Warehousing Requirements

1. Introduction

This Warehousing Requirements is a structured document aimed at guiding the management of various aspects of warehouse operations. The document outlines essential procedures, guidelines, and standards that must be adhered to for efficient and effective warehousing.

2. Warehouse Layout and Design

Space Utilization

Effective space utilization is critical in a warehouse. Implement strategies that maximize storage capacity while ensuring safety and accessibility.

Area | Purpose | Guidelines |

|---|---|---|

Receiving Area | Incoming goods inspection and processing | Designate space near loading docks; ensure adequate equipment and staff. |

Storage Area | Long-term storage of goods | Organize by product type and turnover rate; label rows and aisles. |

Picking Area | Order picking and packing | Ensure easy access to high-demand items; use efficient picking methods. |

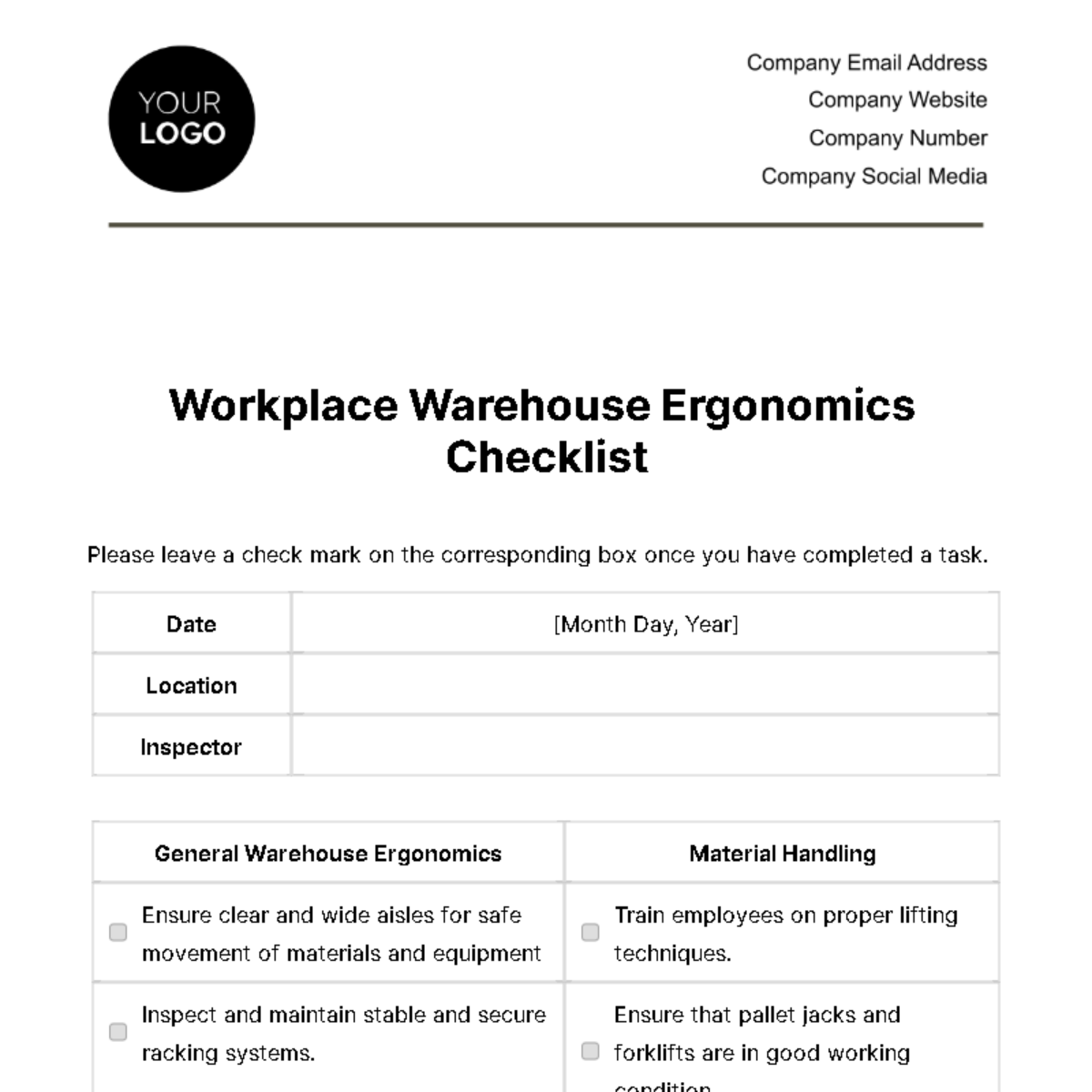

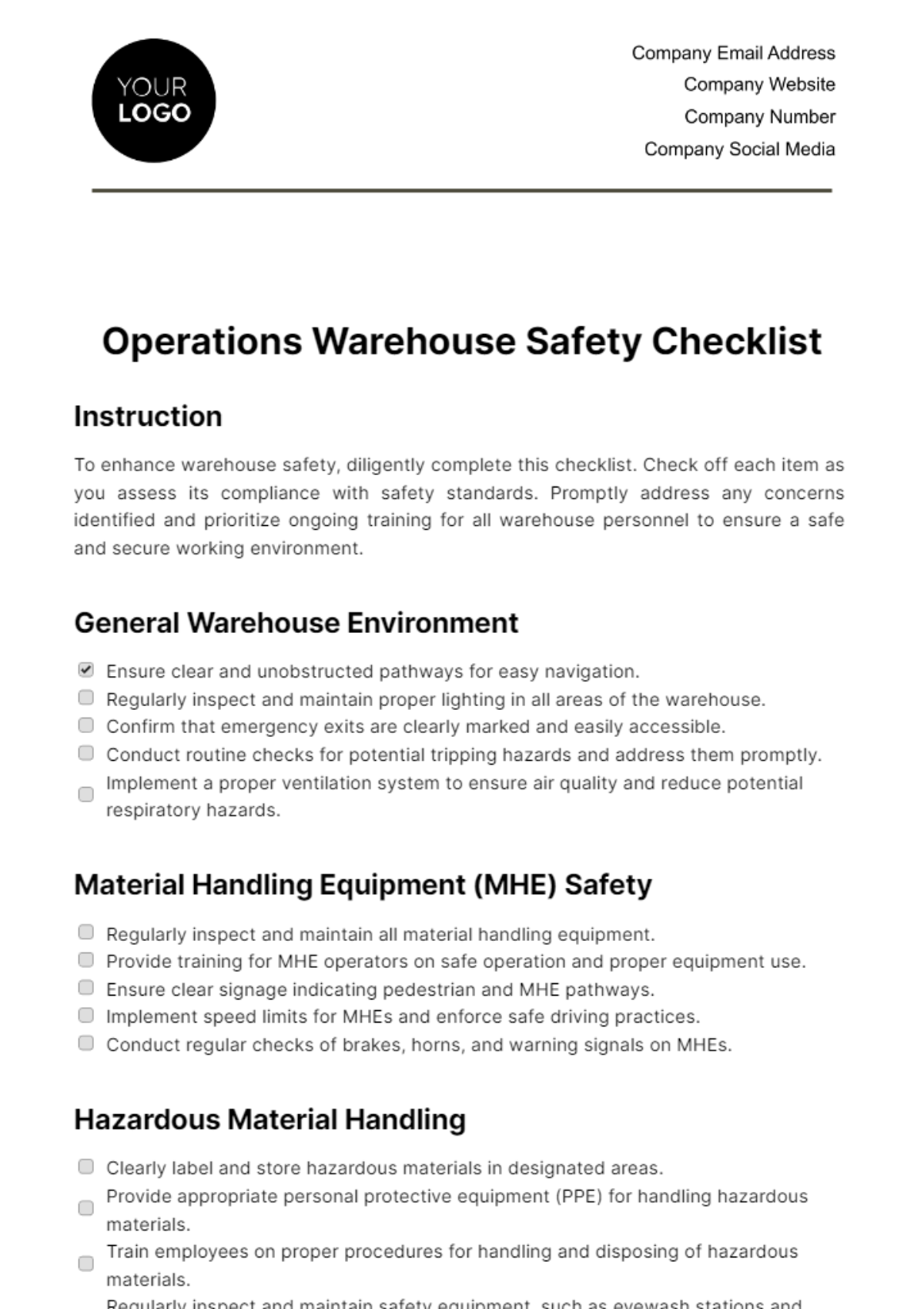

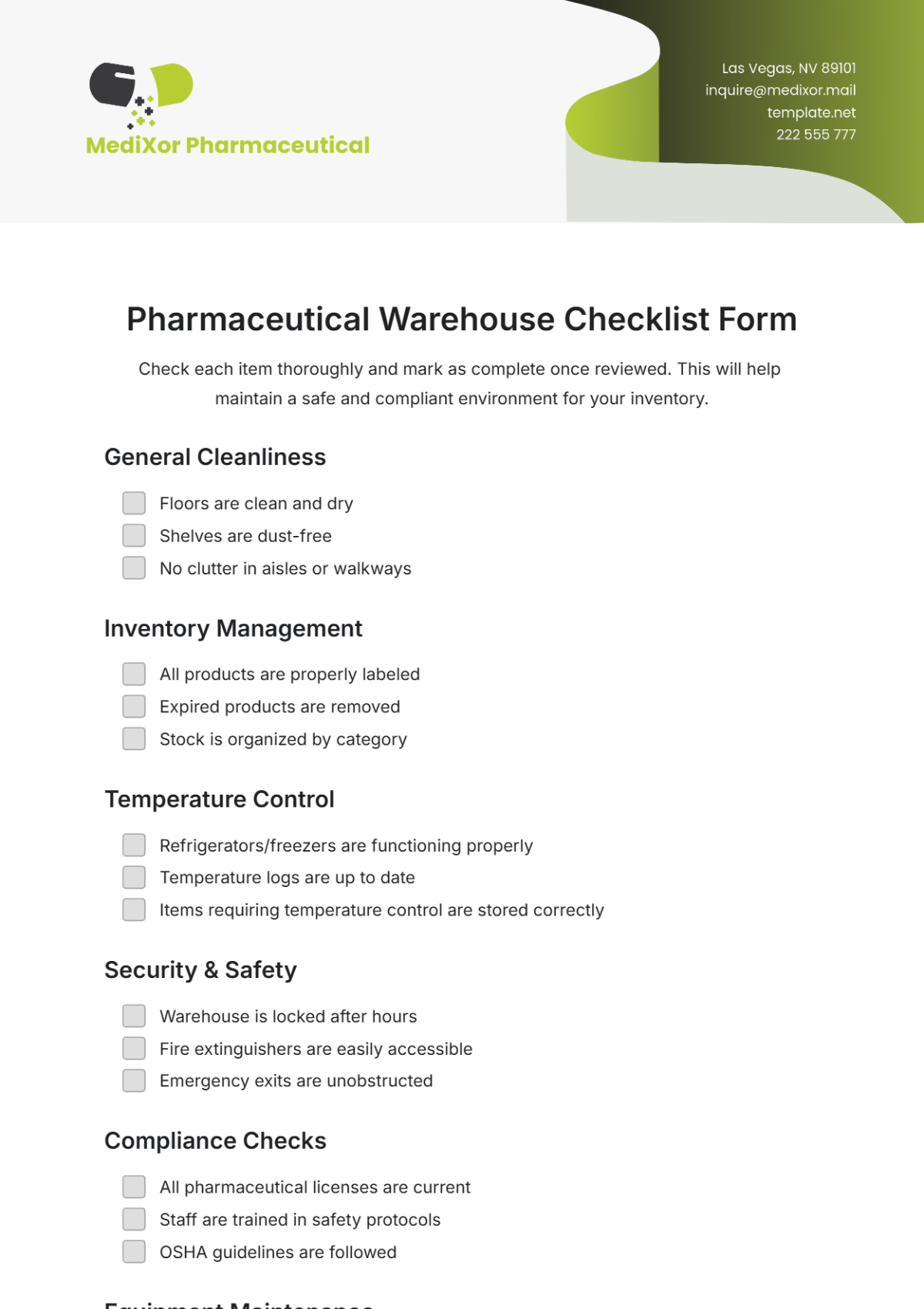

Safety Measures

Maintaining safety in the warehouse is paramount. Implement and regularly review safety protocols to minimize risks.

Conduct regular safety audits and drills: Regular assessments to identify and mitigate potential hazards.

Ensure all staff are trained in emergency procedures: Comprehensive training to prepare staff for emergencies.

Maintain clear and visible signage for exits and safety equipment: Ensure all emergency exits and safety equipment are marked and accessible.

