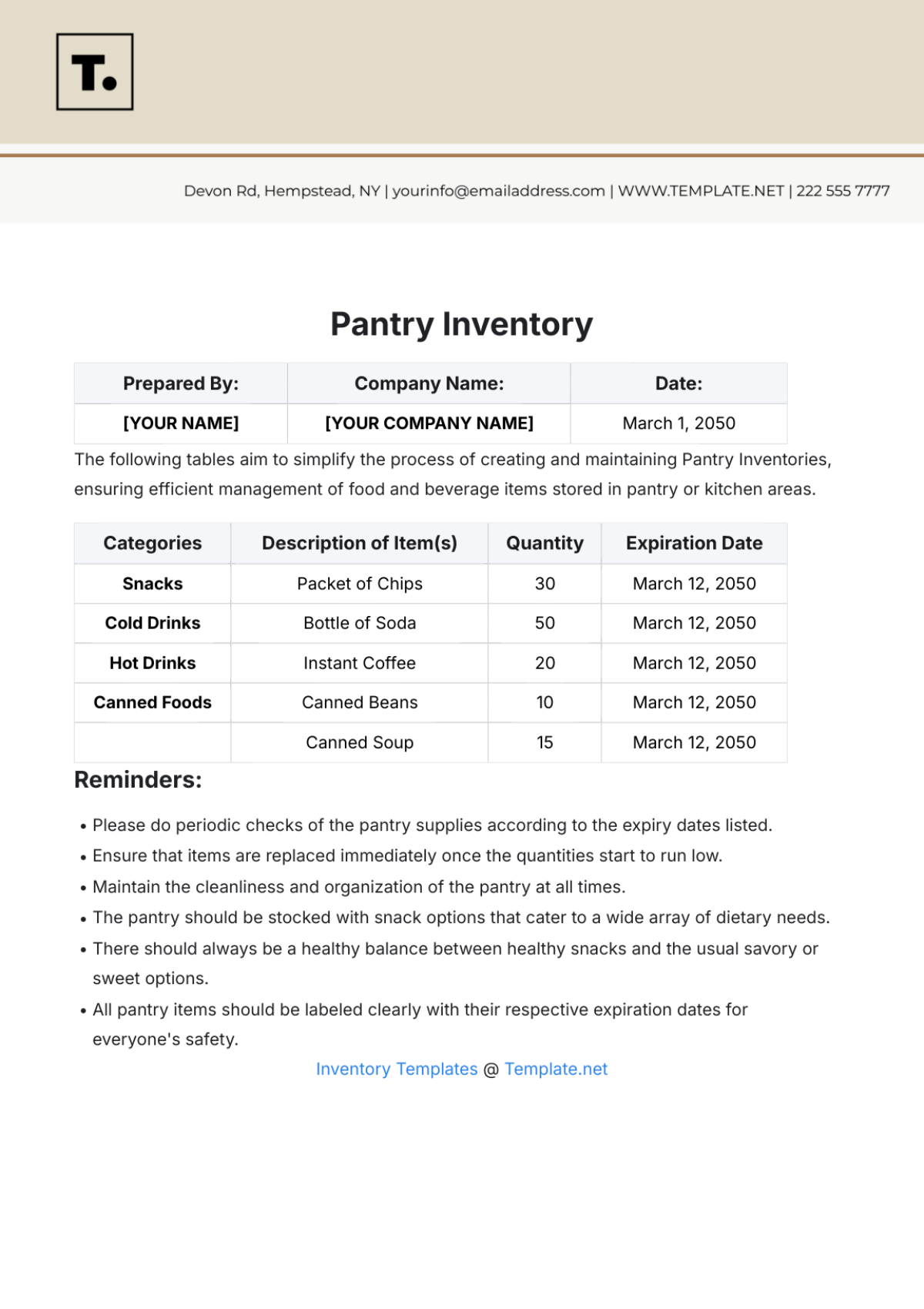

A. Current Inventory Levels

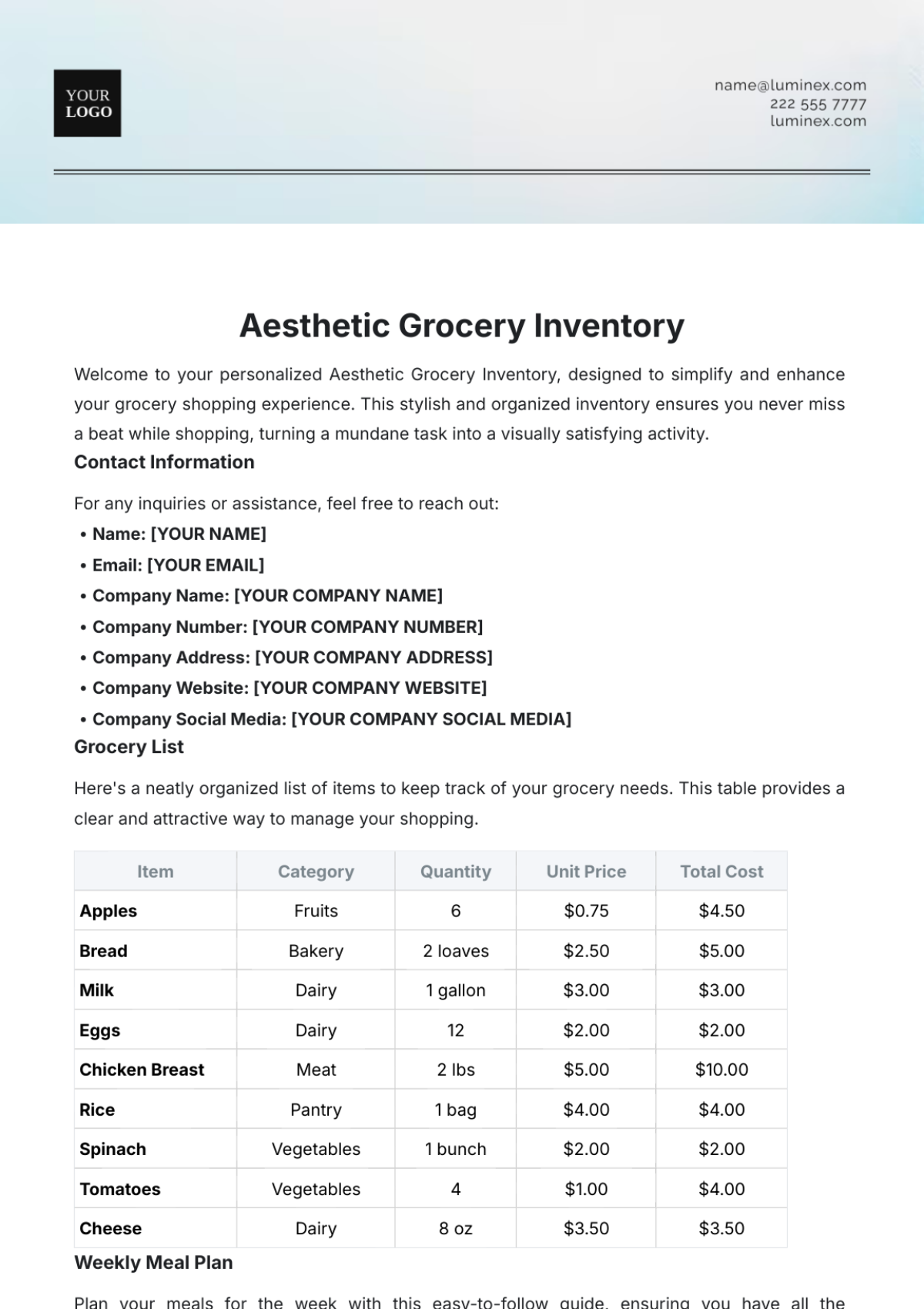

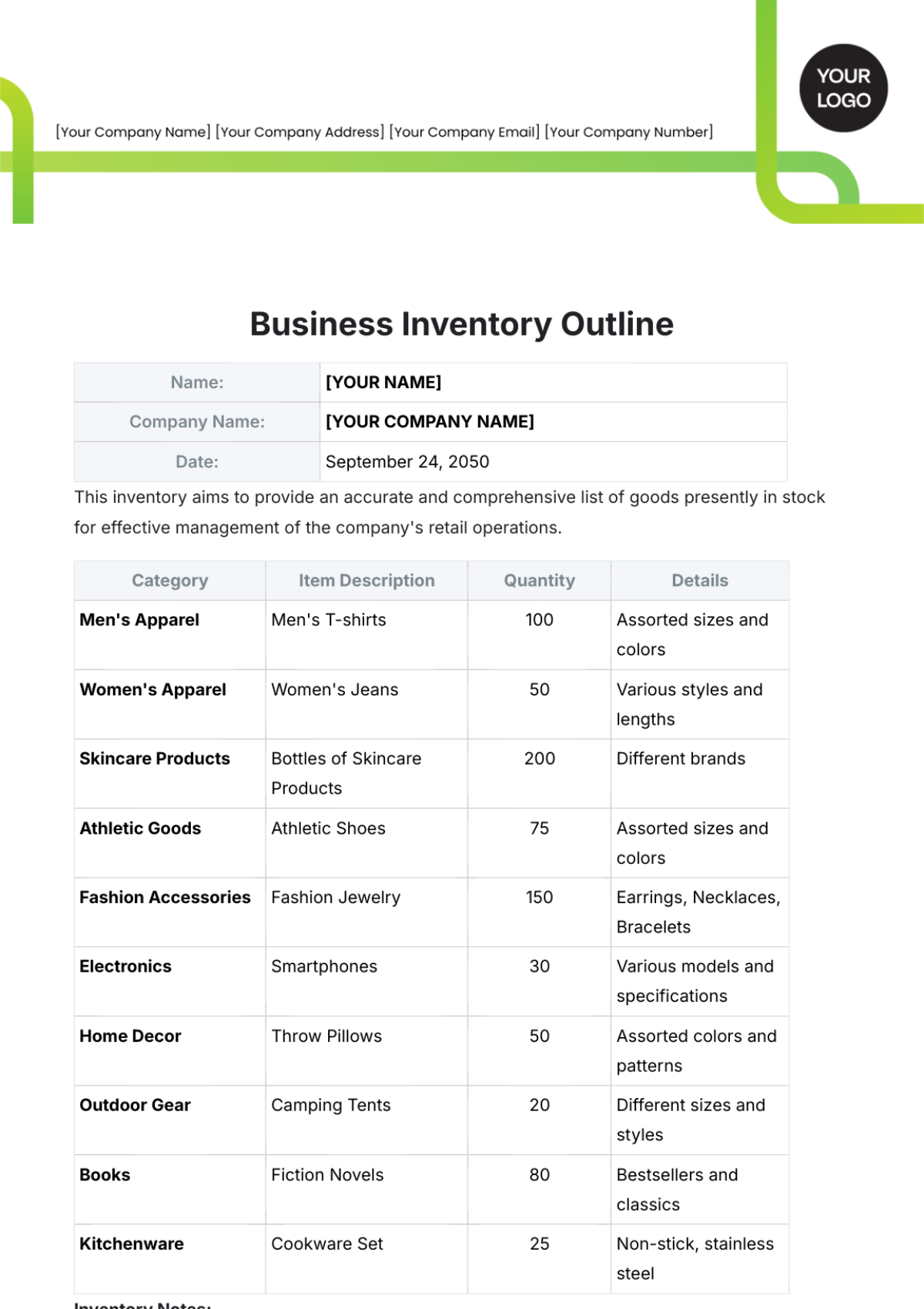

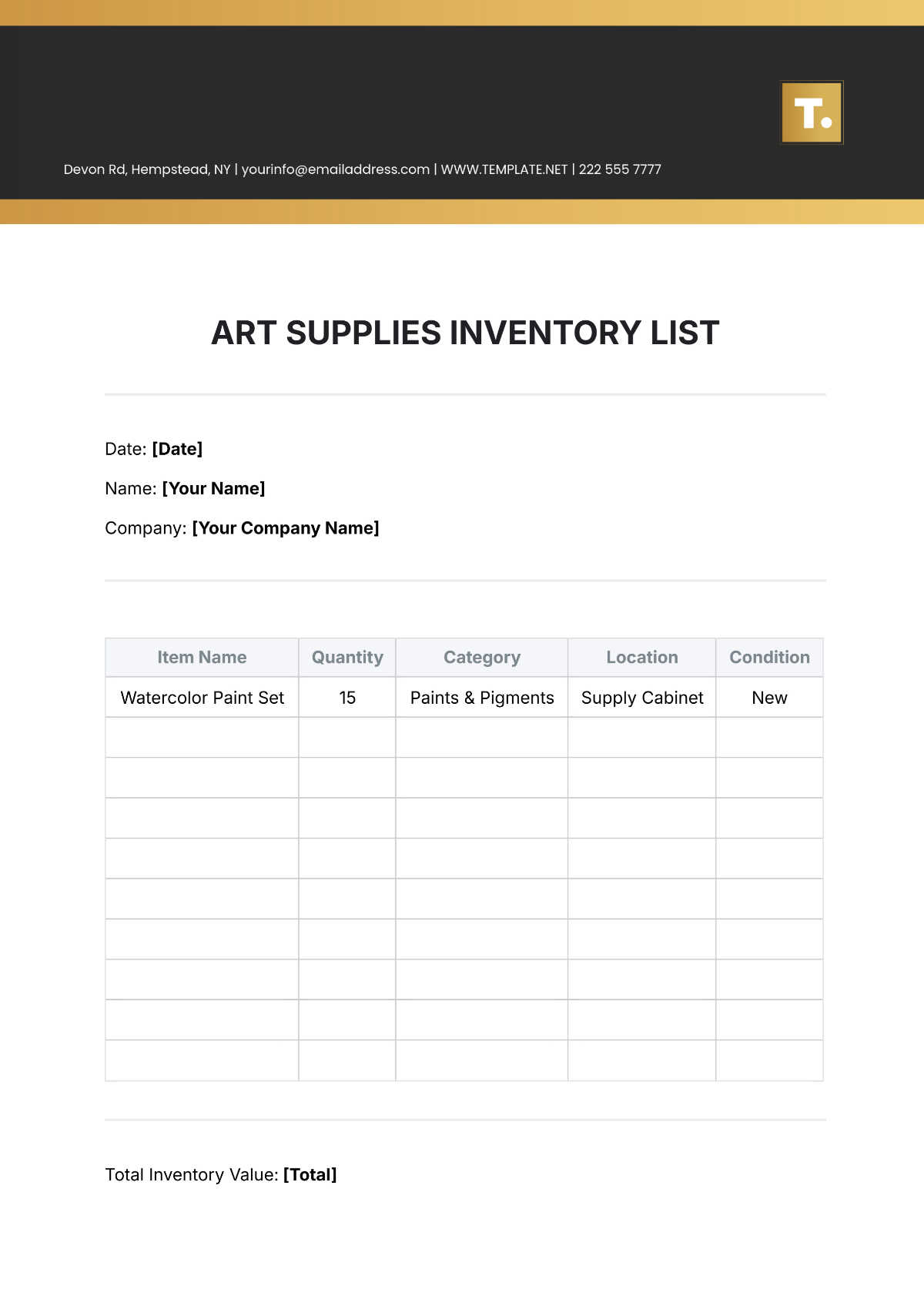

As of the current reporting period, the inventory levels at [Your Company Name] are as follows:

Inventory Category | Current Stock | Reorder Level | Usage Rate |

|---|---|---|---|

Products | 500 units | 100 units | 50 units/month |

Equipment | 50 items | 10 items | 5 items/month |

Supplies | 1000 units | 200 units | 150 units/month |

This table provides a snapshot of the inventory levels, ensuring that stock levels are sufficient to meet customer demand without overstocking.

B. Inventory Categories

The inventory at [Your Company Name] is divided into three main categories: products, equipment, and supplies.

Products

Products include all items sold to customers, such as skincare products, oils, and beauty products. Currently, there are 500 units of products in stock. These products are essential for daily operations and contribute significantly to revenue.

Equipment

Equipment encompasses all machinery and tools used in the spa, such as massage tables, facial machines, and saunas. With 50 items in stock, it is crucial to maintain the equipment in good condition to provide high-quality services to customers.

Supplies

Supplies include consumable items such as towels, cleaning agents, and disposable items. There are 1000 units of supplies available, ensuring that daily operations can continue smoothly without interruption.

III. Inventory Management Process

A. Receiving Inventory

The process of receiving inventory at [Your Company Name] is designed to ensure accuracy and efficiency. Upon arrival, each shipment is inspected for quality and quantity. The following steps outline the receiving process:

Verification of Delivery: Check the delivery against the purchase order to ensure all items are received as expected.

Quality Check: Inspect items for damage or defects. Any discrepancies are reported to the supplier immediately.

Documentation: Record the received items in the inventory management system, updating stock levels accordingly.

B. Inventory Tracking System

[Your Company Name] utilizes an advanced inventory tracking system to monitor stock levels in real time. This system includes barcoding and RFID technology, allowing for accurate and efficient tracking of inventory movements. Key features of the system include:

Real-Time Updates: Stock levels are updated instantly as items are received, used, or sold.

Alerts and Notifications: Automated alerts notify staff when stock levels fall below reorder points.

Reporting and Analysis: Comprehensive reports provide insights into inventory trends, usage rates, and turnover.

C. Inventory Control Procedures

To maintain optimal inventory levels, [Your Company Name] follows strict inventory control procedures. These procedures include:

Regular Audits: Conducting regular physical audits to verify the accuracy of inventory records.

Cycle Counting: Implementing cycle counting to continuously verify inventory accuracy without disrupting operations.

Stock Rotation: Using the first-in, first-out (FIFO) method to ensure older stock is used before newer stock, reducing waste and obsolescence.

IV. Detailed Inventory Analysis

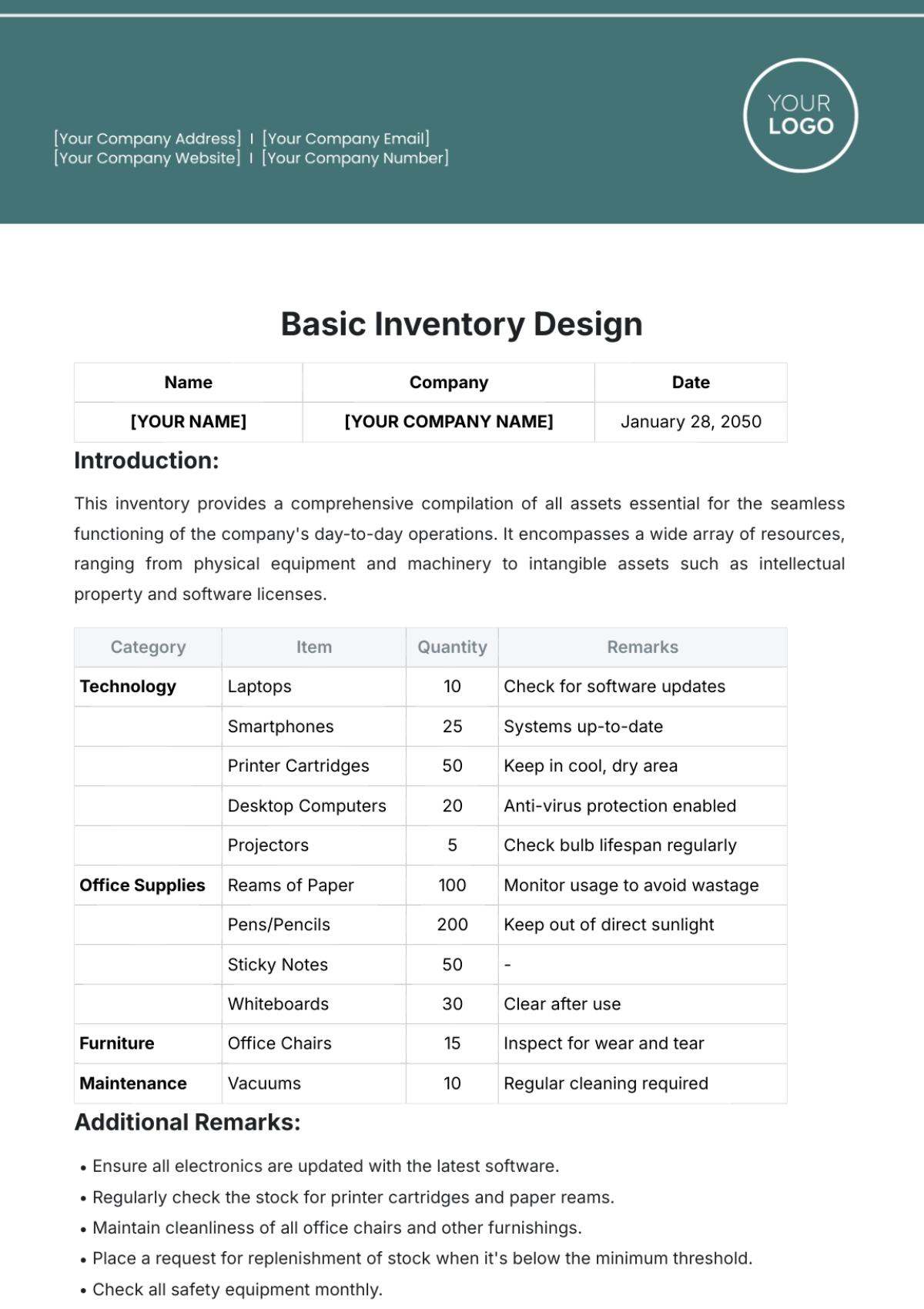

A. Product Inventory

Quantity on Hand

As previously mentioned, there are currently 500 units of products in stock at [Your Company Name]. This includes a variety of items, such as:

Product Type | Quantity on Hand |

|---|---|

Skincare Products | 200 units |

Oils | 150 units |

Beauty Products | 150 units |

This detailed breakdown allows for precise inventory management, ensuring that popular products are always available.

Reorder Levels

To prevent stockouts, reorder levels have been set for each product category. The reorder levels are based on historical usage rates and supplier lead times. For example:

Product Type | Reorder Level |

|---|---|

Skincare Products | 50 units |

Oils | 30 units |

Beauty Products | 20 units |

Usage Rate

The usage rate of each product type is monitored to anticipate future inventory needs. The usage rate for the current period is as follows:

Product Type | Usage Rate (units/month) |

|---|---|

Skincare Products | 20 units |

Oils | 15 units |

Beauty Products | 15 units |

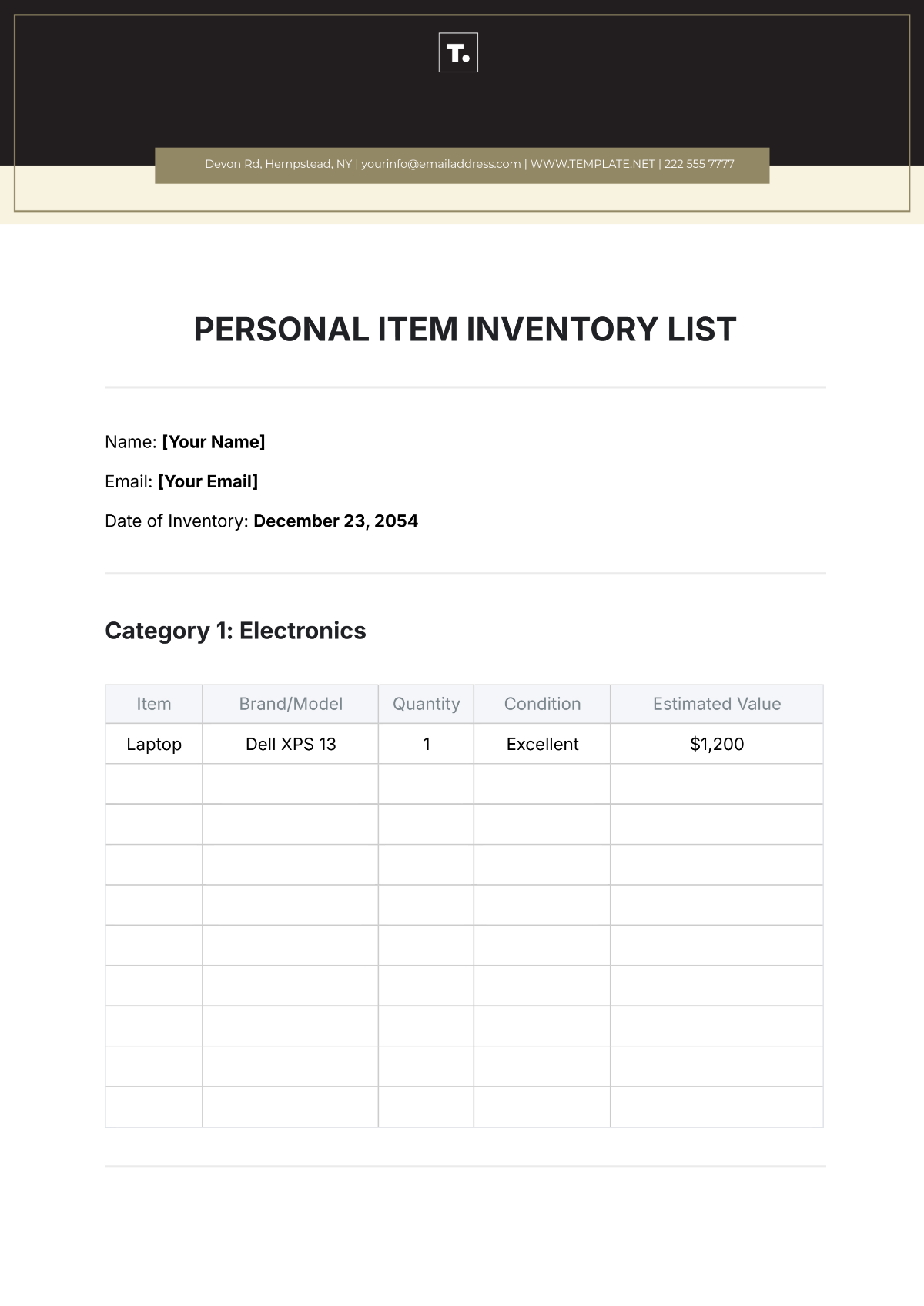

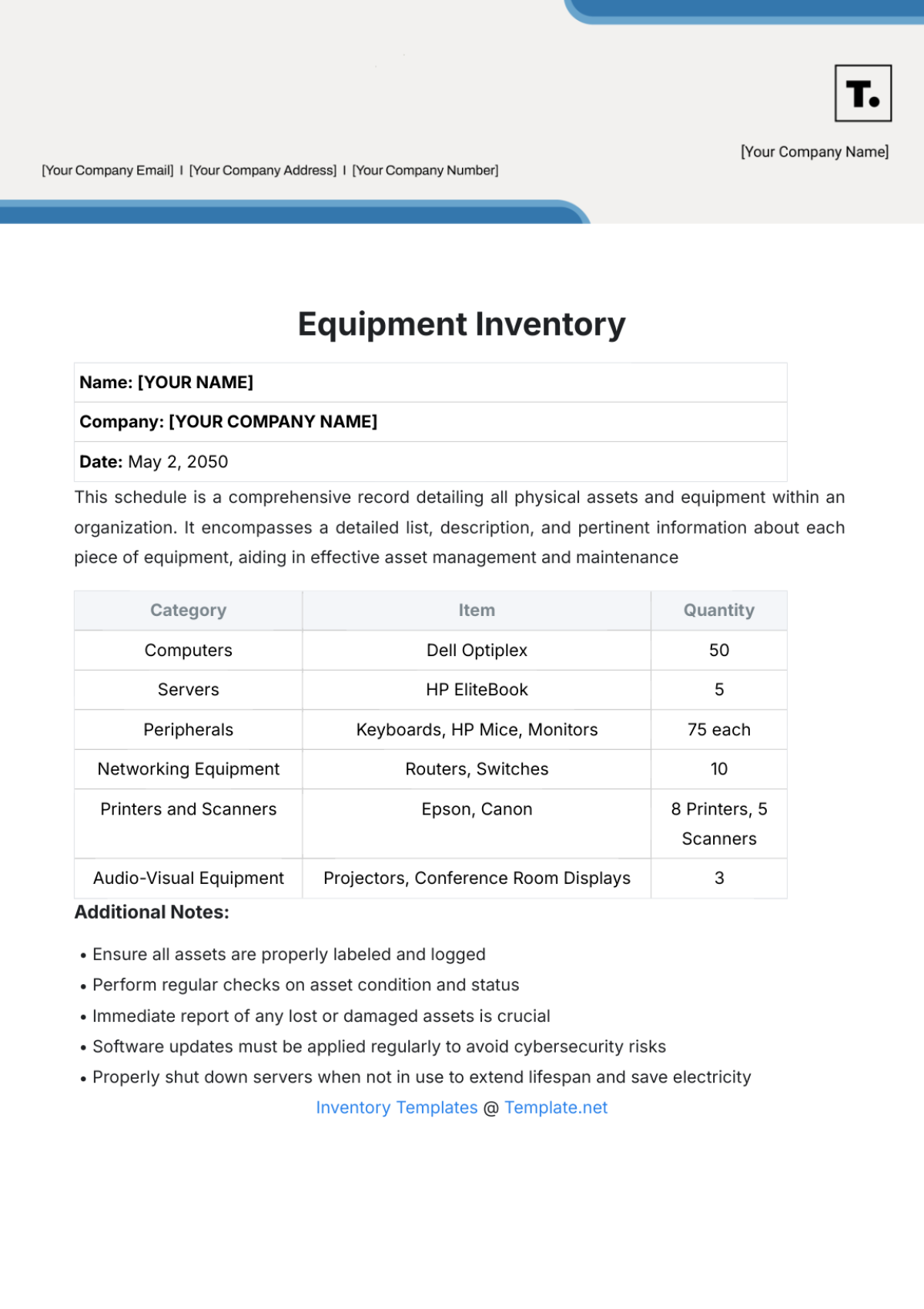

B. Equipment Inventory

Condition and Maintenance

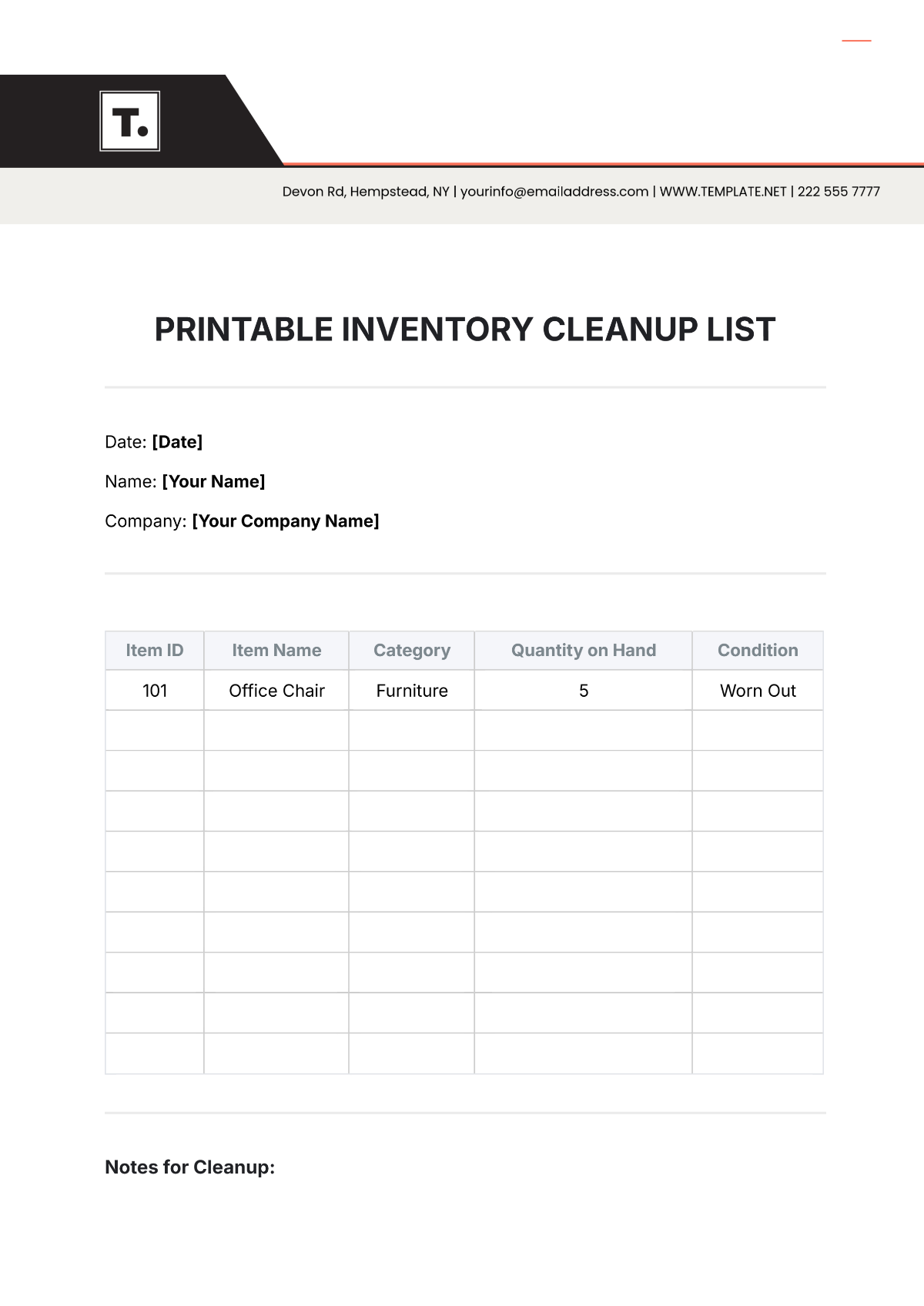

The condition of the equipment is regularly assessed to ensure it is functioning correctly and safely. A maintenance schedule is in place to perform routine checks and repairs. The current condition and maintenance status are as follows:

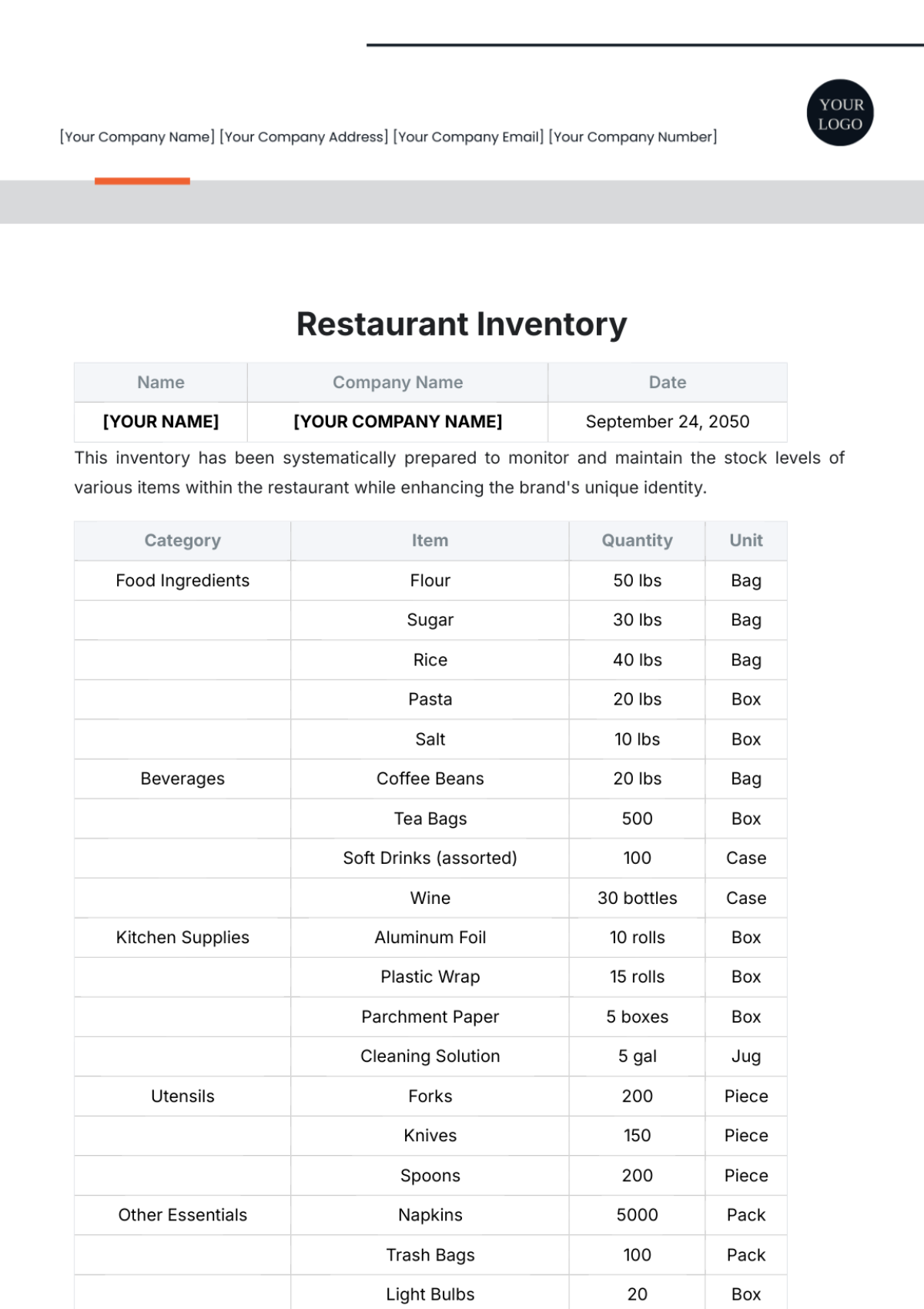

Equipment Type | Quantity | Condition | Maintenance Schedule |

|---|---|---|---|

Massage Tables | 20 | Good | Monthly |

Facial Machines | 15 | Excellent | Quarterly |

Saunas | 10 | Fair | Bi-Annually |

Miscellaneous Tools | 5 | Good | As Needed |

Replacement Schedule

To maintain service quality, a replacement schedule for equipment has been established. This schedule ensures that outdated or worn-out equipment is replaced promptly. The replacement plan includes:

Equipment Type | Replacement Cycle | Next Replacement |

|---|---|---|

Massage Tables | 5 years | [Year] |

Facial Machines | 3 years | |

Saunas | 7 years | |

Miscellaneous Tools | 4 years |

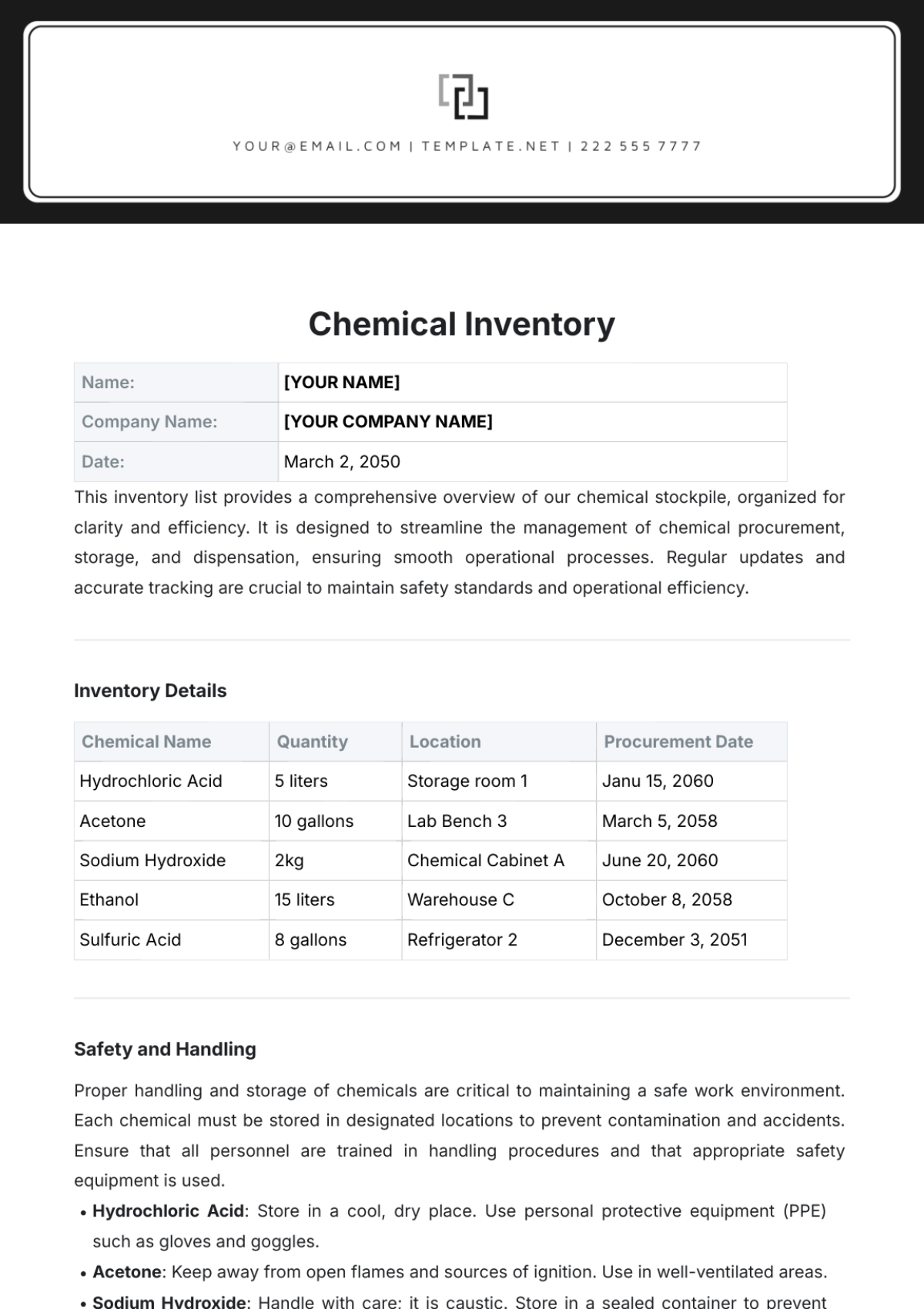

C. Supplies Inventory

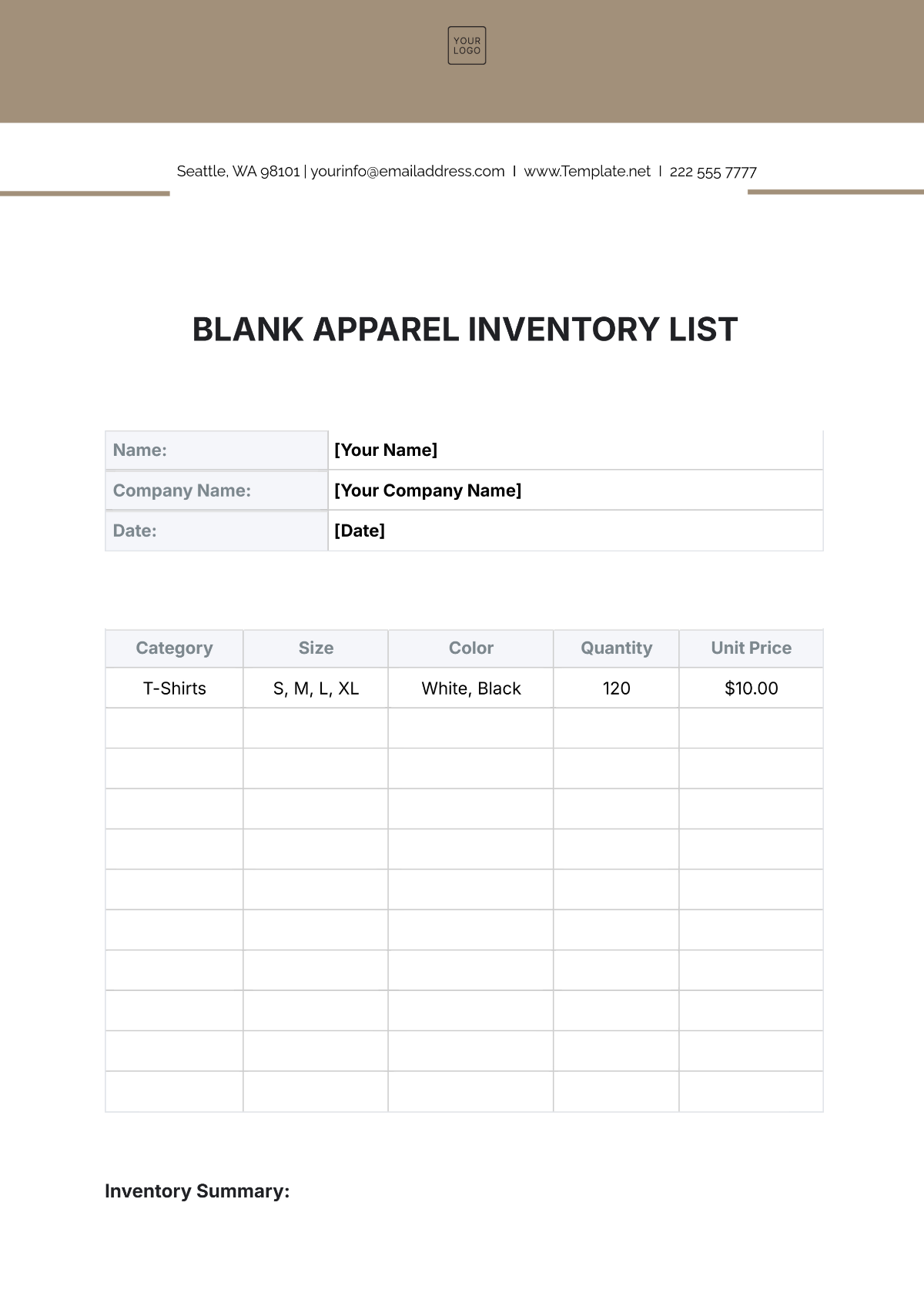

Stock Levels

The stock levels of supplies are monitored to ensure they are adequate to support daily operations. The current stock levels are as follows:

Supply Type | Quantity on Hand |

|---|---|

Towels | 500 units |

Cleaning Agents | 300 units |

Disposable Items | 200 units |

Consumption Rate

The consumption rate of supplies is tracked to manage stock effectively. The consumption rate for the current period is:

Supply Type | Consumption Rate (units/month) |

|---|---|

Towels | 100 units |

Cleaning Agents | 75 units |

Disposable Items | 50 units |

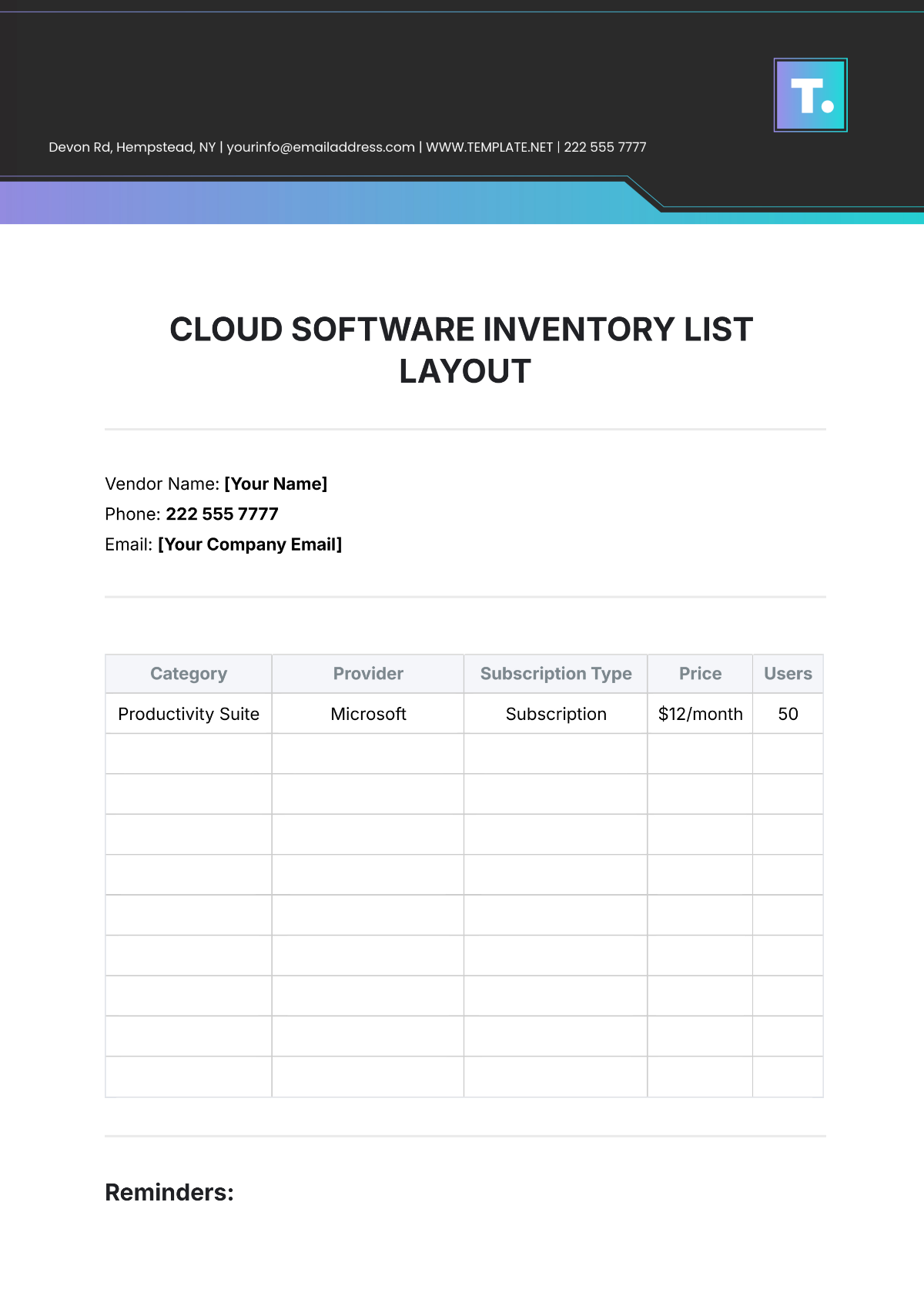

V. Inventory Valuation

A. Methodology

The valuation of inventory at [Your Company Name] is conducted using the weighted average cost method. This method calculates the average cost of inventory items over a specific period, providing a more accurate representation of inventory value.

