Agriculture Cost Reduction Analysis

I. Introduction

Cost reduction in agriculture is crucial for ensuring long-term sustainability and competitiveness. By identifying and eliminating inefficiencies, we can enhance productivity, improve profitability, and strengthen our position in the market. This Agriculture Cost Reduction Analysis aims to systematically identify cost-saving opportunities, optimize processes, and implement innovative solutions to achieve significant cost reductions while maintaining high standards of quality and productivity.

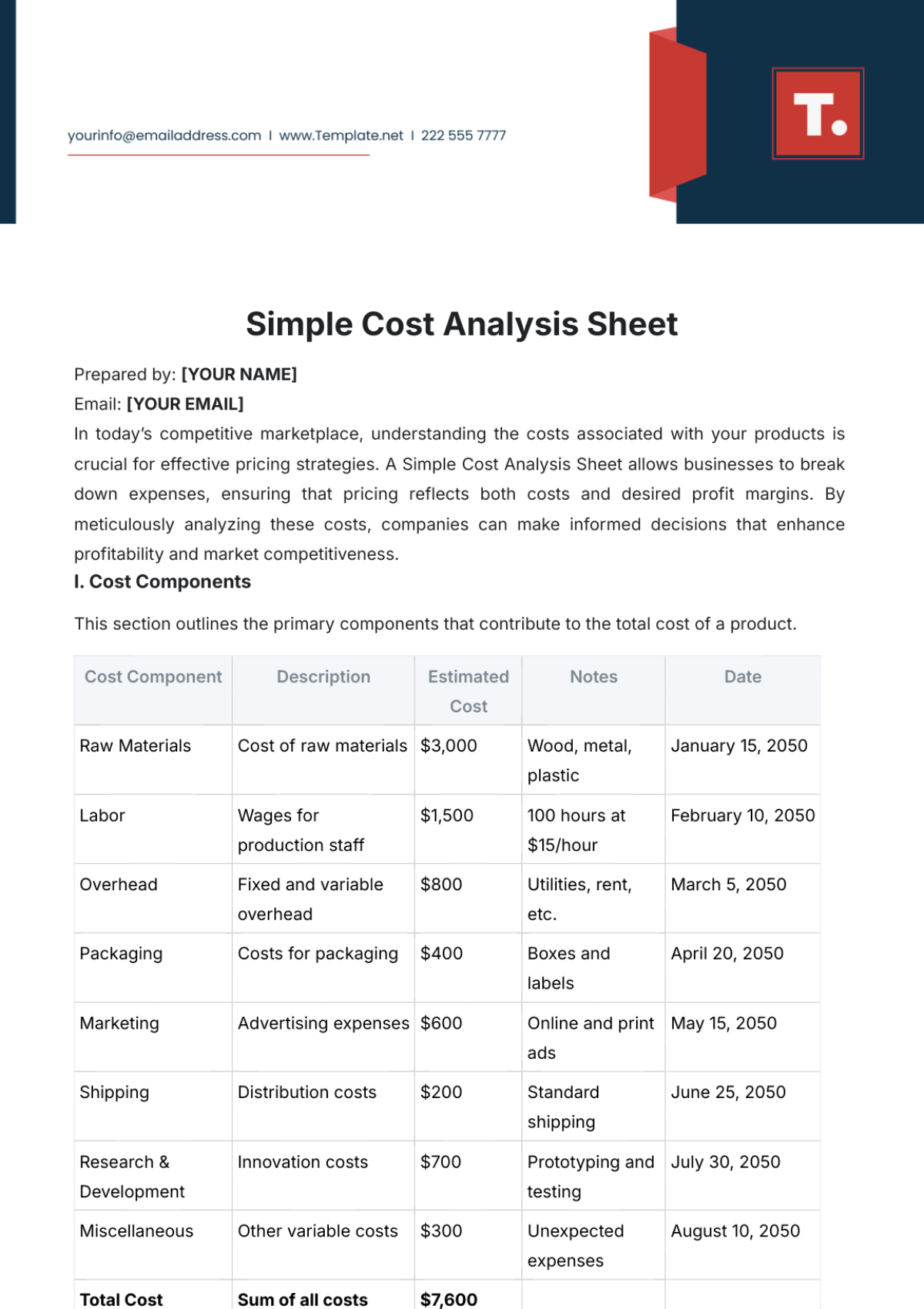

II. Current Cost Structure

Understanding our current cost structure is the first step towards identifying areas for improvement. We have conducted a thorough analysis of our expenses, categorizing them into fixed and variable costs.