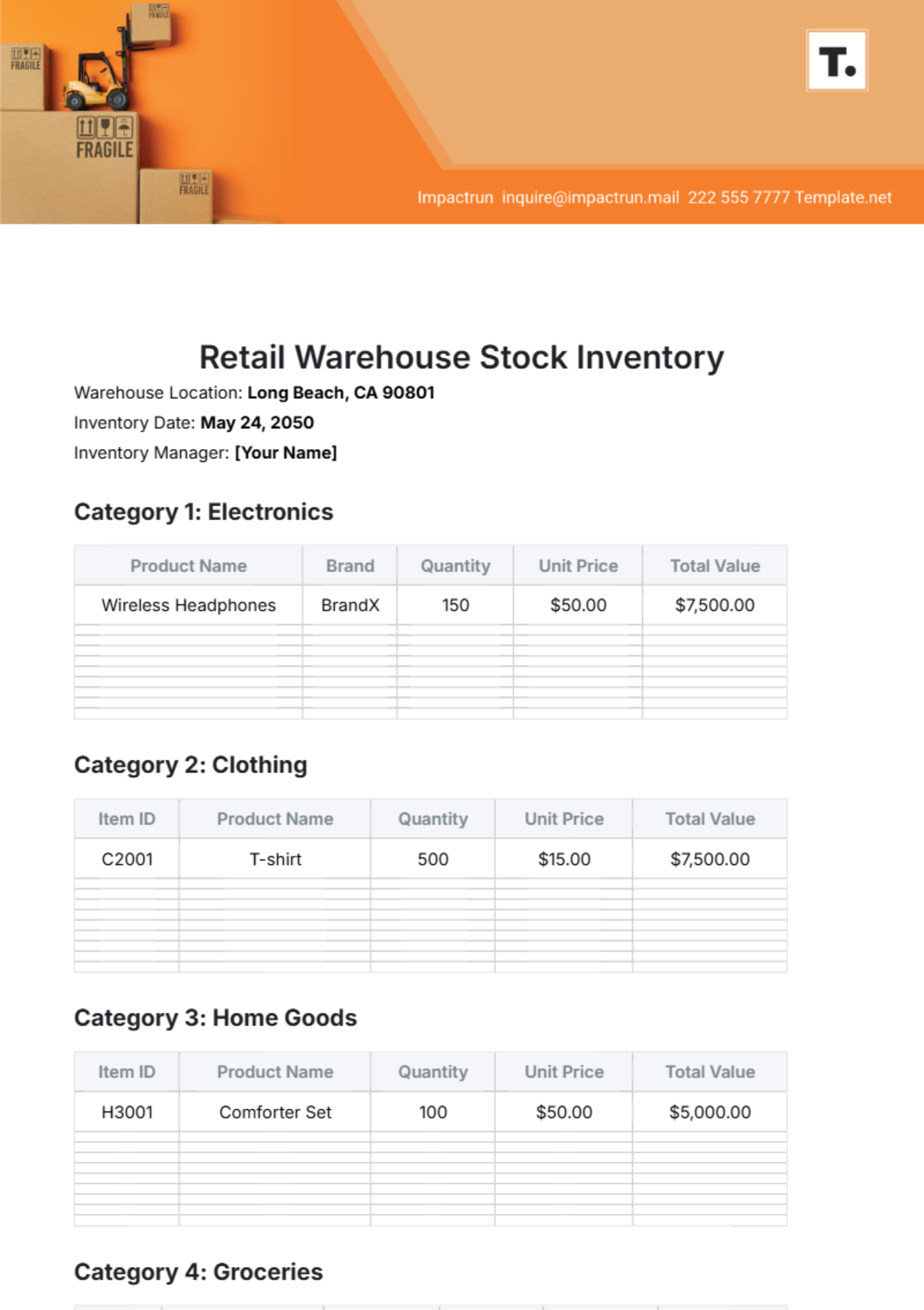

