Monthly Inventory Report

I. Executive Summary

In this section, an overview of the inventory status for the month of June 2050 will be provided, highlighting key metrics and observations.

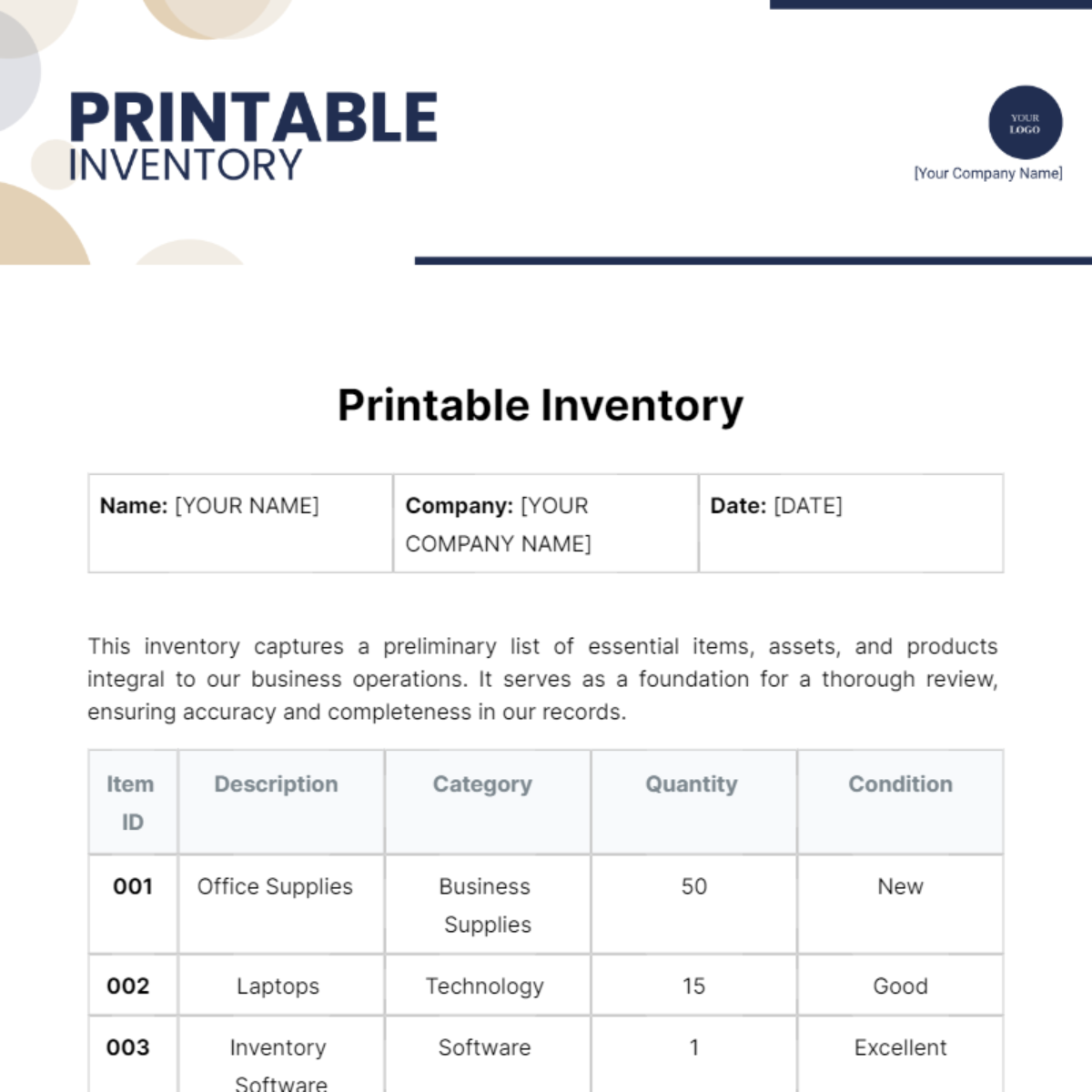

II. Inventory Performance Analysis

A. Overall Inventory Metrics

