Agriculture Tool Investment Analysis

1. Introduction

1.1 Overview

Investing in the right agricultural tools is critical for enhancing the efficiency, productivity, and sustainability of farming operations. Modern agricultural tools and technologies can significantly improve various aspects of farming, from planting and harvesting to irrigation and pest control. The use of advanced tools helps in reducing manual labor, increasing precision, and optimizing resource use, ultimately leading to higher yields and better-quality produce.

This comprehensive analysis aims to evaluate the potential return on investment (ROI) for acquiring new agricultural tools for [Your Company Name]. The analysis covers several key areas essential for informed decision-making:

Current Tool Inventory: An in-depth review of our existing tool inventory to understand its current state, including the condition, age, and performance of the tools.

Proposed Investments: Identification and justification of new tools required to replace outdated equipment and to supplement the existing inventory to meet future operational needs.

Cost-Benefit Analysis: A detailed financial analysis comparing the costs associated with acquiring new tools against the expected benefits, including increased productivity, reduced maintenance costs, and improved operational efficiency.

Financial Projections: Projections of the financial outcomes of the investment over a specified period, including estimated revenue increases and cost savings.

Strategic Recommendations: Practical and actionable recommendations to guide the acquisition and implementation of new tools, ensuring alignment with [Your Company Name]'s strategic goals and long-term vision.

1.2 Objectives

The objectives of this investment analysis are multifaceted, focusing on a thorough assessment of our current tool inventory, identifying critical needs, and providing a sound financial rationale for the proposed investments. The primary objectives include:

1. Assess the Current State of Agricultural Tools

Evaluating the existing tools is the first crucial step. This involves:

Inventory Review: Conducting a comprehensive inventory audit to document the types and quantities of tools currently in use. This includes manual tools, power tools, irrigation systems, planting and harvesting equipment, and any other specialized tools.

Condition Assessment: Examining the physical condition and functional performance of each tool. Tools that are outdated, frequently breaking down, or inefficient in operation will be flagged for replacement.

Usage Analysis: Understanding how often each tool is used, the tasks it performs, and its importance in daily operations. This helps prioritize which tools are critical for immediate investment.

2. Identify Tools Required to Improve Operational Efficiency

The next objective is to pinpoint specific tools that can enhance operational efficiency:

Needs Analysis: Identifying gaps in the current tool inventory that hinder operational efficiency. This could involve recognizing tools that are missing, underperforming, or not suited to modern farming practices.

Technological Advancements: Exploring new technologies and tools available in the market that can bring significant improvements to our operations. This includes tools with advanced features such as automation, precision farming capabilities, and sustainability benefits.

Operational Integration: Considering how new tools will integrate with existing processes and systems. Ensuring compatibility and ease of adoption is crucial for smooth implementation and maximizing benefits.

3. Conduct a Financial Analysis of the Proposed Investments

A detailed financial analysis is essential to justify the investment:

Cost Estimation: Estimating the total costs associated with purchasing new tools, including purchase price, installation, and any necessary training for employees.

Benefit Projection: Projecting the financial benefits of the new tools, such as increased revenue from higher yields, reduced labor costs, and lower maintenance expenses.

ROI Calculation: Calculating the expected return on investment over a specified period. This involves comparing the costs and benefits to determine the financial viability and profitability of the investment.

Sensitivity Analysis: Performing sensitivity analysis to understand how changes in key assumptions (e.g., tool lifespan, maintenance costs, yield improvements) impact the ROI. This helps assess the risk and uncertainty associated with the investment.

4. Provide Strategic Recommendations for Tool Acquisition

The final objective is to offer strategic recommendations based on the analysis:

Prioritization: Prioritizing tool acquisitions based on their impact on operational efficiency and financial performance. High-priority tools should be those that offer the greatest benefits relative to their costs.

Implementation Plan: Developing a phased implementation plan that outlines the timeline for acquiring and deploying new tools. This ensures a structured and manageable approach to upgrading the tool inventory.

Training and Support: Recommending training programs for employees to ensure they are proficient in using the new tools. Providing ongoing support and maintenance plans to maximize tool performance and longevity.

