Car Wash Inventory Report Sample

I. Introduction

This Car Wash Inventory Report of [Your Company Name] provides a detailed account of the current inventory levels, usage, and replenishment needs. This report aims to ensure optimal inventory management to maintain efficient operations and meet customer demand.

A. Purpose

Inventory Management: The primary purpose of this report is to track inventory levels accurately. Effective management helps prevent stockouts and overstock situations.

Operational Efficiency: By maintaining optimal inventory levels, the report ensures smooth operations. Consistent availability of supplies is crucial for uninterrupted service delivery.

Cost Control: Monitoring inventory helps in identifying cost-saving opportunities. Efficient inventory control reduces waste and unnecessary expenses.

B. Scope

Supplies: This report covers all essential car wash supplies, including cleaning agents and tools. Comprehensive tracking includes various categories of supplies.

Equipment: Inventory levels of critical equipment and their maintenance status are also included. Ensuring functional equipment is vital for operational efficiency.

Replenishment Needs: This report identifies items that need replenishment based on usage patterns. Timely replenishment prevents service disruptions.

C. Inventory Categories

Cleaning Agents: Includes all types of soaps, detergents, and waxes used in the car wash process. Each type has specific usage rates and replenishment cycles.

Tools and Accessories: Covers brushes, sponges, towels, and other accessories. Regular inventory checks ensure all tools are available for use.

Equipment: Includes high-pressure washers, vacuum cleaners, and other machinery. Proper maintenance schedules are part of inventory tracking.

Safety Supplies: Ensures availability of gloves, masks, and other safety equipment. Safety supplies are crucial for employee protection.

Office Supplies: Tracks items like paper, pens, and other administrative supplies. Office supplies support the operational and administrative functions.