Inventory Turnover Rate: 4.5

Stockout Rate: 2%

Inventory Accuracy: 98%

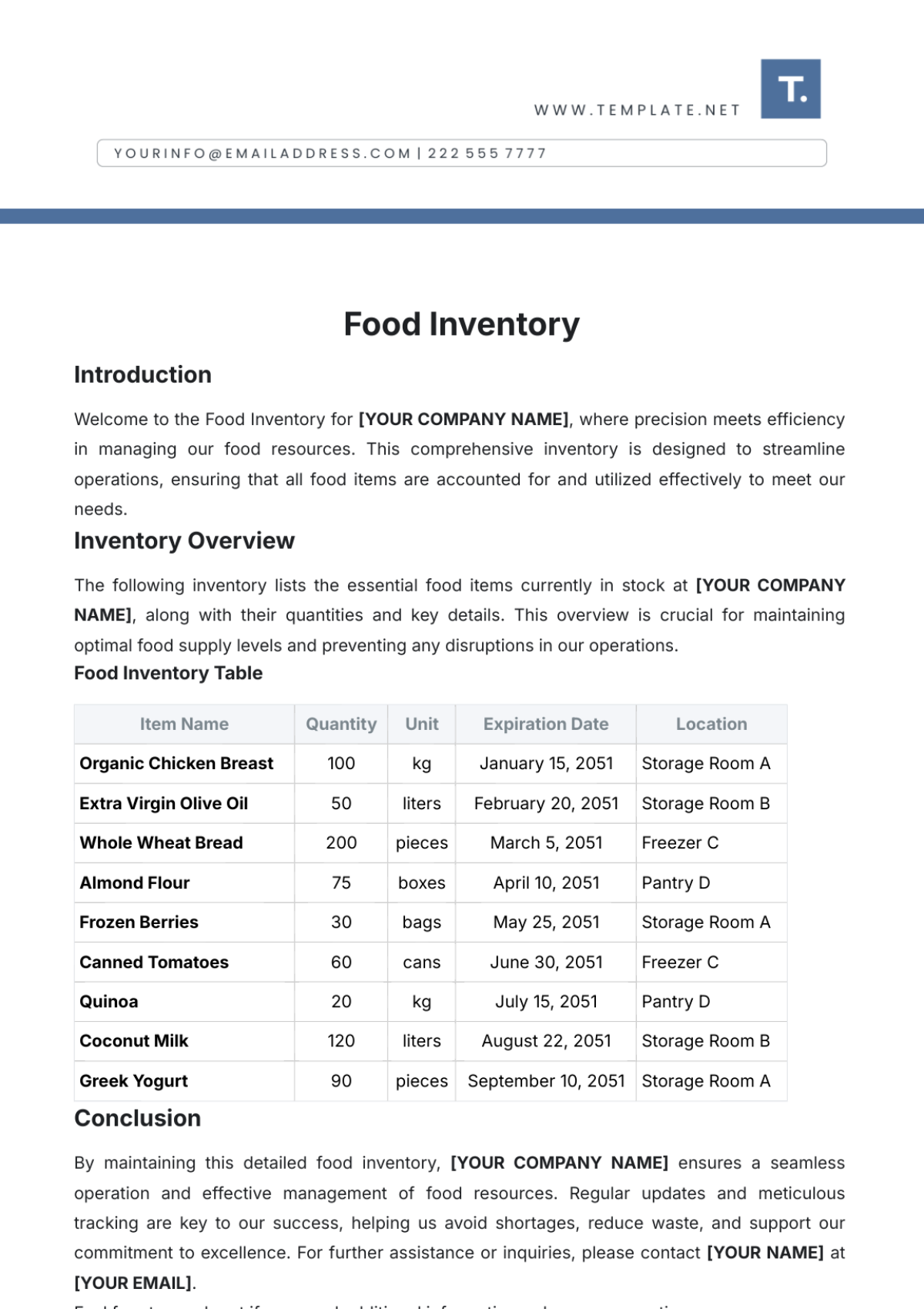

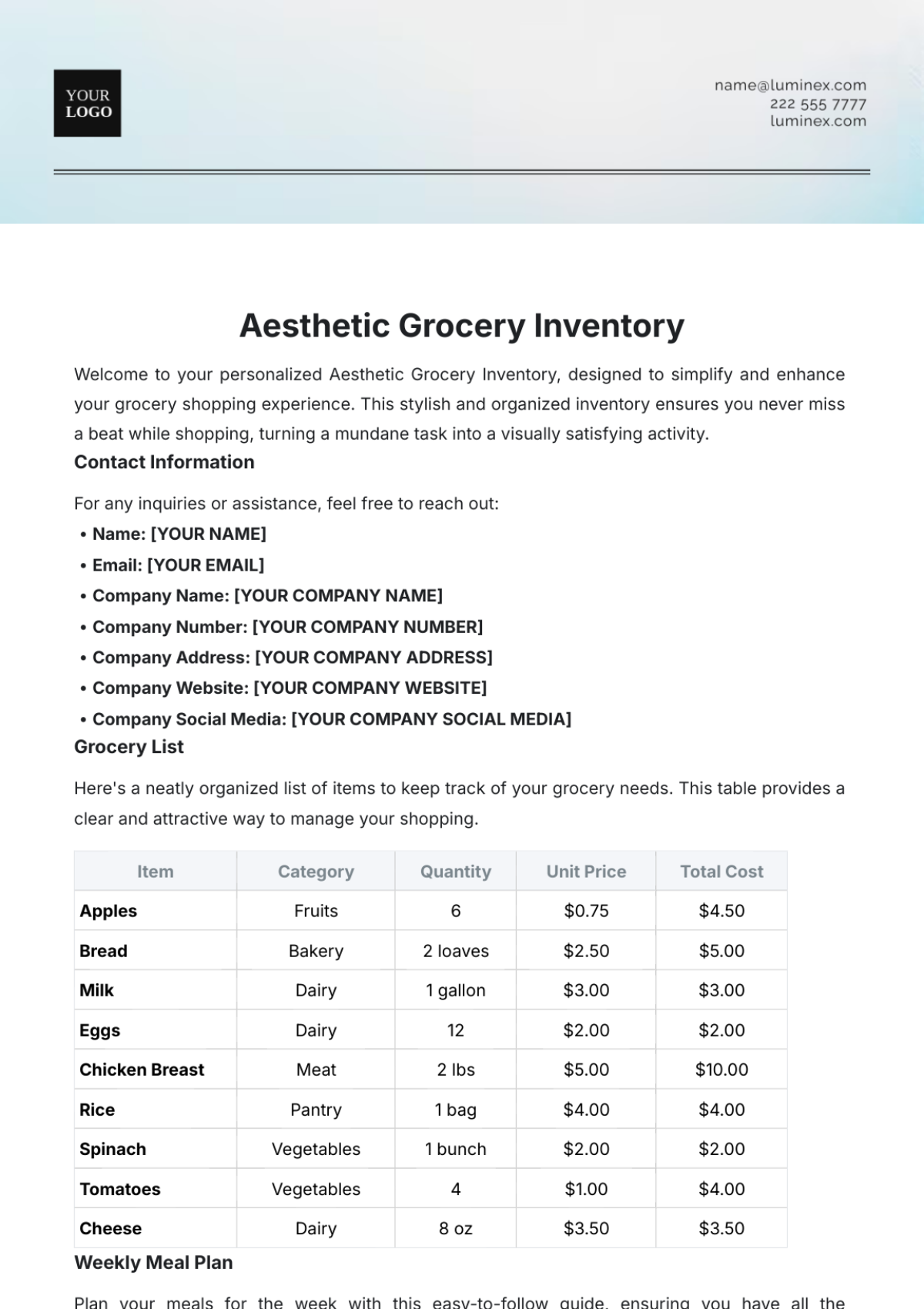

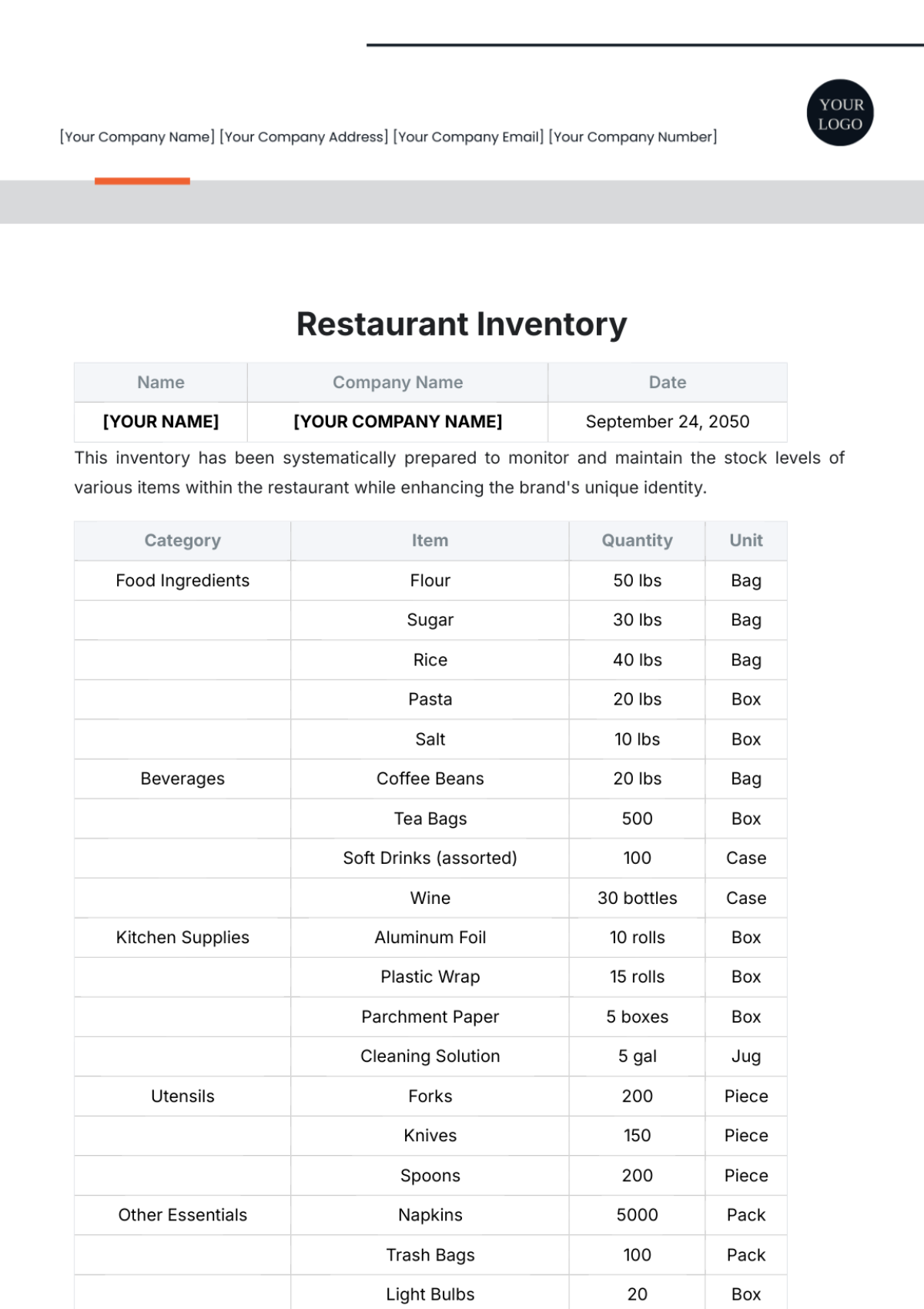

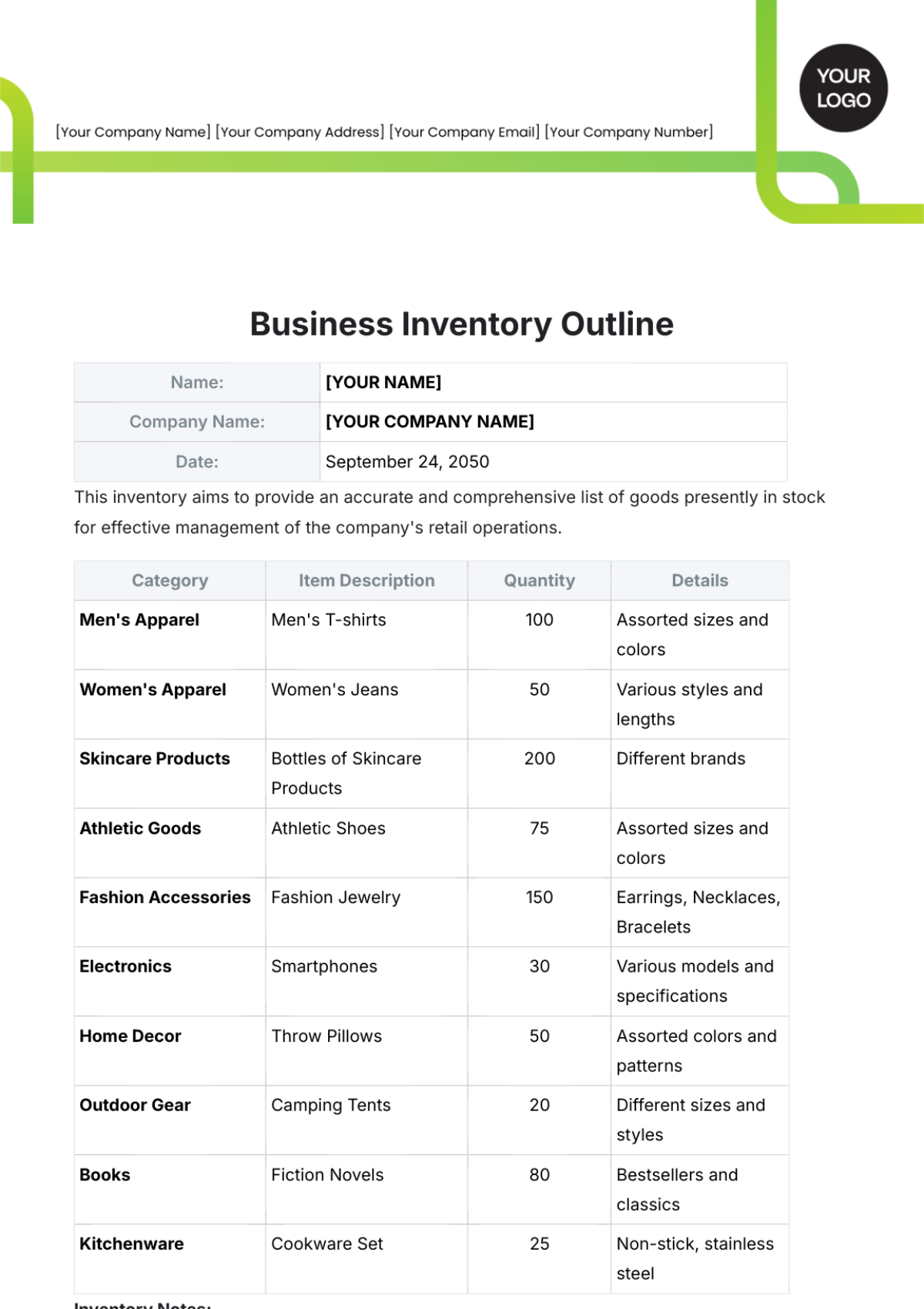

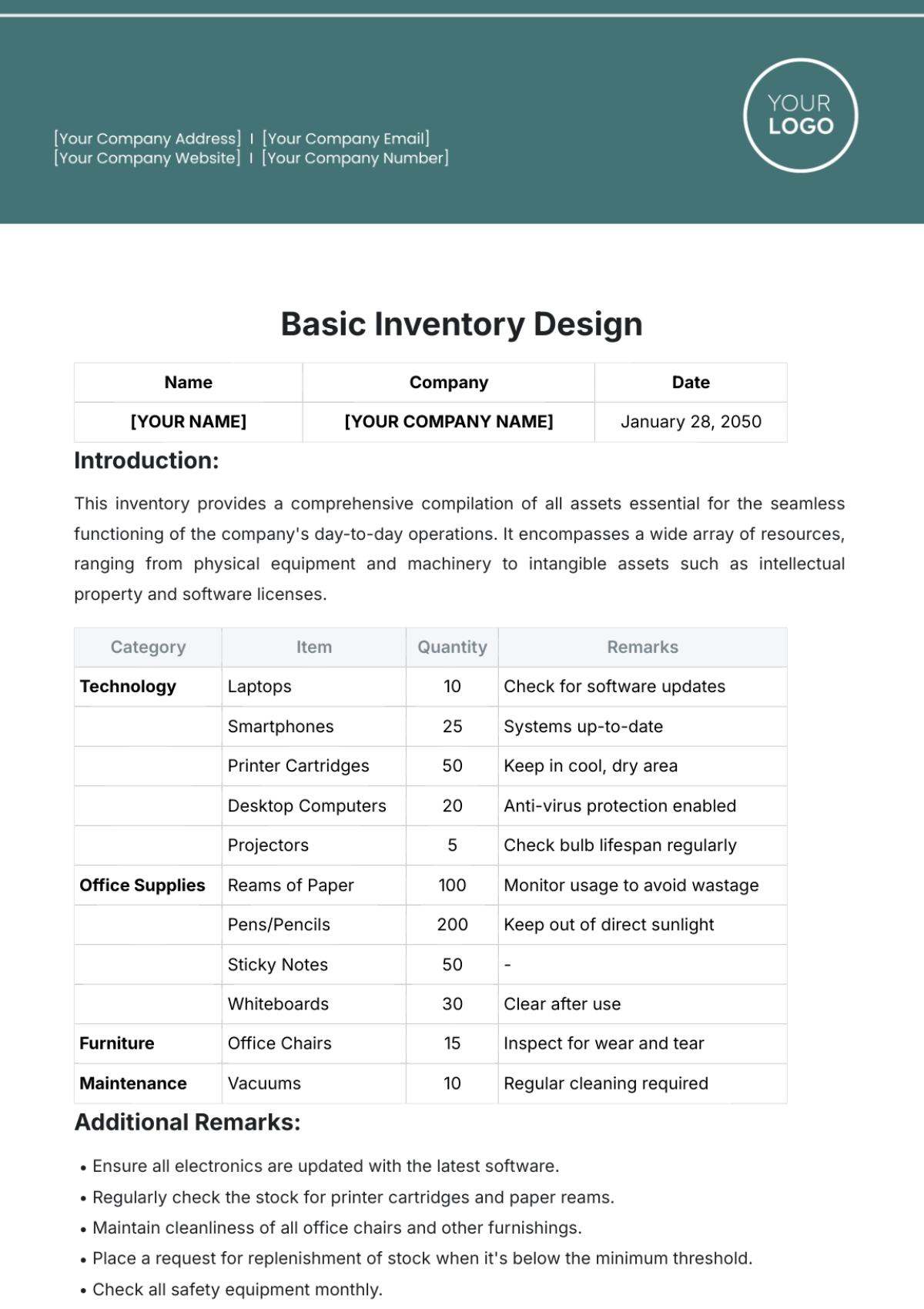