Sustainability Considerations: Ensuring that the chosen tools align with [Your Company Name]'s commitment to sustainability. This includes selecting tools that are energy-efficient, environmentally friendly, and support sustainable farming practices.

Continuous Improvement: Establishing metrics and processes for ongoing evaluation and improvement of the tool inventory. Regular reviews and updates will ensure that the tools remain effective and relevant to evolving operational needs.

By achieving these objectives, [Your Company Name] will be well-positioned to enhance its farming operations through strategic investments in advanced agricultural tools. This will lead to improved productivity, reduced costs, and a stronger competitive position in the agricultural industry. The following sections will delve deeper into each aspect of the analysis, providing detailed insights and actionable recommendations to guide the investment decision.

2. Current Tool Inventory

2.1 Existing Tools

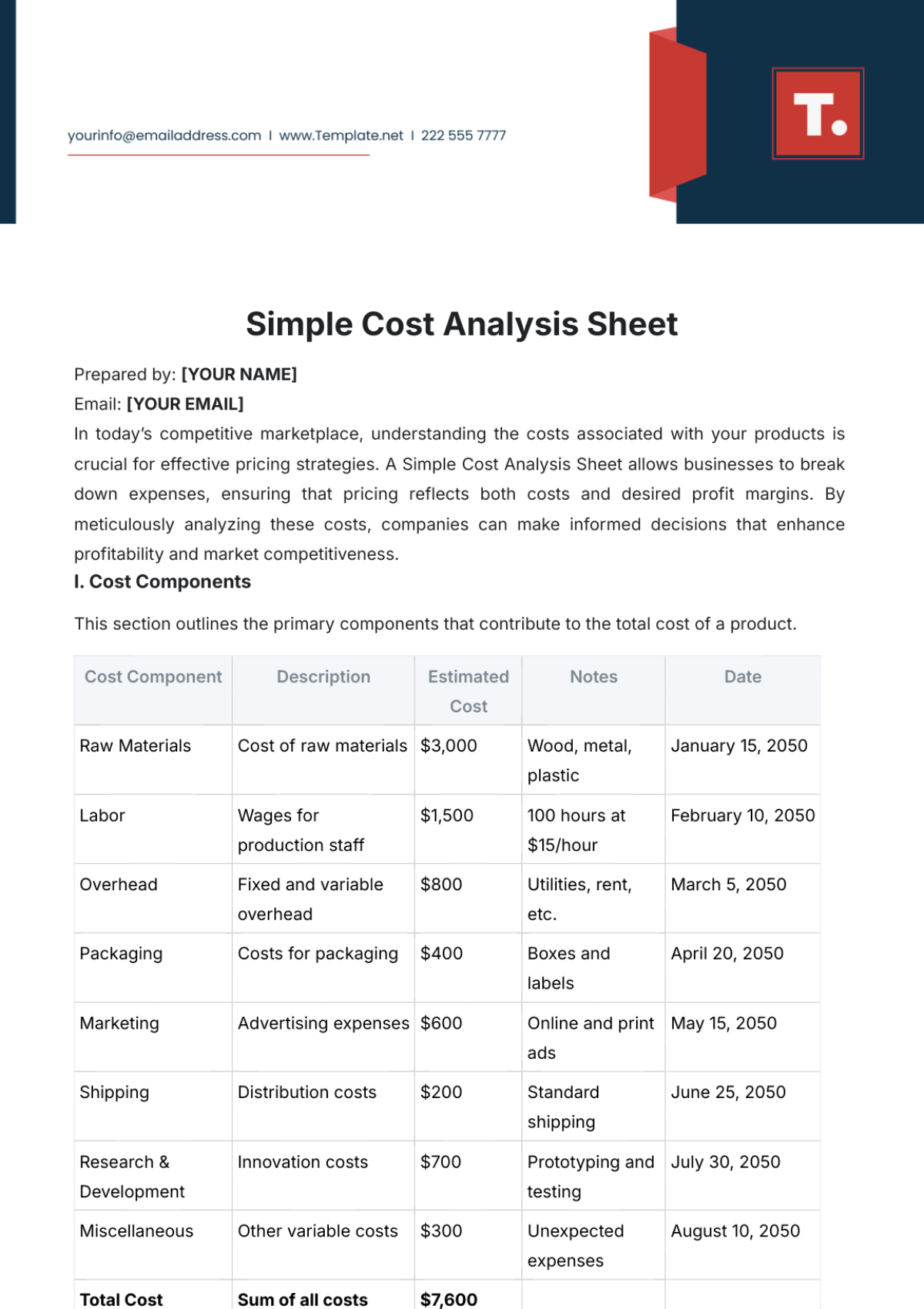

The following table provides an overview of the current tool inventory at [Your Company Name], including the quantity, average age, and condition of each type of tool.

