Free Machinery Maintenance Schedule

I. Introduction

Maintaining machinery is crucial for ensuring optimal performance and longevity. A structured maintenance schedule helps in identifying and addressing potential issues before they become significant problems. This document outlines the regular maintenance tasks, frequencies, and responsibilities for machinery upkeep.

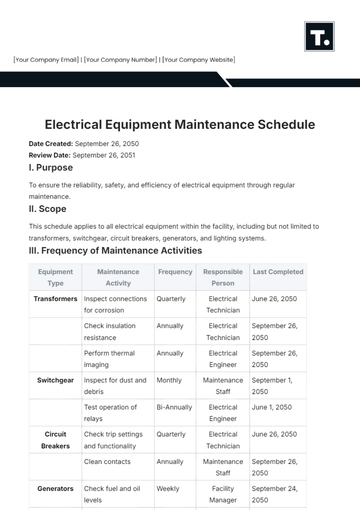

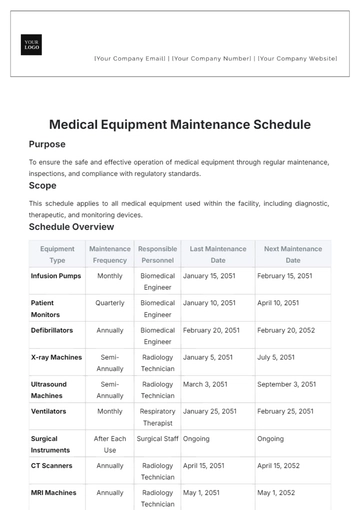

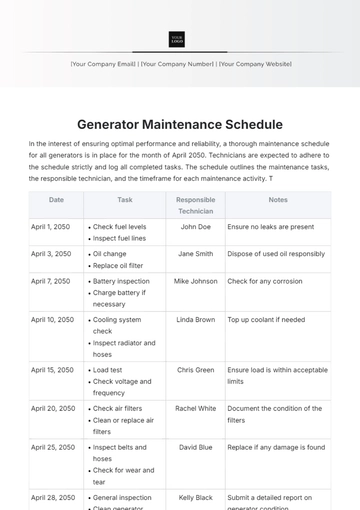

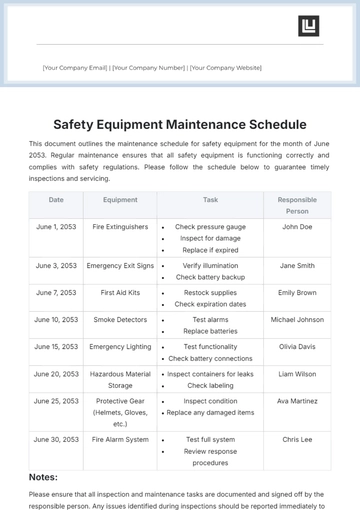

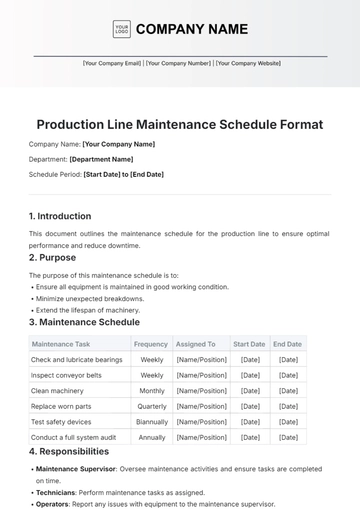

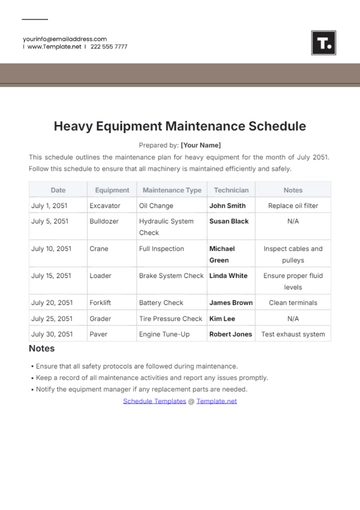

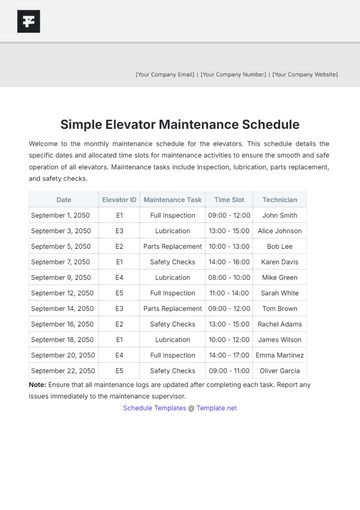

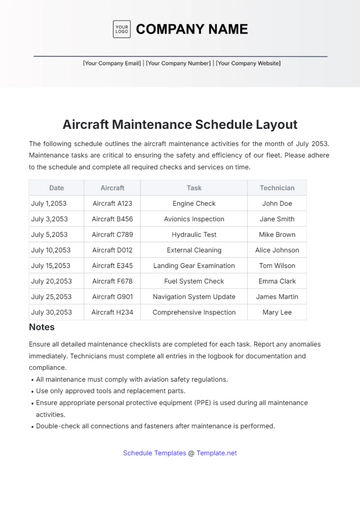

II. Maintenance Schedule Overview

A. Objectives

To ensure machinery operates at peak efficiency.

To minimize downtime and repair costs.

To extend the lifespan of the machinery.

To maintain safety standards.

B. Scope

This schedule applies to all machinery within the facility, including but not limited to production machines, conveyor systems, and auxiliary equipment.