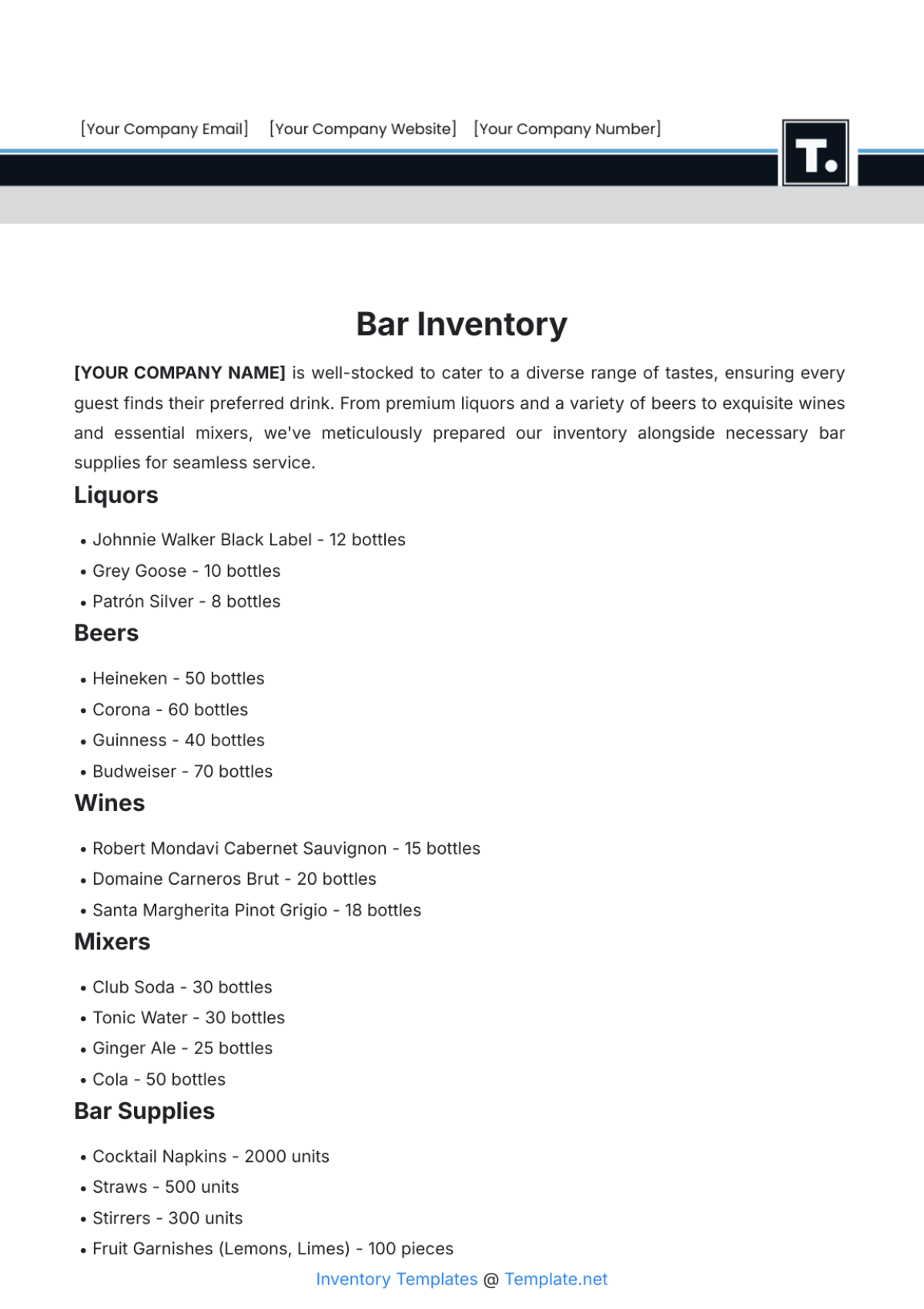

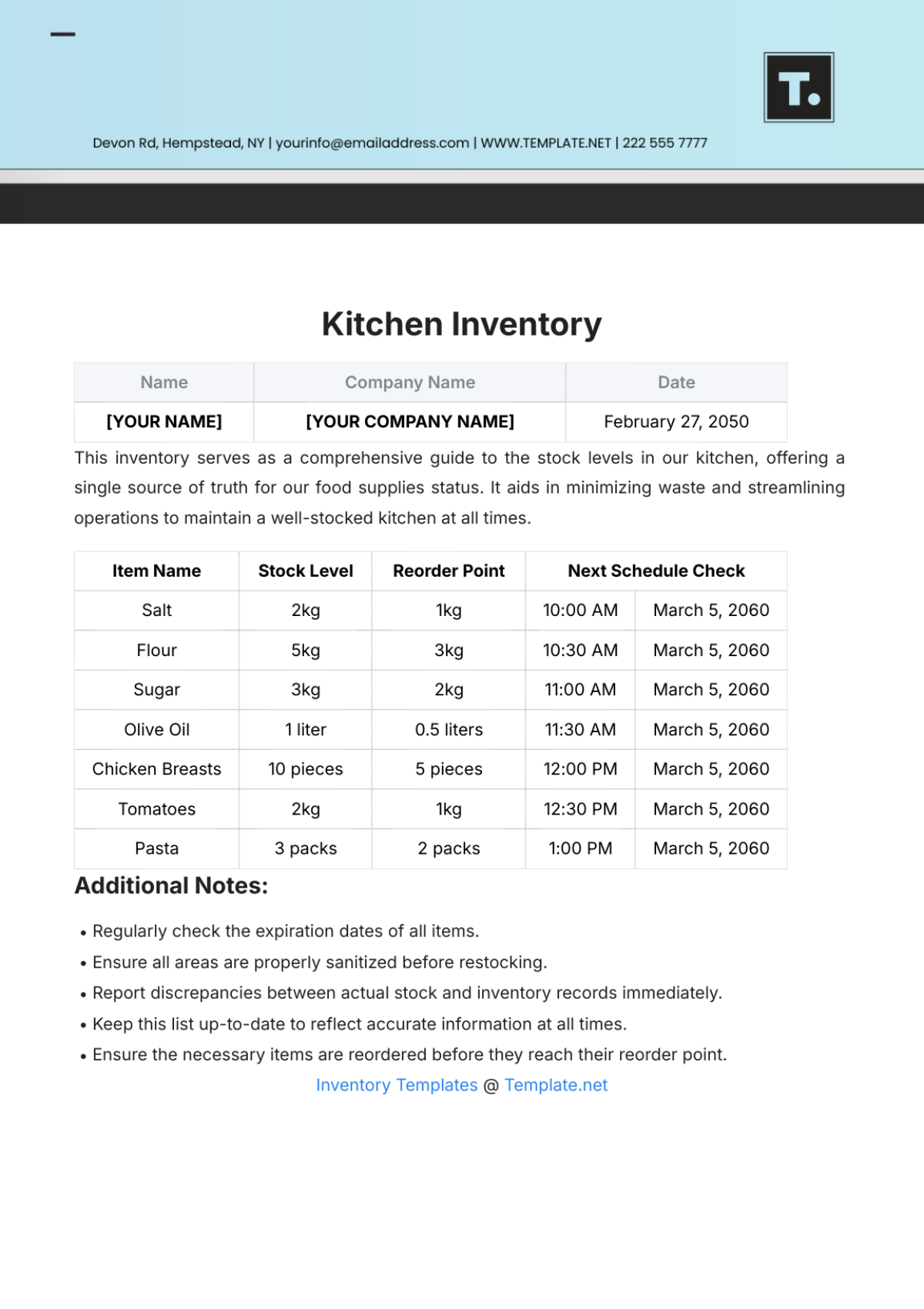

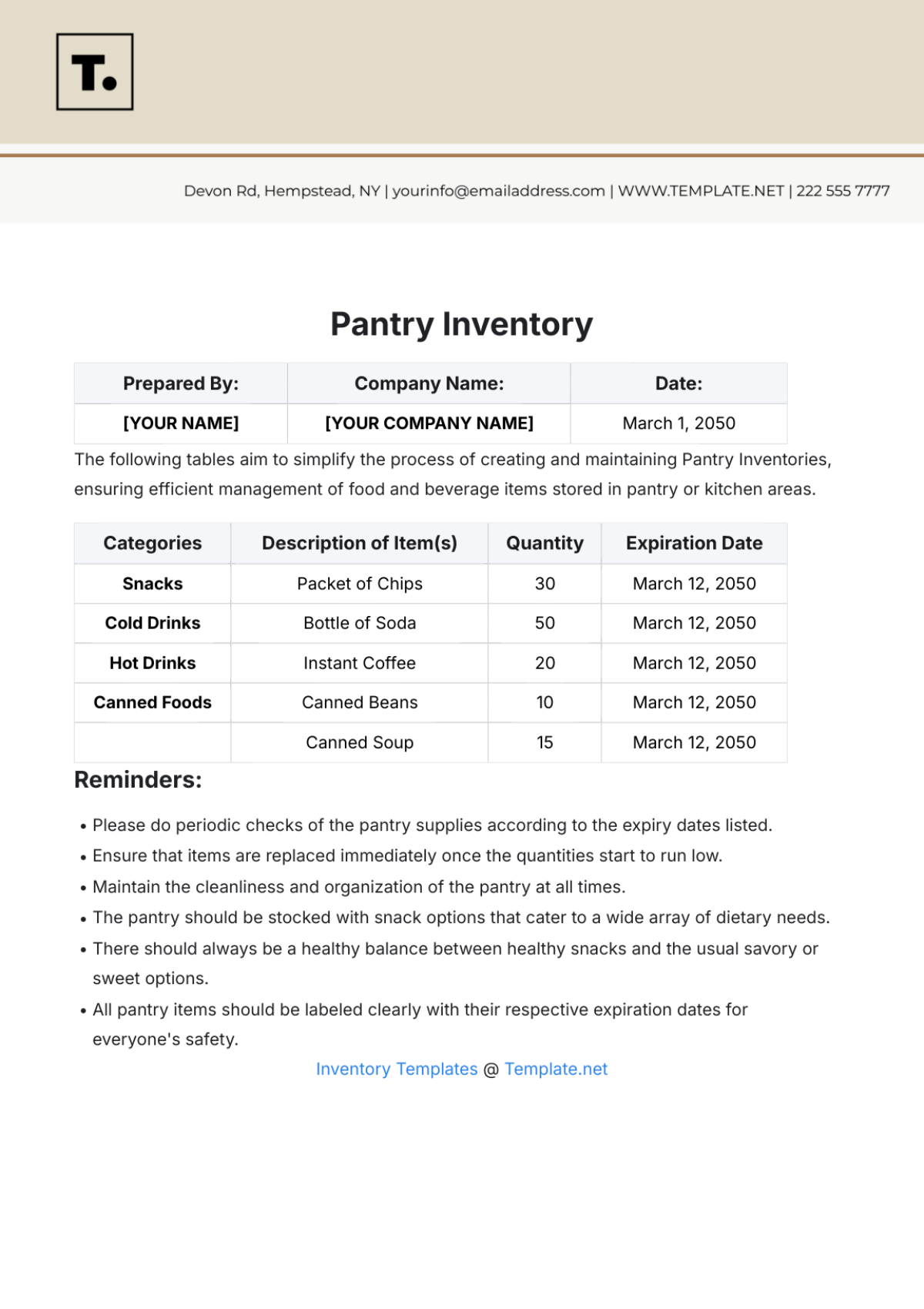

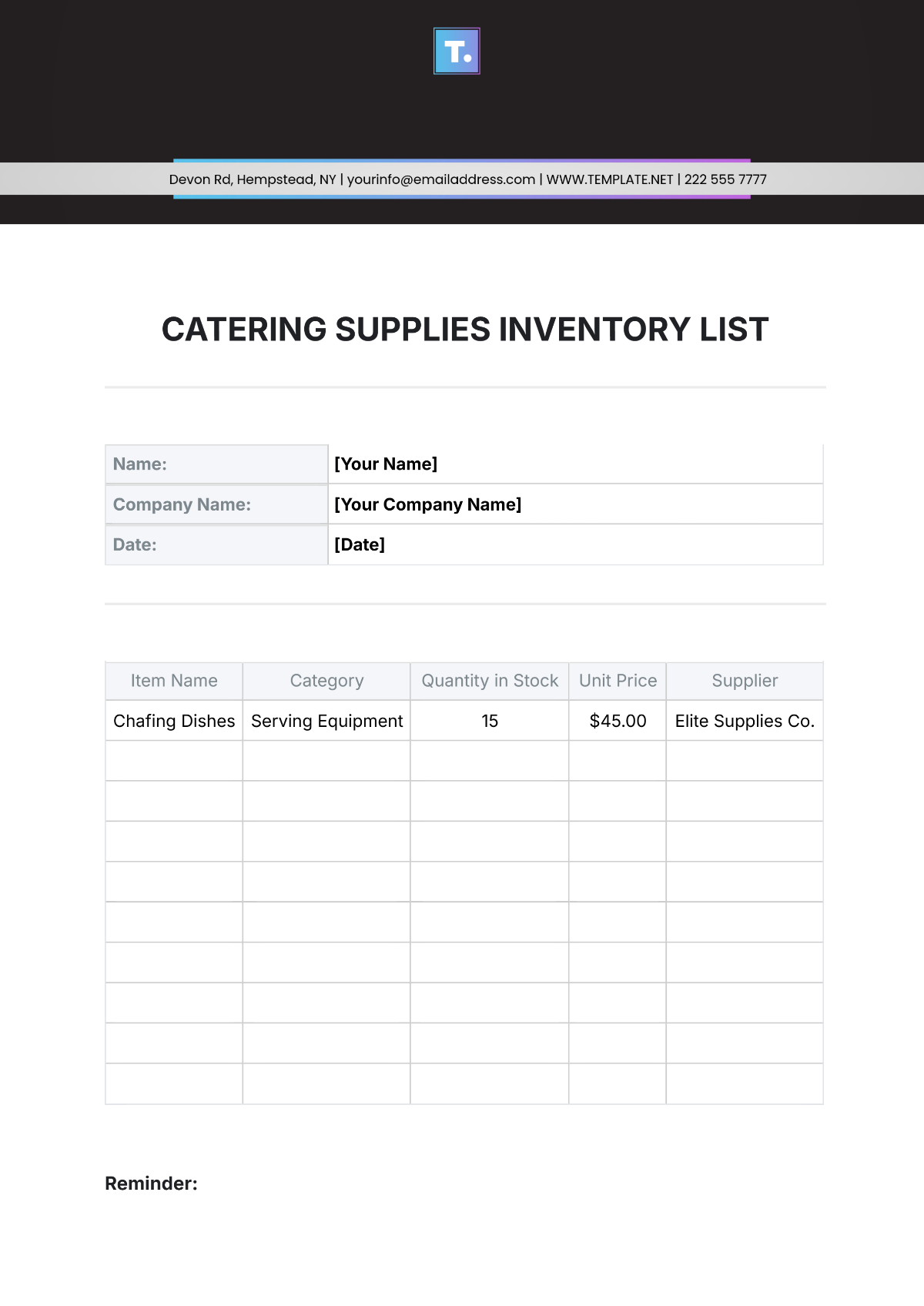

B. Category-Wise Analysis

1. Raw Materials

Total Raw Material Inventory: 5000 units

Raw Material Usage: 3000 units