Tool Type | Quantity | Average Age (Years) | Condition |

|---|---|---|---|

Hand Tools | 100 | 5 | Fair |

Power Tools | 50 | 3 | Good |

Sprayers | 30 | 4 | Fair |

Irrigation Systems | 20 | 6 | Poor |

Harvesting Equipment | 15 | 7 | Poor |

Planting Equipment | 25 | 4 | Fair |

2.2 Maintenance Costs

The following table outlines the annual maintenance costs for the current tool inventory over the past three years.

Tool Type | Annual Maintenance Cost ($) 2050 | Annual Maintenance Cost ($) 2049 | Annual Maintenance Cost ($) 2048 |

|---|---|---|---|

Hand Tools | 10,000 | 9,000 | 8,500 |

Power Tools | 15,000 | 14,000 | 13,500 |

Sprayers | 12,000 | 11,000 | 10,500 |

Irrigation Systems | 20,000 | 18,000 | 17,000 |

Harvesting Equipment | 25,000 | 23,000 | 22,000 |

Planting Equipment | 18,000 | 16,500 | 15,000 |

Total | 100,000 | 91,500 | 86,500 |

2.3 Operational Challenges

Frequent Breakdowns: Older tools and equipment are prone to frequent breakdowns, causing operational delays.

High Maintenance Costs: Rising maintenance expenses are straining the budget.

Inefficiency: Outdated tools limit the efficiency and productivity of farming operations.

3. Proposed Tool Investments

3.1 New Tools Acquisition

We propose acquiring the following new tools to replace and supplement our existing inventory:

Tool Type | Quantity | Estimated Cost per Unit ($) | Total Cost ($) |

|---|---|---|---|

Hand Tools | 120 | 150 | 18,000 |

Power Tools | 60 | 500 | 30,000 |

Advanced Sprayers | 40 | 800 | 32,000 |

Smart Irrigation Systems | 25 | 2,000 | 50,000 |

Modern Harvesting Equipment | 20 | 10,000 | 200,000 |

Precision Planting Equipment | 30 | 5,000 | 150,000 |

Total | 480,000 |

3.2 Technology Integration

Integrating advanced technology into our tools is essential for enhancing efficiency and productivity. Key technologies to be integrated include:

GPS and Auto-Guidance Systems: For precise planting, spraying, and harvesting.

Sensor Technology: To monitor soil conditions, moisture levels, and crop health.

Data Analytics Platforms: For real-time data collection and analysis, supporting informed decision-making.

3.3 Training and Development

To maximize the benefits of the new tools, comprehensive training programs will be implemented for our workforce. Training will cover:

Operation of New Tools: Ensuring employees are proficient in using the new equipment.

Maintenance Procedures: Training on regular maintenance tasks to minimize downtime.

Technology Utilization: Educating staff on how to leverage new technologies for improved productivity.

4. Financial Analysis

4.1 Cost Breakdown

The total cost for the proposed tool investment is $480,000. The following table provides a detailed cost breakdown:

Expense Category | Cost ($) |

|---|---|

New Tools Acquisition | 480,000 |

Technology Integration | 50,000 |

Training and Development | 20,000 |

Total | 550,000 |

4.2 Funding Plan

To finance the tool investment, we propose the following funding plan:

Internal Reserves: Utilize $200,000 from internal reserves.

Bank Loan: Secure a $300,000 loan from our banking partner at an interest rate of 5%.

Government Grants: Apply for $50,000 in agricultural equipment grants available from government programs.