B. Valuation Summary

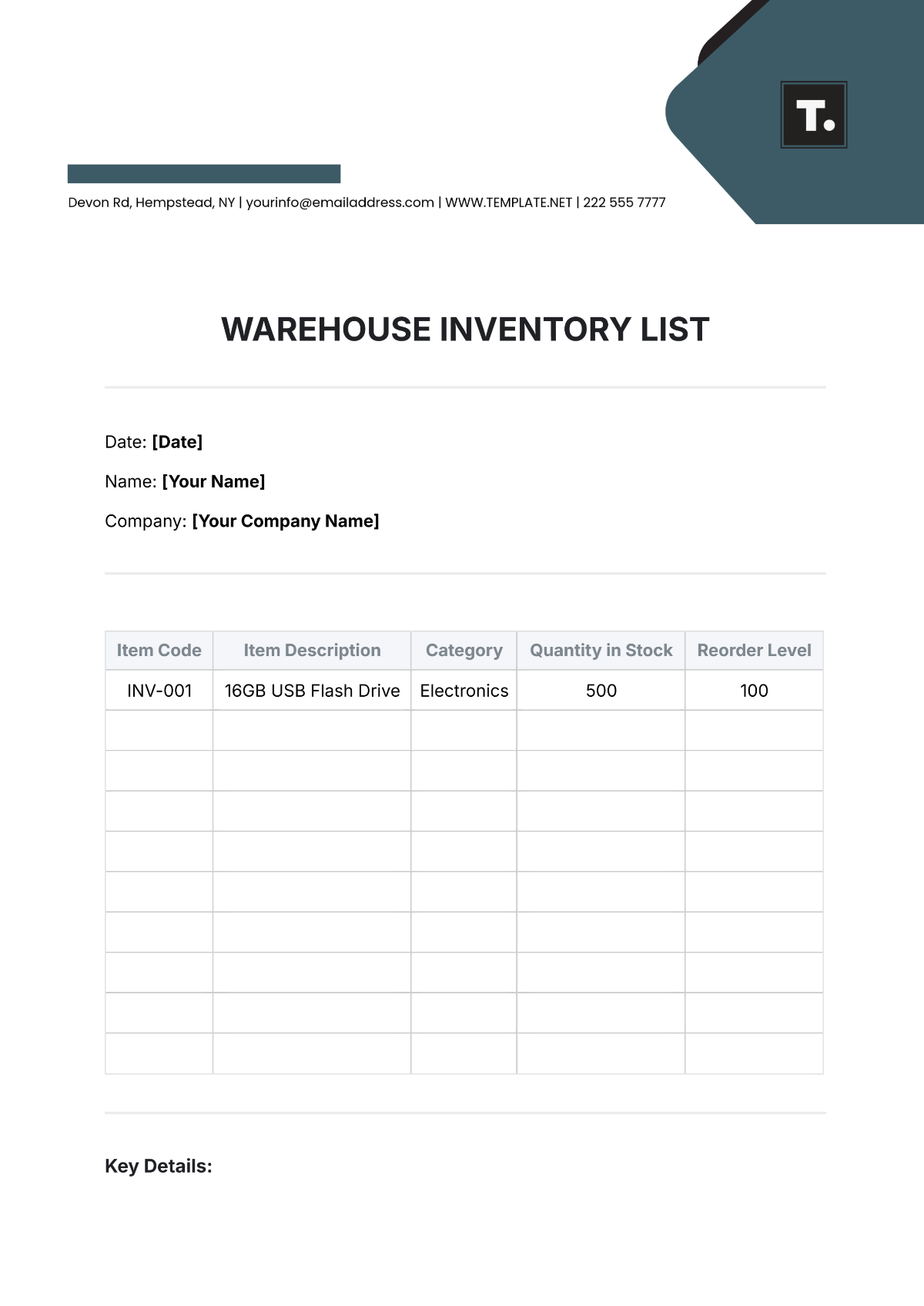

The current value of the inventory is summarized in the table below:

Inventory Category | Value |

|---|---|

Products | $15,000 |

Equipment | $50,000 |

Supplies | $5,000 |

Total | $70,000 |

C. Cost Analysis

A detailed cost analysis has been performed to identify opportunities for cost savings. The analysis includes:

Product Cost: The cost of products is evaluated to ensure competitive pricing from suppliers.

Equipment Cost: The cost of equipment is analyzed to determine the most cost-effective maintenance and replacement strategies.

Supply Cost: The cost of supplies is reviewed to identify potential savings through bulk purchasing and supplier negotiations.

By implementing these cost-saving measures, [Your Company Name] can reduce overall inventory costs while maintaining high-quality services.