Raw Material Variance: +10% compared to the previous month

2. Work-in-Progress (WIP)

Total WIP Inventory: 2000 units

WIP Production Output: 1500 units

WIP Defect Rate: 1.5%

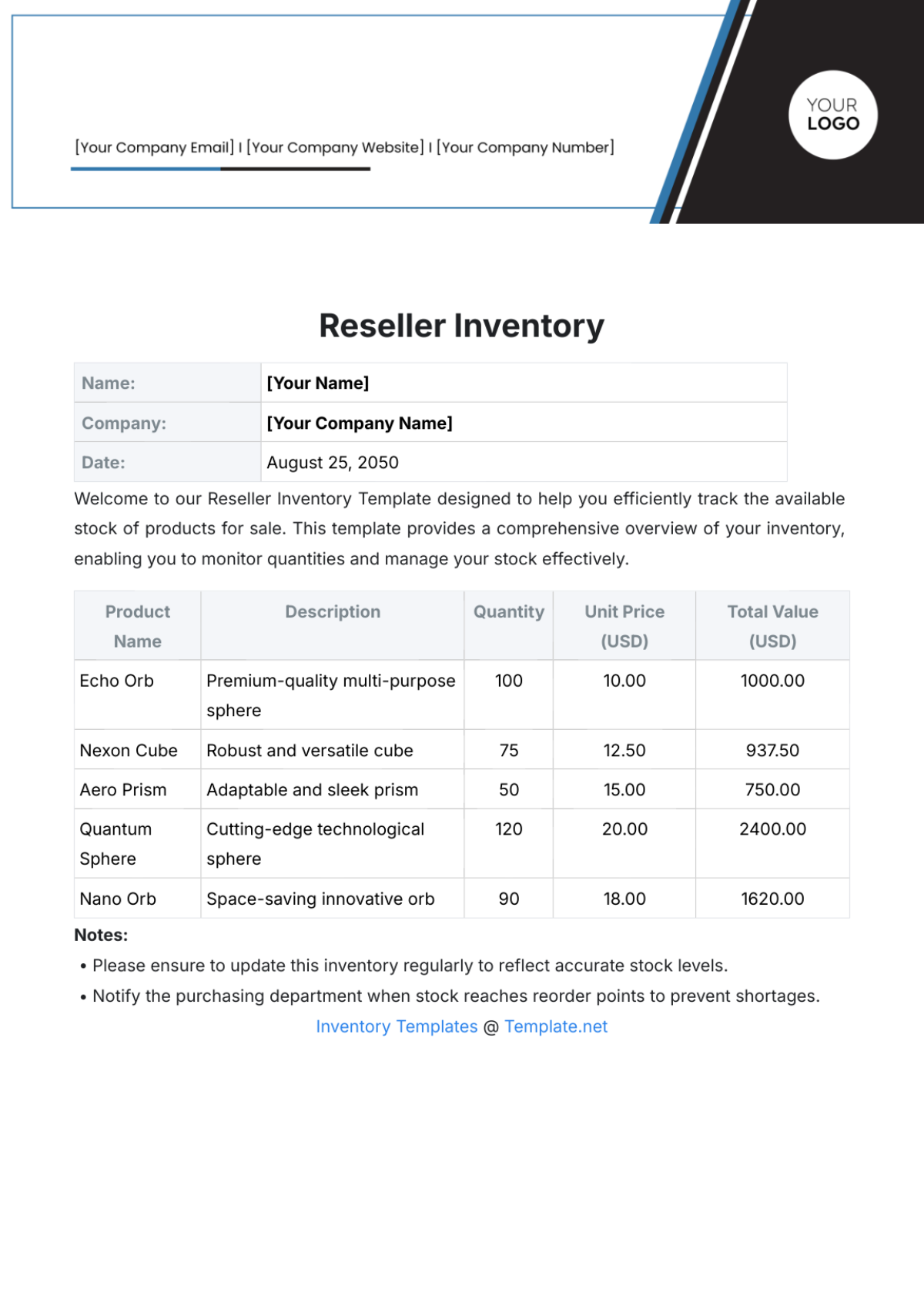

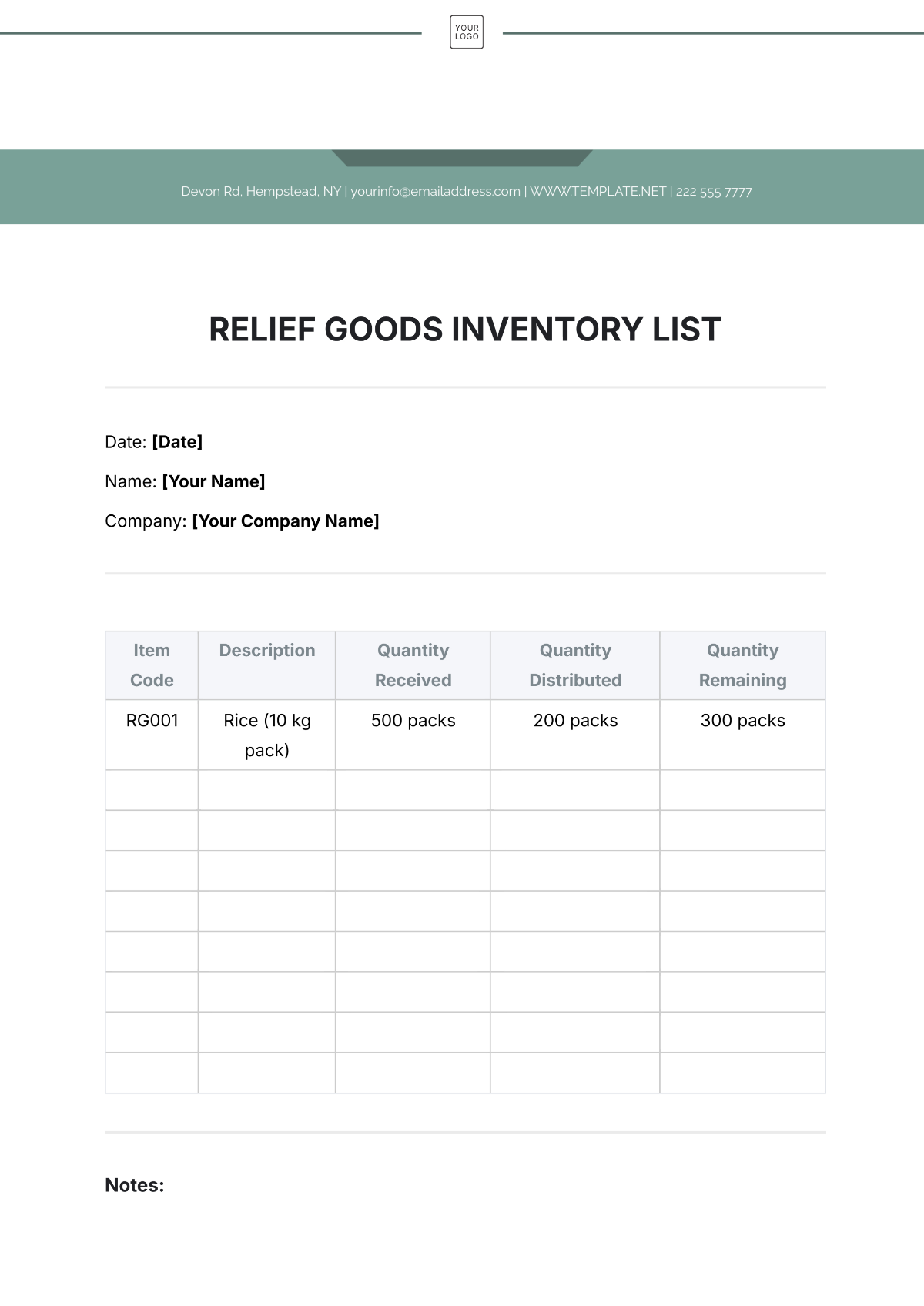

3. Finished Goods