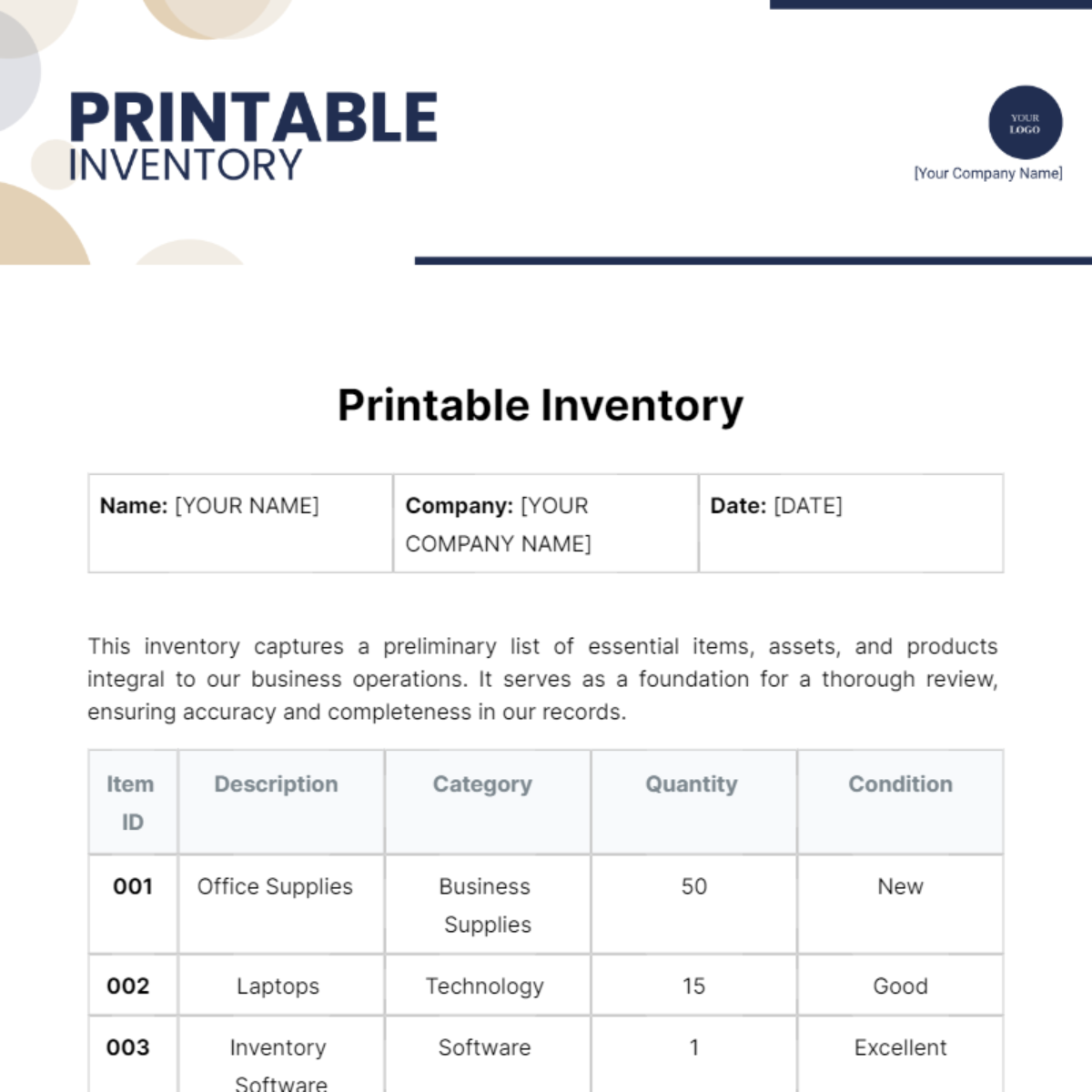

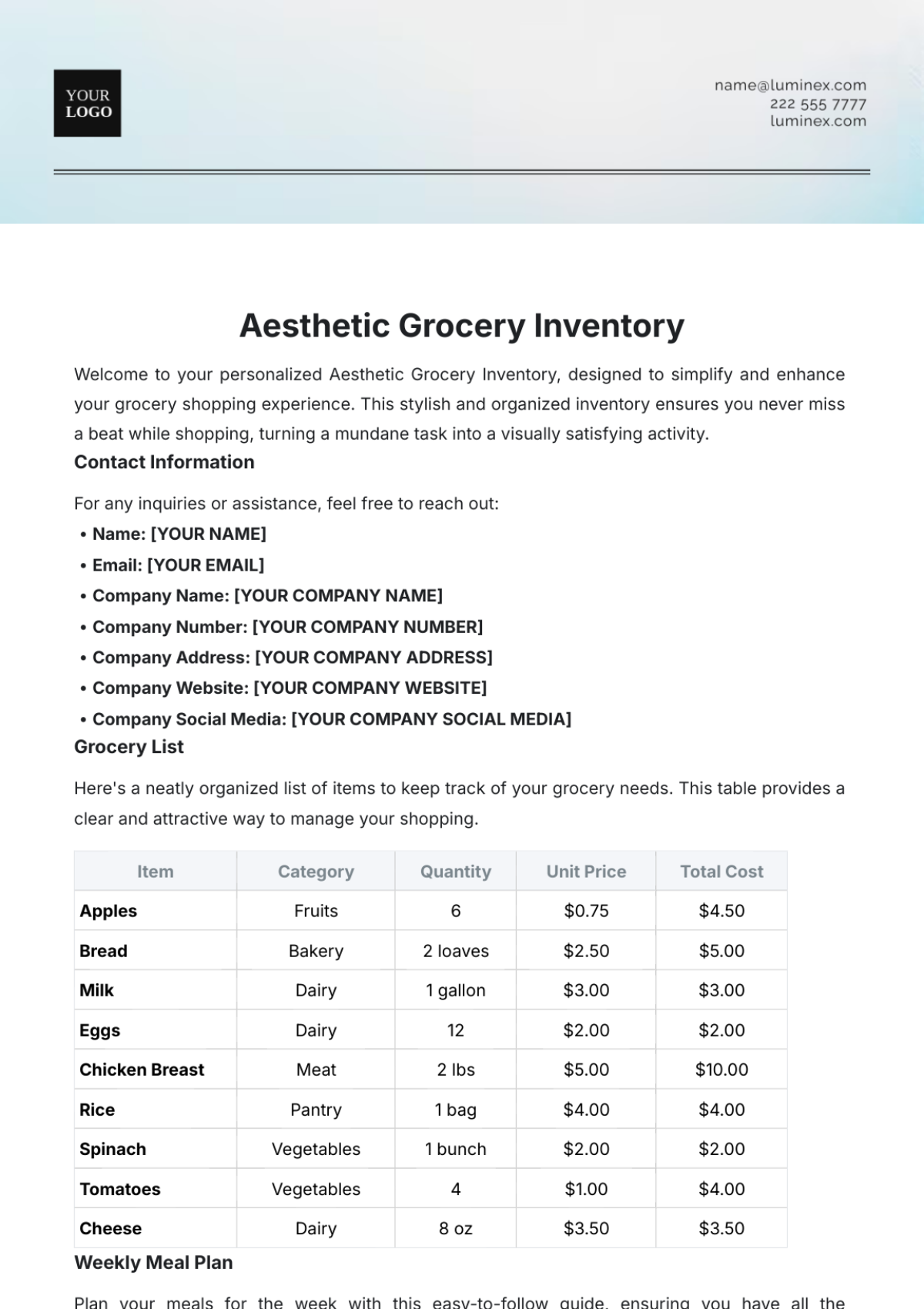

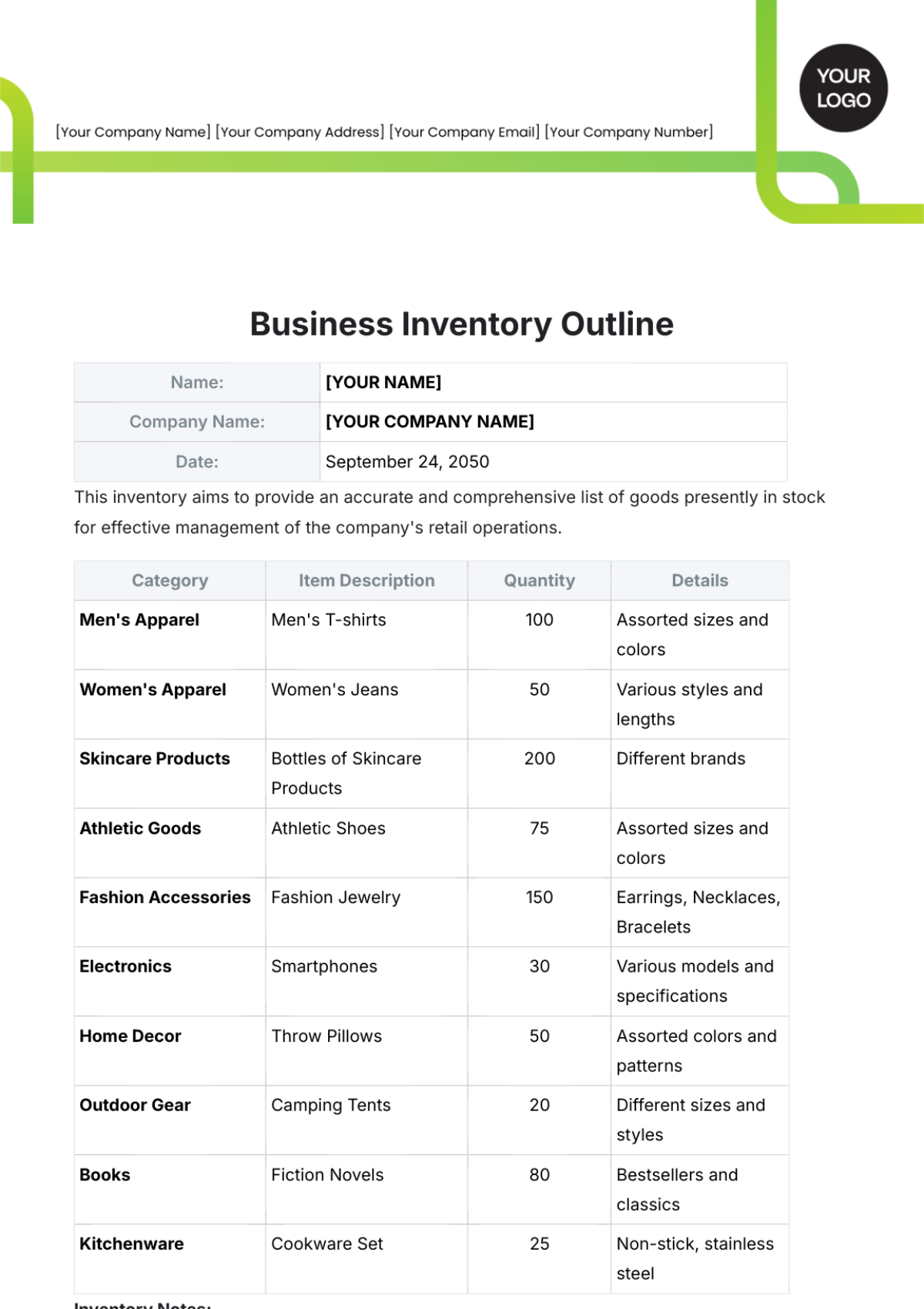

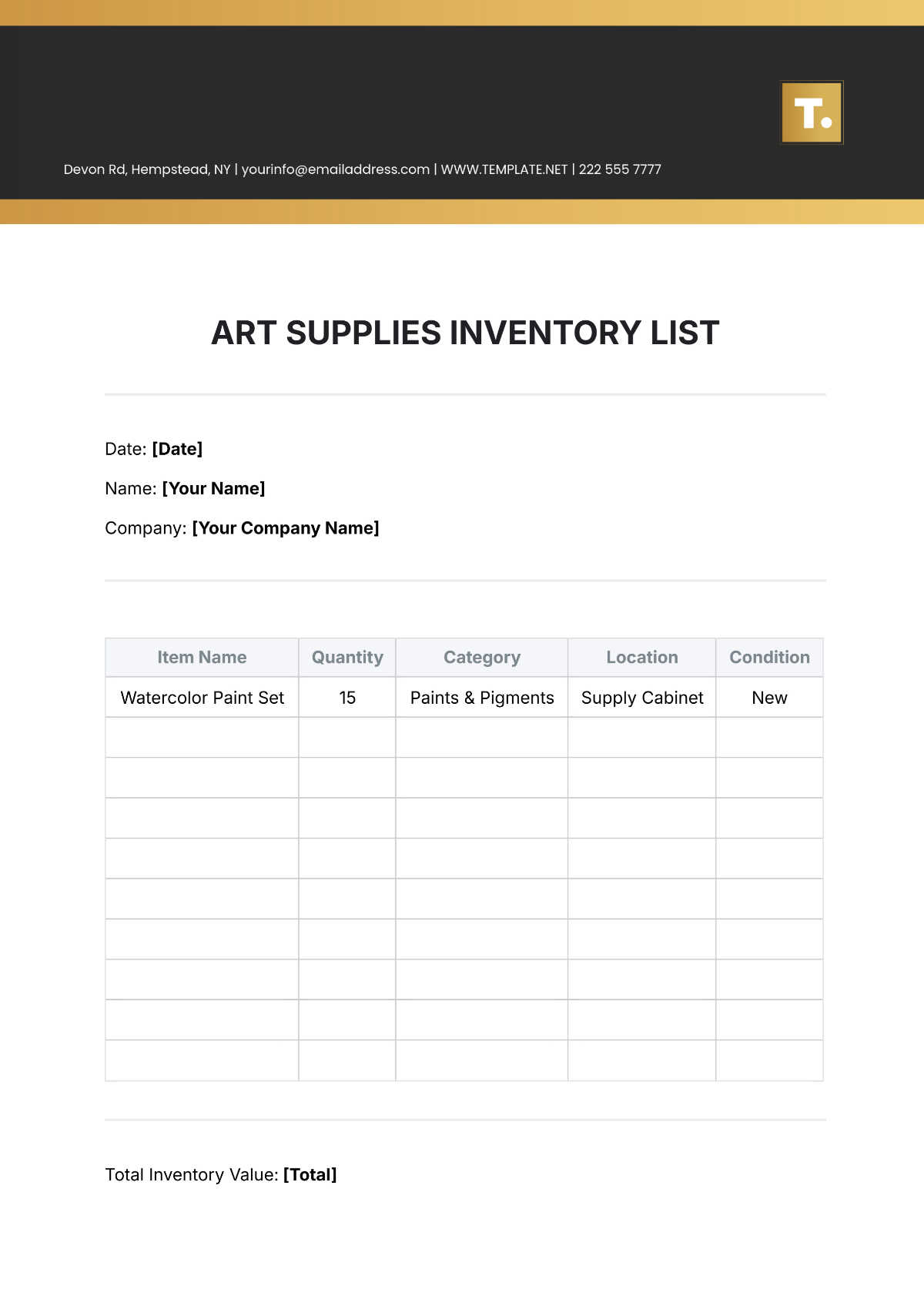

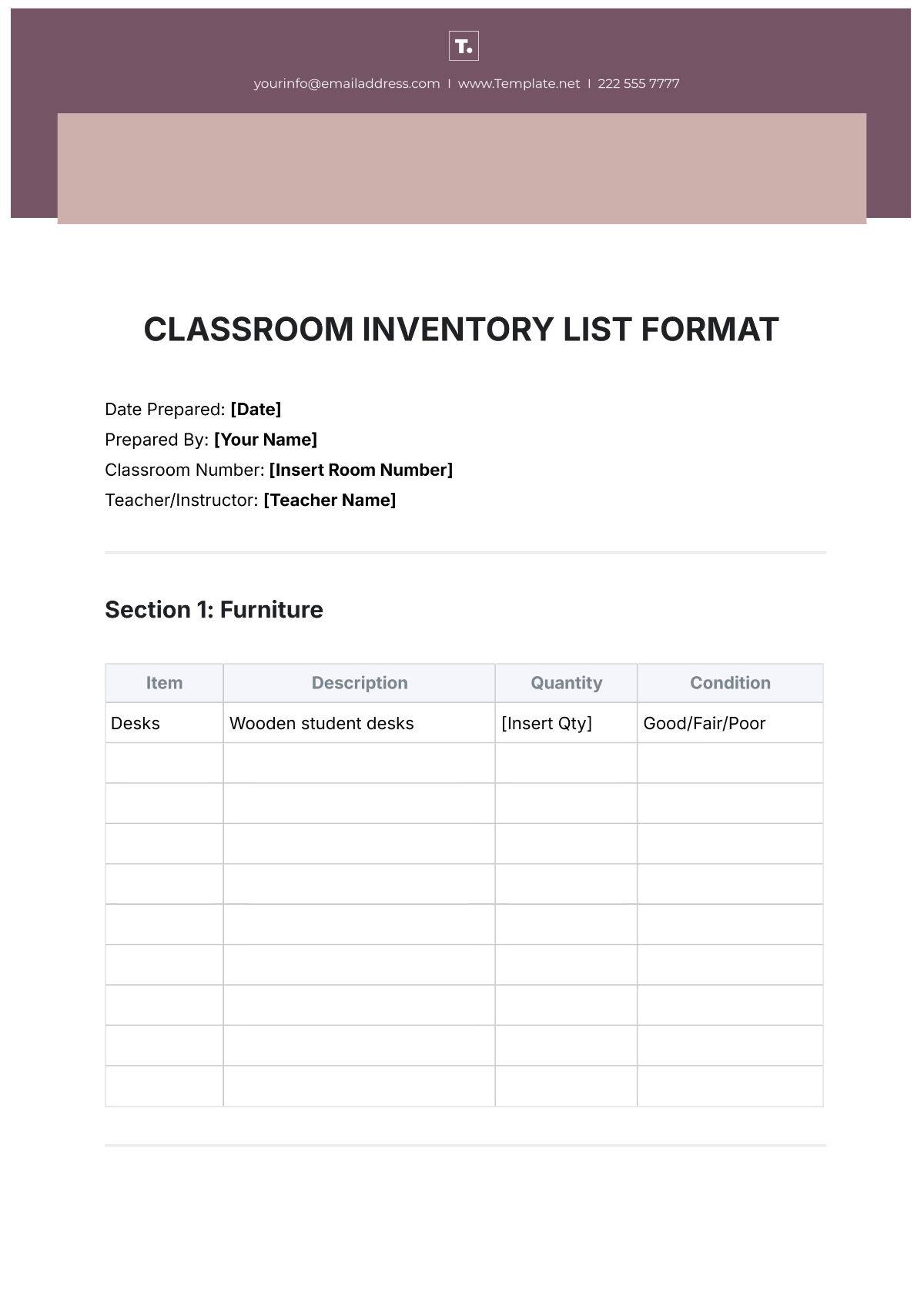

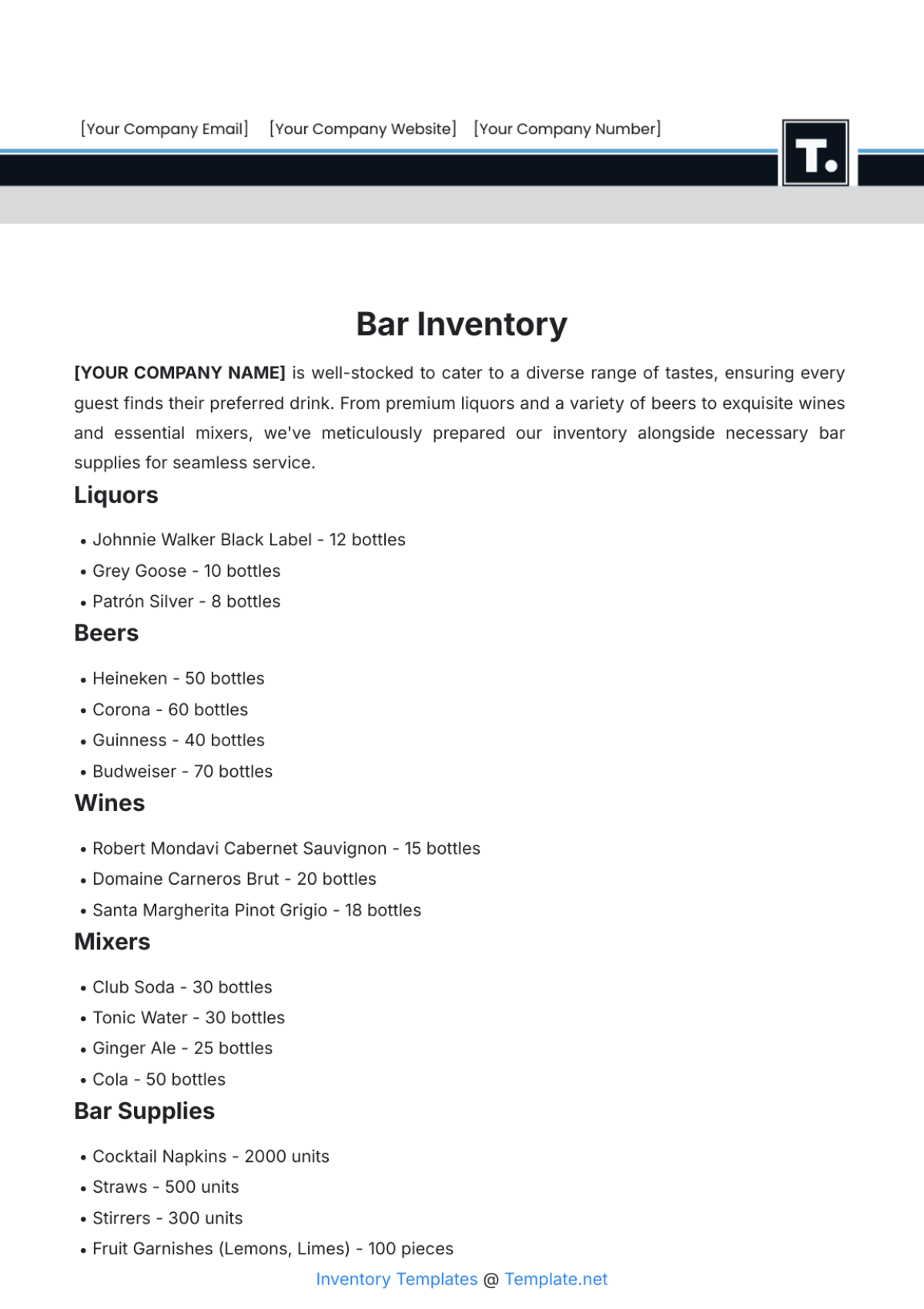

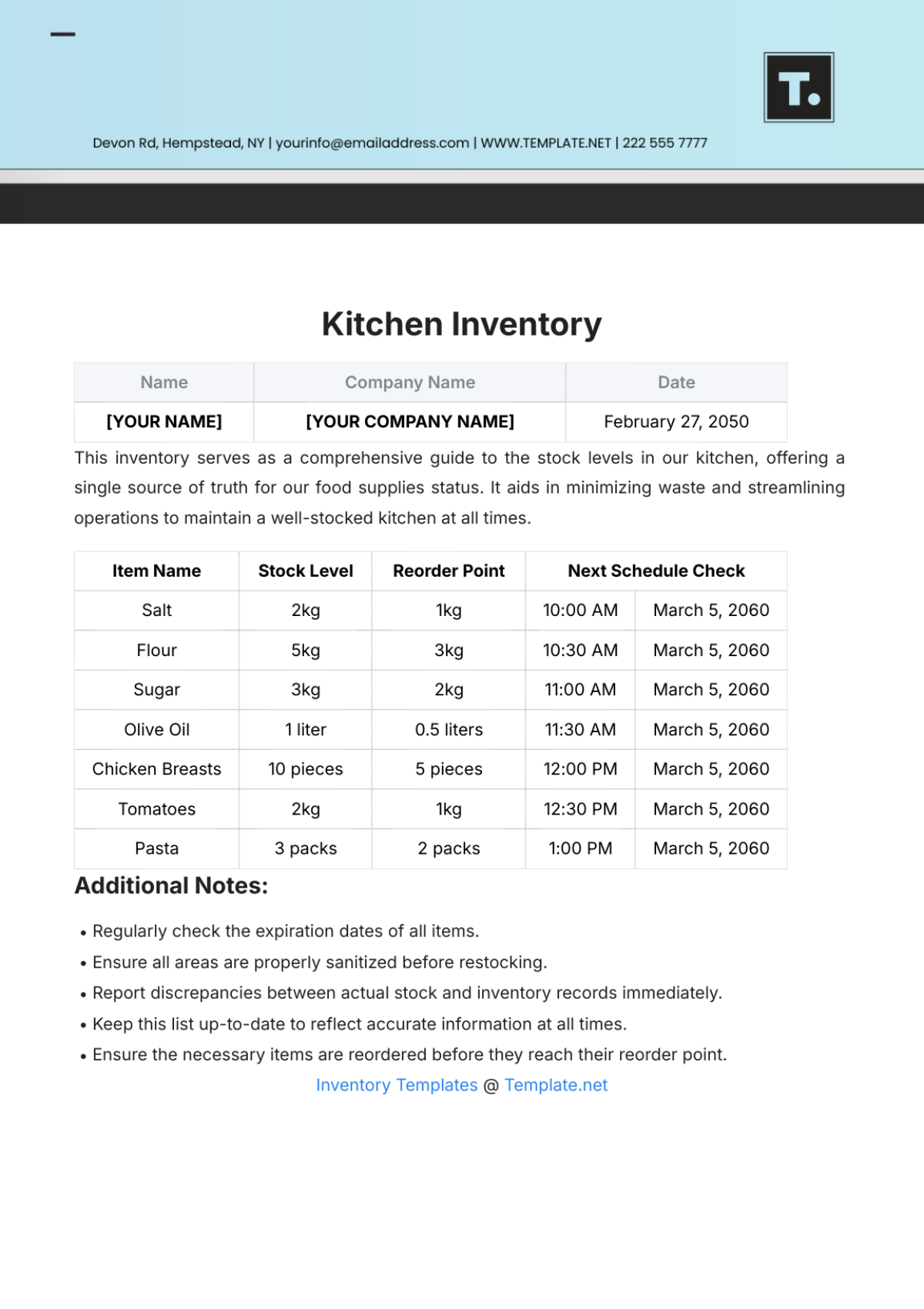

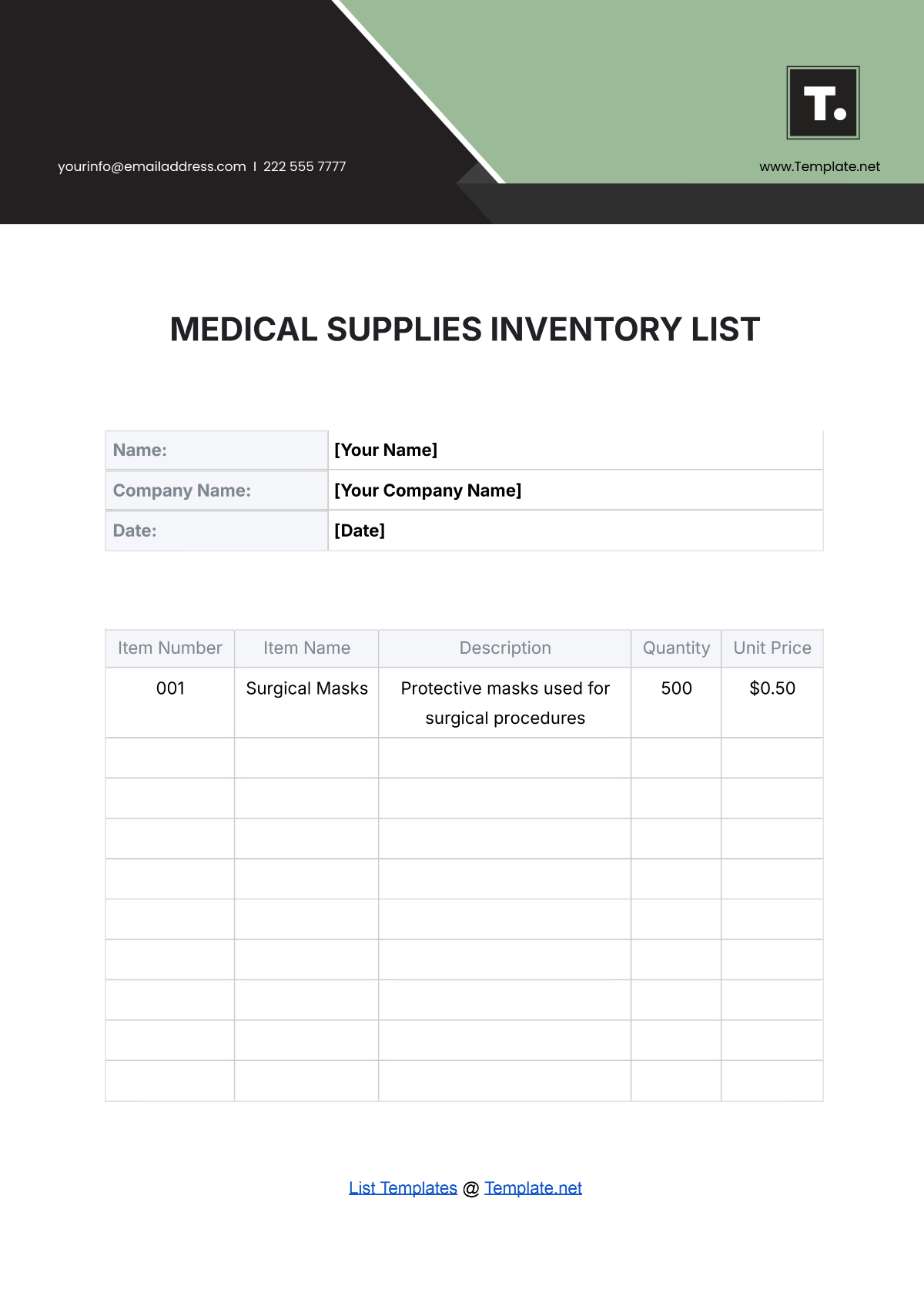

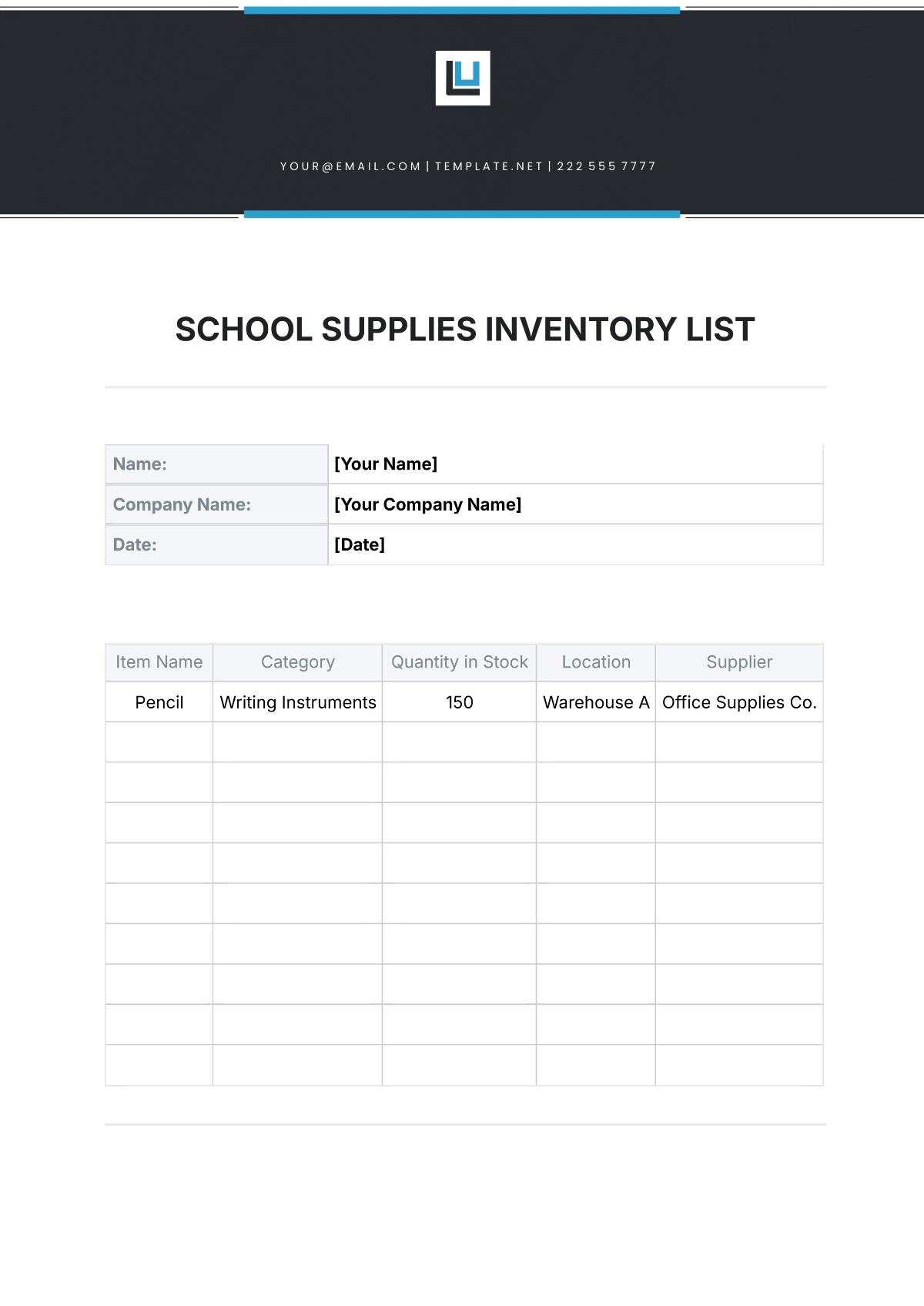

II. Current Inventory Overview

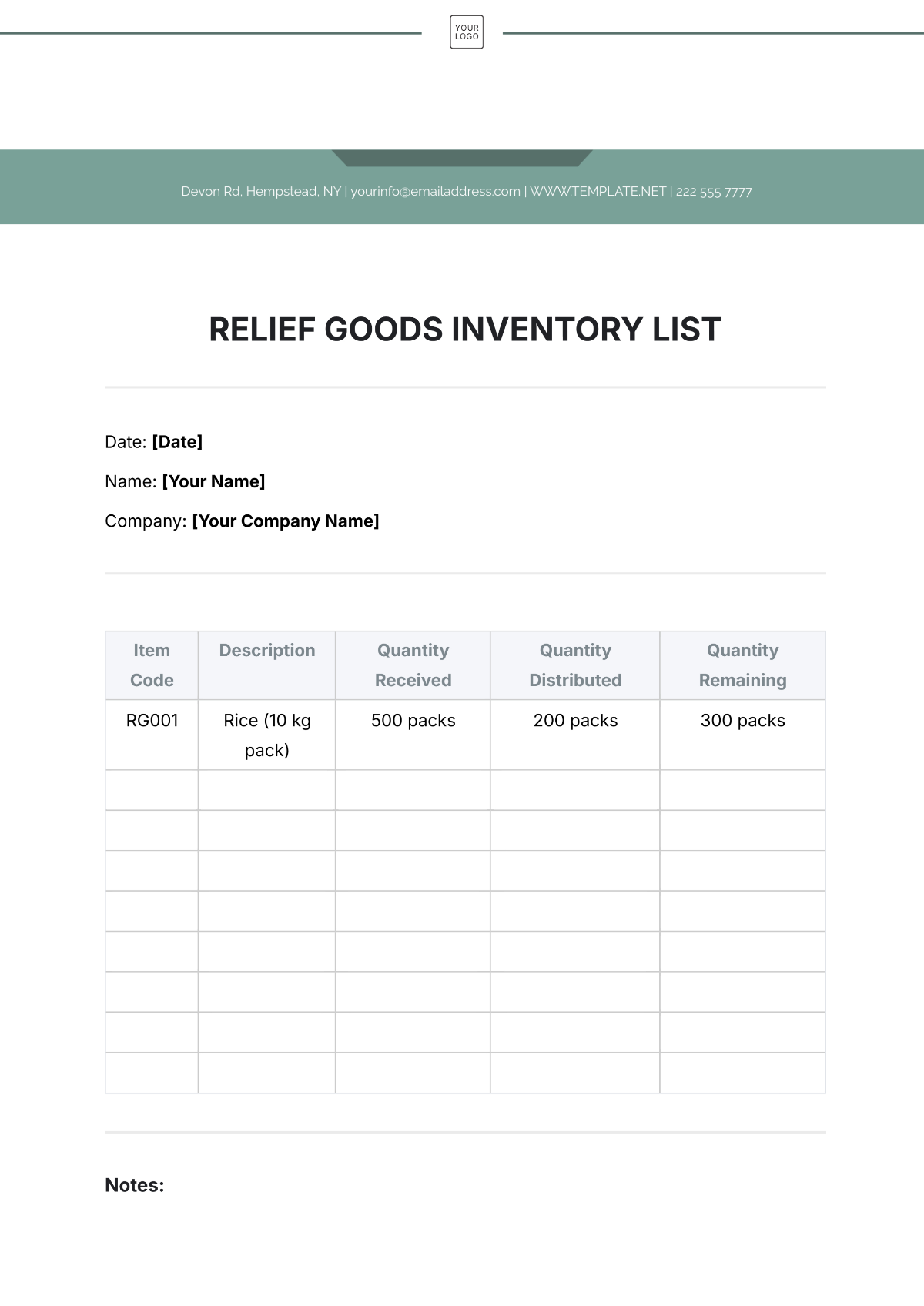

The following table summarizes the current inventory levels for [Your Company Name]:

No. | Category | Item | Quantity | Unit Price | Total Value |

|---|---|---|---|---|---|

1 | Cleaning Agents | Car Soap | 50 | $10 | $500 |

2 | Cleaning Agents | Wax | 30 | $15 | $450 |

3 | Tools | Brushes | 100 | $5 | $500 |

4 | Tools | Towels | 200 | $2 | $400 |

5 | Equipment | High-Pressure Washer | 5 | $150 | $750 |

6 | Equipment | Vacuum Cleaner | 3 | $100 | $300 |

7 | Safety Supplies | Gloves | 200 | $1 | $200 |

8 | Safety Supplies | Masks | 100 | $2 | $200 |

9 | Office Supplies | Paper | 500 | $0.1 | $50 |

10 | Office Supplies | Pens | 100 | $0.5 | $50 |

Total | $3,400 |

A. Cleaning Agents

Car Soap: The inventory currently holds 50 units of car soap at $10 per unit, totaling $500. This item is essential for the initial cleaning phase and needs regular replenishment.

Wax: With 30 units in stock, each priced at $15, the total value is $450. Waxing is a crucial service offering that enhances the car's appearance and protection.

Usage Patterns: These cleaning agents are used daily, requiring close monitoring of stock levels. High usage rates necessitate frequent reordering to avoid shortages.

Replenishment Schedule: Based on current usage, car soap and wax should be reordered monthly. Ensuring timely deliveries prevents operational hiccups.

B. Tools

Brushes: The inventory includes 100 brushes, each costing $5, amounting to $500. Brushes are vital for thorough cleaning, especially for tough stains and intricate parts.

Towels: There are 200 towels in stock, priced at $2 each, with a total value of $400. Towels are used for drying and detailing, and their availability ensures quality service.

Maintenance: Regular checks ensure that tools are in good condition and replaced when worn out. Proper tool maintenance enhances service efficiency and quality.

Reordering: Tools are durable, but usage rates dictate the need for periodic replenishment. Planning for replacements avoids sudden shortages and maintains service standards.