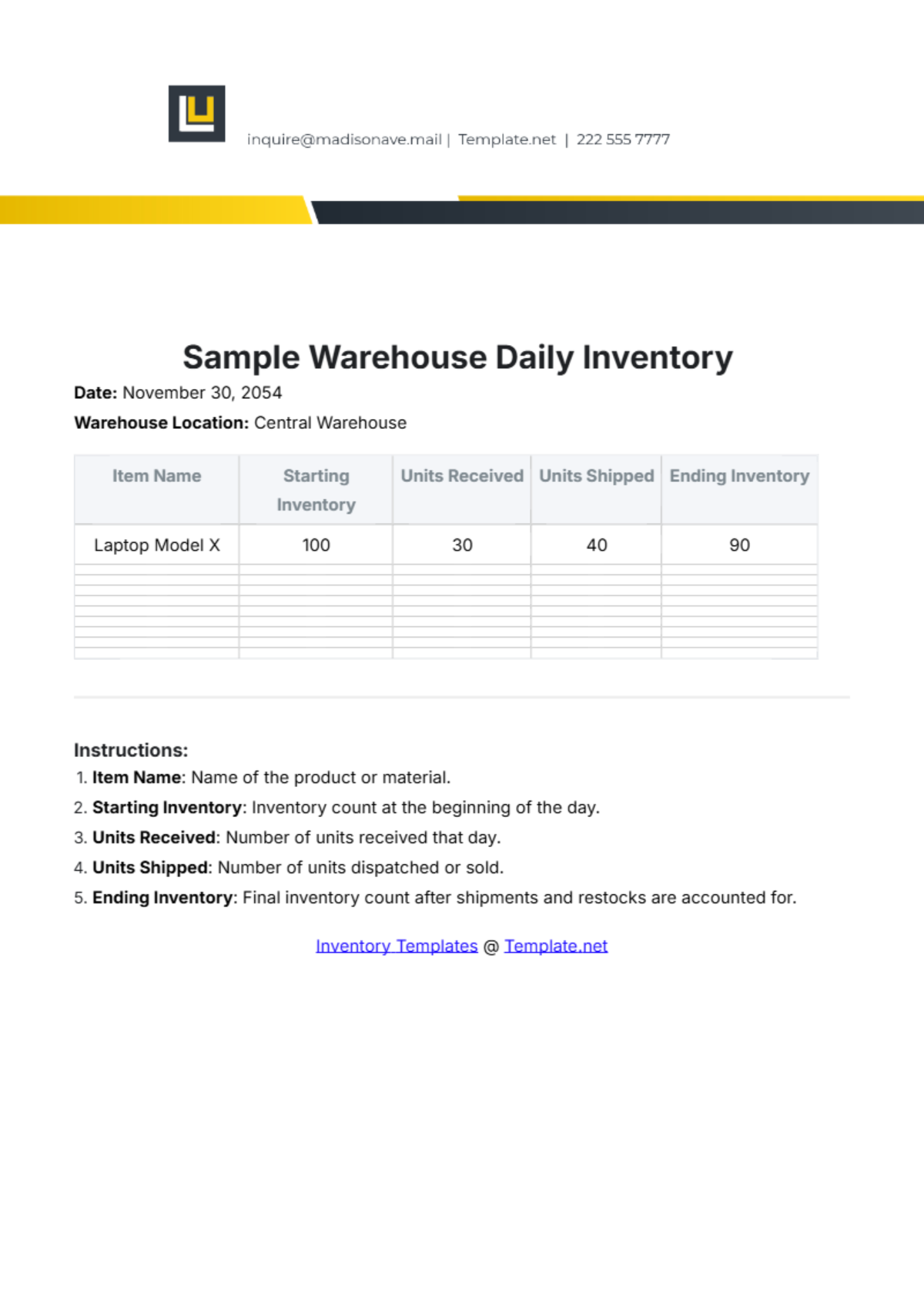

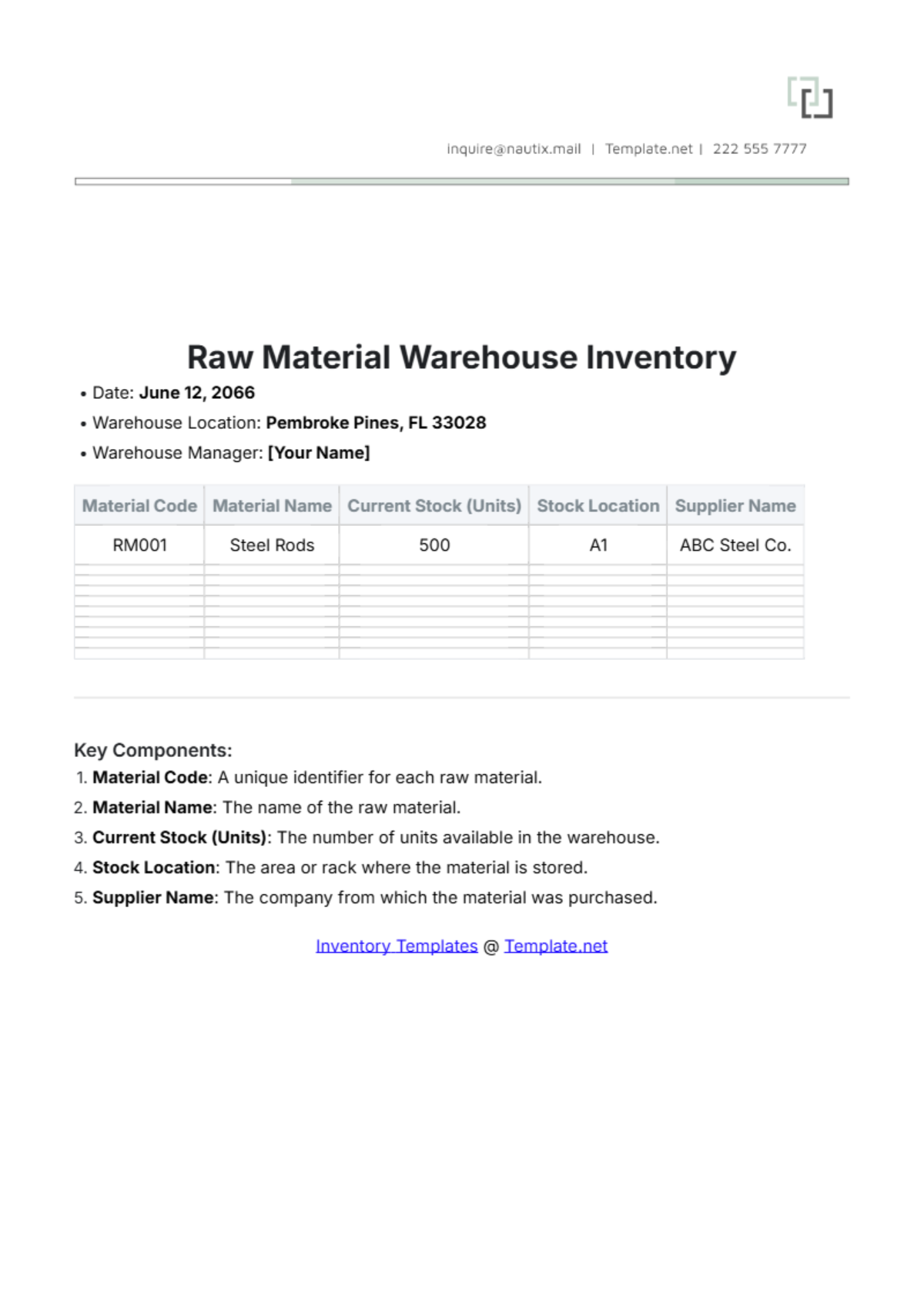