Total Finished Goods Inventory: 8000 units

Finished Goods Sales: 6,000 units

Finished Goods Return Rate: 3%

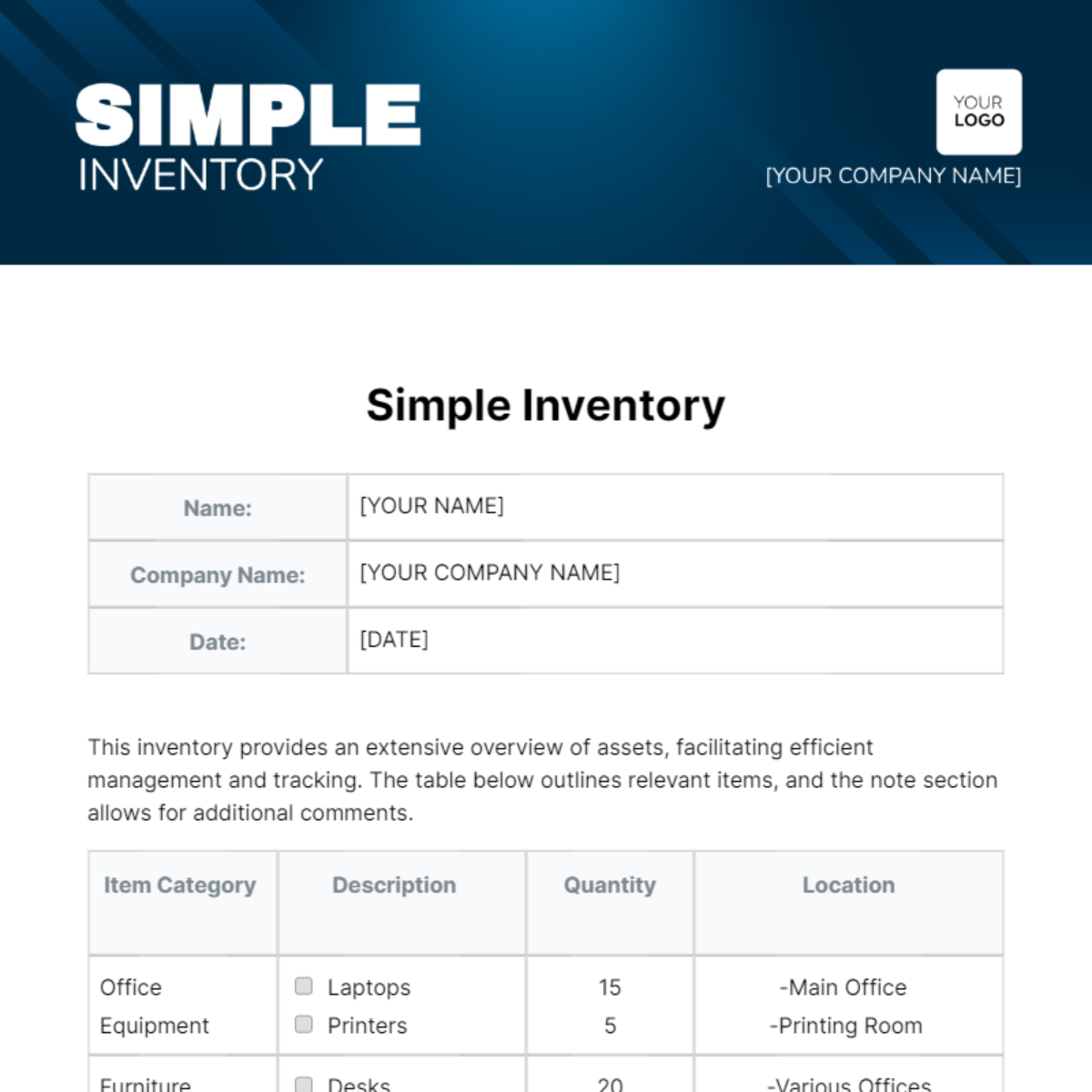

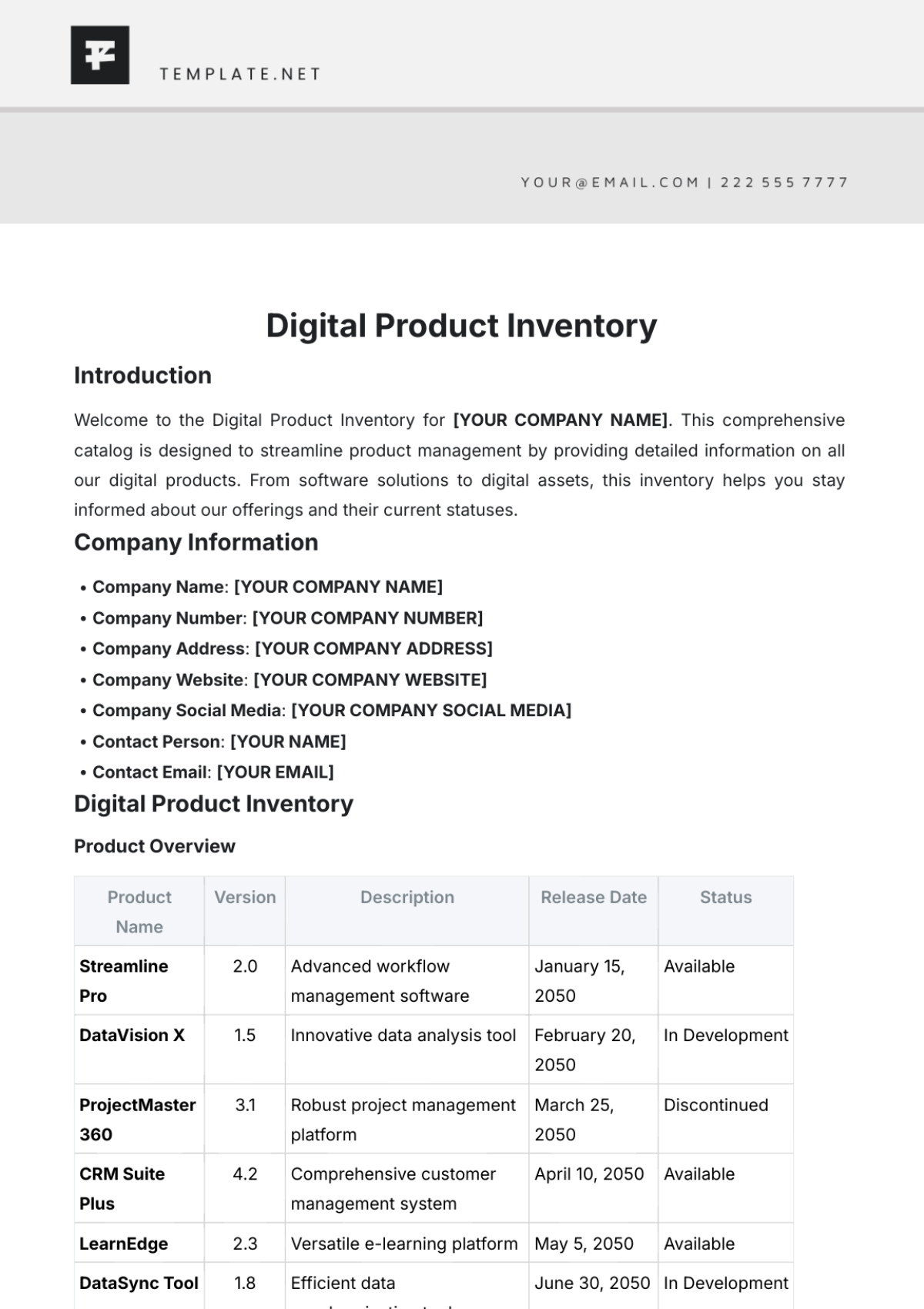

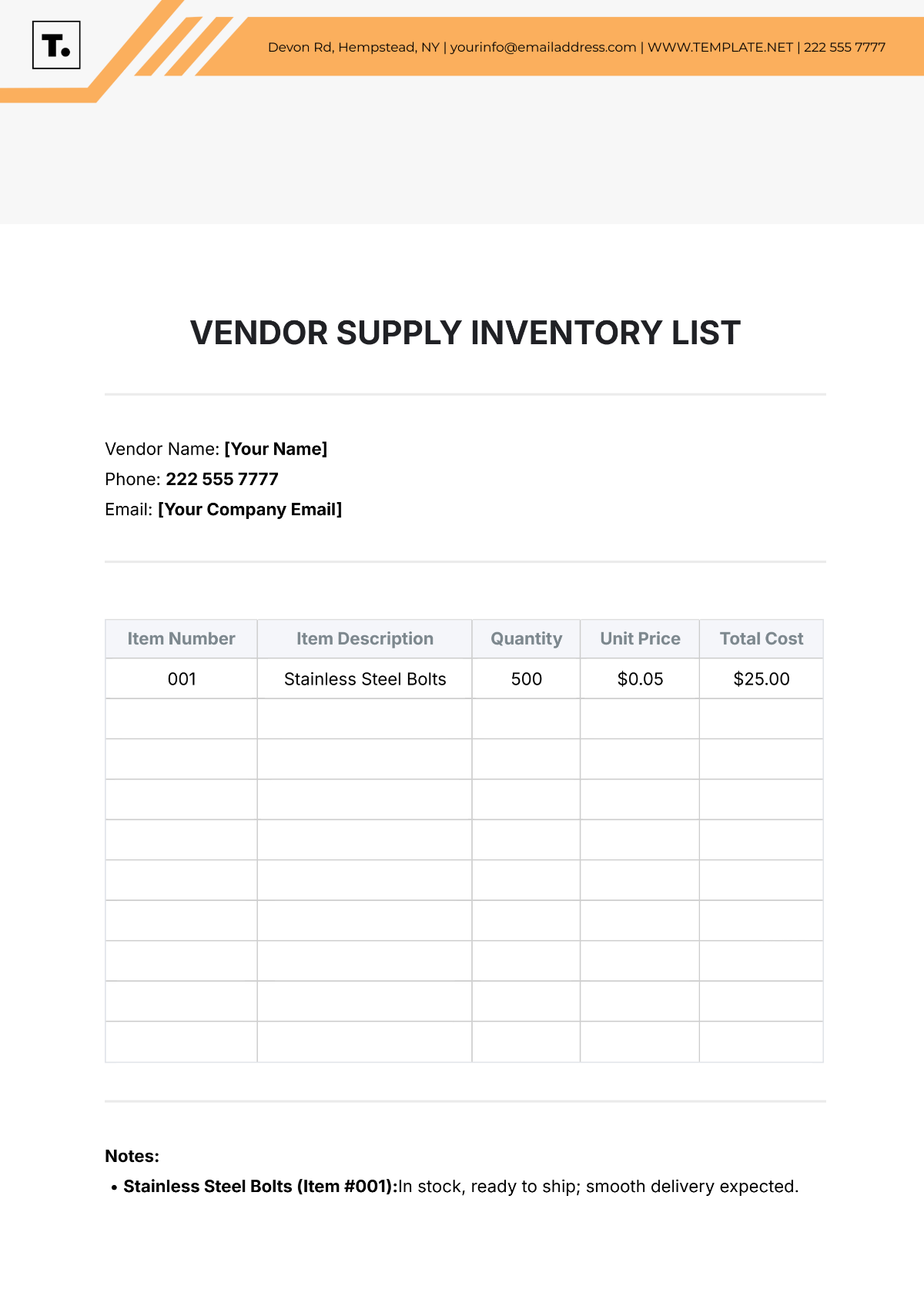

III. Inventory Forecast and Planning

A. Demand Forecast

Market Trends: Increasing demand for product X due to seasonal trends.

Customer Orders: Projected increase in customer orders by 10%.

B. Supply Planning

Supplier Performance: Supplier A has shown a decrease in lead times by 15%.

Lead Times: Anticipated lead times for procurement have decreased by 2 days.