C. Equipment

High-Pressure Washer: The inventory holds 5 high-pressure washers, each valued at $150, totaling $750. These machines are crucial for effective car washing, especially for removing tough dirt.

Vacuum Cleaner: There are 3 vacuum cleaners in stock, priced at $100 each, with a total value of $300. Vacuum cleaners are essential for interior cleaning and detailing.

Maintenance: Regular maintenance checks and servicing ensure that the equipment functions optimally. Well-maintained equipment extends the lifespan and prevents breakdowns.

Upgrades: Periodic evaluation for upgrading equipment can enhance efficiency and service quality. Investing in advanced technology keeps the business competitive.

D. Safety Supplies

Gloves: The inventory includes 200 pairs of gloves, each costing $1, totaling $200. Gloves are essential for employee safety and hygiene during car wash operations.

Masks: There are 100 masks in stock, priced at $2 each, with a total value of $200. Masks protect employees from inhaling harmful chemicals and dust.

Compliance: Ensuring adequate safety supplies aligns with health and safety regulations. Compliance with safety standards is critical for employee welfare.

Replenishment: Safety supplies should be replenished regularly to maintain adequate stock levels. Ensuring availability prevents health hazards and promotes a safe working environment.

E. Office Supplies

Paper: The inventory holds 500 sheets of paper, each costing $0.1, totaling $50. Paper is used for administrative tasks, including documentation and reporting.

Pens: There are 100 pens in stock, priced at $0.5 each, with a total value of $50. Pens are essential for everyday administrative activities.

Efficiency: Having sufficient office supplies ensures smooth administrative operations. Adequate stock levels prevent interruptions in office work.

Regular Checks: Conducting regular checks and reordering office supplies as needed maintains efficiency. Keeping track of usage patterns helps in planning for replenishment.

The inventory levels reveal the importance of maintaining optimal stock to ensure seamless operations. Proper inventory management not only prevents service disruptions but also contributes to cost control and efficient resource utilization. By regularly monitoring and replenishing stock levels, [Your Company Name] can maintain high service standards and meet customer expectations.