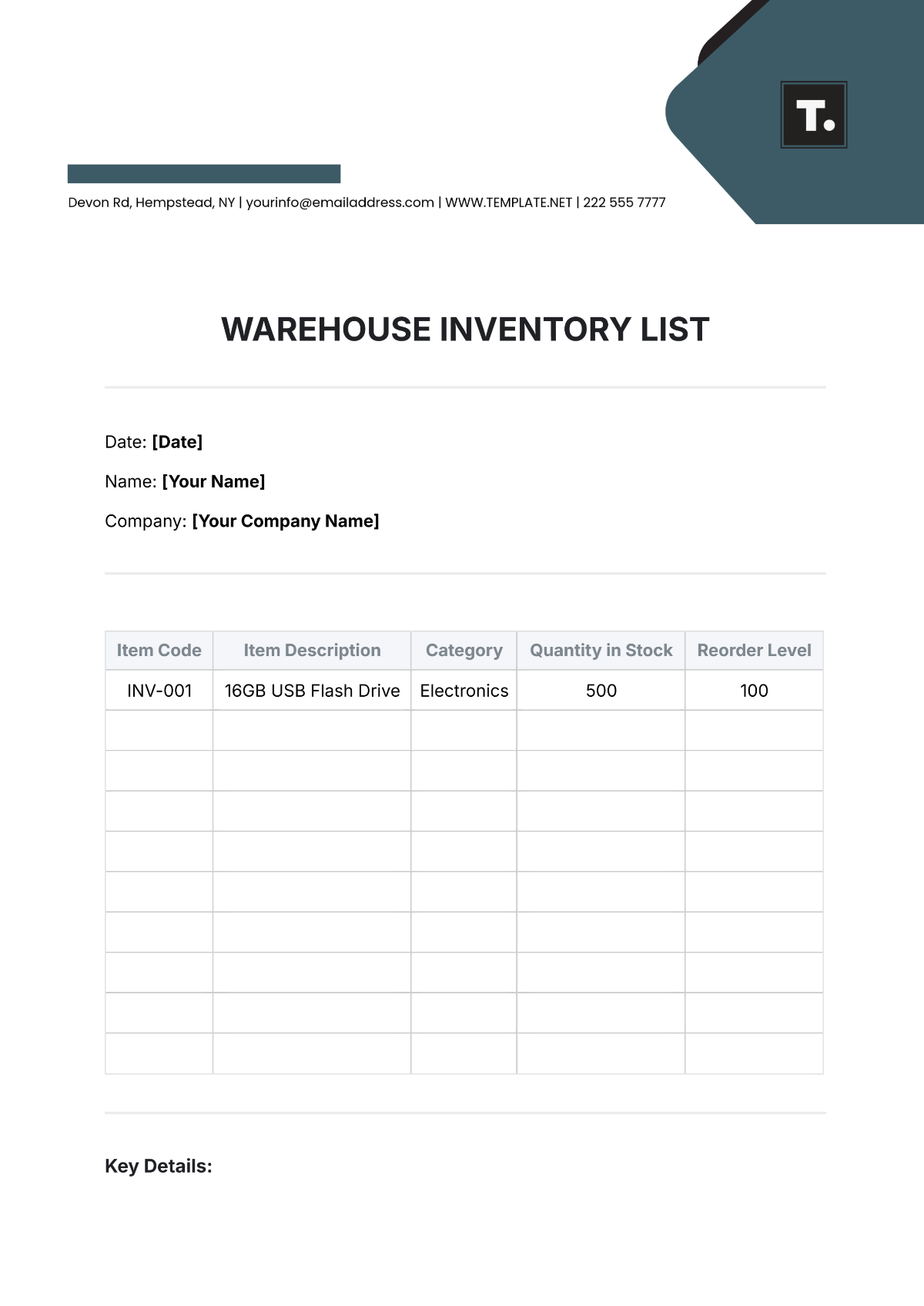