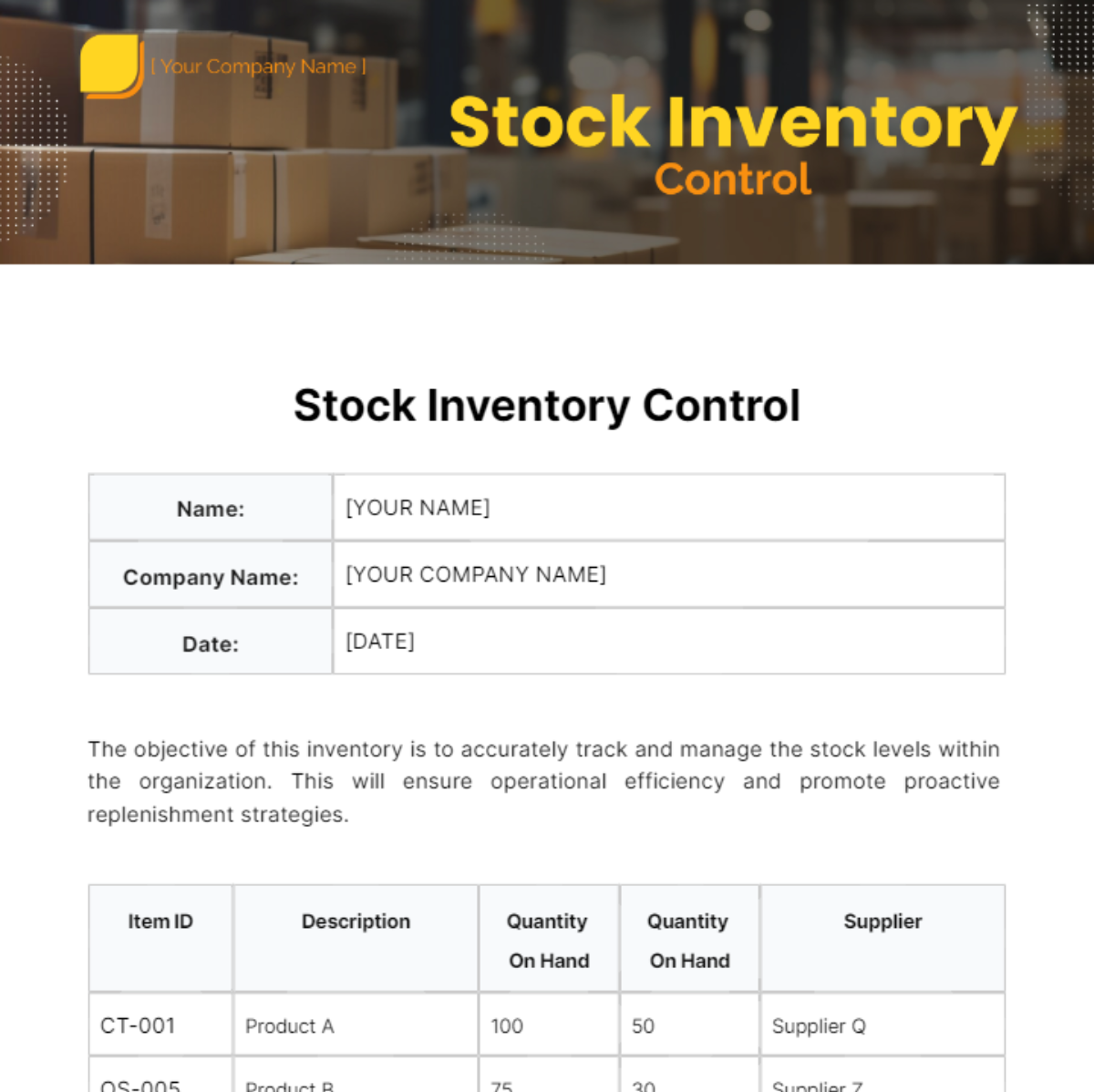

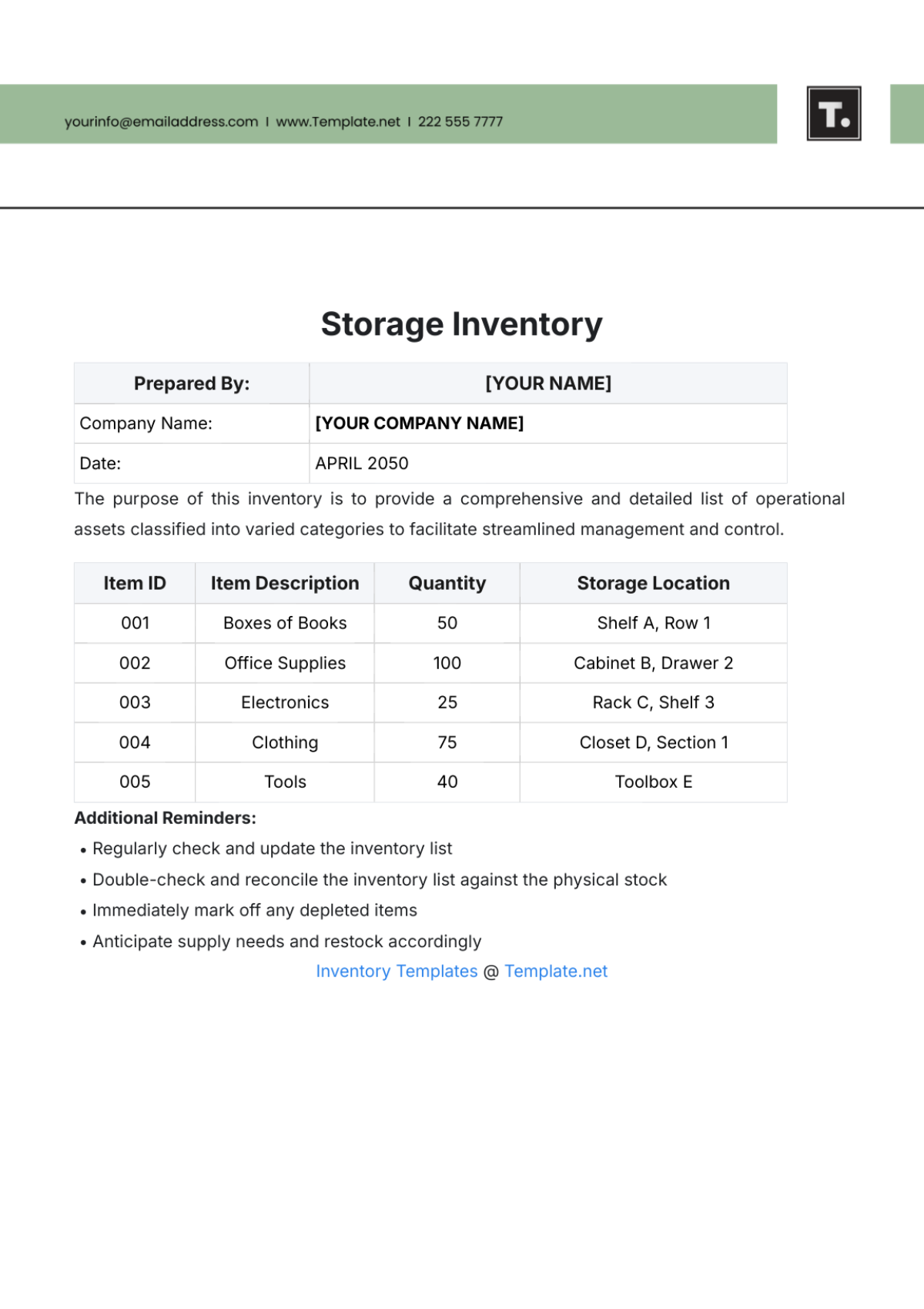

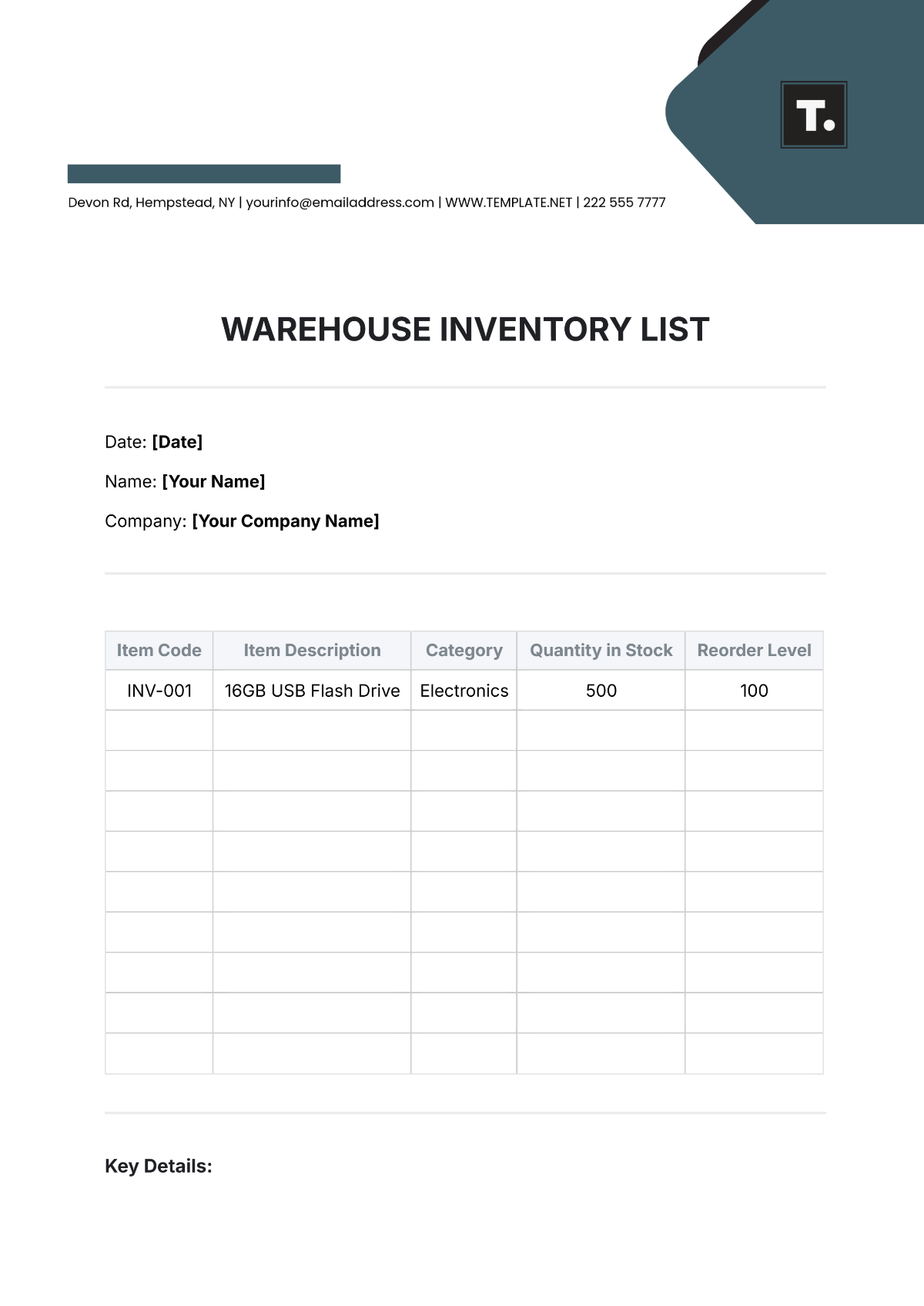

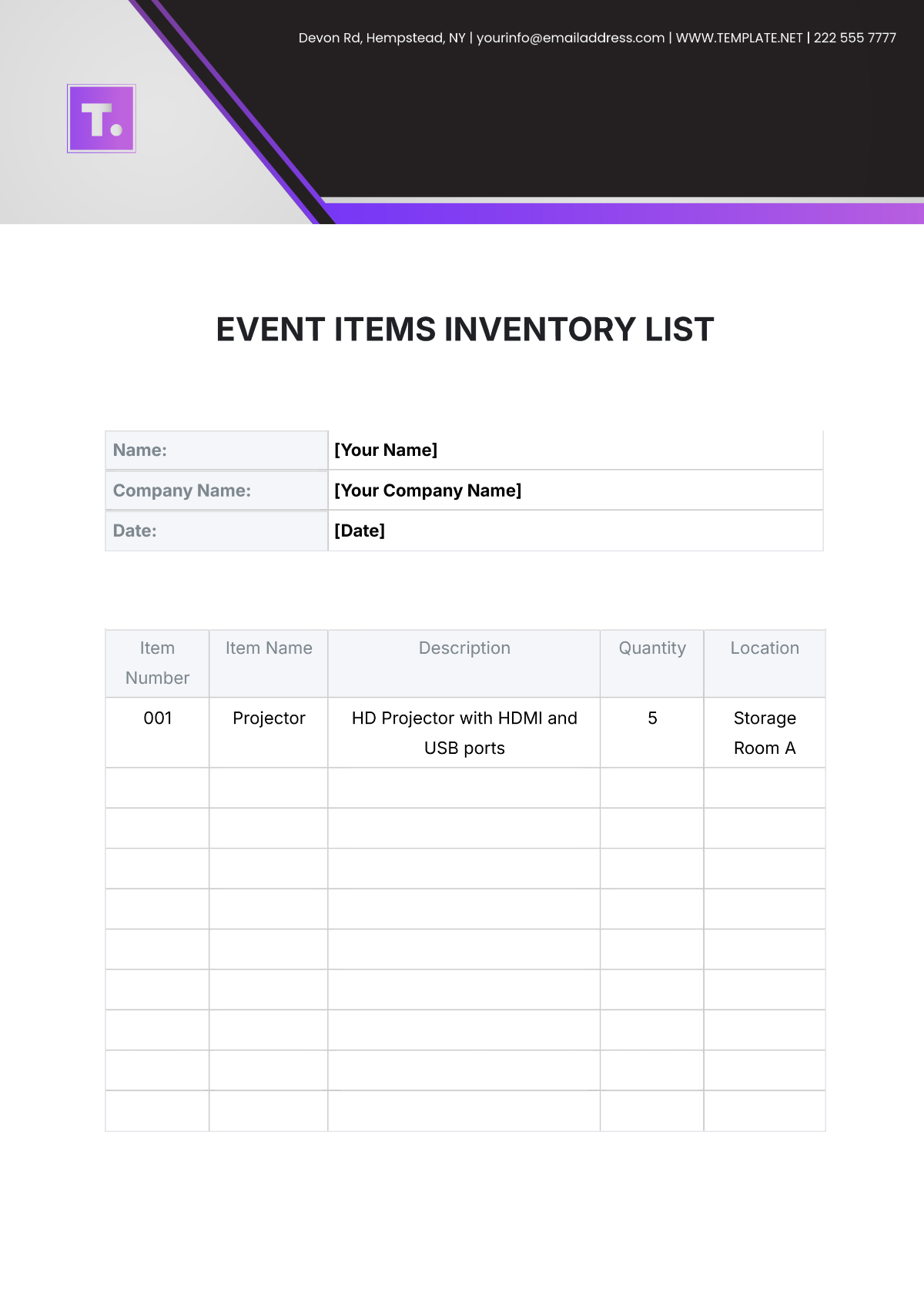

IV. Inventory Management Strategies

A. Inventory Optimization

ABC Analysis: Category A items contribute to 80% of the inventory value.

EOQ Calculation: EOQ analysis suggests ordering 1500 units for optimal replenishment.

B. Risk Mitigation

Buffer Stock: Recommendation for maintaining a buffer stock of 1000 units for critical items.