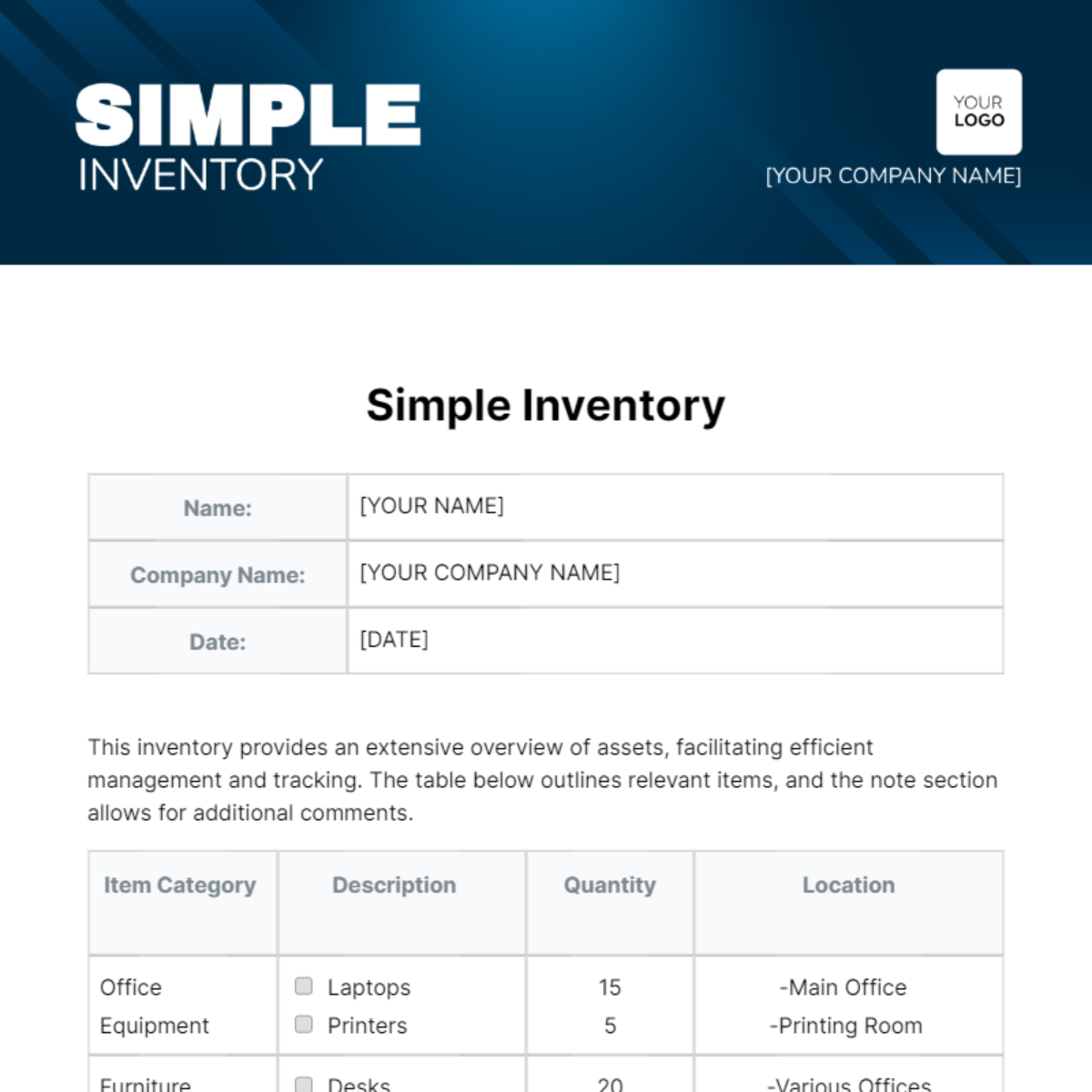

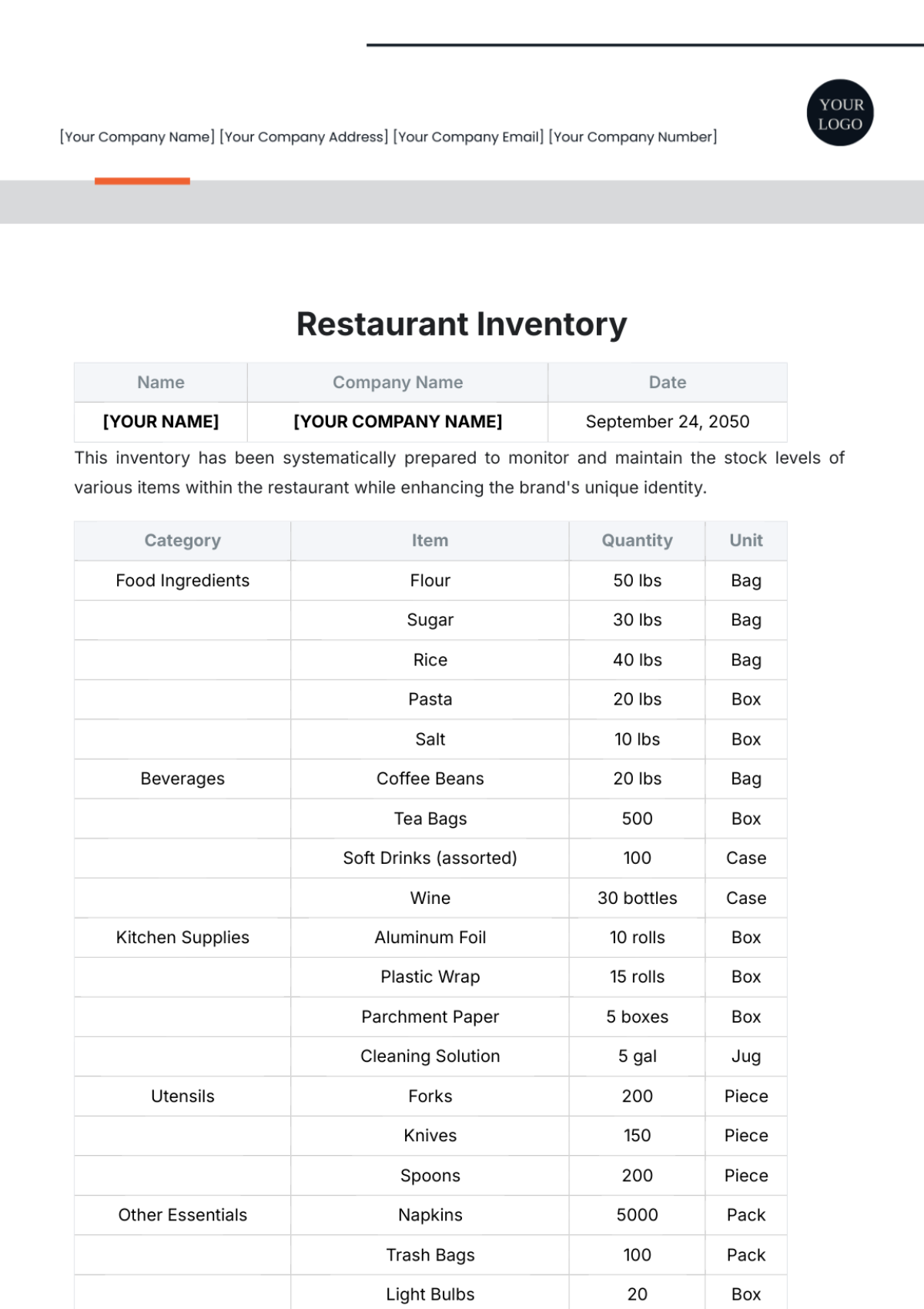

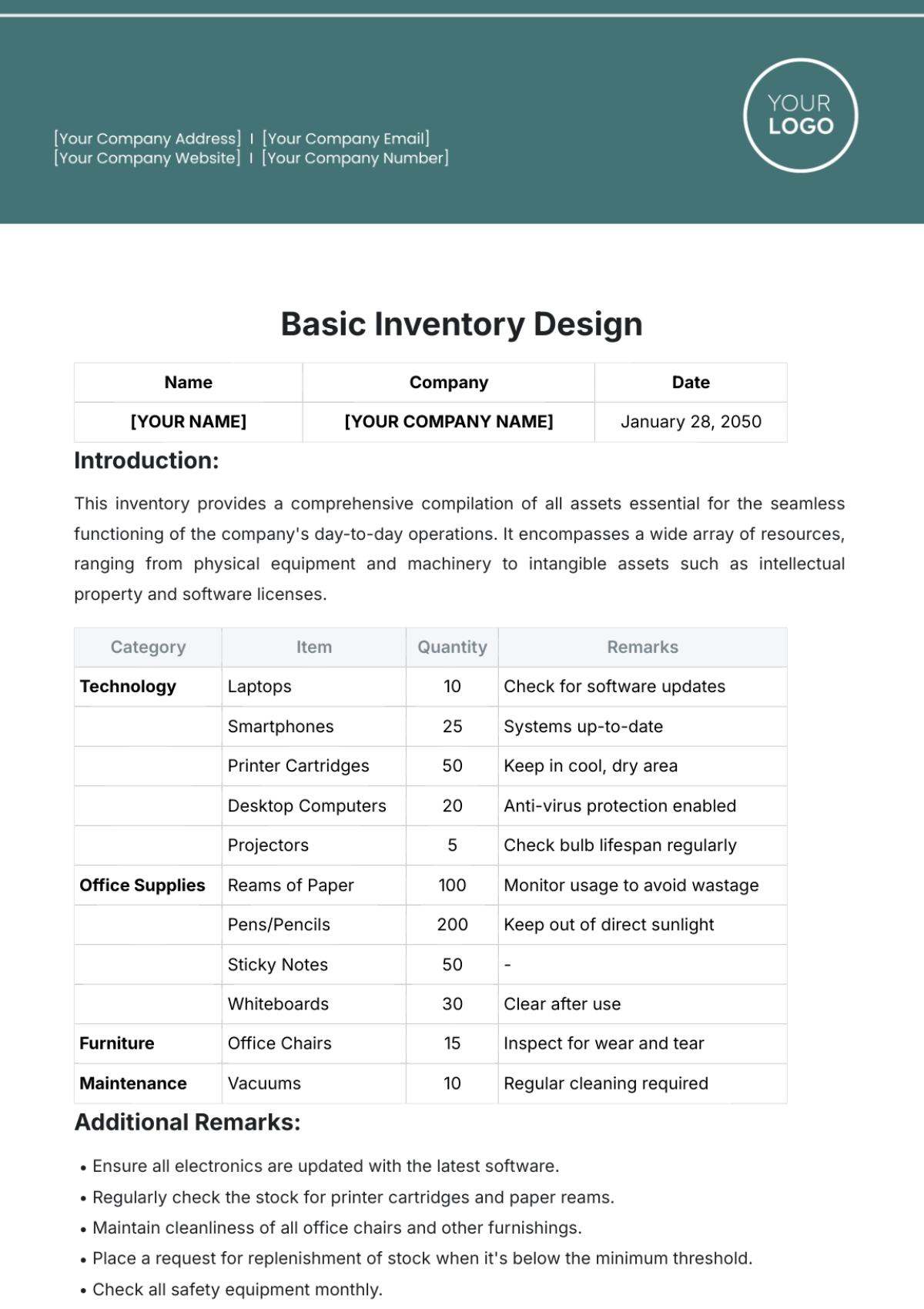

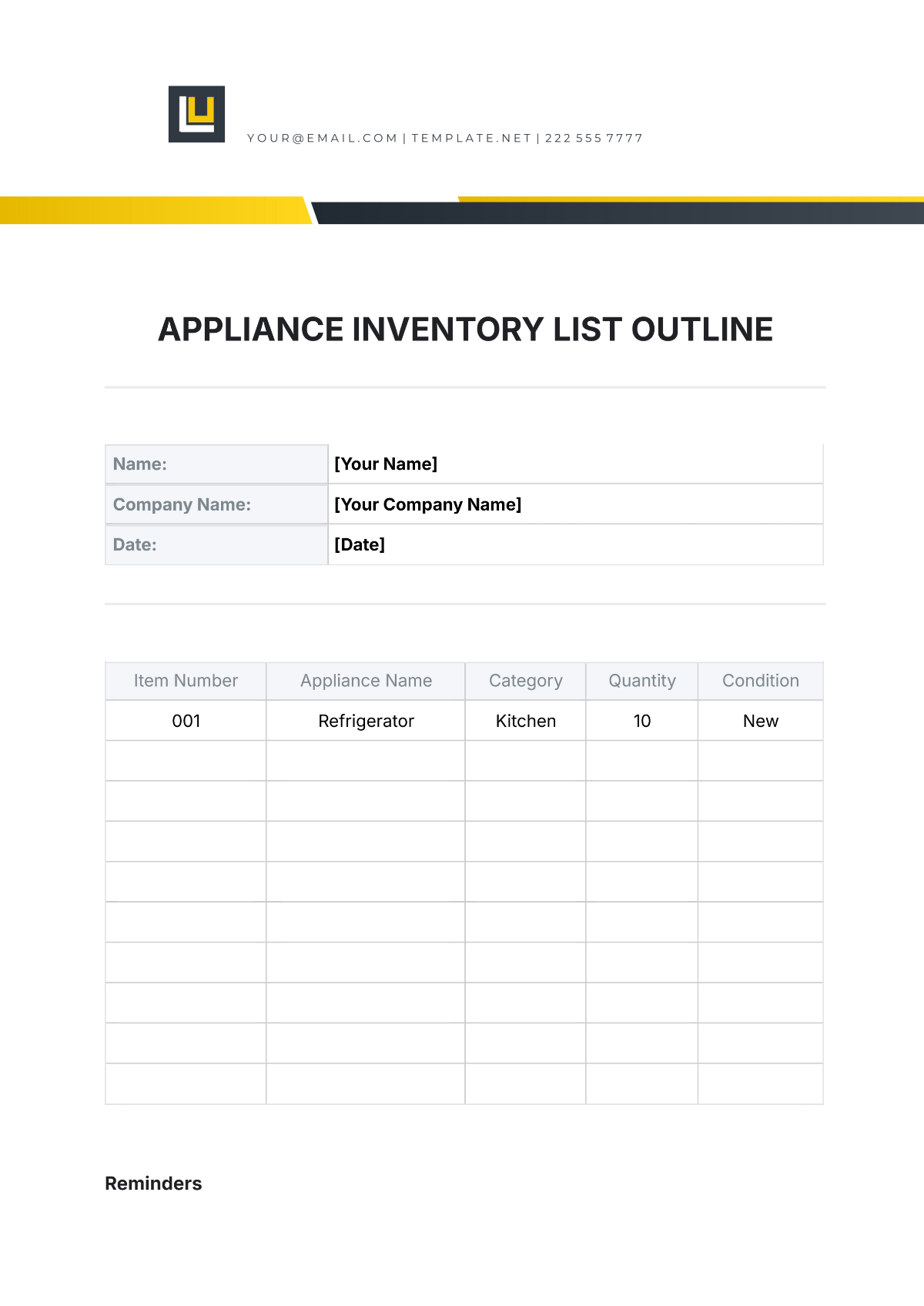

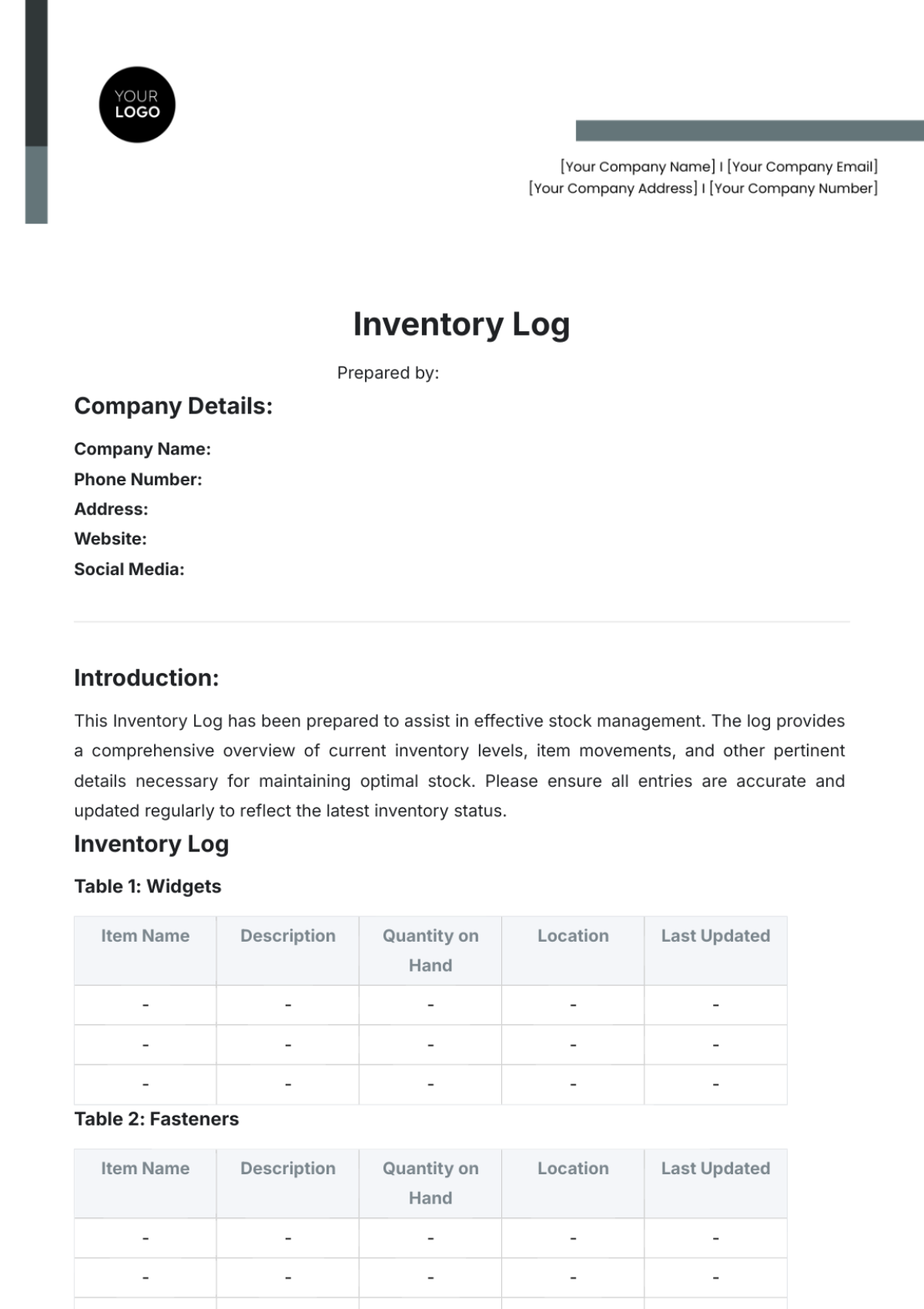

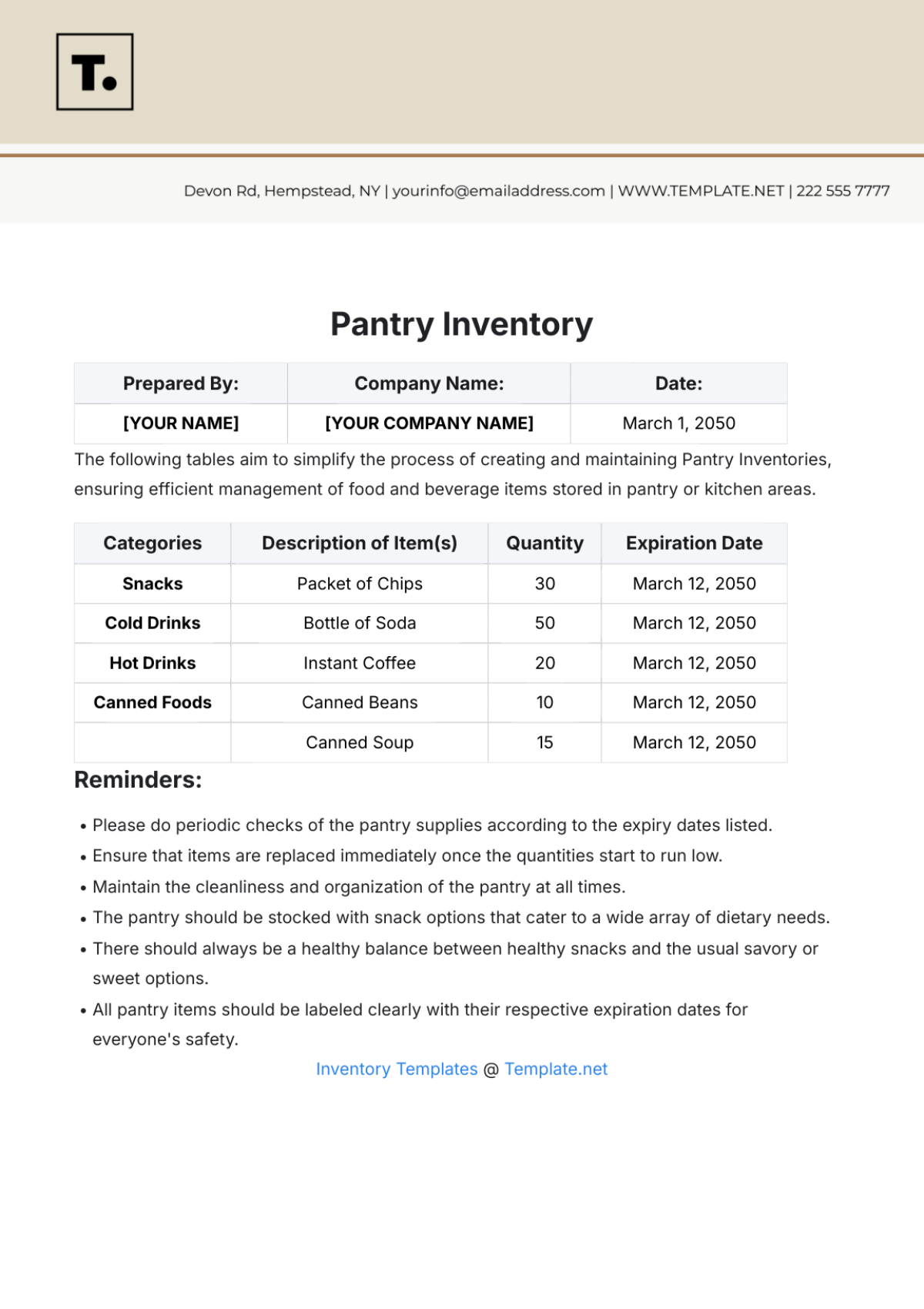

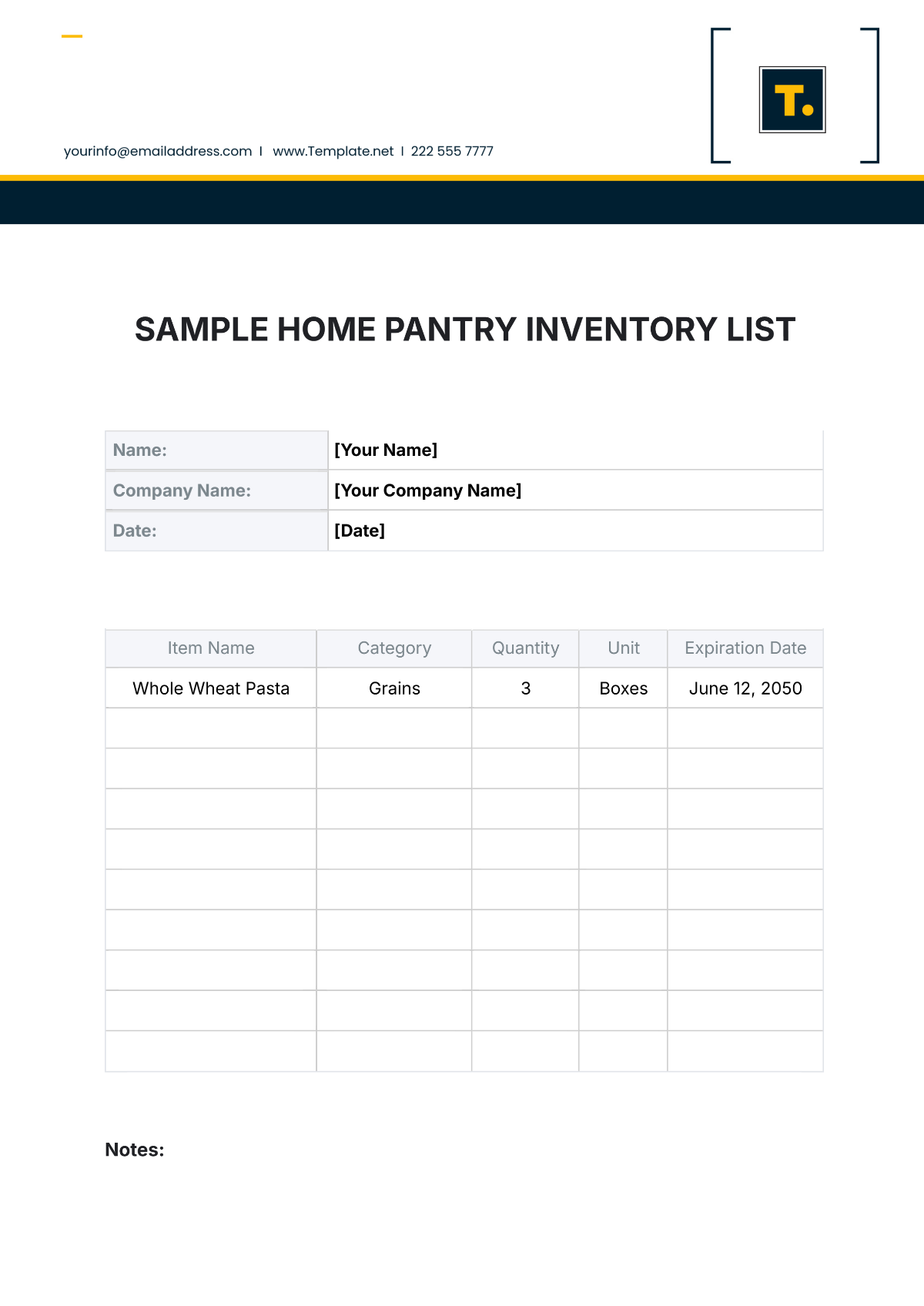

III. Usage Analysis

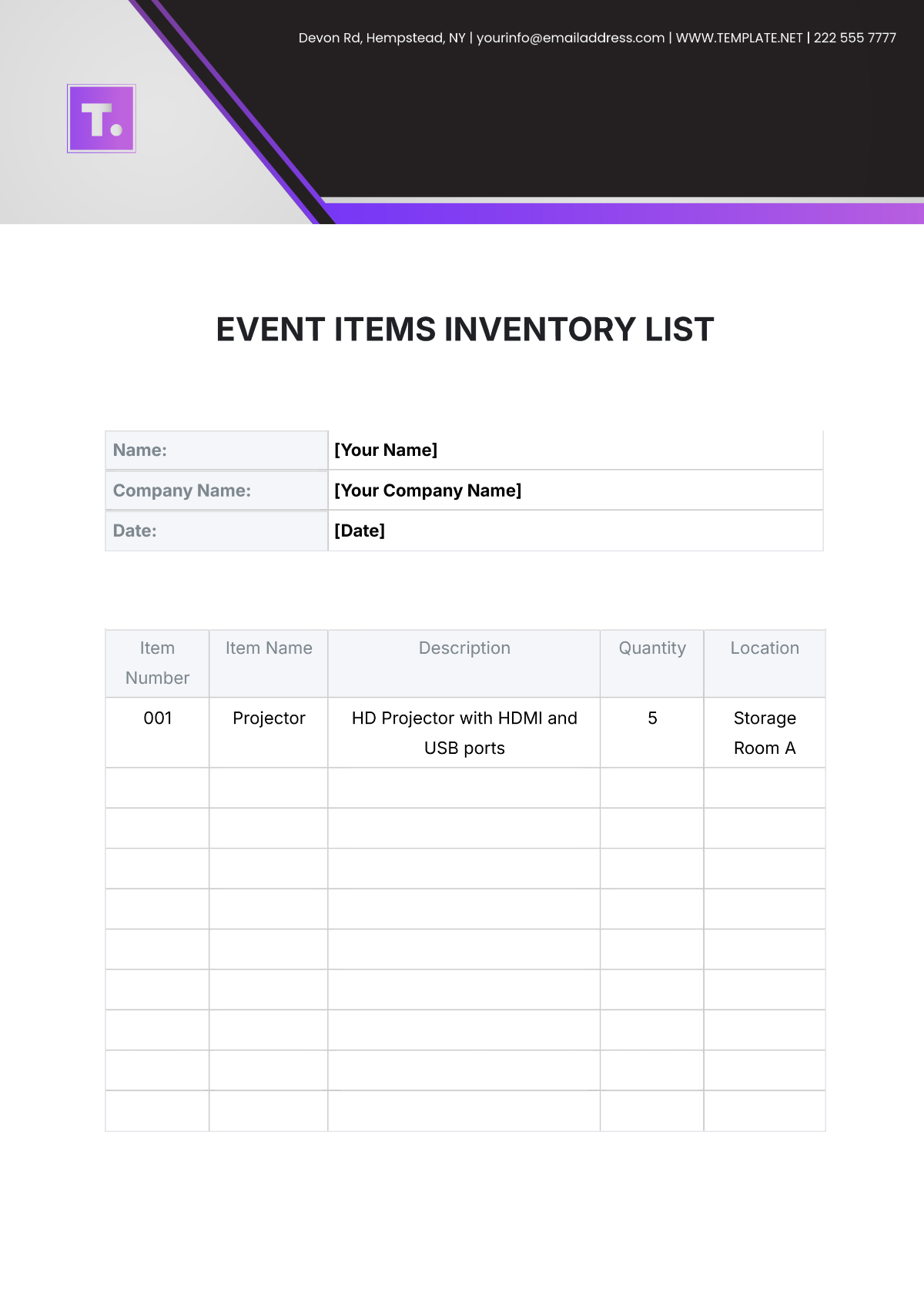

The following table provides an overview of the monthly usage rates for various inventory items at [Your Company Name]:

No. | Item | Monthly Usage | Reorder Level | Current Stock |

|---|---|---|---|---|

1 | Car Soap | 40 | 30 | 50 |

2 | Wax | 25 | 20 | 30 |

3 | Brushes | 80 | 60 | 100 |

4 | Towels | 180 | 150 | 200 |

5 | High-Pressure Washer | 2 | 1 | 5 |

6 | Vacuum Cleaner | 1 | 1 | 3 |

7 | Gloves | 150 | 100 | 200 |

8 | Masks | 80 | 50 | 100 |

9 | Paper | 300 | 200 | 500 |

10 | Pens | 50 | 30 | 100 |

A. Car Soap and Wax

Car Soap: The monthly usage rate for car soap is 40 units, with a reorder level set at 30 units. Maintaining a higher stock level ensures a continuous supply and prevents service interruptions.