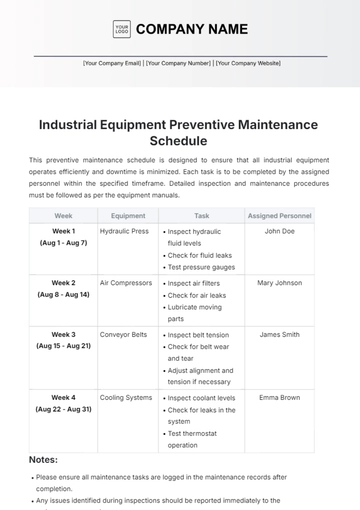

III. Maintenance Schedule

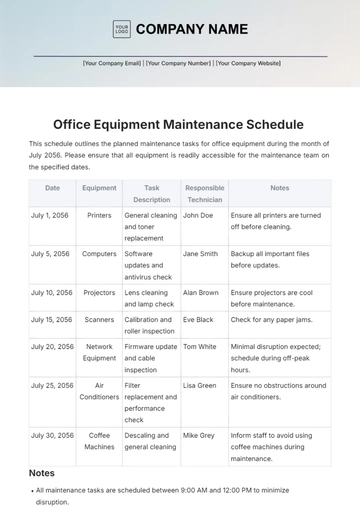

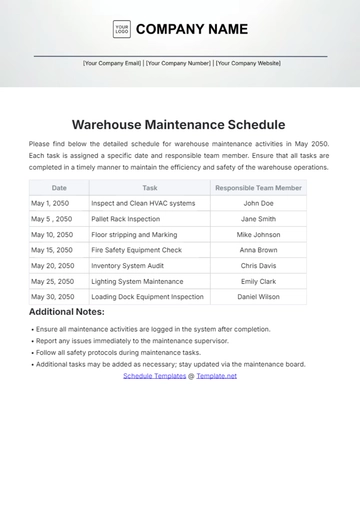

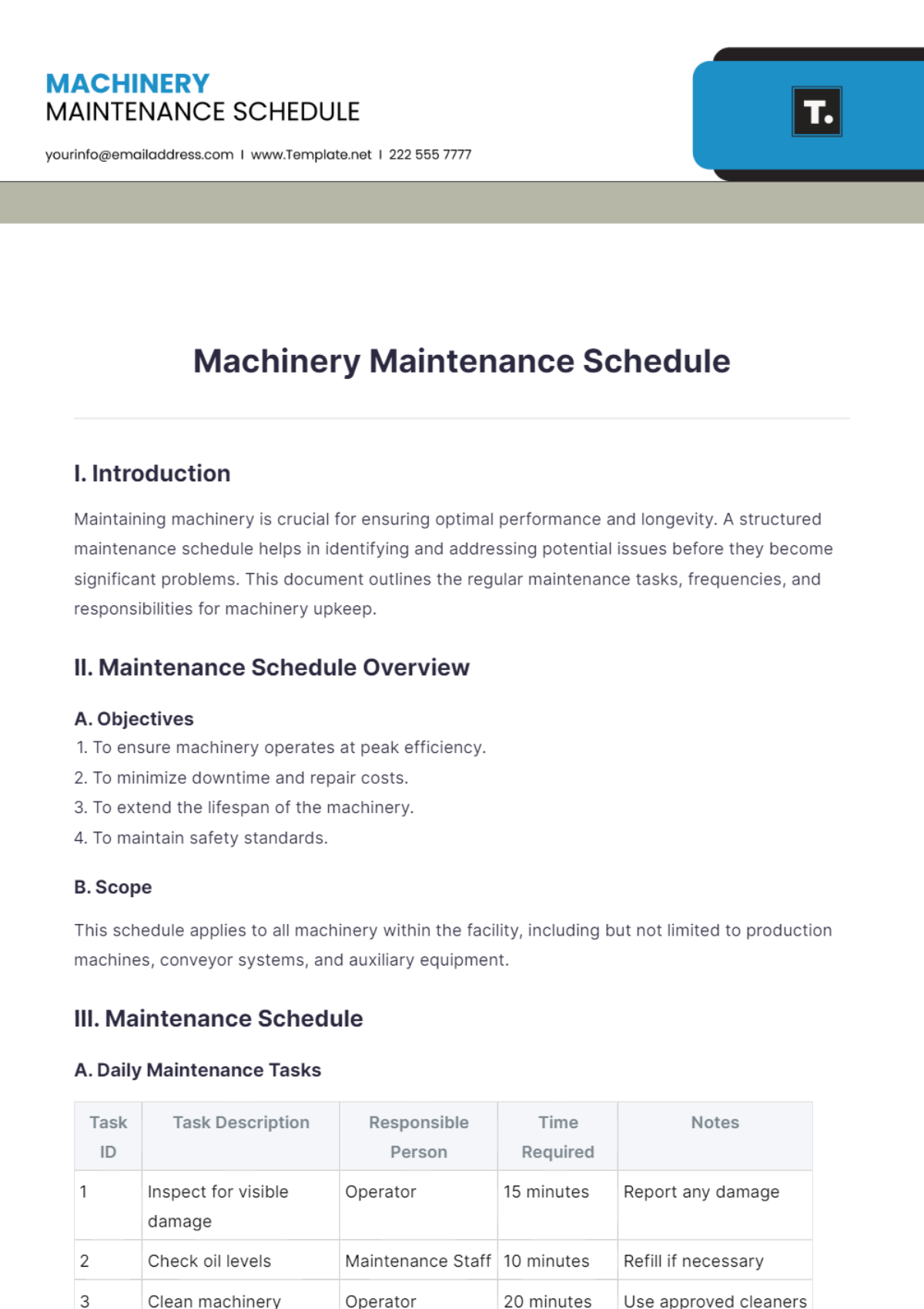

A. Daily Maintenance Tasks

Task ID | Task Description | Responsible Person | Time Required | Notes |

|---|---|---|---|---|

1 | Inspect for visible damage | Operator | 15 minutes | Report any damage |

2 | Check oil levels | Maintenance Staff | 10 minutes | Refill if necessary |