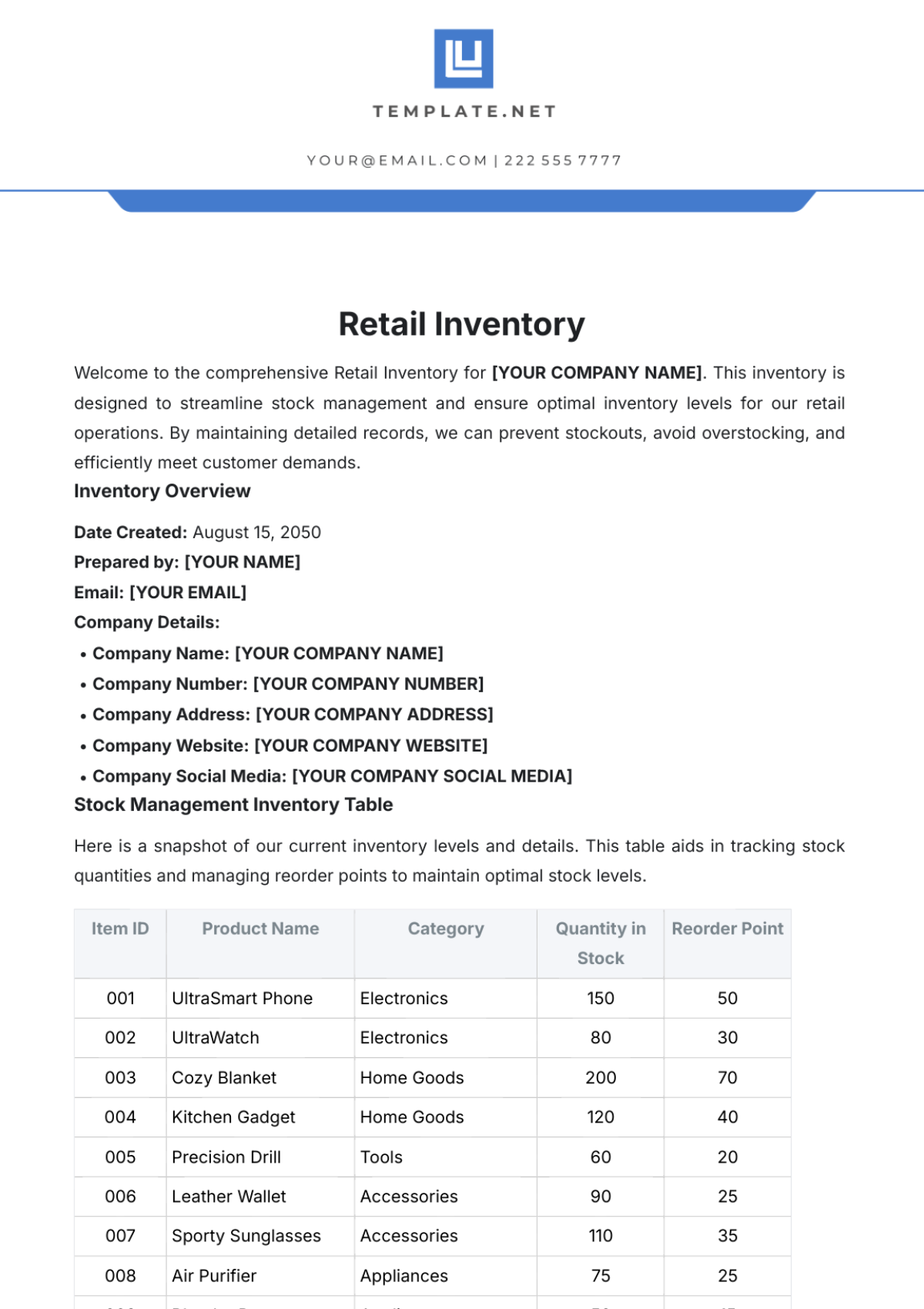

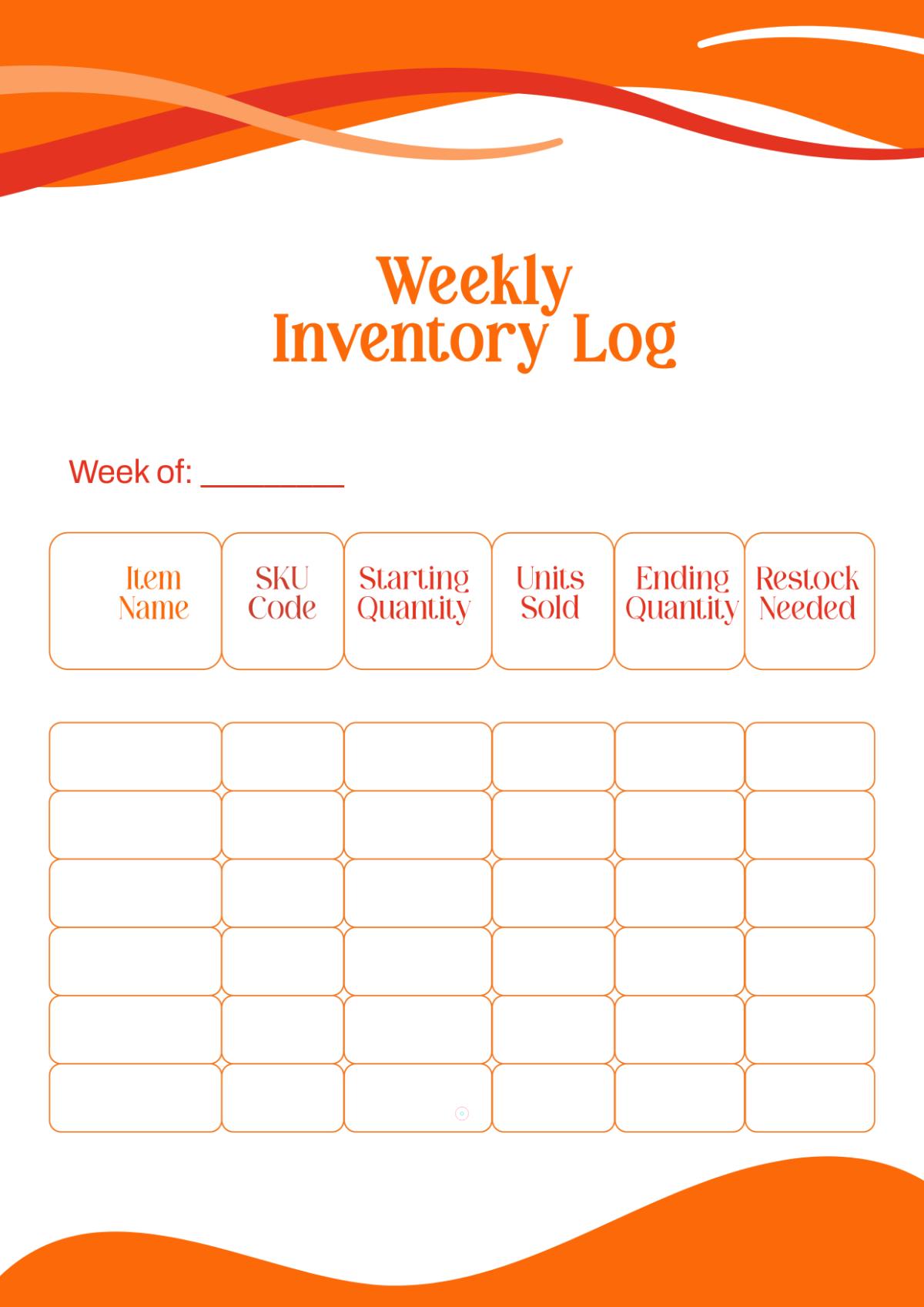

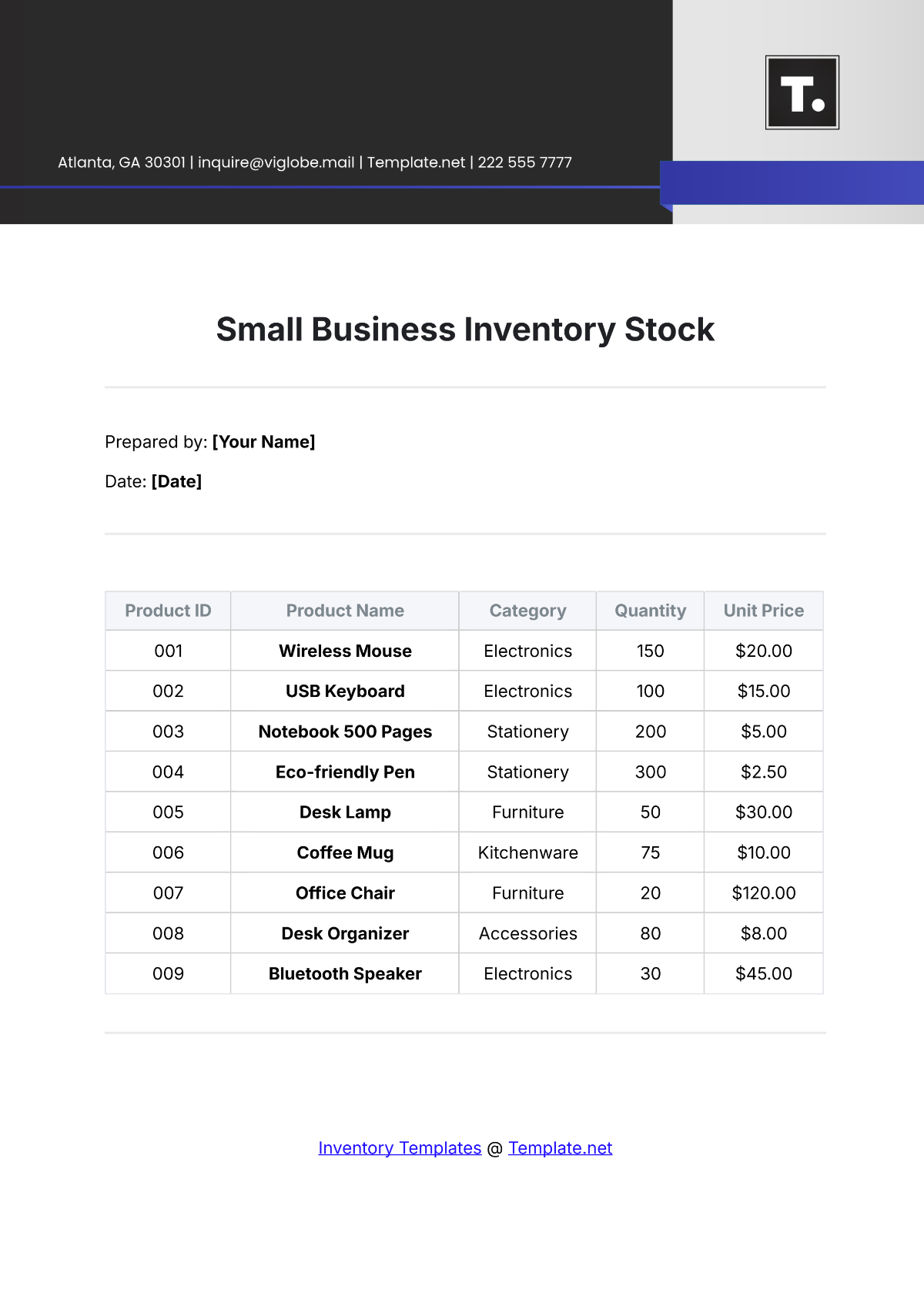

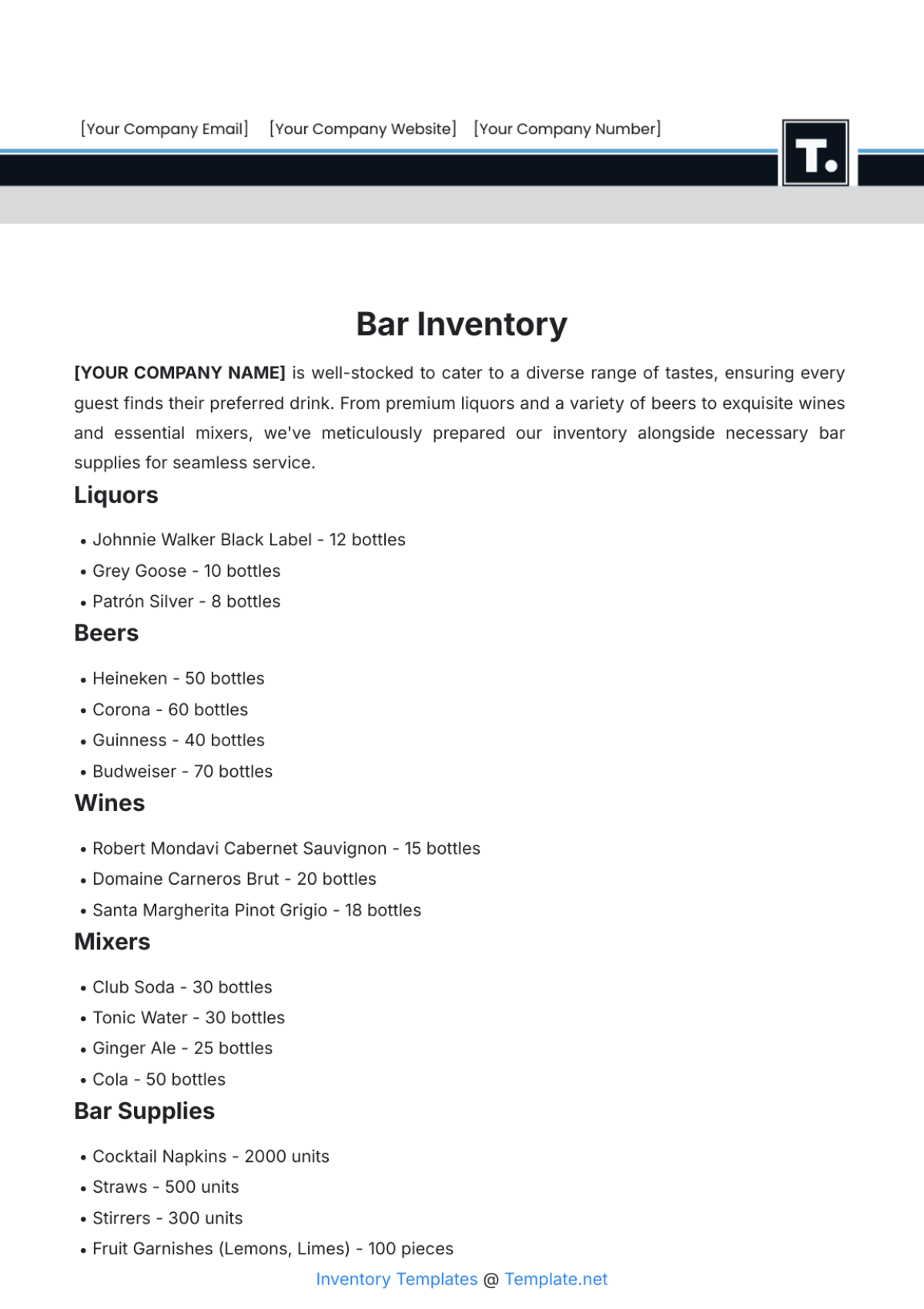

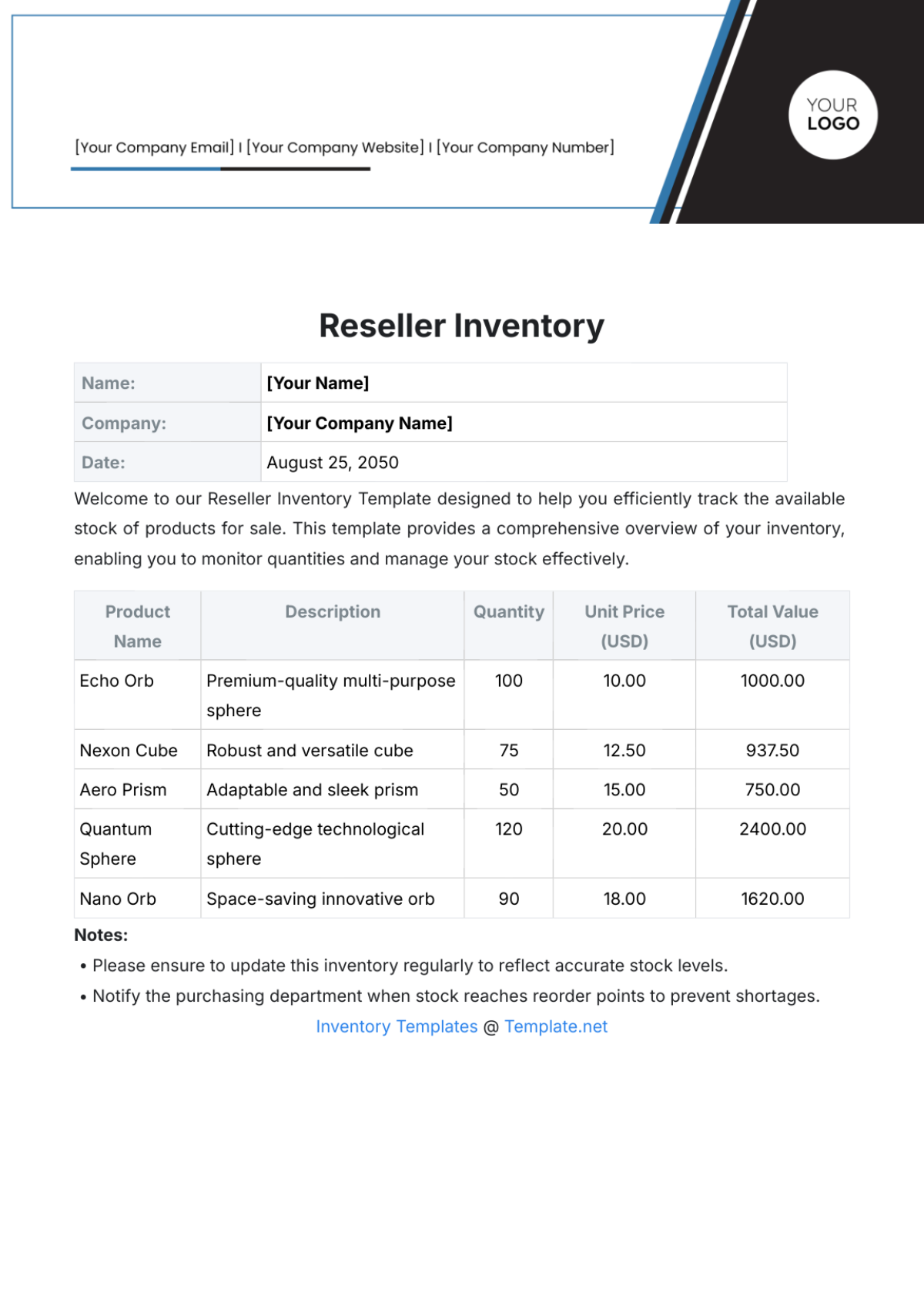

VI. Inventory Turnover

The inventory turnover rate measures how often inventory is sold and replaced over a period.

Inventory Category | Cost of Goods Sold | Average Inventory | Turnover Rate |

|---|---|---|---|

Products | $120,000 | $15,000 | 8 |

Equipment | $30,000 | $50,000 | 0.6 |

Supplies | $10,000 | $5,000 | 2 |

A. Analysis of Turnover Rates by Category

The analysis of turnover rates by category reveals the efficiency of inventory management. A high turnover rate indicates effective inventory control, while a low rate suggests potential overstocking. The turnover rates for products and supplies are within acceptable ranges, indicating efficient management. However, the turnover rate for equipment is relatively low, suggesting a need for review and potential improvement.

B. Implications for Inventory Management