Wax: Wax is used at a rate of 25 units per month, with a reorder level of 20 units. Adequate stock levels of wax are crucial for providing quality finishing services.

Usage Patterns: Regular tracking of usage patterns helps in adjusting reorder levels as needed. Predicting future demand based on past usage ensures preparedness.

Stock Levels: Keeping an optimal stock level helps in managing inventory costs effectively. Overstocks and stockouts can both impact the operational efficiency and financial health.

B. Brushes and Towels

Brushes: The monthly usage of brushes is 80 units, with a reorder level of 60 units. Brushes are essential for thorough cleaning, and maintaining their availability is critical.

Towels: Towels are used at a rate of 180 units per month, with a reorder level of 150 units. Towels are indispensable for drying and detailing, ensuring a clean and polished finish.

Inventory Checks: Regular checks ensure that the stock levels are maintained as per the usage rate. Consistent availability of brushes and towels enhances service quality.

Replenishment Planning: Planning for replenishment based on usage trends prevents shortages. Timely ordering and receiving of supplies streamline the inventory process.

C. Equipment

High-Pressure Washer: The usage rate for high-pressure washers is low, with only 2 units used monthly. The reorder level is set at 1 unit, ensuring a buffer for unexpected needs.

Vacuum Cleaner: Vacuum cleaners are used sparingly, with a usage rate of 1 unit per month. The reorder level is set at 1 unit to maintain readiness for replacement or breakdowns.

Equipment Lifespan: Regular maintenance and proper usage extend the lifespan of the equipment. Investing in quality equipment ensures durability and reduces long-term costs.

Inventory Management: Efficient inventory management includes tracking the usage and condition of equipment. Proactive maintenance schedules minimize downtime and enhance operational efficiency.

D. Safety Supplies

Gloves: The monthly usage rate for gloves is 150 units, with a reorder level of 100 units. Gloves are essential for employee safety and hygiene during operations.

Masks: Masks are used at a rate of 80 units per month, with a reorder level of 50 units. Masks protect employees from inhaling harmful substances and ensure a safe working environment.

Compliance: Ensuring compliance with safety standards and regulations is critical. Adequate stock of safety supplies prevents health hazards and promotes employee well-being.

Replenishment Cycle: Regular replenishment cycles ensure continuous availability of safety supplies. Monitoring usage rates helps in maintaining appropriate stock levels.

E. Office Supplies

Paper: The monthly usage of paper is 300 sheets, with a reorder level set at 200 sheets. Paper is essential for administrative tasks and record-keeping.

Pens: Pens are used at a rate of 50 units per month, with a reorder level of 30 units. Pens are necessary for daily administrative activities and documentation.

Efficiency: Maintaining sufficient office supplies ensures uninterrupted administrative functions. Efficient inventory management of office supplies supports overall business operations.

Planning: Proper planning and forecasting based on usage trends help in maintaining optimal stock levels. Avoiding stockouts ensures smooth functioning of the office.

The usage patterns reveal the importance of regular inventory checks and proactive replenishment planning. By understanding the usage rates and setting appropriate reorder levels, [Your Company Name] can ensure a seamless supply of essential items, enhancing overall operational efficiency and service quality.