4.3 Return on Investment (ROI)

Investing in new tools is expected to yield significant returns through increased productivity, reduced maintenance costs, and enhanced crop yields. The following table outlines the projected ROI over the next five years:

Year | Increased Revenue ($) | Cost Savings ($) | Total Benefits ($) | Cumulative ROI (%) |

|---|---|---|---|---|

2050 | 100,000 | 20,000 | 120,000 | 22% |

2051 | 120,000 | 25,000 | 145,000 | 26% |

2052 | 150,000 | 30,000 | 180,000 | 33% |

2053 | 170,000 | 35,000 | 205,000 | 37% |

2054 | 200,000 | 40,000 | 240,000 | 44% |

Total | 740,000 | 150,000 | 890,000 | 32.5% |

4.4 Cost-Benefit Analysis

The benefits of the tool investment extend beyond financial returns. Key benefits include:

Increased Efficiency: Enhanced tools and technology reduce operational time and labor costs.

Improved Crop Yields: Precision farming techniques increase crop yields and quality.

Reduced Environmental Impact: Eco-friendly tools reduce emissions and resource usage.

Enhanced Worker Safety: Modern tools with advanced safety features improve workplace safety.

5. Implementation Plan

5.1 Project Timeline

The implementation of the tool investment will follow a phased approach, ensuring minimal disruption to ongoing operations. The following table outlines the proposed project timeline:

Phase | Duration | Activities |

|---|---|---|

Planning and Procurement | January - February 2050 | Finalize tool specifications, place orders with vendors. |

Tool Delivery | March - April 2050 | Receive and inspect new tools. |

Technology Integration | May - June 2050 | Install and integrate advanced technologies. |

Training and Development | July - August 2050 | Conduct comprehensive training programs for employees. |

Full Implementation | September - October 2050 | Complete rollout and commence full-scale operations. |

5.2 Risk Management

Identifying and mitigating risks is essential for the successful implementation of the tool investment. Key risks and mitigation strategies include:

Supply Chain Delays: Establish multiple suppliers to ensure timely delivery of tools.

Technical Challenges: Engage with technology experts for seamless integration and troubleshooting.

Budget Overruns: Monitor expenses closely and adjust the budget as necessary.

Employee Resistance: Involve employees early in the planning process and provide incentives for participation.

5.3 Monitoring and Evaluation

Ongoing monitoring and evaluation will ensure the successful implementation and operation of the new tools. Key metrics to be monitored include:

Tool Performance: Regular performance assessments to ensure tools are operating optimally.

Productivity Metrics: Tracking improvements in productivity and efficiency.

Maintenance Records: Monitoring maintenance activities to prevent equipment failures.

Financial Performance: Regular financial reviews to evaluate ROI and cost savings.

6. Strategic Recommendations

6.1 Continuous Training

Investing in ongoing training programs will ensure that employees remain proficient in using the new tools and technologies. Continuous training will also help employees adapt to any future technological advancements.

6.2 Supplier Partnerships

Developing strong partnerships with multiple suppliers will ensure a reliable supply chain for new tools and replacement parts. These partnerships can also provide opportunities for bulk purchasing discounts and priority service.

6.3 Technology Upgrades

Regularly upgrading technology and tools will keep [Your Company Name] at the forefront of agricultural innovation. Investing in the latest advancements will enhance operational efficiency and maintain a competitive edge.

6.4 Sustainable Practices

Implementing sustainable practices in tool usage and maintenance will reduce environmental impact and support long-term agricultural sustainability. This includes using eco-friendly tools, reducing waste, and promoting resource conservation.

6.5 Financial Planning

Careful financial planning and monitoring will ensure that the investment in new tools is cost-effective and aligns with the company's long-term financial goals. Regular financial reviews will help identify areas for cost savings and efficiency improvements.

7. Conclusion

7.1 Summary

The proposed investment in new agricultural tools is a strategic initiative that will significantly enhance [Your Company Name]'s operational efficiency, productivity, and sustainability. By acquiring advanced tools and integrating cutting-edge technologies, we will improve crop yields, reduce maintenance costs, and support sustainable farming practices.

7.2 Final Recommendations

We recommend proceeding with the proposed tool investment to capitalize on the numerous benefits and opportunities it offers. For further information or to discuss the proposal in detail, please contact [Your Name] at [Your Email] or [Your Company Number].