The turnover rate analysis provides insights into inventory management practices. To optimize inventory levels and improve turnover rates, [Your Company Name] should:

Review Product Reordering: Ensure that products are reordered based on accurate usage forecasts to maintain optimal stock levels.

Evaluate Equipment Utilization: Assess the utilization of equipment to identify underused items and consider reallocating or disposing of them.

Monitor Supply Consumption: Regularly monitor the consumption of supplies to prevent overstocking and reduce waste.

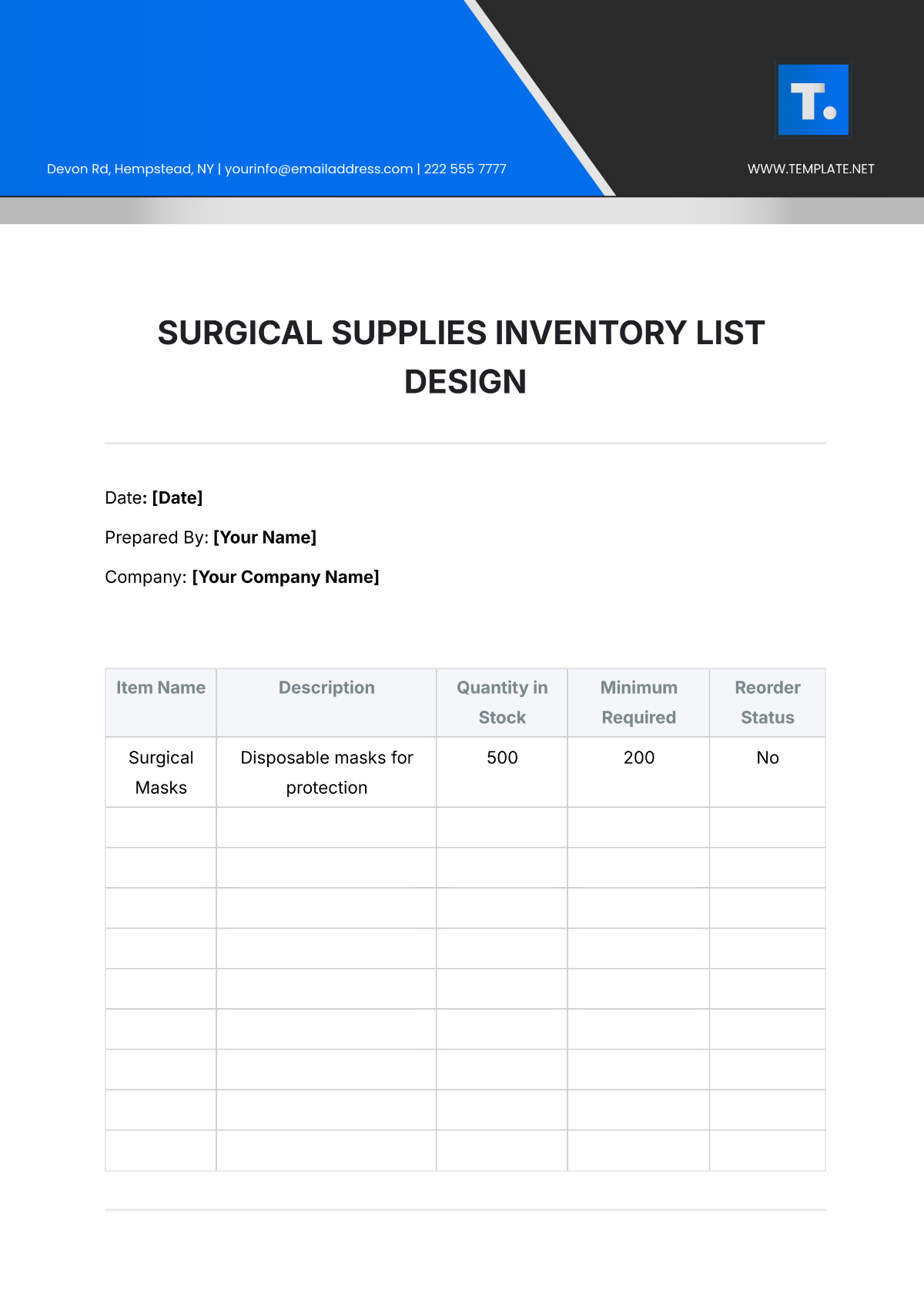

VII. Inventory Issues and Challenges

A. Stockouts and Overstocks

One of the primary challenges faced by [Your Company Name] is managing stockouts and overstocks. Stockouts occur when inventory levels fall below the necessary levels to meet customer demand, leading to potential lost sales and dissatisfied customers. On the other hand, overstocks happen when there is an excess of inventory that exceeds demand, resulting in increased holding costs and potential obsolescence.