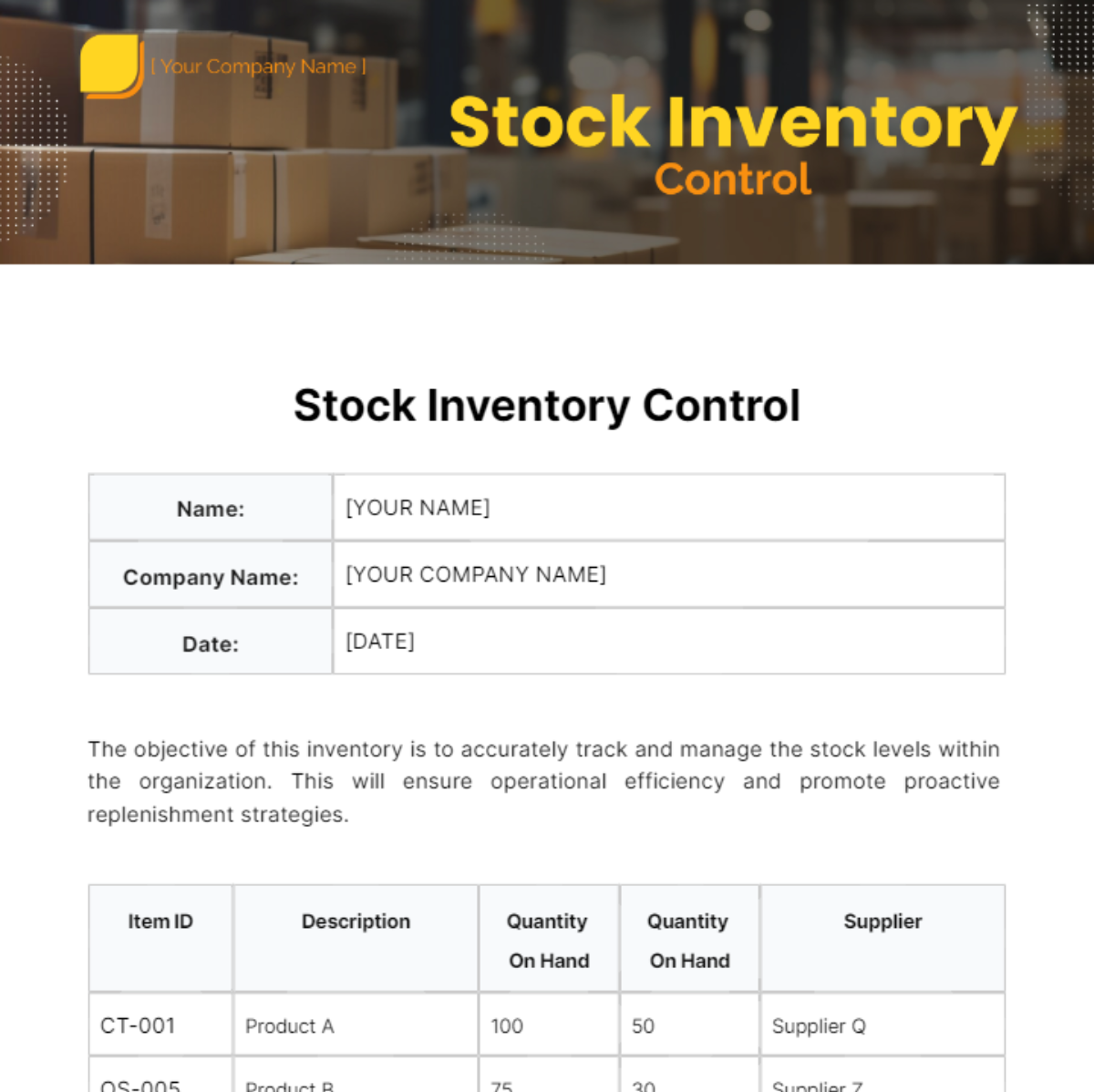

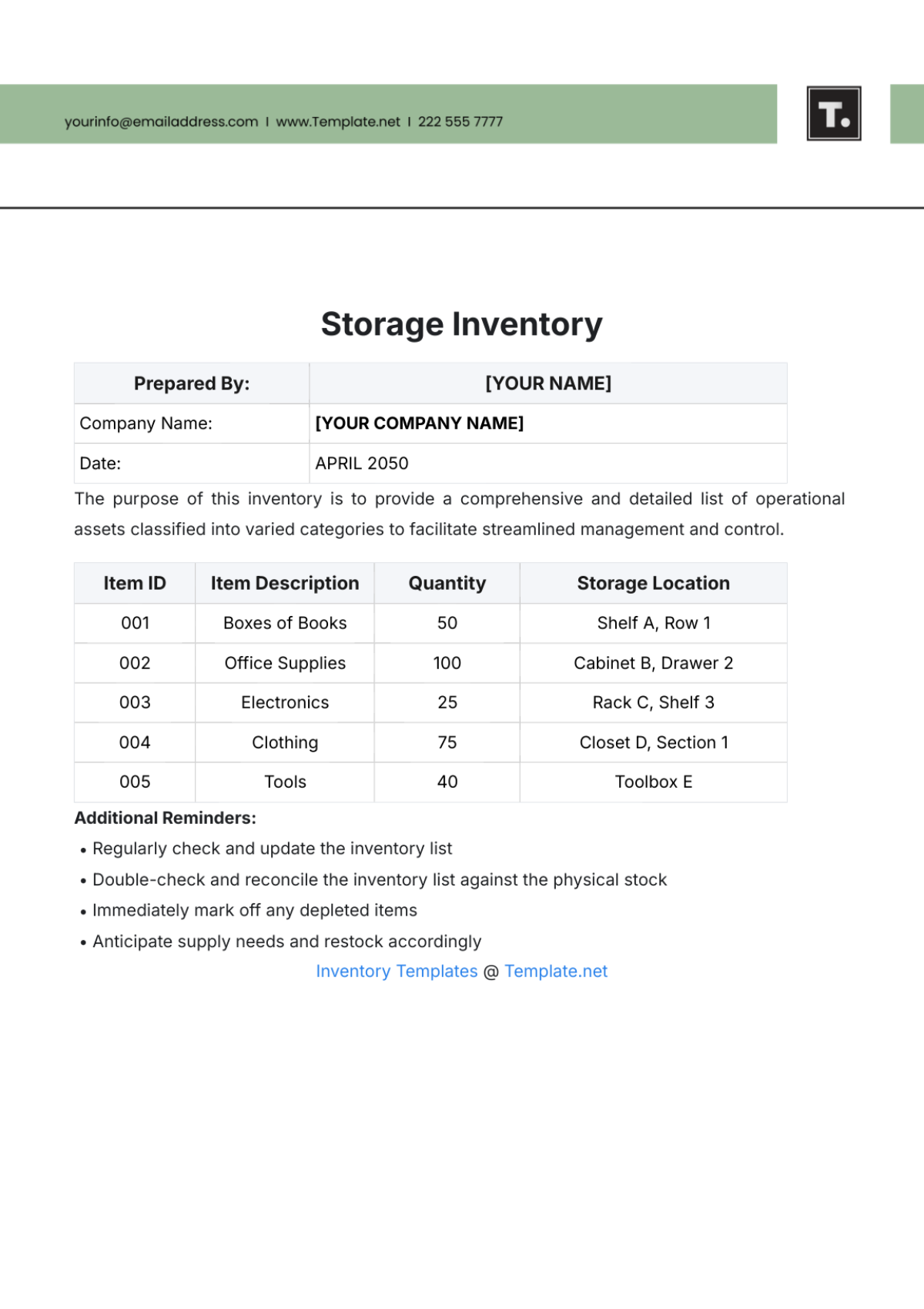

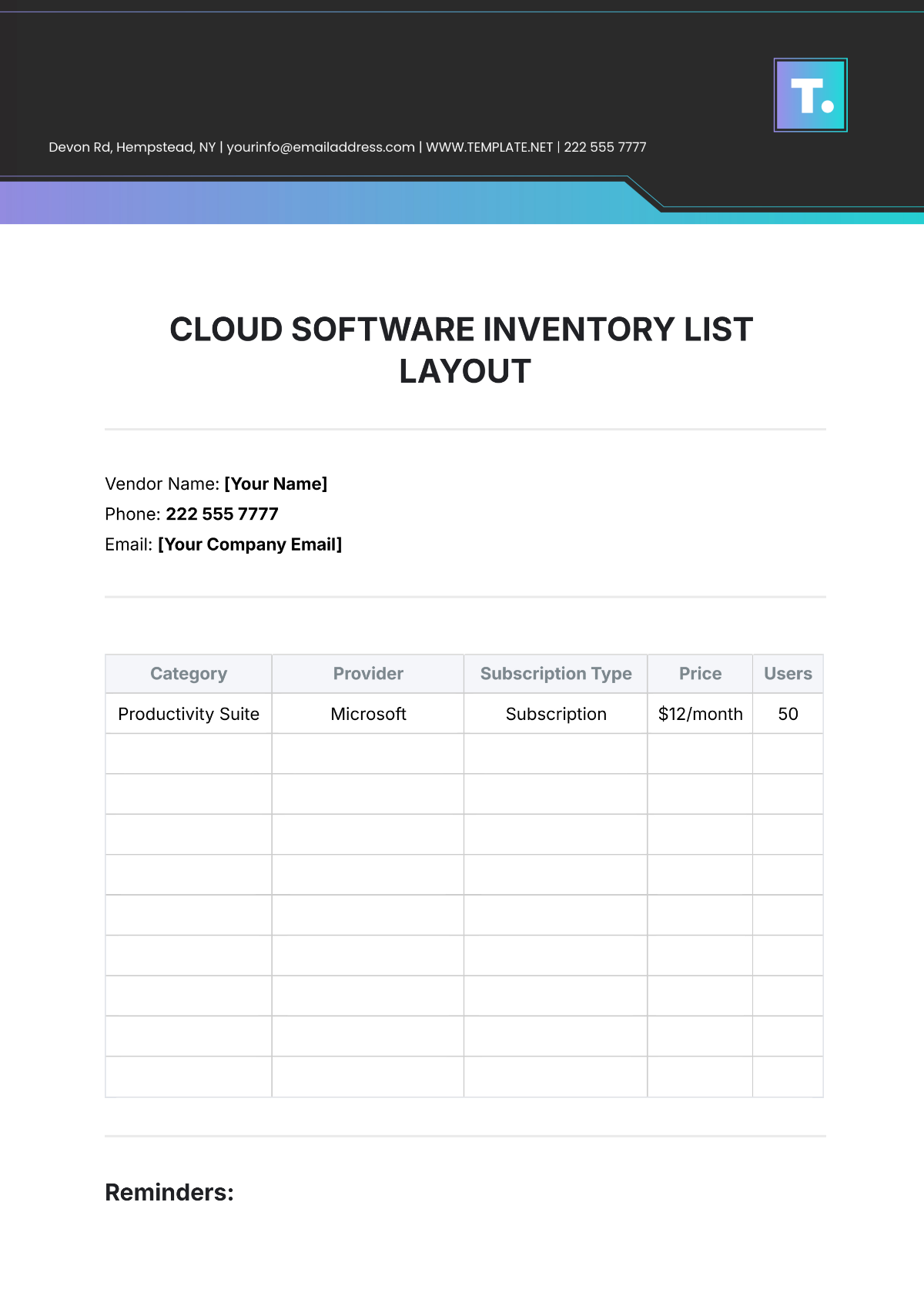

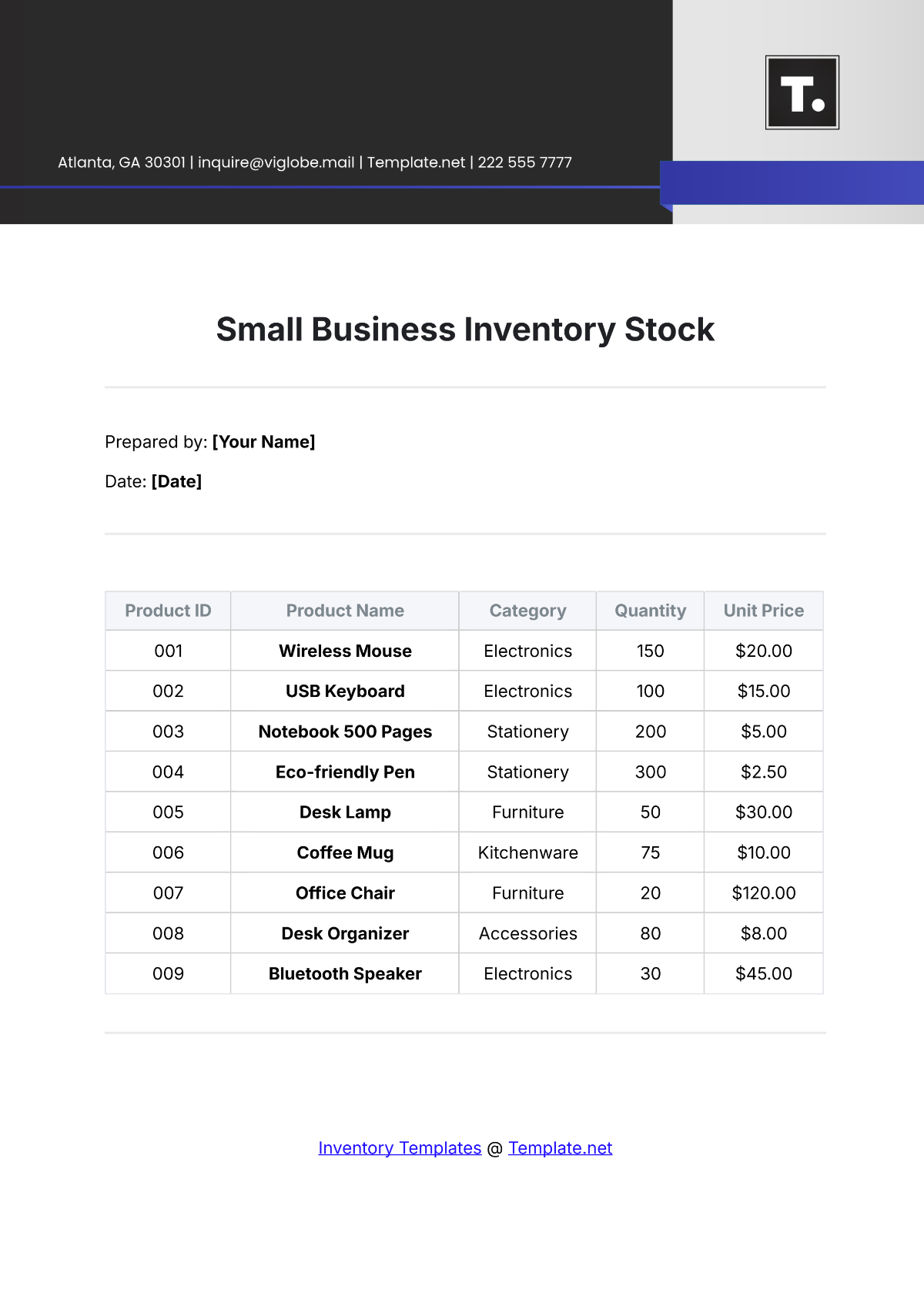

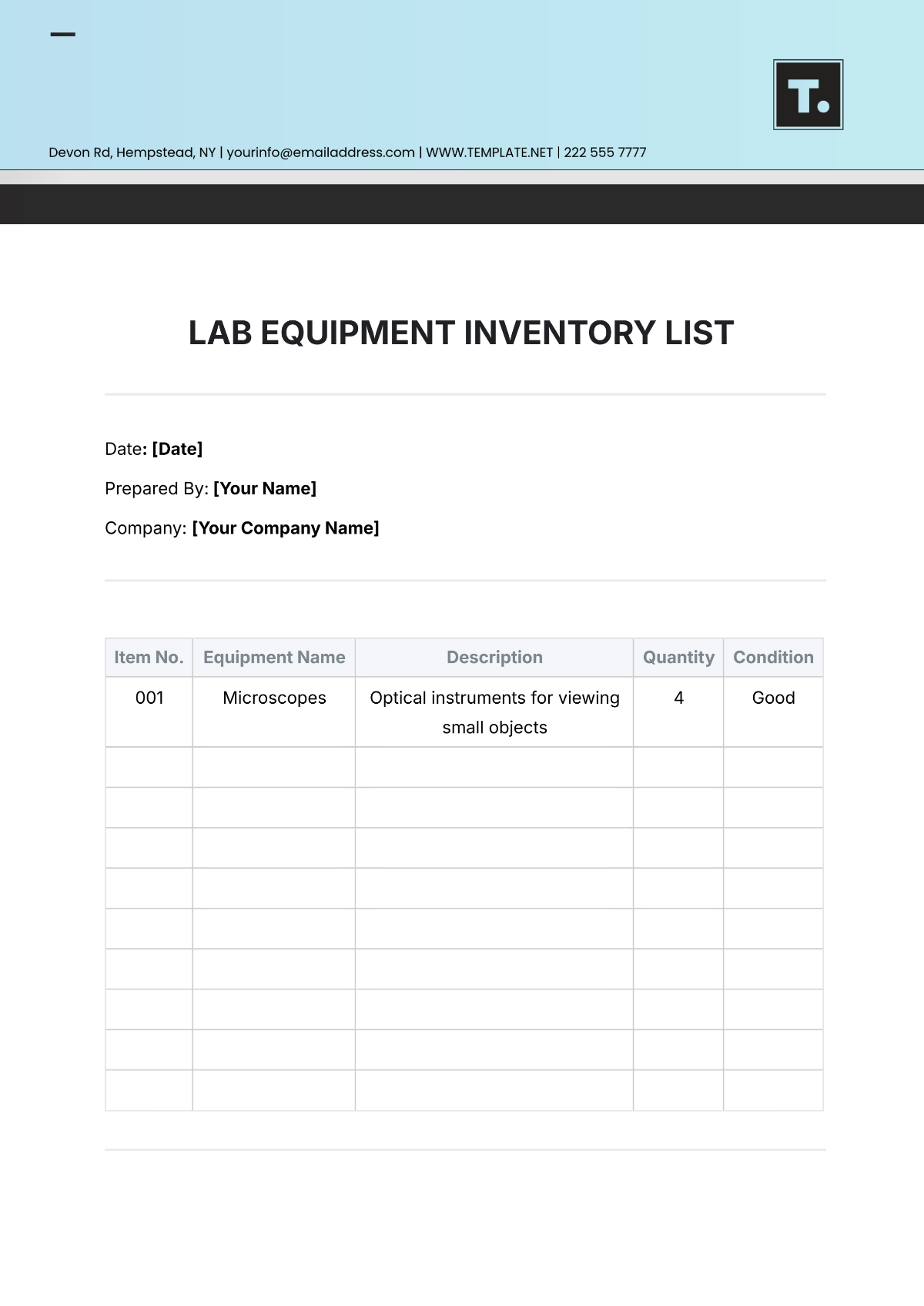

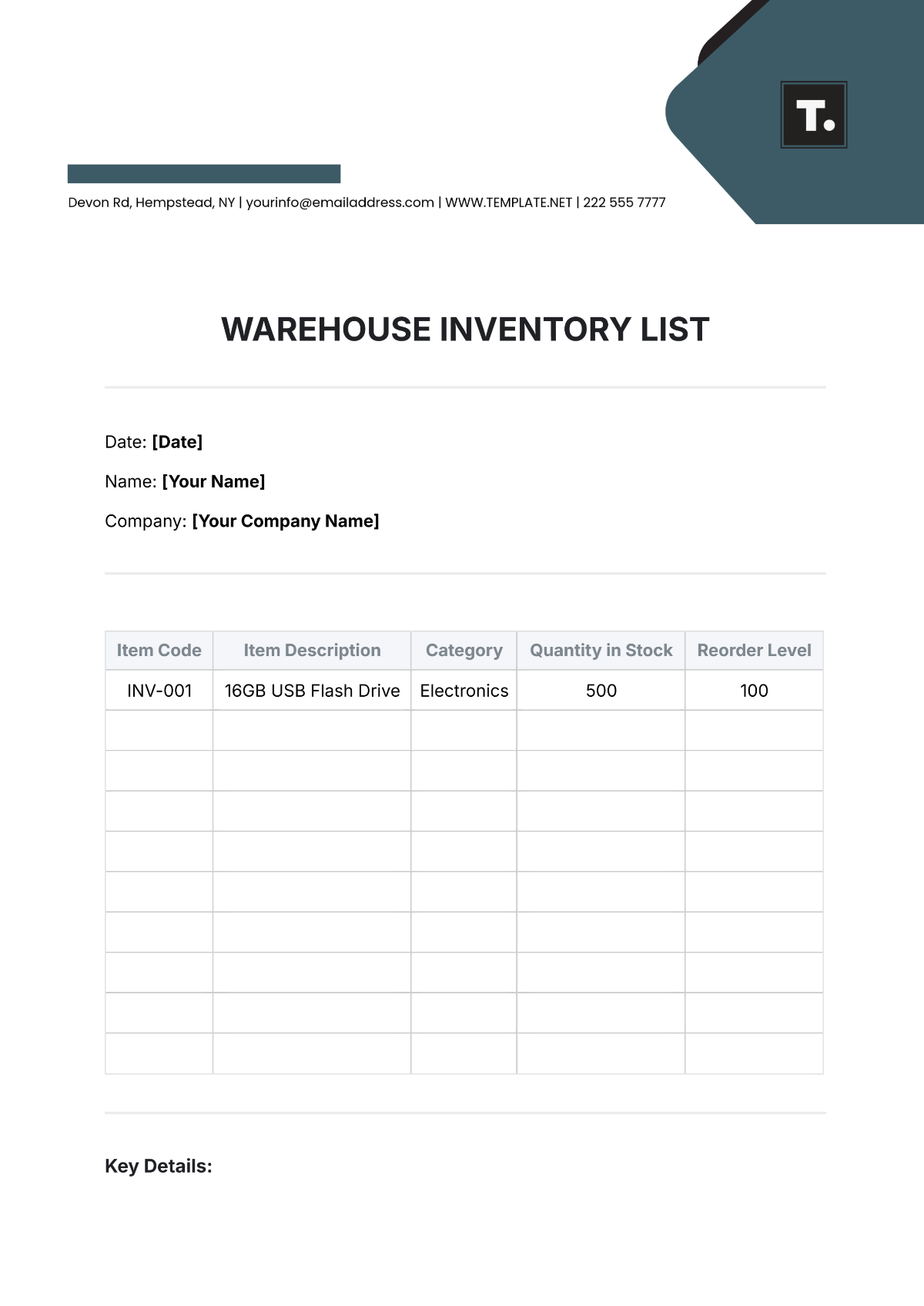

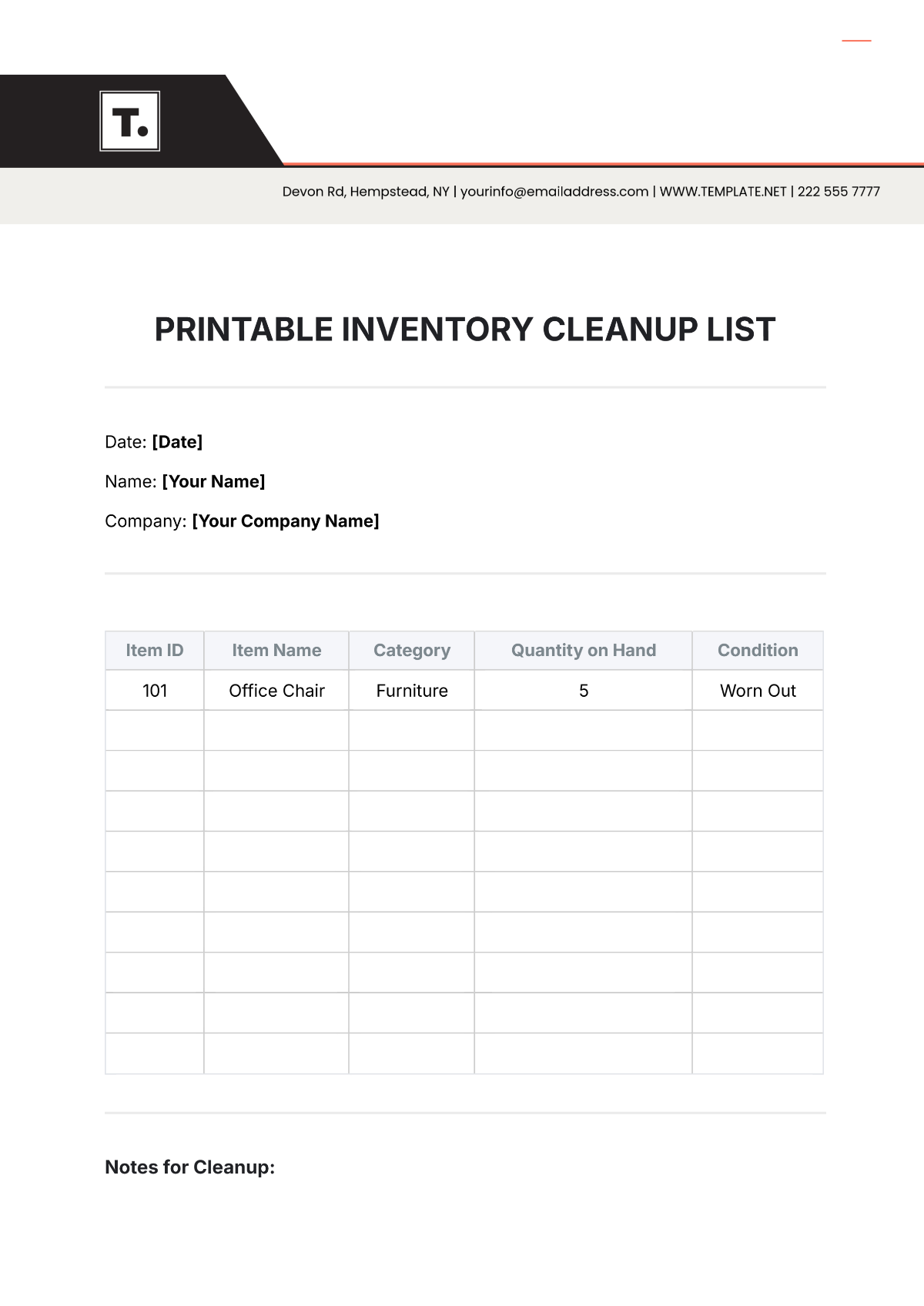

IV. Inventory Turnover

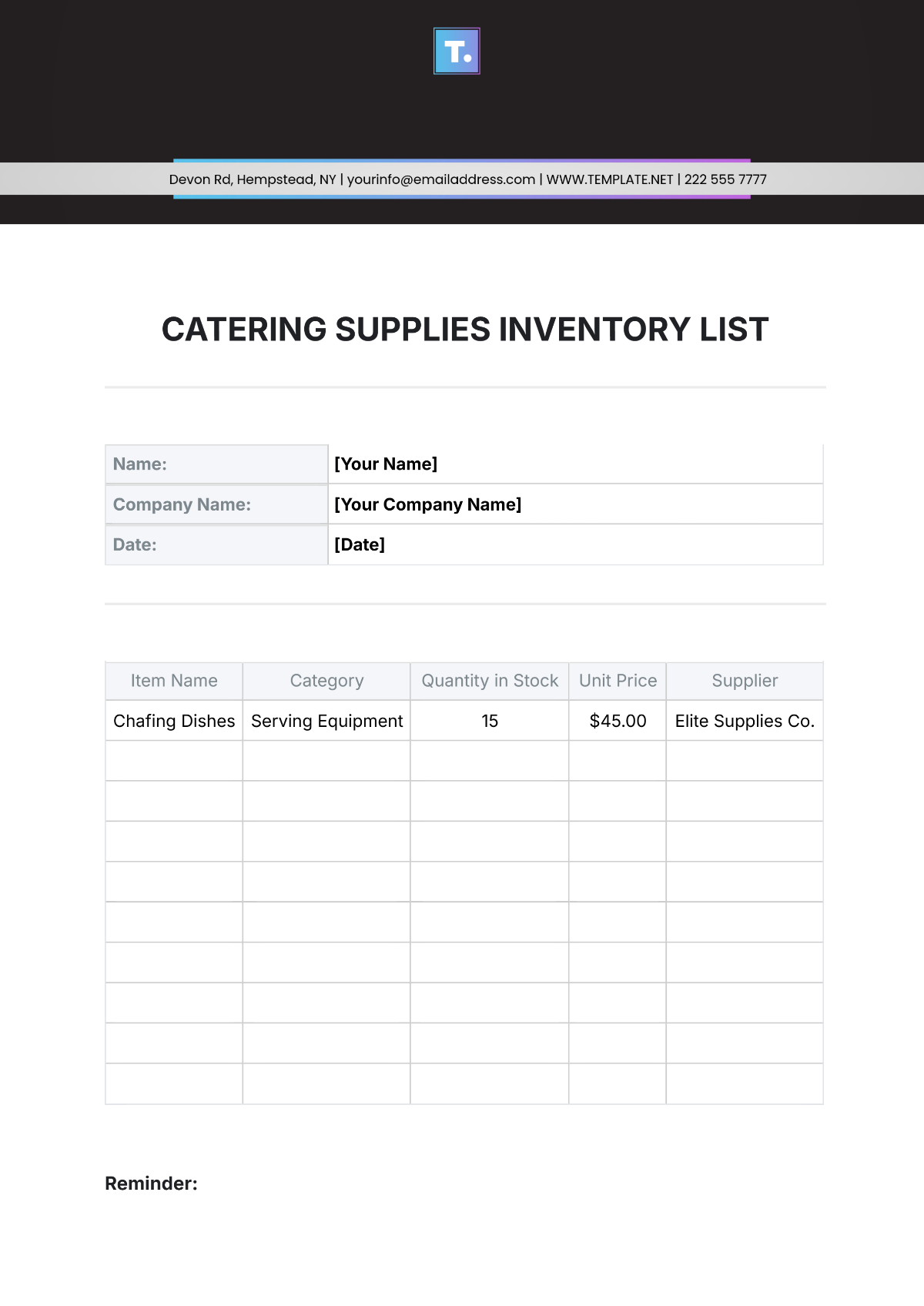

The following table provides an overview of the inventory turnover rates for various items at [Your Company Name]:

No. | Item | Annual Usage | Average Stock | Turnover Rate |

|---|---|---|---|---|

1 | Car Soap | 480 | 40 | 12 |

2 | Wax | 300 | 25 | 12 |

3 | Brushes | 960 | 80 | 12 |

4 | Towels | 2160 | 180 | 12 |

5 | High-Pressure Washer | 24 | 2 | 12 |

6 | Vacuum Cleaner | 12 | 1 | 12 |

7 | Gloves | 1800 | 150 | 12 |

8 | Masks | 960 | 80 | 12 |

9 | Paper | 3600 | 300 | 12 |

10 | Pens | 600 | 50 | 12 |

A. Cleaning Agents

Car Soap: The annual usage rate for car soap is 480 units, with an average stock level of 40 units, resulting in a turnover rate of 12. This indicates a high rate of inventory turnover, reflecting frequent replenishment needs.