3 | Clean machinery surfaces | Operator | 20 minutes | Use approved cleaners |

4 | Check for unusual noises | Operator | 10 minutes | Record observations |

5 | Inspect safety guards | Operator | 5 minutes | Ensure functionality |

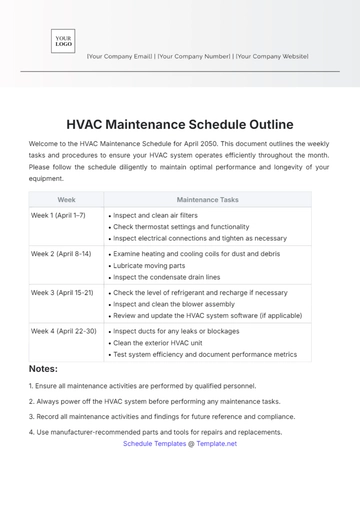

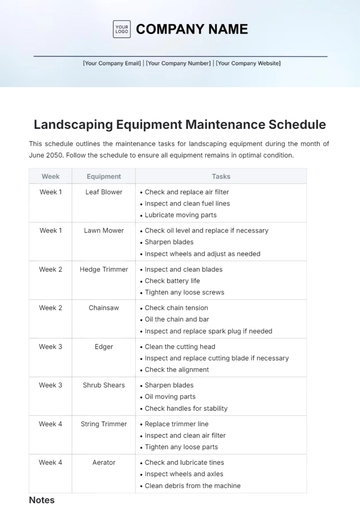

B. Weekly Maintenance Tasks

Task ID | Task Description | Responsible Person | Time Required | Notes |

|---|---|---|---|---|

1 | Lubricate moving parts | Maintenance Staff | 30 minutes | Use specified lubricant |