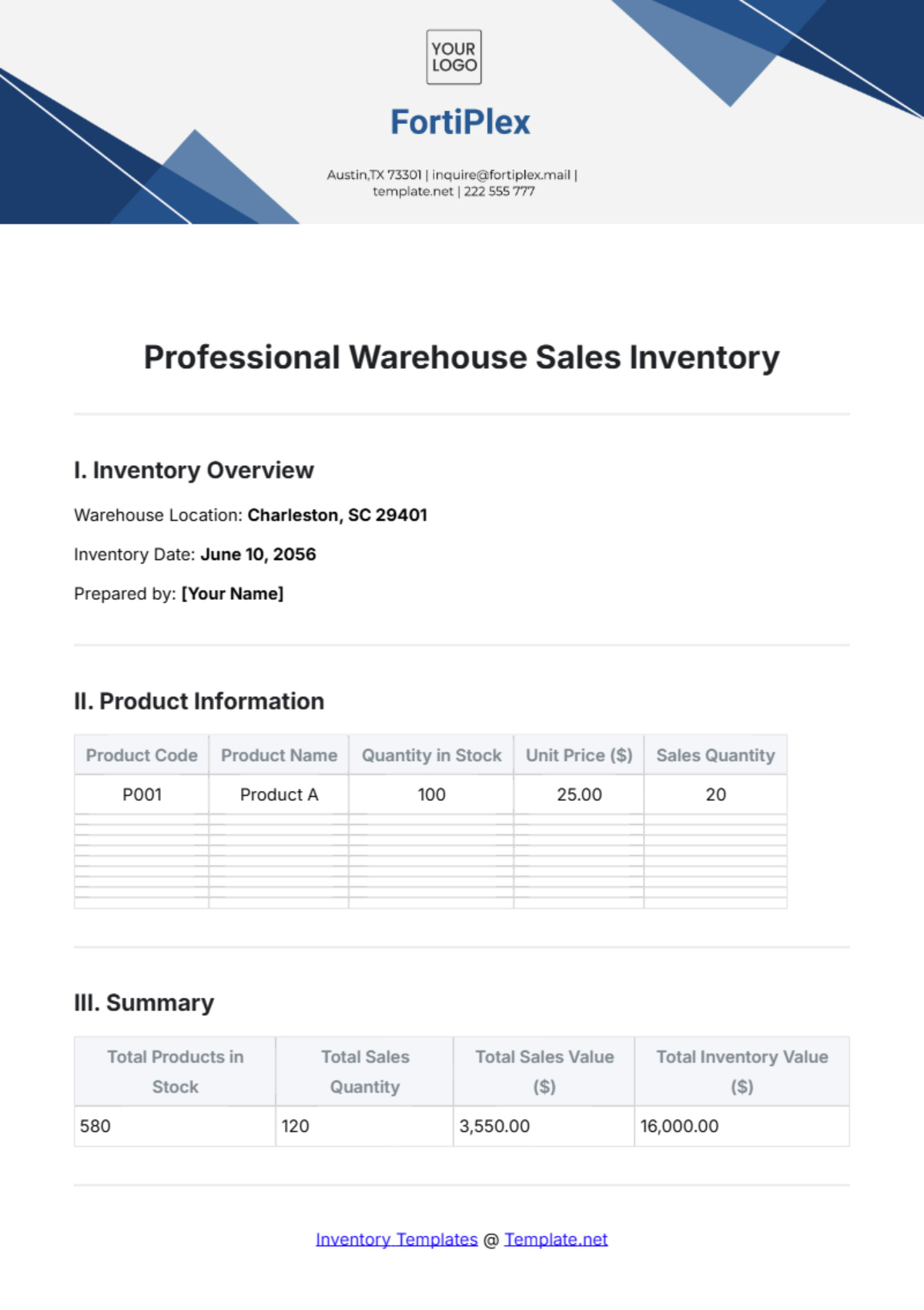

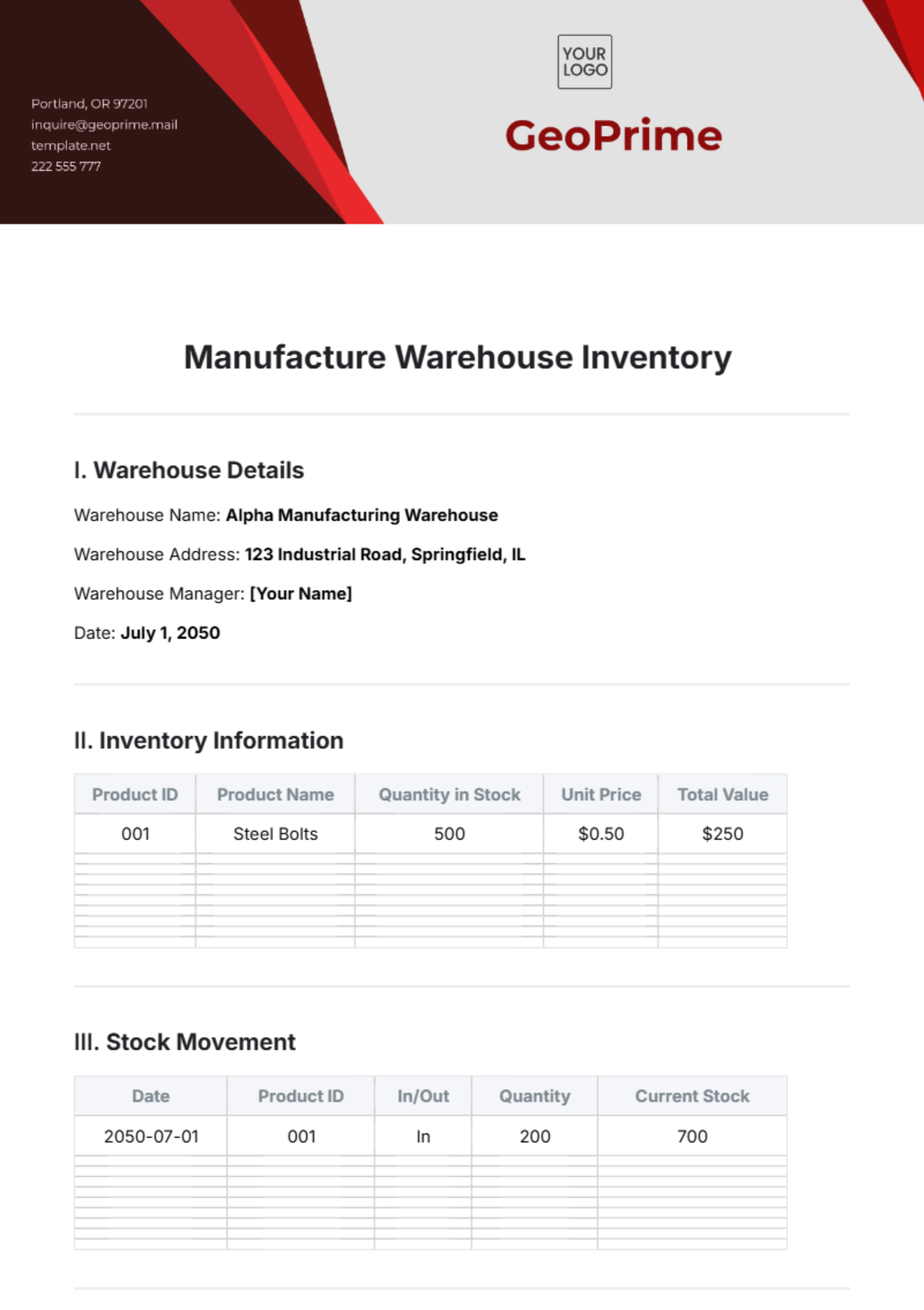