Wax: Wax has an annual usage rate of 300 units, with an average stock level of 25 units, resulting in a turnover rate of 12. This high turnover rate indicates a consistent demand for waxing services.

Turnover Analysis: High turnover rates for cleaning agents suggest efficient inventory management. Regular replenishment ensures that stock levels are maintained to meet customer demand.

Inventory Optimization: Optimizing inventory levels based on turnover rates helps in maintaining a balance between stock availability and cost control. High turnover rates reflect effective inventory utilization.

B. Tools

Brushes: The annual usage rate for brushes is 960 units, with an average stock level of 80 units, resulting in a turnover rate of 12. This high turnover rate indicates frequent use and the need for regular replenishment.

Towels: Towels have an annual usage rate of 2160 units, with an average stock level of 180 units, resulting in a turnover rate of 12. This high turnover rate reflects their essential role in the car wash process.

Turnover Analysis: High turnover rates for tools indicate efficient usage and inventory management. Regular monitoring of usage patterns helps in planning for timely replenishment.

Inventory Optimization: Maintaining optimal stock levels based on turnover rates ensures that tools are always available for use. High turnover rates reflect effective inventory utilization and operational efficiency.

C. Safety and Maintenance Equipment

High-Pressure Washer: The high-pressure washer has an annual usage rate of 24 units, with an average stock level of 2 units, resulting in a turnover rate of 12. This turnover rate indicates a consistent need for this equipment in daily operations.

Vacuum Cleaner: The vacuum cleaner shows an annual usage rate of 12 units, with an average stock level of 1 unit, resulting in a turnover rate of 12. This highlights the importance of maintaining a reliable stock of essential cleaning equipment.

Turnover Analysis: High turnover rates for safety and maintenance equipment highlight their critical role in ensuring smooth operations. Regular replenishment of these items ensures that the equipment is always functional and ready for use.

Inventory Optimization: By maintaining high turnover rates for safety and maintenance equipment, we ensure that these essential items are always in stock. This not only supports operational efficiency but also enhances safety and service quality.

D. Protective Gear

Gloves: Gloves have an annual usage rate of 1800 units, with an average stock level of 150 units, resulting in a turnover rate of 12. This high turnover rate highlights the importance of protective gear in maintaining safety standards.

Masks: Masks show an annual usage rate of 960 units, with an average stock level of 80 units, resulting in a turnover rate of 12. This indicates a consistent need for protective equipment to ensure employee safety.

Turnover Analysis: High turnover rates for protective gear underscore the priority placed on safety. Regular replenishment of these items ensures that employees are always equipped with necessary protective gear, reducing the risk of workplace incidents.

Inventory Optimization: By maintaining high turnover rates for protective gear, we ensure that safety standards are consistently met. This not only protects our employees but also supports compliance with health and safety regulations, contributing to a safer work environment.

E. Office Supplies

Paper: The annual usage rate for paper is 3600 units, with an average stock level of 300 units, resulting in a turnover rate of 12. This high turnover rate indicates the frequent need for paper in administrative tasks.

Pens: Pens have an annual usage rate of 600 units, with an average stock level of 50 units, resulting in a turnover rate of 12. This reflects the constant demand for basic office supplies.

Turnover Analysis: High turnover rates for office supplies indicate efficient inventory management. Ensuring regular replenishment of these items supports the smooth functioning of administrative tasks and overall business operations.

Inventory Optimization: Maintaining high turnover rates for office supplies ensures that necessary items are always available, minimizing disruptions in daily operations. Effective management of office supplies contributes to overall business efficiency and productivity.

Inventory turnover highlight the importance of regular replenishment and efficient inventory management. High turnover rates indicate a consistent demand for essential items, reflecting effective inventory utilization and operational efficiency.

V. Inventory Control Measures

A. Regular Stock Checks

Monitoring Levels: Regular stock checks are conducted to monitor inventory levels accurately. This helps in identifying discrepancies and ensuring that stock levels are maintained as per requirements.

Identifying Shortages: Stock checks help in identifying shortages and preventing stockouts. Regular monitoring ensures that essential items are always available for use.

Improving Accuracy: Regular stock checks improve the accuracy of inventory records. Accurate records help in making informed decisions about replenishment and inventory management.

Preventing Overstocks: Stock checks also help in preventing overstock situations. Maintaining optimal stock levels reduces carrying costs and improves inventory efficiency.

B. Reorder Point System

Triggering Replenishment: A reorder point system is implemented to trigger replenishment when stock levels reach a predefined threshold. This ensures timely ordering and receiving of supplies.

Optimizing Inventory: The reorder point system helps in optimizing inventory levels based on usage patterns. Setting appropriate reorder points ensures that stock levels are maintained to meet demand.

Preventing Stockouts: The reorder point system helps in preventing stockouts by ensuring timely replenishment. Maintaining adequate stock levels ensures uninterrupted operations.

Streamlining Processes: The reorder point system streamlines the inventory management process. Automated triggers for replenishment reduce manual intervention and improve efficiency.

C. Usage Tracking

Adjusting Stock Levels: Tracking usage patterns helps in adjusting stock levels as needed. Understanding usage trends helps in making informed decisions about inventory management.

Predicting Demand: Usage tracking helps in predicting future demand based on past usage patterns. Accurate demand forecasting helps in maintaining optimal stock levels.

Preventing Shortages: Tracking usage patterns helps in preventing shortages by ensuring timely replenishment. Regular monitoring of usage trends helps in maintaining adequate stock levels.

Improving Efficiency: Usage tracking improves inventory management efficiency by providing insights into usage patterns. Accurate tracking helps in optimizing inventory levels and reducing waste.