2 | Check and tighten loose bolts | Maintenance Staff | 45 minutes | Refer to torque specifications |

3 | Inspect electrical connections | Electrician | 60 minutes | Look for wear and corrosion |

4 | Clean air filters | Maintenance Staff | 20 minutes | Replace if necessary |

5 | Test emergency stop buttons | Safety Officer | 10 minutes | Ensure they are operational |

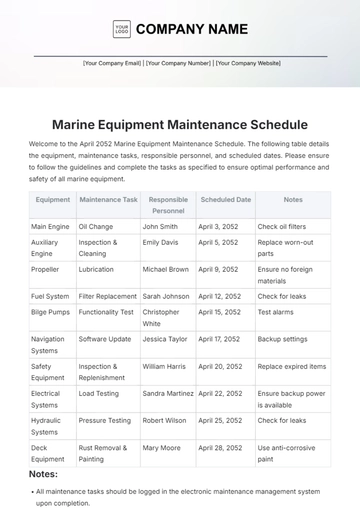

C. Monthly Maintenance Tasks

Task ID | Task Description | Responsible Person | Time Required | Notes |

|---|---|---|---|---|

1 | Perform comprehensive inspection | Maintenance Supervisor | 2 hours | Follow detailed checklist |

2 | Test backup systems | IT Technician | 1 hour | Ensure data integrity and restore |

3 | Inspect hydraulic systems | Hydraulic Specialist | 1.5 hours | Check for leaks and pressure |

4 | Clean internal components | Maintenance Staff | 3 hours | Follow disassembly procedures |

5 | Update maintenance records | Administrative Staff | 1 hour | Ensure all tasks are documented |

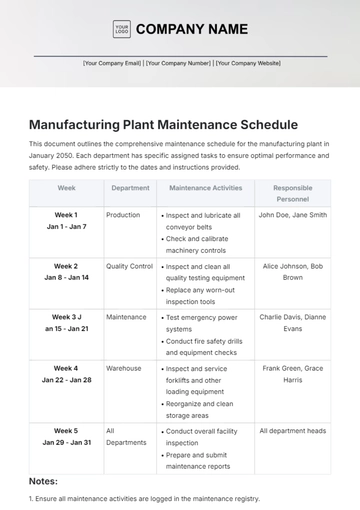

D. Quarterly Maintenance Tasks

Task ID | Task Description | Responsible Person | Time Required | Notes |

|---|---|---|---|---|

1 | Calibrate sensors and gauges | Calibration Technician | 4 hours | Use calibration standards |

2 | Inspect structural integrity | Structural Engineer | 5 hours | Check for stress and fatigue |

3 | Replace worn-out components | Maintenance Supervisor | 6 hours | Follow replacement protocol |

4 | Test machine performance | Production Manager | 3 hours | Conduct performance tests |

5 | Review and update safety protocols | Safety Manager | 2 hours | Ensure compliance with regulations |

E. Annual Maintenance Tasks

Task ID | Task Description | Responsible Person | Time Required | Notes |

|---|---|---|---|---|

1 | Overhaul critical components | Maintenance Team | 2 days | Schedule during downtime |

2 | Conduct full system diagnostics | IT and Maintenance | 1 day | Use diagnostic tools |

3 | Review maintenance schedule | Management | 4 hours | Adjust as necessary |

4 | Train staff on new procedures | HR and Training Dept | 1 day | Ensure all staff are updated |

5 | Audit maintenance records | External Auditor | 1 day | Verify accuracy and completeness |

IV. Responsibilities

A. Operators

Perform daily checks and report any issues.

Maintain cleanliness of machinery.

B. Maintenance Staff

Conduct weekly and monthly maintenance tasks.