Obsolete Inventory Management: Strategies for handling obsolete inventory include implementing discounts and repurposing initiatives.

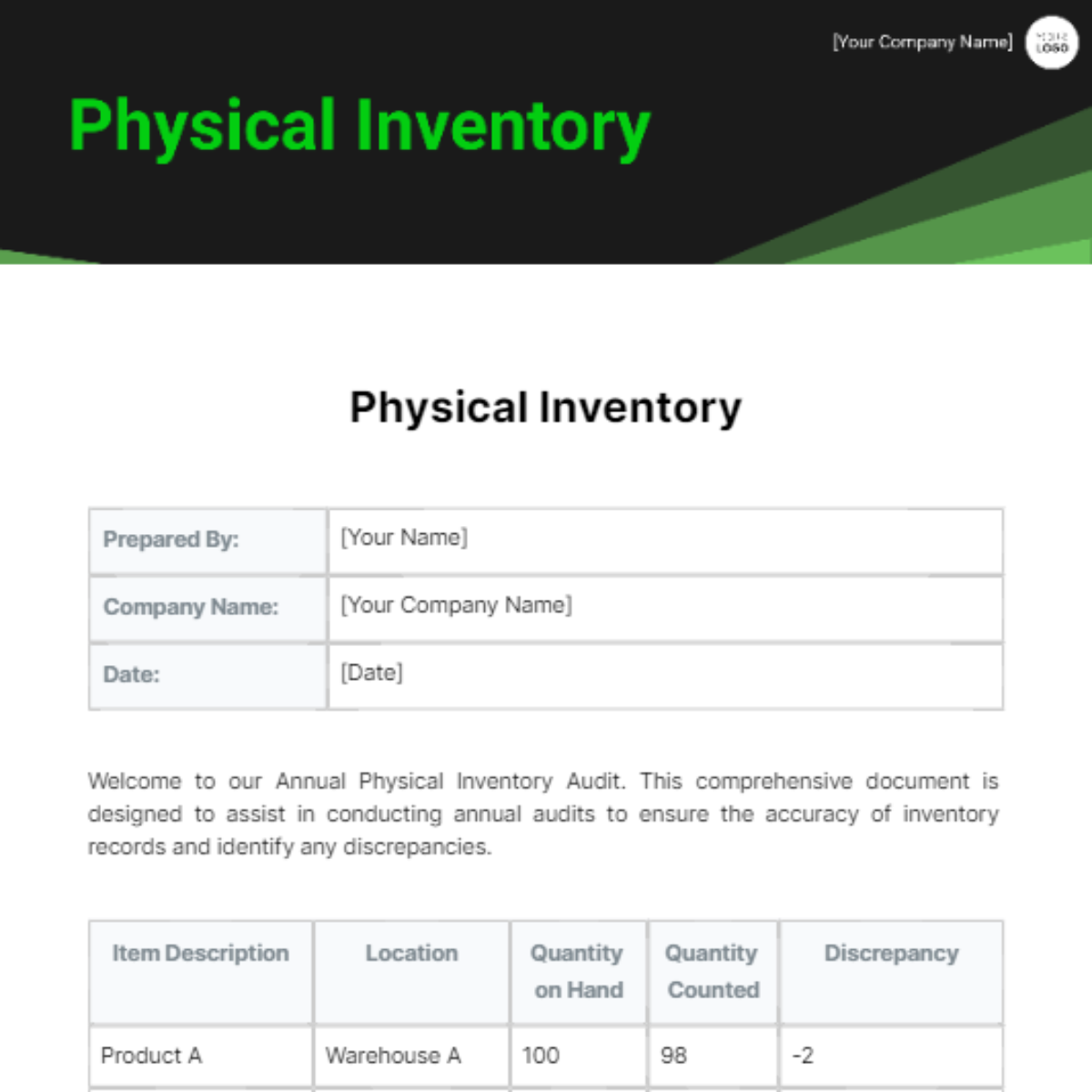

V. Recommendations

In this section, recommendations based on the analysis and insights provided will be presented to improve inventory management efficiency and effectiveness.

For any inquiries or further information, please contact:

[Your Name]

[Your Email]

[Your Company Name]

[Your Company Number]

[Your Company Address]

[Your Company Email]

[Your Company Website]

[Your Company Social Media]