Cost Component | Cost (USD) | Percentage |

|---|---|---|

Labor Costs | $1,200,000 | 30% |

Equipment and Machinery | $800,000 | 20% |

Fertilizers and Pesticides | $600,000 | 15% |

Seeds and Planting Material | $500,000 | 12.5% |

Irrigation and Water | $300,000 | 7.5% |

Energy Costs | $250,000 | 6.25% |

Transportation and Logistics | $150,000 | 3.75% |

Maintenance and Repairs | $200,000 | 5% |

Miscellaneous | $100,000 | 2.5% |

Total | $4,100,000 | 100% |

The analysis reveals that labor costs, equipment and machinery, and fertilizers and pesticides are the primary cost drivers, accounting for 65% of the total costs. These areas present significant opportunities for cost savings through optimization and innovative practices.

III. Cost Reduction Objectives

To achieve our cost reduction goals, we have identified several key objectives:

Reduce Labor Costs: Implement automation and mechanization to reduce reliance on manual labor.

Optimize Equipment Utilization: Enhance the efficiency and lifespan of equipment through regular maintenance and upgrades.

Minimize Input Costs: Optimize the use of fertilizers, pesticides, and seeds to reduce wastage and costs.

Improve Water and Energy Efficiency: Implement advanced irrigation systems and renewable energy sources to reduce water and energy costs.

Streamline Logistics: Optimize transportation and logistics to reduce costs and improve efficiency.

Enhance Maintenance Practices: Implement preventive maintenance programs to reduce repair costs and downtime.

IV. Cost Reduction Opportunities

We have identified several cost-saving opportunities across different areas of our operations. Each opportunity has been evaluated for its potential impact and priority.

Cost-Saving Area | Impact | Priority |

|---|---|---|

Automation of Labor | High | High |

Precision Agriculture | Medium | Medium |

Drip Irrigation Systems | High | High |

Renewable Energy Sources | Medium | Low |

Bulk Purchasing of Inputs | Low | Medium |

Preventive Maintenance | High | High |

Route Optimization for Logistics | Medium | Medium |

Implementing these opportunities can lead to significant cost savings. For example, automation of labor can drastically reduce labor costs, while precision agriculture can optimize input usage, reducing overall input costs. Drip irrigation systems can improve water efficiency, and preventive maintenance can reduce downtime and repair costs.

V. Process Optimization

Identifying and addressing inefficiencies in our processes is crucial for achieving cost reductions. We have identified several inefficiencies that need to be addressed:

High reliance on manual labor for repetitive tasks.

Lack of regular maintenance leading to frequent breakdowns.

Over-application of fertilizers and pesticides.

Ineffective irrigation methods leading to water wastage.

Reliance on non-renewable energy sources.

Poor route planning and high transportation costs.

To address these inefficiencies, we will implement the following improvements:

Invest in machinery and automation to reduce manual labor.

Establish a preventive maintenance program to extend equipment lifespan and reduce breakdowns.

Utilize data-driven approaches to optimize the use of fertilizers and pesticides.

Implement drip irrigation to enhance water efficiency.

Transition to renewable energy sources to reduce energy costs.

Use route optimization software to improve transportation efficiency.

These improvements will streamline our operations, reduce costs, and enhance overall efficiency, contributing to significant cost savings and improved productivity.

VI. Labor and Workforce Management

Labor costs are a significant component of our overall expenditure. By managing our workforce more efficiently and adopting labor-saving technologies, we can significantly reduce costs. Our analysis of labor costs is detailed below.