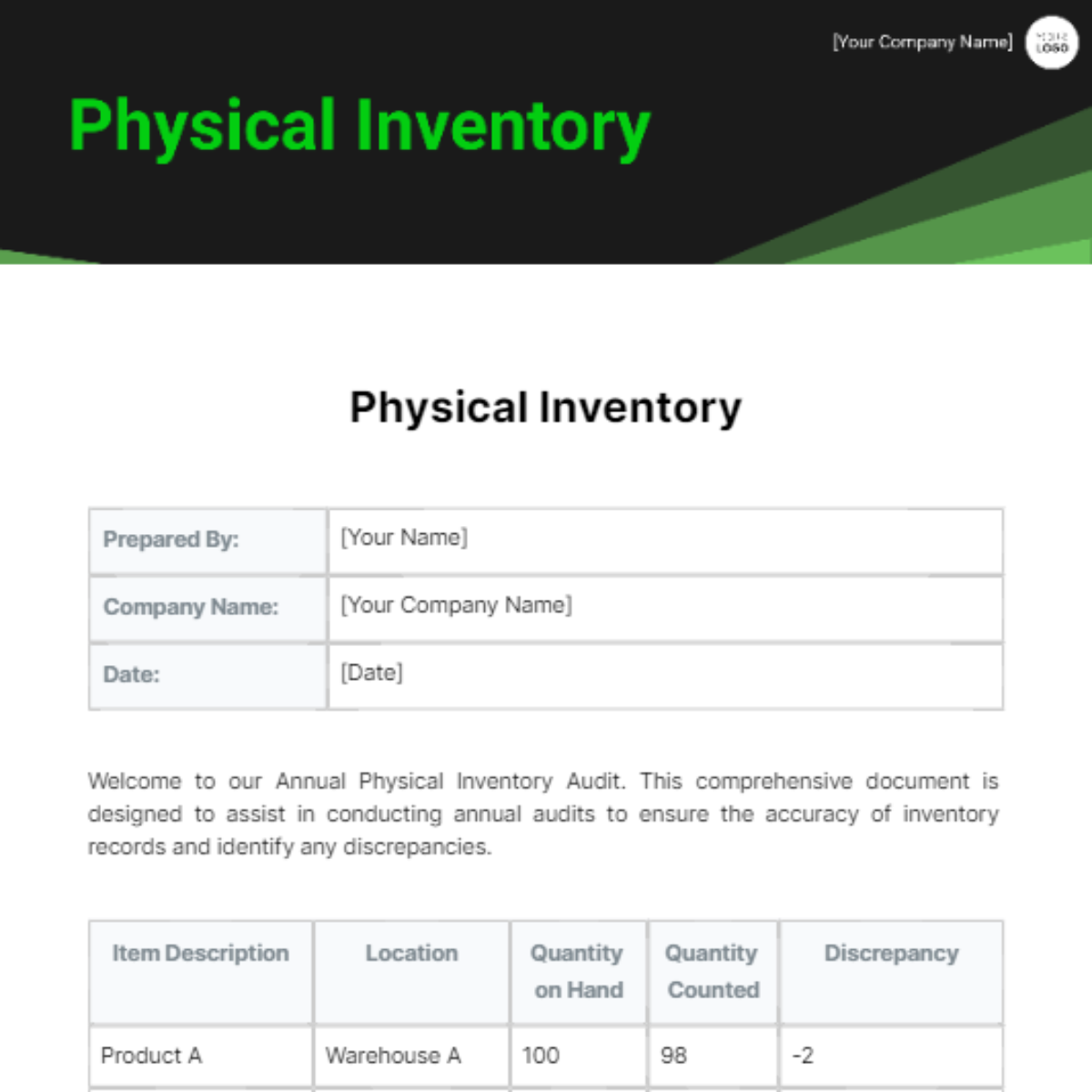

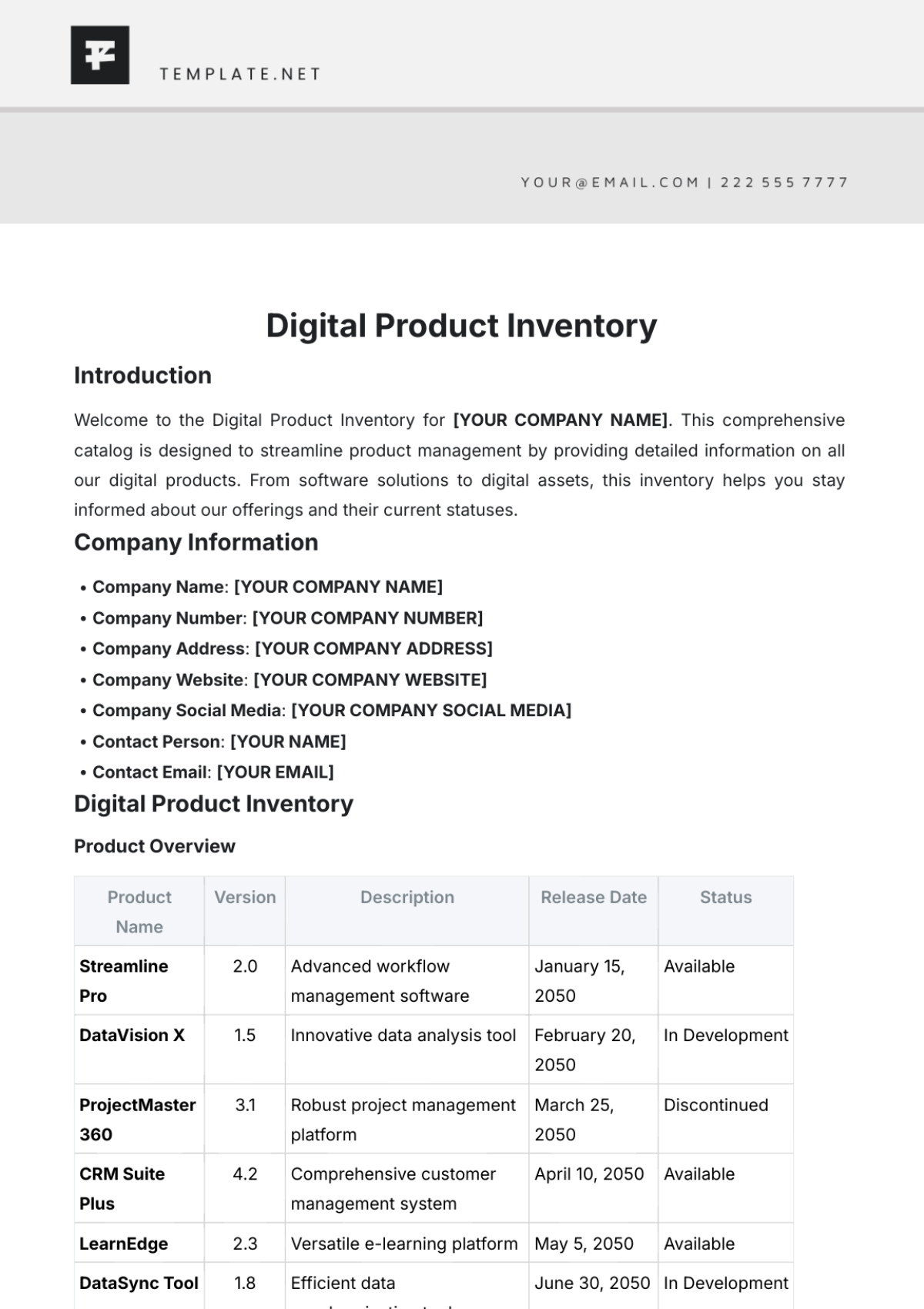

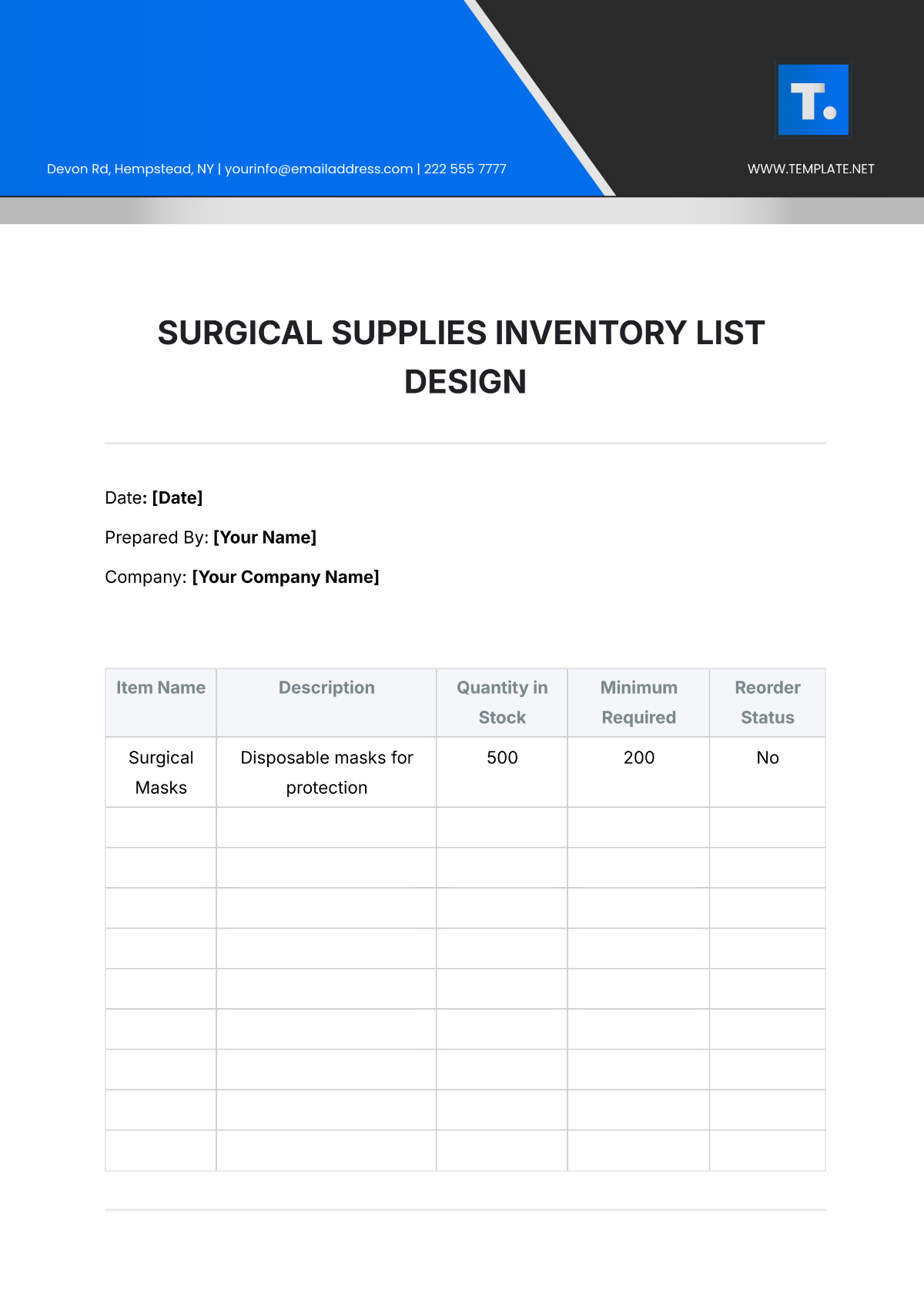

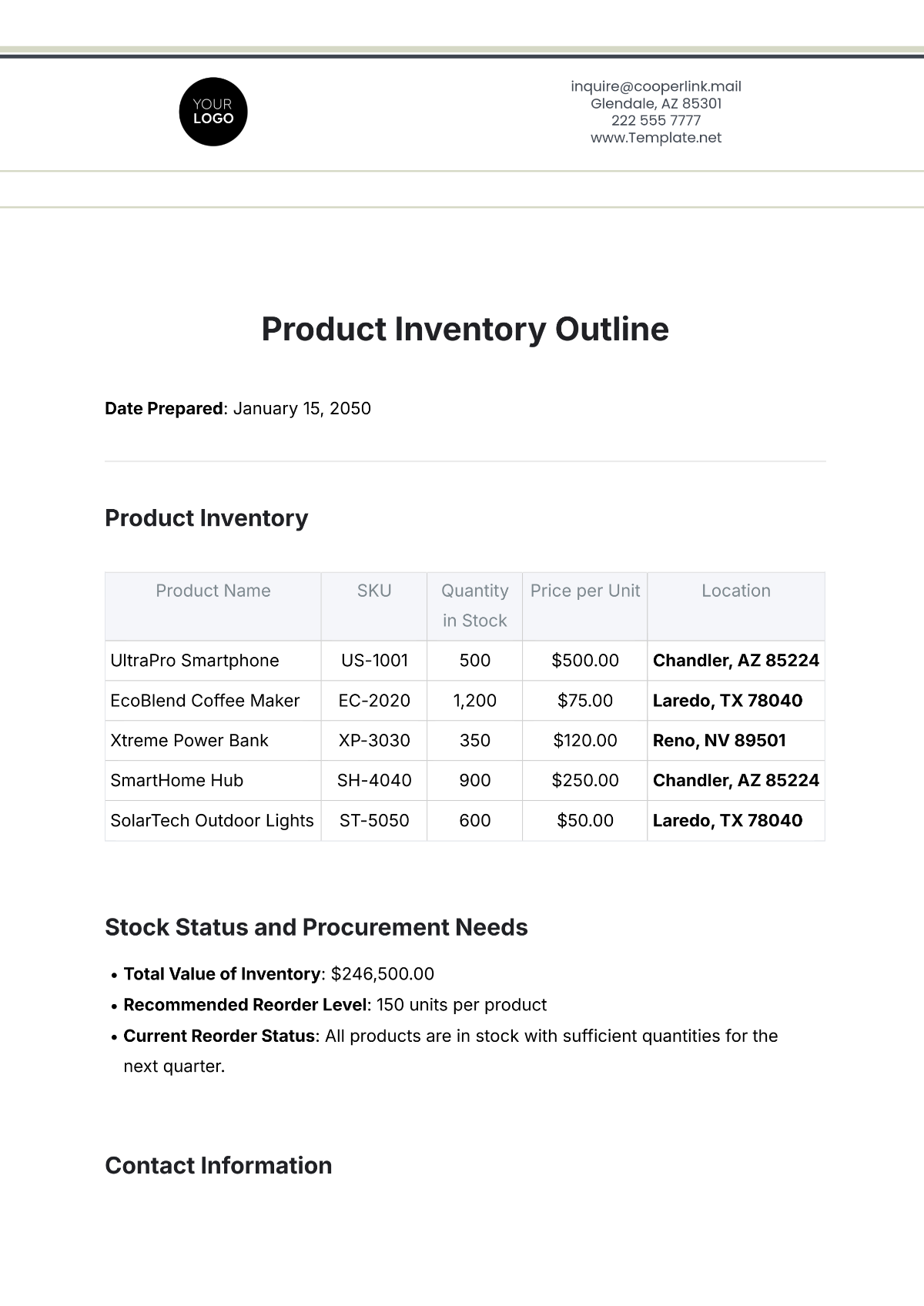

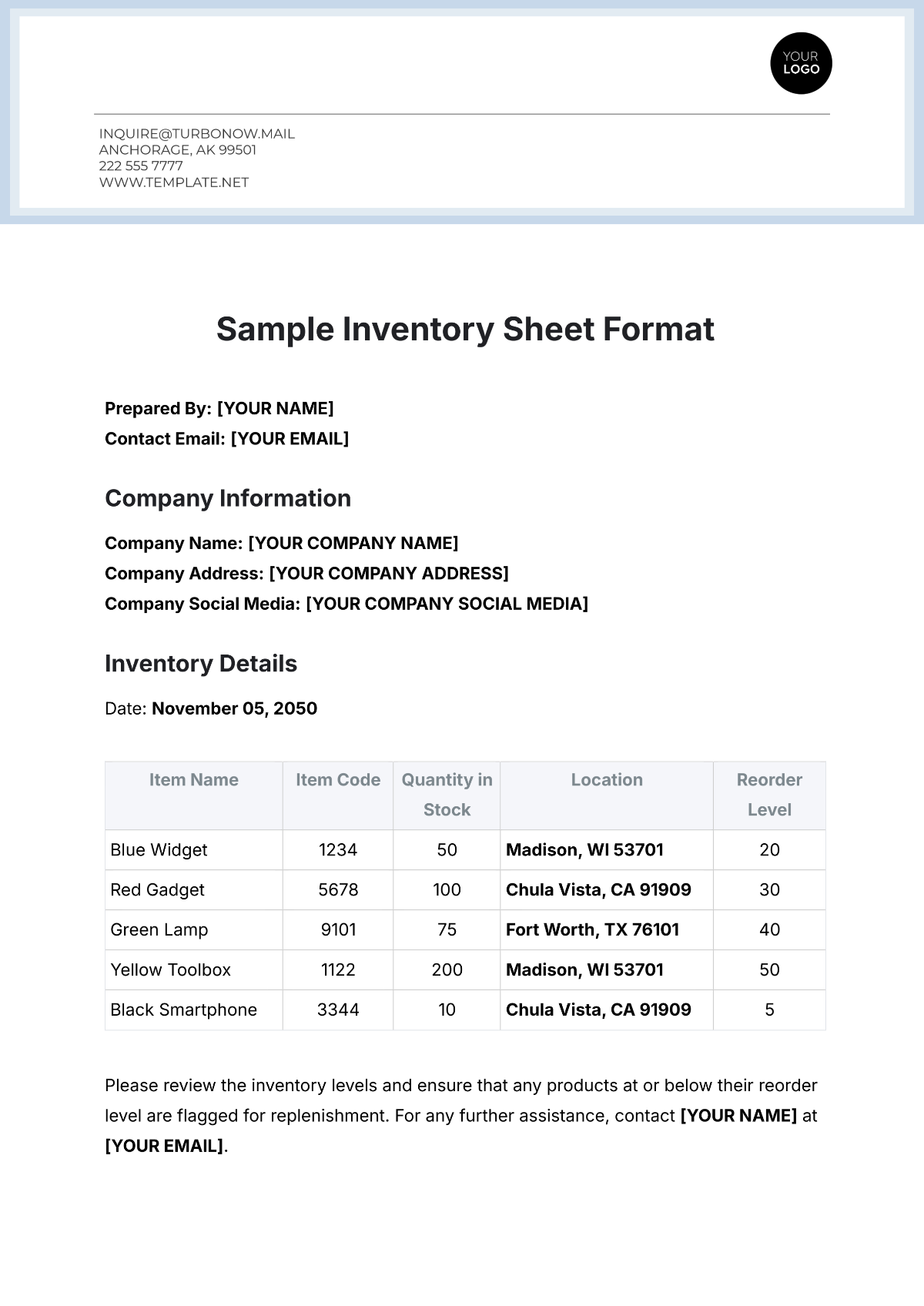

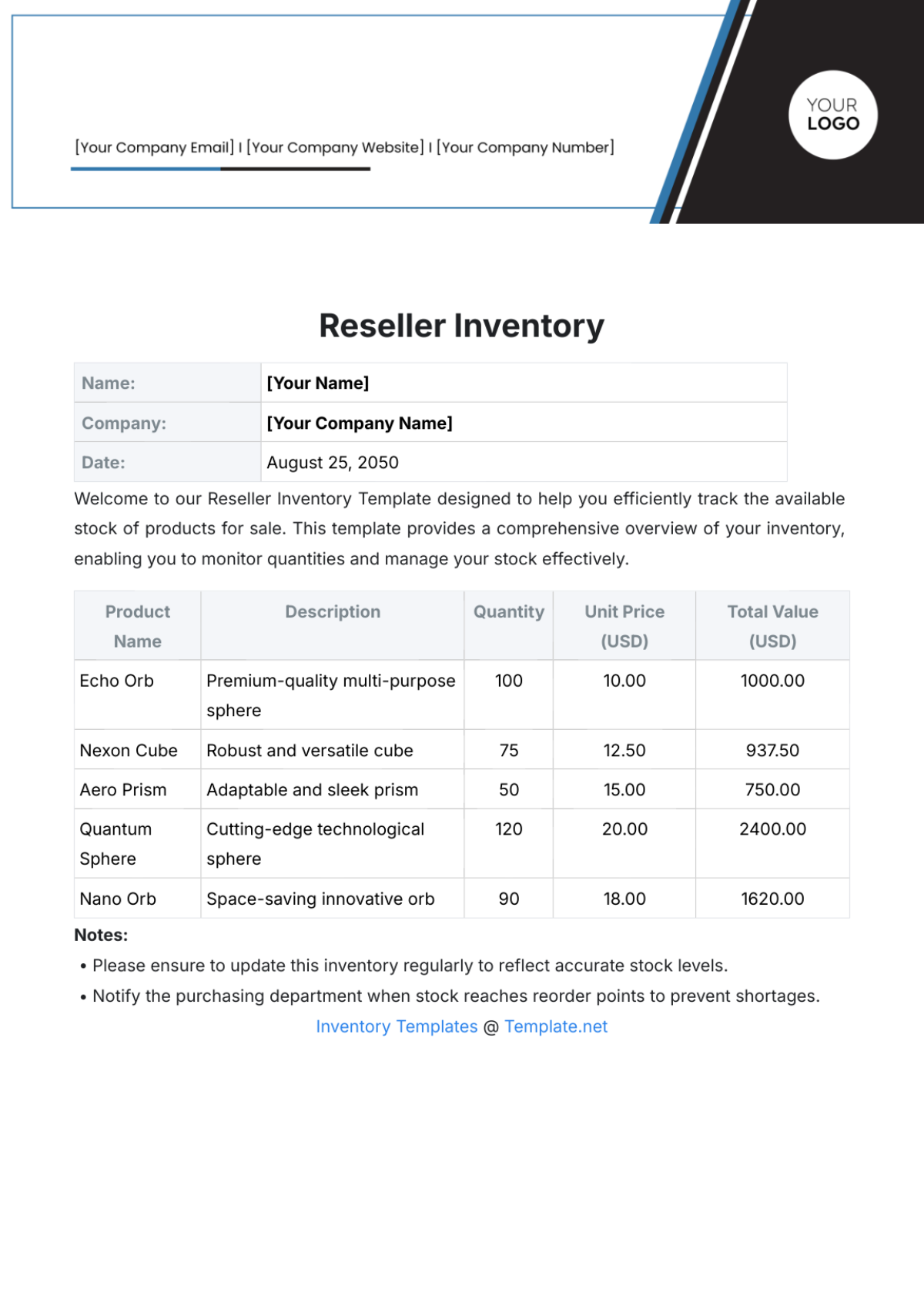

VI. Inventory Replenishment

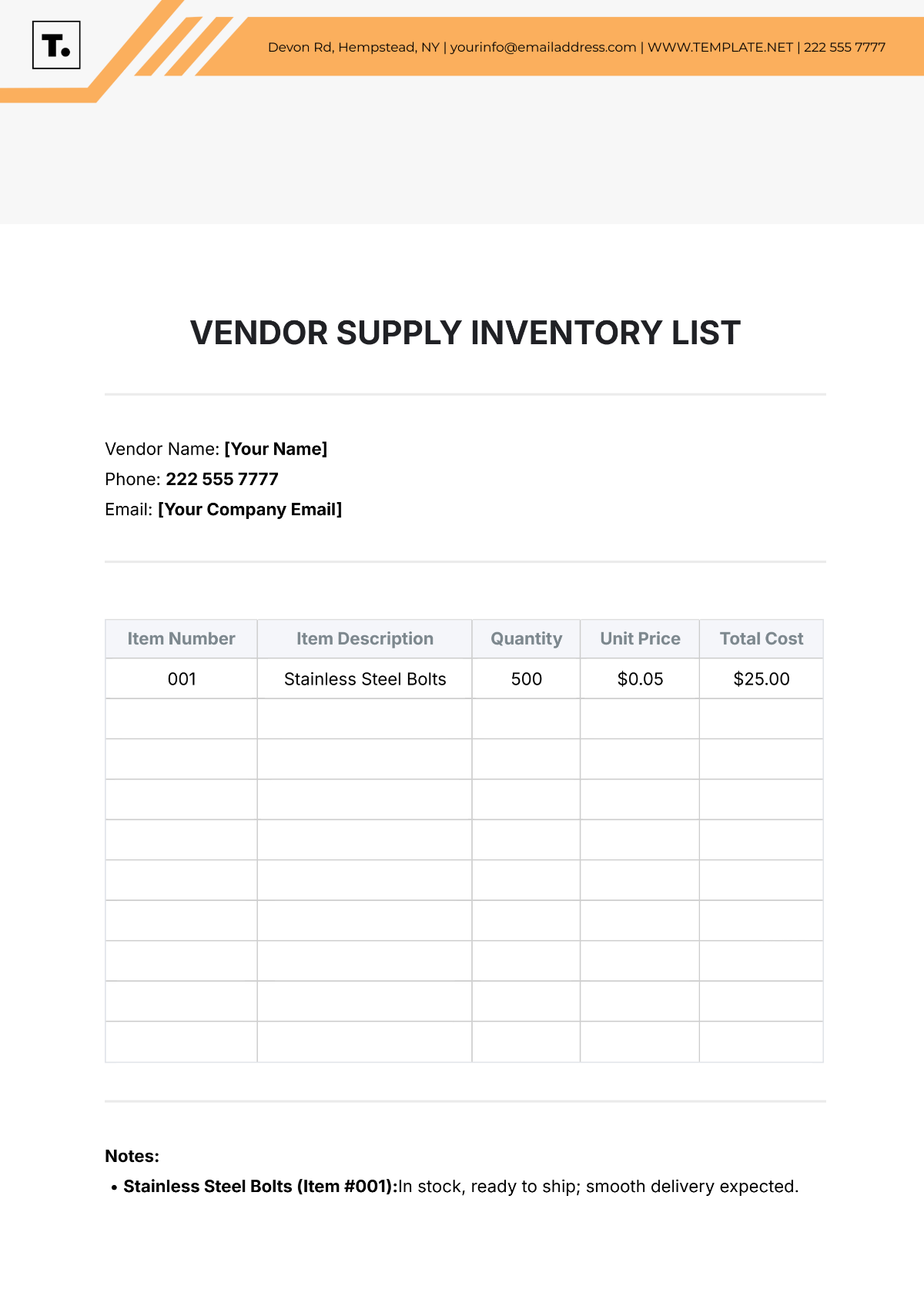

The following table provides an overview of the inventory replenishment schedule for [Your Company Name]:

No. | Item | Replenishment Frequency |

|---|---|---|

1 | Car Soap | Monthly |

2 | Wax | Monthly |

3 | Brushes | Quarterly |

4 | Towels | Quarterly |

5 | High-Pressure Washer | Annually |

6 | Vacuum Cleaner | Annually |

7 | Gloves | Monthly |

8 | Masks | Monthly |

9 | Paper | Quarterly |

10 | Pens | Quarterly |

A. Monthly Replenishment

Car Soap: Car soap is replenished monthly. Monthly replenishment ensures that this essential cleaning agent is always available for use.

Wax: Wax is replenished monthly. Regular replenishment ensures that waxing services can be provided consistently without interruption.

Gloves and Masks: Safety supplies such as gloves and masks are replenished monthly. Maintaining adequate stock of safety supplies ensures employee protection and compliance with safety standards.

B. Quarterly Replenishment

Brushes: Brushes are replenished quarterly. Regular replenishment ensures that brushes are always available for effective cleaning.

Towels: Towels are replenished quarterly. Quarterly replenishment ensures that towels are available for drying and detailing.

Office Supplies: Paper and pens are replenished quarterly. Regular replenishment ensures that office supplies are available for administrative tasks.

C. Annual Replenishment

High-Pressure Washer: High-pressure washers are replenished annually. Annual replenishment ensures that these essential machines are available for effective car washing.

Vacuum Cleaner: Vacuum cleaners are replenished annually. Annual replenishment ensures that vacuum cleaners are available for interior cleaning and detailing.

Inventory replenishment highlight the importance of regular and timely replenishment to maintain optimal stock levels. By following a structured replenishment schedule, [Your Company Name] can ensure that essential items are always available for use, enhancing operational efficiency and service quality.

VII. Recommendations

Based on the findings of the inventory report, the following recommendations are made to enhance inventory management at [Your Company Name]:

A. Regular Stock Checks

Implementing Regular Checks: Conduct regular stock checks to monitor inventory levels accurately. This helps in identifying discrepancies and ensuring that stock levels are maintained as per requirements.

Improving Accuracy: Regular stock checks improve the accuracy of inventory records. Accurate records help in making informed decisions about replenishment and inventory management.

Preventing Stockouts: Stock checks help in identifying shortages and preventing stockouts. Regular monitoring ensures that essential items are always available for use.

B. Reorder Point System

Setting Appropriate Reorder Points: Implement a reorder point system to trigger replenishment when stock levels reach a predefined threshold. This ensures timely ordering and receiving of supplies.

Optimizing Inventory Levels: The reorder point system helps in optimizing inventory levels based on usage patterns. Setting appropriate reorder points ensures that stock levels are maintained to meet demand.

Preventing Overstock Situations: The reorder point system helps in preventing overstock situations. Maintaining optimal stock levels reduces carrying costs and improves inventory efficiency.

C. Usage Tracking

Tracking Usage Patterns: Track usage patterns to adjust stock levels as needed. Understanding usage trends helps in making informed decisions about inventory management.

Predicting Future Demand: Usage tracking helps in predicting future demand based on past usage patterns. Accurate demand forecasting helps in maintaining optimal stock levels.

Improving Inventory Efficiency: Usage tracking improves inventory management efficiency by providing insights into usage patterns. Accurate tracking helps in optimizing inventory levels and reducing waste.

The inventory management reveal the importance of regular monitoring and proactive management. Implementing effective inventory control measures and following a structured replenishment schedule ensures that stock levels are maintained to meet customer demand and enhance operational efficiency.

VIII. Conclusion

This Car Wash Inventory Report of [Your Company Name] highlights the importance of maintaining optimal stock levels to ensure smooth operations and high service quality. Regular monitoring, accurate tracking, and timely replenishment of inventory are crucial for effective inventory management.

The findings of the inventory report emphasize the need for proactive inventory management to prevent stockouts and overstock situations. By following a structured approach to inventory control and replenishment, [Your Company Name] can maintain high service standards, meet customer expectations, and ensure the smooth functioning of the car wash business.