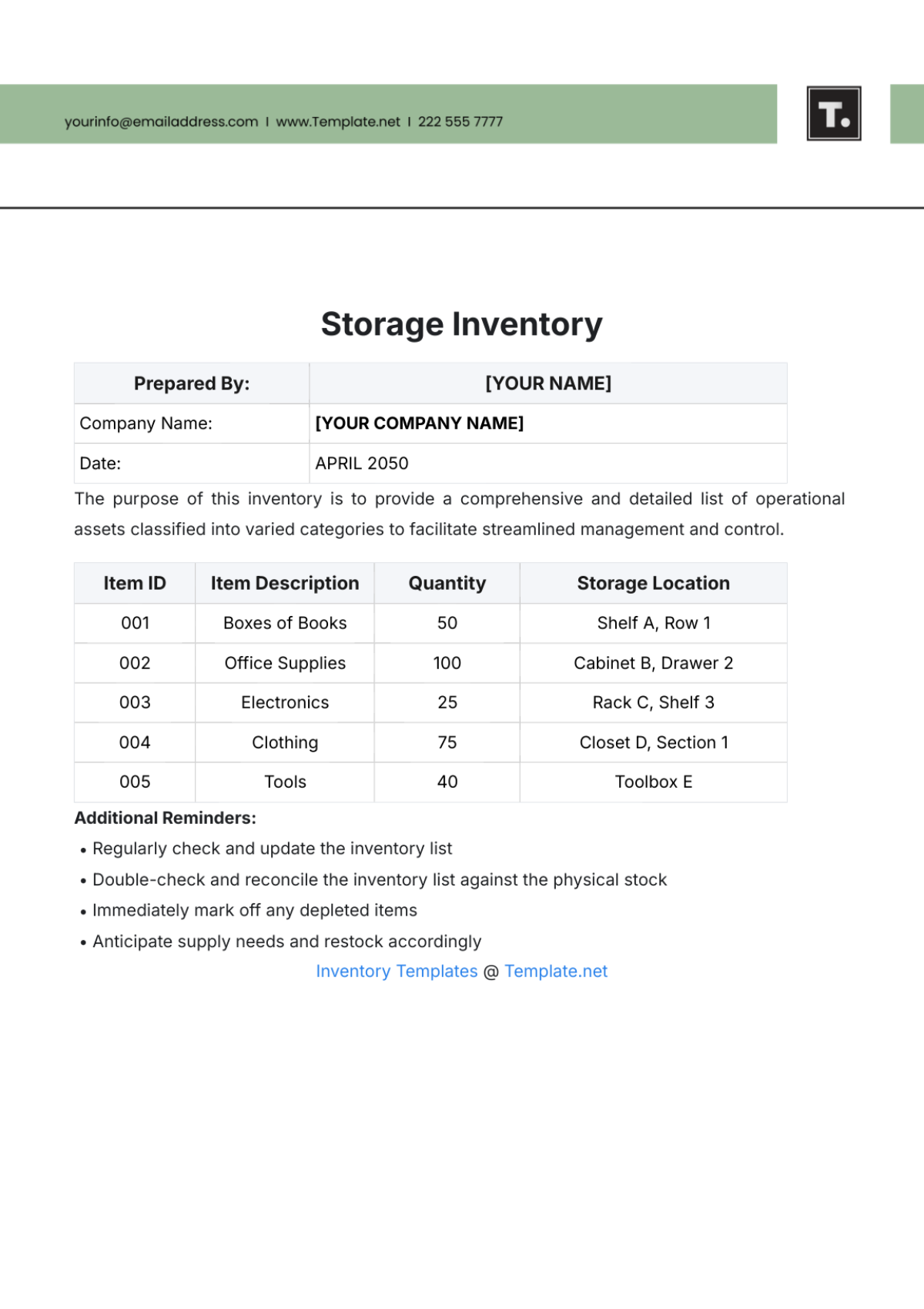

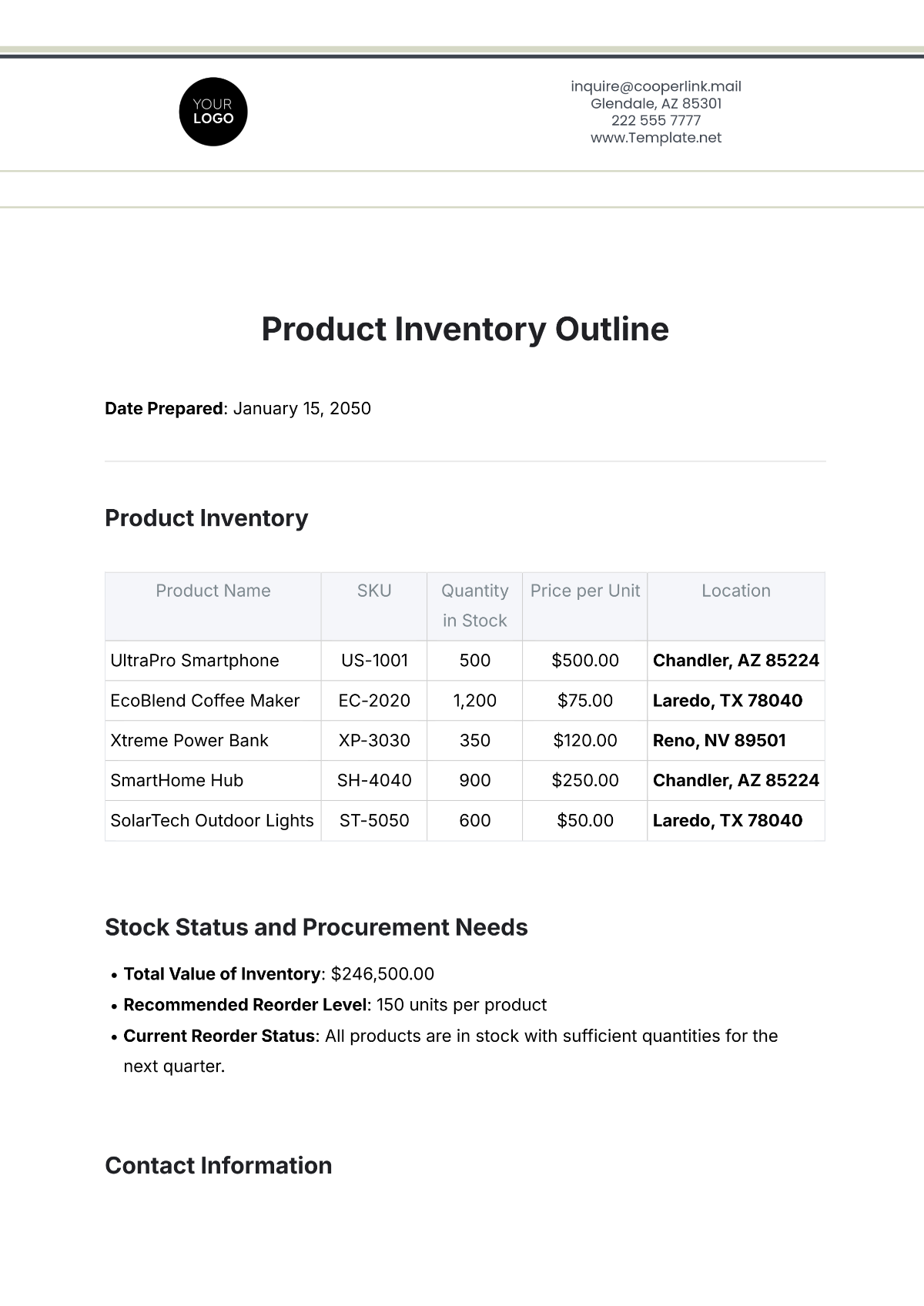

Recent data indicates that [Your Company Name] experienced stockouts in certain popular product categories such as skincare products and oils. This issue can be attributed to inaccurate demand forecasting and delays in supplier delivery. The table below highlights the stockout incidents over the past quarter:

Product Type | Stockout Incidents | Average Duration (days) |

|---|---|---|

Skincare Products | 3 | 5 |

Oils | 2 | 4 |

Beauty Products | 1 | 3 |

Conversely, overstocks have been identified in categories like disposable items and certain equipment, which are not used as frequently. This overstock situation ties up capital and storage space, increasing costs without adding value.

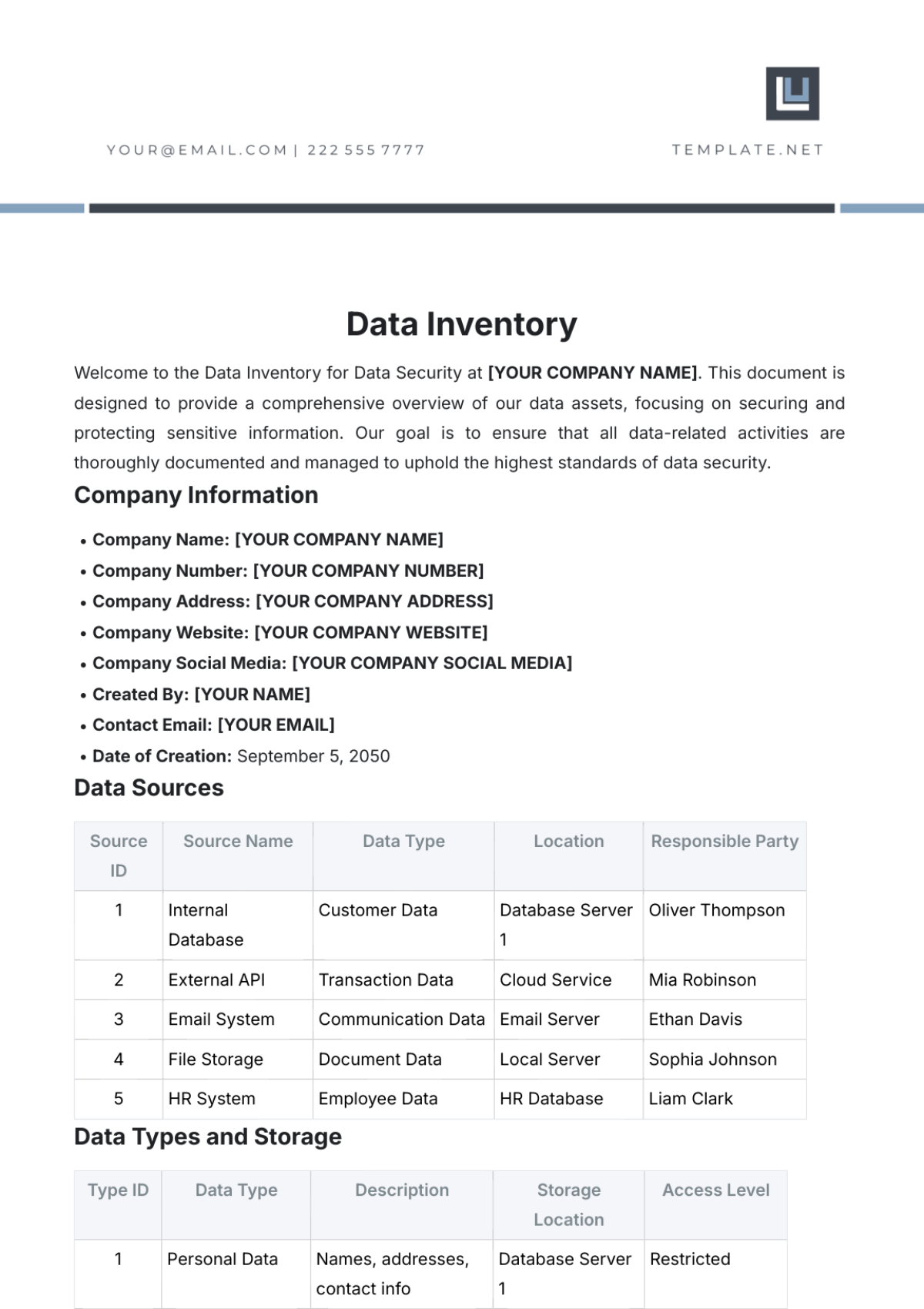

B. Damaged or Expired Inventory

Another significant challenge is managing damaged or expired inventory. Products that are mishandled during shipping or storage can become unsellable, leading to financial losses. Similarly, items with a limited shelf life, such as certain skincare products, can expire before they are used or sold.