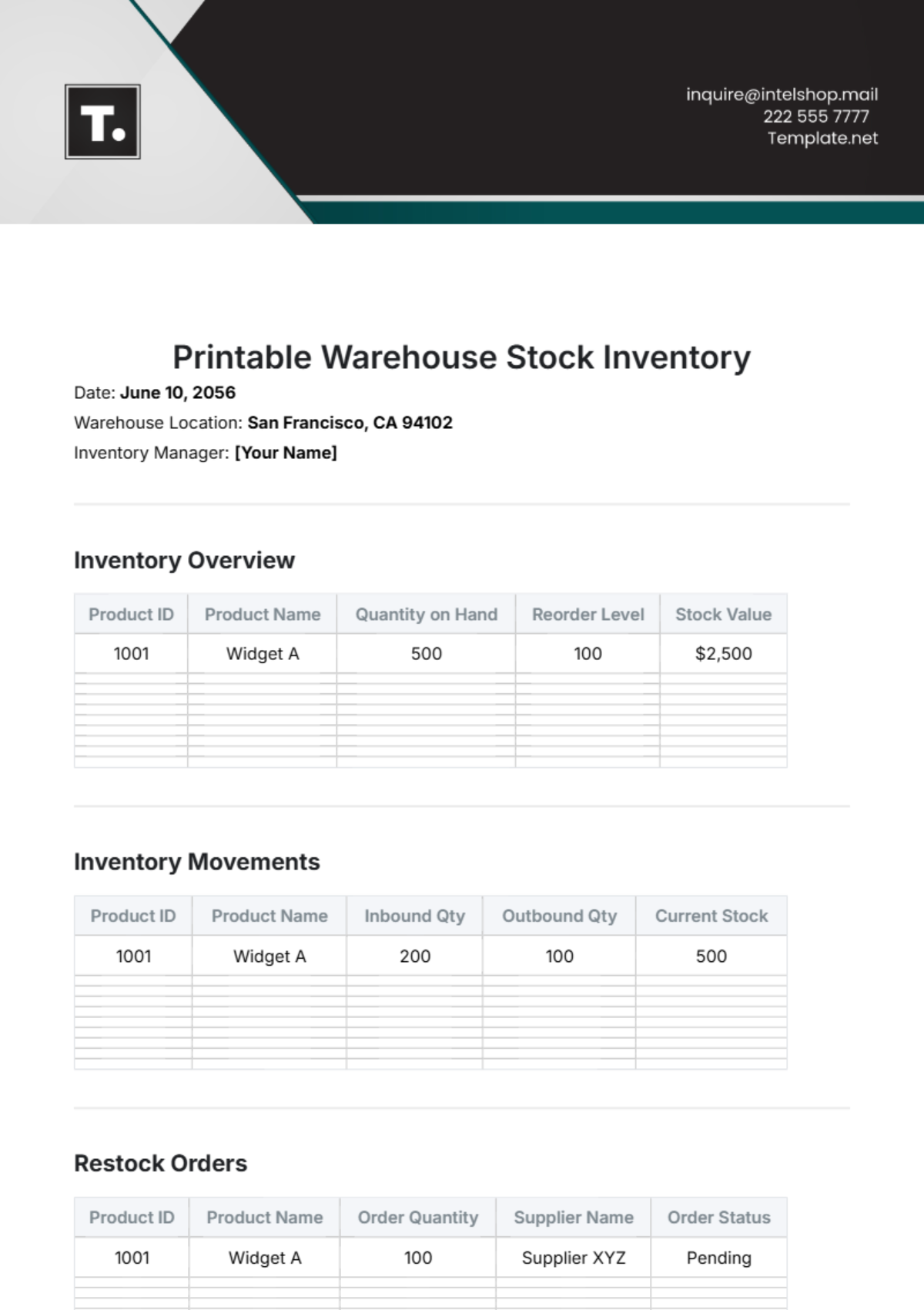