Ensure proper lubrication and tightening of parts.

C. Supervisors and Managers

Oversee quarterly and annual maintenance activities.

Ensure compliance with maintenance schedule and protocols.

D. Safety Officers

Conduct regular safety inspections.

Test emergency systems and review safety protocols.

By adhering to this maintenance schedule, [YOUR COMPANY NAME] ensures the reliability, safety, and longevity of its machinery, thereby supporting continuous and efficient operations.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Ensure your machinery operates efficiently with Template.net's customizable Machinery Maintenance Schedule Template. It is designed to help you plan and track regular maintenance tasks, reducing downtime and extending the life of your equipment. Editable in our Ai Editor Tool, it allows you to tailor the schedule to fit your machinery's specific requirements.

You may also like

- Schedule Appointment

- Work Schedule

- Weekly Schedule

- Cleaning Schedule

- Payment Schedule

- School Schedule

- Maintenance Schedule

- Daily Schedule

- Class Schedule

- Workout Schedule

- Event Schedule

- Marketing Schedule

- Weekly Cleaning Schedule

- Work From Home Schedule

- Payroll Schedule

- Restaurant Schedule

- Kitchen Cleaning Schedule

- Schedule of Values

- Hourly Schedule

- Study Schedule

- University Schedule

- Construction Schedule

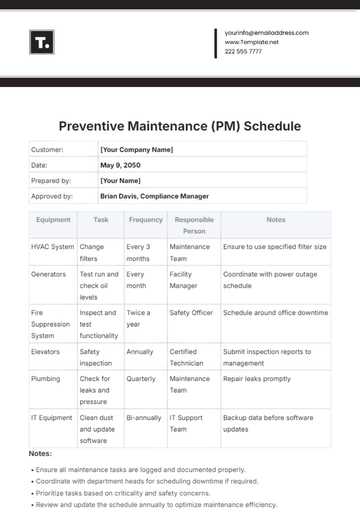

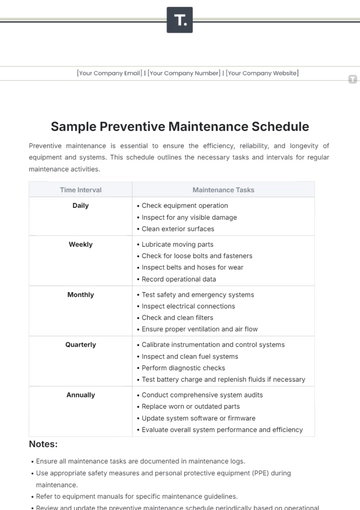

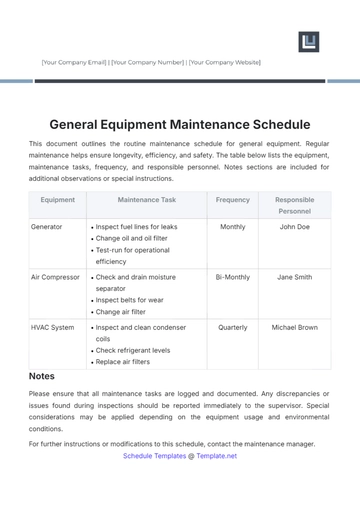

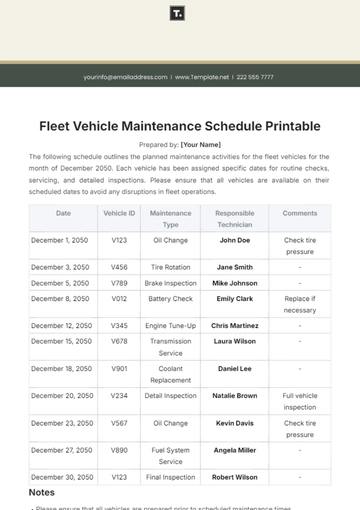

- Preventive Maintenance Schedule

- Fitness Schedule

- Education Schedule

- Training Schedule

- Agency Schedule

- Panel Schedule

- Monthly Schedule

- Nursing Home Schedule

- Project Schedule

- Real Estate Schedule

- Freelancer Schedule

- Medication Schedule

- IT and Software Schedule

- Interior Design Schedule

- Travel Schedule

- Travel Agency Schedule

- Hotel Schedule

- Wedding Schedule

- Camp Schedule