In the last six months, [Your Company Name] recorded the following incidents of damaged or expired inventory:

Inventory Category | Incidents (units) | Financial Loss ($) |

|---|---|---|

Skincare Products | 50 | $1,000 |

Equipment | 5 | $2,500 |

Supplies | 100 | $300 |

To mitigate these issues, [Your Company Name] has implemented stricter quality control measures during receiving and handling processes. Regular inspections and proper storage practices are essential to minimize damage and ensure that items are used within their expiration dates.

C. Discrepancies in Records

Accurate inventory records are crucial for effective inventory management. Discrepancies between physical stock and recorded inventory levels can lead to operational inefficiencies, such as ordering unnecessary stock or failing to order needed items. At [Your Company Name], periodic audits have revealed discrepancies in several categories, indicating a need for improved inventory tracking and record-keeping.

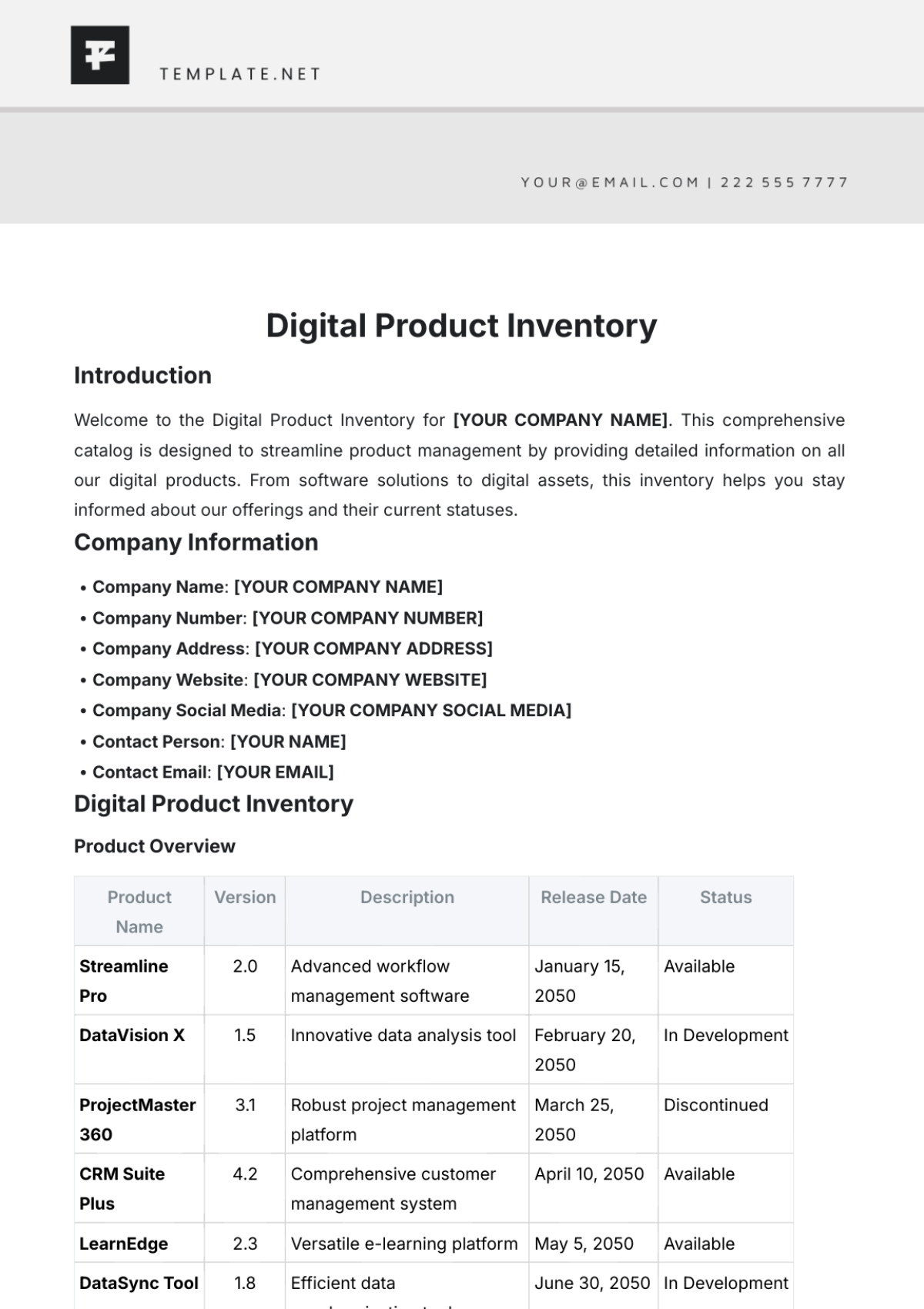

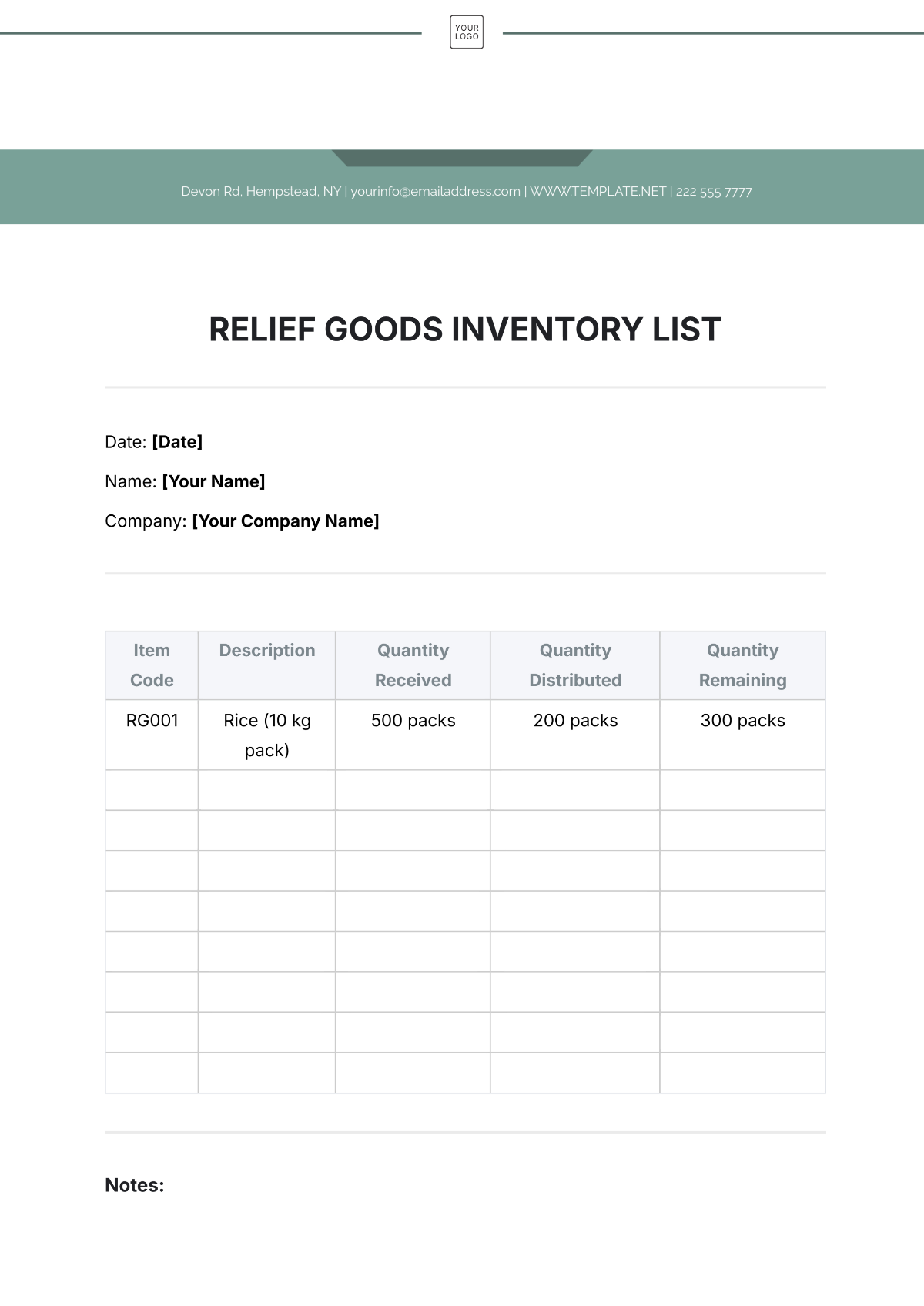

The table below outlines the discrepancies found during the most recent audit:

Inventory Category | Recorded Stock | Physical Stock | Discrepancy (units) |

|---|---|---|---|

Products | 500 | 480 | -20 |

Equipment | 50 | 48 | -2 |

Supplies | 1000 | 990 | -10 |

To address these discrepancies, [Your Company Name] is enhancing its inventory tracking system with more frequent cycle counts and improved data entry protocols.

VIII. Recommendations

A. Improvement in Inventory Management Practices

To enhance inventory management practices, [Your Company Name] should consider implementing the following recommendations:

Enhanced Forecasting Methods: Utilize advanced forecasting techniques, such as demand sensing and predictive analytics, to better anticipate customer needs and adjust inventory levels accordingly.

Vendor Management: Strengthen relationships with suppliers to ensure timely deliveries and negotiate better terms. Implement vendor performance tracking to identify and address issues proactively.

Automated Inventory Replenishment: Invest in automated replenishment systems that trigger reorder alerts based on real-time inventory levels and predefined reorder points. This can help prevent stockouts and overstocks.

B. Suggestions for Reducing Costs

Cost reduction is critical for maintaining profitability while ensuring inventory availability. [Your Company Name] can achieve cost savings through the following strategies:

Bulk Purchasing: Negotiate bulk purchasing agreements with suppliers for frequently used items to benefit from volume discounts.

Lean Inventory Practices: Adopt lean inventory practices to minimize waste and reduce carrying costs. This includes just-in-time (JIT) inventory management, which aligns inventory levels closely with actual demand.

Inventory Turnover Optimization: Regularly review and adjust inventory turnover rates to ensure that stock levels are optimized for each category. This can help reduce holding costs and improve cash flow.

C. Strategies for Optimizing Inventory Levels

Optimizing inventory levels is essential for balancing supply and demand while minimizing costs. [Your Company Name] can implement the following strategies:

ABC Analysis: Conduct an ABC analysis to categorize inventory items based on their importance and value. Focus on managing A-category items (high-value, high-usage) more closely while streamlining management of B and C-category items.

Safety Stock Levels: Establish appropriate safety stock levels for critical items to buffer against demand fluctuations and supply chain disruptions.

Inventory Visibility: Enhance inventory visibility across the supply chain to enable better coordination and decision-making. Implementing a centralized inventory management system can provide real-time insights into stock levels and movements.

IX. Conclusion

A. Summary of Key Points

This Spa Inventory Report has provided a comprehensive analysis of the current inventory status at [Your Company Name]. Key findings include:

Current inventory levels and categories have been detailed, with a focus on products, equipment, and supplies.

The inventory management process, including receiving, tracking, and control procedures, has been outlined to ensure efficiency and accuracy.

Detailed inventory analysis has highlighted the quantity on hand, reorder levels, and usage rates for each inventory category.

Inventory valuation has been conducted using the weighted average cost method, providing a clear picture of inventory value and cost analysis.

Inventory turnover rates have been calculated and analyzed to identify opportunities for improvement in inventory management.

B. Future Actions

To enhance inventory management practices and achieve cost savings, [Your Company Name] should focus on implementing the recommendations provided in this report. This includes improving forecasting methods, strengthening vendor management, adopting lean inventory practices, and optimizing inventory levels through ABC analysis and safety stock adjustments.

C. Closing Remarks

Effective inventory management is crucial for maintaining high service levels, reducing costs, and ensuring the smooth operation of [Your Company Name]. By implementing the strategies outlined in this report, [Your Company Name] can achieve greater efficiency, improve customer satisfaction, and enhance overall business performance.

With continued attention to inventory management practices and regular assessments of inventory levels and processes, [Your Company Name] can maintain a competitive edge in the spa industry and continue to provide exceptional service to its customers.