Labor Category | Annual Cost (USD) |

|---|---|

Field Workers | $800,000 |

Equipment Operators | $250,000 |

Maintenance Personnel | $100,000 |

Administrative Staff | $50,000 |

Total | $1,200,000 |

To reduce labor costs, we will implement the following strategies:

Automation and Mechanization: Invest in machinery and automation to perform repetitive and labor-intensive tasks, reducing the need for field workers.

Training and Upskilling: Provide training programs to enhance the skills of our current workforce, enabling them to operate new technologies and equipment more efficiently.

Flexible Workforce Management: Implement flexible labor arrangements, such as part-time and seasonal contracts, to align workforce capacity with seasonal demand.

VII. Resource Management

Efficient resource management is essential to reducing costs and promoting sustainability. We have analyzed our current resource usage to identify areas for improvement.

Resource | Annual Usage | Cost (USD) |

|---|---|---|

Water | 10,000,000 gallons | $300,000 |

Energy | 1,000,000 kWh | $250,000 |

Fertilizers | 500 tons | $300,000 |

Pesticides | 100 tons | $300,000 |

Seeds and Planting Material | 50,000 units | $500,000 |

Total | $1,650,000 |

We will implement the following strategies to optimize resource usage:

Precision Agriculture: Use data analytics and precision farming techniques to apply the right amount of inputs (fertilizers, pesticides) at the right time, minimizing wastage.

Advanced Irrigation Systems: Implement drip and precision irrigation systems to reduce water usage.

Energy Efficiency Measures: Invest in energy-efficient equipment and explore renewable energy sources to reduce energy costs.

VIII. Risk Management

Identifying and mitigating risks is crucial to ensuring the success of our cost reduction initiatives. The table below outlines the key risks, their likelihood, and impact.

Risk | Likelihood | Impact |

|---|---|---|

Technology Integration Issues | Medium | High |

Regulatory Compliance Challenges | Low | Medium |

Financial Constraints | Medium | High |

Training Effectiveness | Low | Medium |

Market Acceptance | Medium | High |

To mitigate these risks, we will implement the following strategies:

Establish a team to manage technology integration and provide ongoing support.

Regularly audit our operations to ensure regulatory compliance.

Secure multiple funding sources to ensure financial stability.

Continuously evaluate and improve training programs to ensure their effectiveness.

Conduct thorough market research to understand and address potential market acceptance issues.

IX. Monitoring and Evaluation

Effective monitoring and evaluation are essential to track the progress and success of our cost reduction initiatives. The table below outlines the key metrics and target values.

Metric | Target Value |

|---|---|

Reduction in Labor Costs | 20% annually |

Reduction in Resource Usage | 15% annually |

Increase in Equipment Efficiency | 25% annually |

Compliance with Regulations | 100% |

Employee Satisfaction Rate | 85% positive feedback |

We will implement a robust monitoring and reporting system to track these metrics. Regular reports will be generated and reviewed by the management team, and any deviations from the target values will be promptly addressed through corrective actions.

X. Implementation Plan

The implementation plan outlines the key milestones, timelines, and responsibilities for executing our cost reduction initiatives.

Milestone | Timeline | Responsibility |

|---|---|---|

Technology Procurement | Procurement Manager | |

Training Program Launch | HR Manager | |

Precision Agriculture Implementation | Operations Manager | |

Drip Irrigation Installation | Project Manager | |

Renewable Energy Setup | Energy Manager | |

Preventive Maintenance Program | Maintenance Manager | |

Logistics Optimization | Logistics Manager |

This phased implementation approach ensures that each initiative is rolled out systematically, with clear timelines and assigned responsibilities.

XI. Next Steps

Our next steps involve mobilizing the resources required to kick-start the implementation of our cost reduction initiatives. This includes securing the necessary funding, procuring technology and equipment, and setting up training programs for our workforce. We will also establish a dedicated project management team to oversee the execution of the plan and ensure that we stay on track to achieve our cost reduction objectives. Continuous communication and collaboration with all stakeholders will be essential to the success of this plan, as we strive to build a more efficient and sustainable agricultural operation.