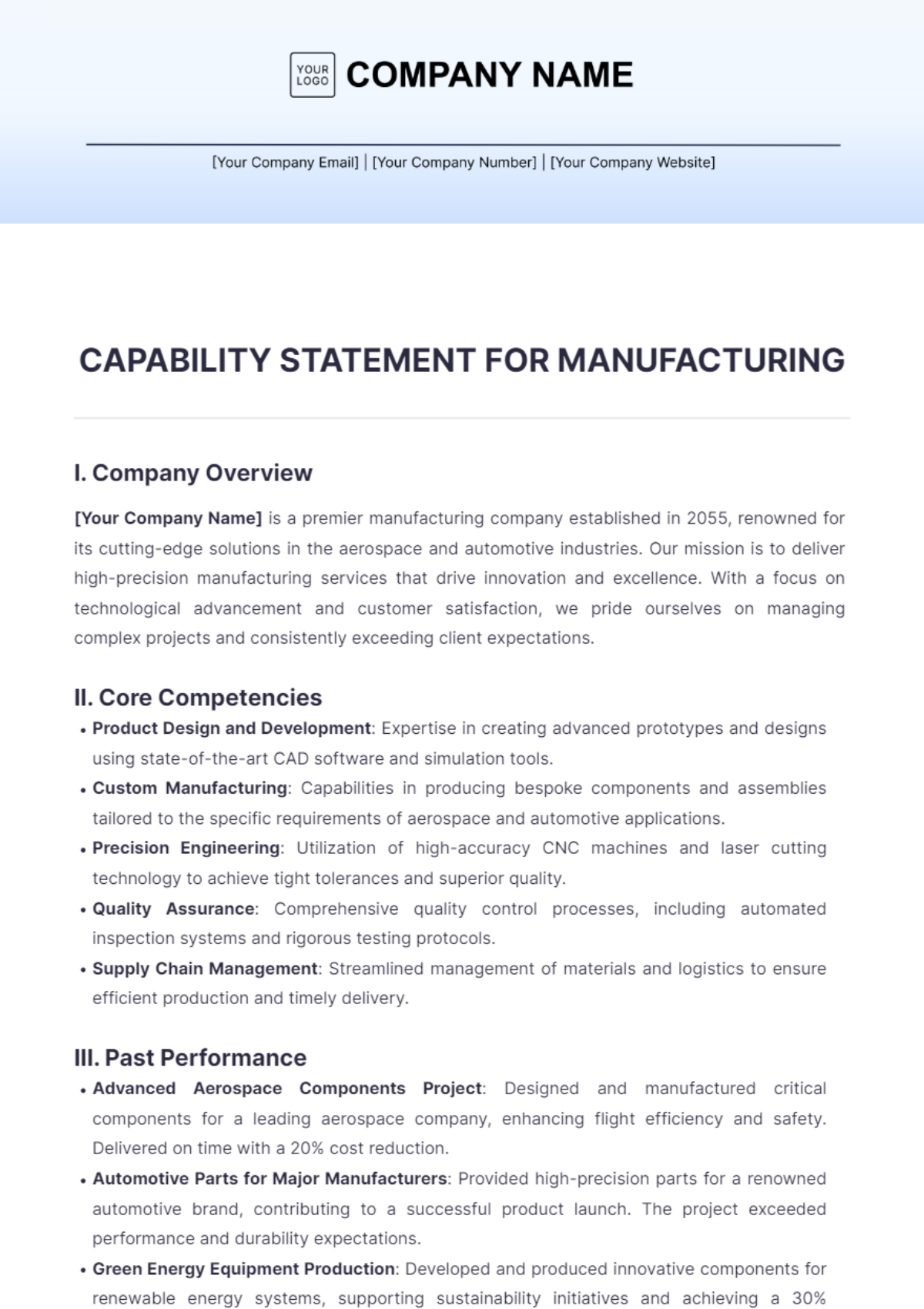

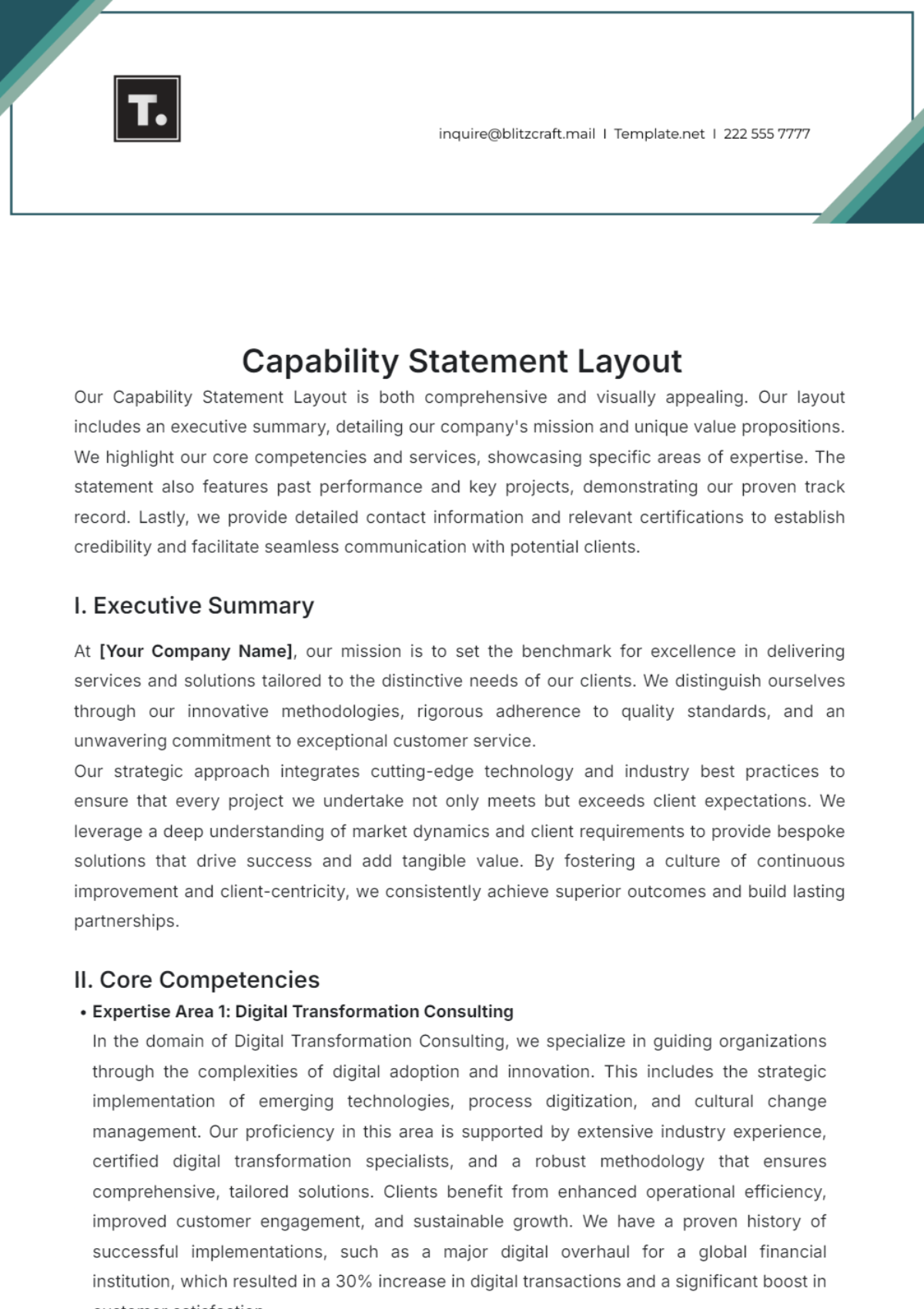

Free Capability Statement for Manufacturing

Enhance your manufacturing business presentations with Template.net's Capability Statement for Manufacturing Template. This fully customizable and editable template is designed to impress. Editable in our Ai Editor Tool, it allows you to tailor every detail to suit your needs, ensuring a professional and polished presentation every time. Elevate your business communication effortlessly with this versatile template.