Workplace Program Audit Report

I. Introduction

This OSHA Safety Program Audit Report has been prepared by [Your Company Name] to assess the compliance and effectiveness of our workplace safety programs as per Occupational Safety and Health Administration (OSHA) standards. The audit was conducted by [Your Name] on December 1, 2050.

II. Audit Objectives

The primary objectives of the audit are to:

Identify potential safety hazards in the workplace

Ensure compliance with OSHA regulations

Evaluate the effectiveness of current safety protocols

Provide recommendations for improvement

III. Audit Scope

The audit covered the following areas:

Employee Safety Training Programs

Emergency Evacuation Procedures

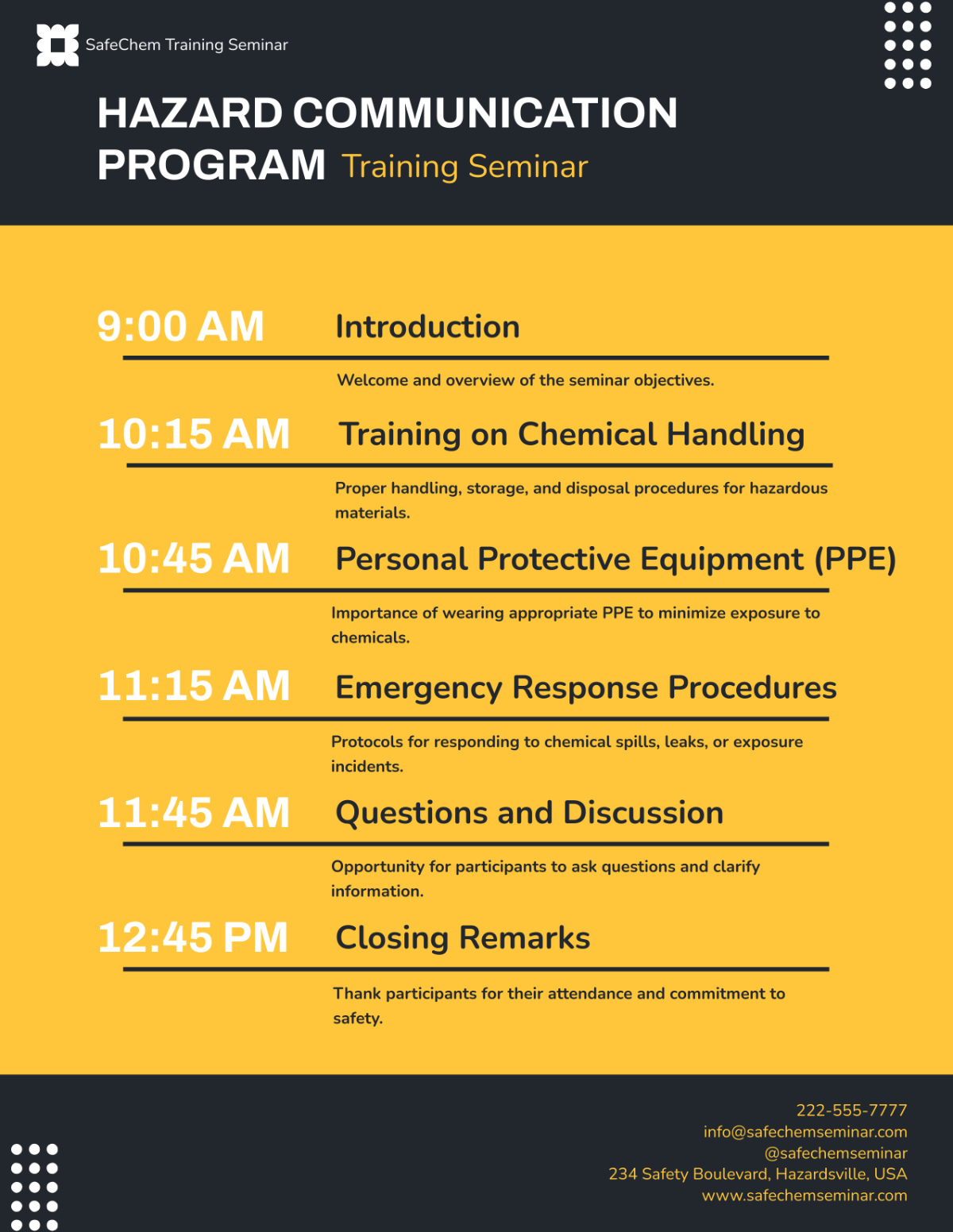

Personal Protective Equipment (PPE) Usage

Accident and Incident Reporting

Workplace Safety Inspections

IV. Methodology

The following methods were used to conduct the audit:

Review of safety training records

Interviews with employees and safety officers

On-site inspections and observations

Review of incident and accident reports

V. Findings

1. Employee Safety Training Programs

Observation: Training records indicate that 95% of employees have completed the mandatory safety training. However, 5% of new hires have not yet undergone safety orientation.

Recommendation: Ensure all new hires complete safety orientation within the first week of employment.

2. Emergency Evacuation Procedures

Observation: Emergency evacuation drills are conducted bi-annually. However, some exit routes are obstructed by equipment.

Recommendation: Conduct monthly inspections of exit routes to ensure they remain clear at all times.

3. Personal Protective Equipment (PPE) Usage

Observation: PPE usage is generally good, but there are instances of non-compliance in the manufacturing area.

Recommendation: Reinforce the importance of PPE usage and conduct random checks to ensure compliance.

4. Accident and Incident Reporting

Observation: All incidents are reported promptly, but the follow-up investigations are sometimes delayed.

Recommendation: Establish a stricter timeline for follow-up investigations to be completed within 48 hours of an incident.

5. Workplace Safety Inspections

Observation: Regular safety inspections are conducted, but there is a lack of documented corrective actions.

Recommendation: Maintain detailed records of corrective actions taken in response to identified hazards.

VI. Conclusion

The audit revealed several areas where [Your Company Name] is compliant with OSHA standards, as well as areas requiring improvement. By addressing the recommendations provided, the safety program can be further enhanced to ensure a safe workplace environment.

VII. Auditor's Information

[Your Name]

[Your Email]