3. Inventory Management

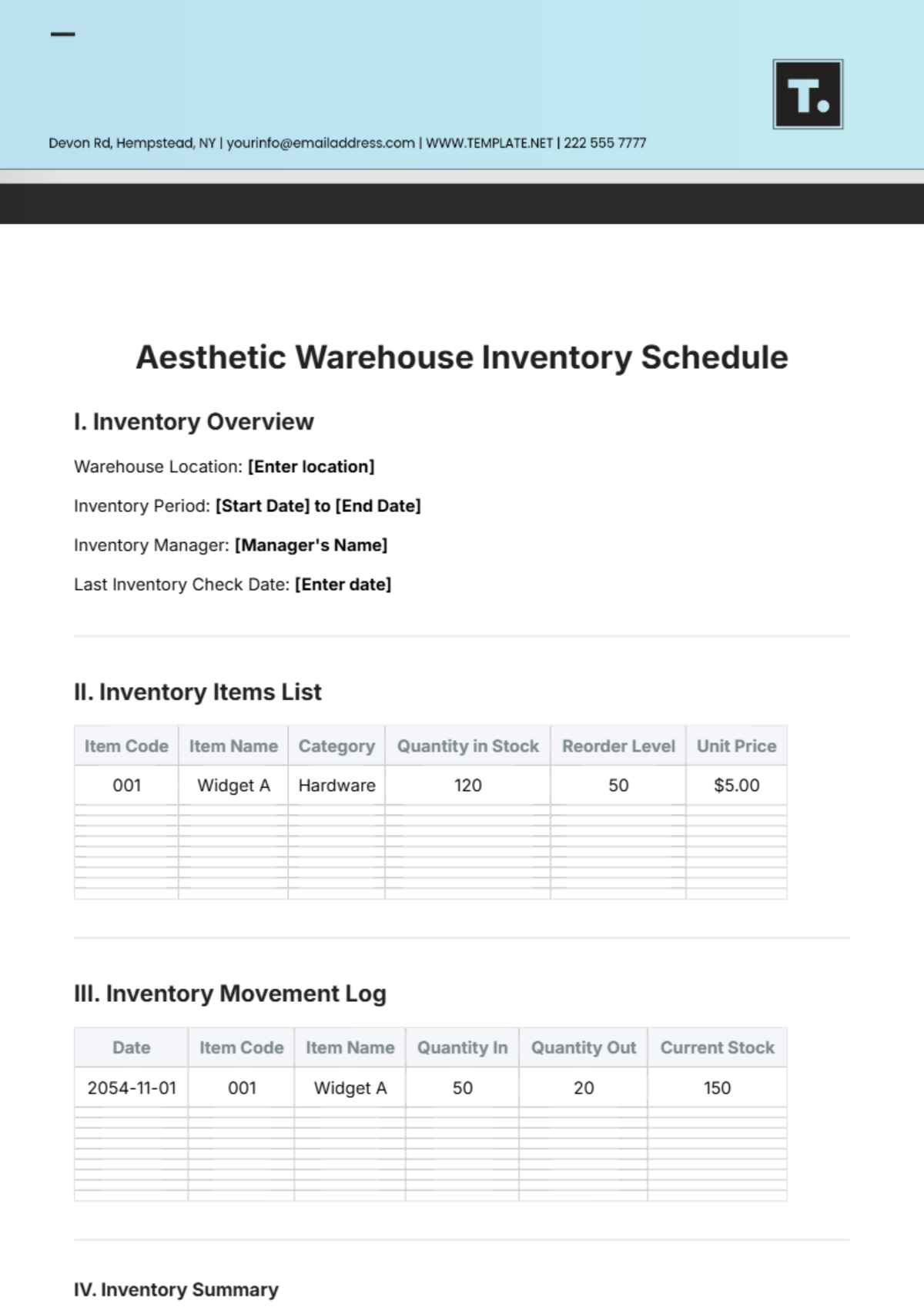

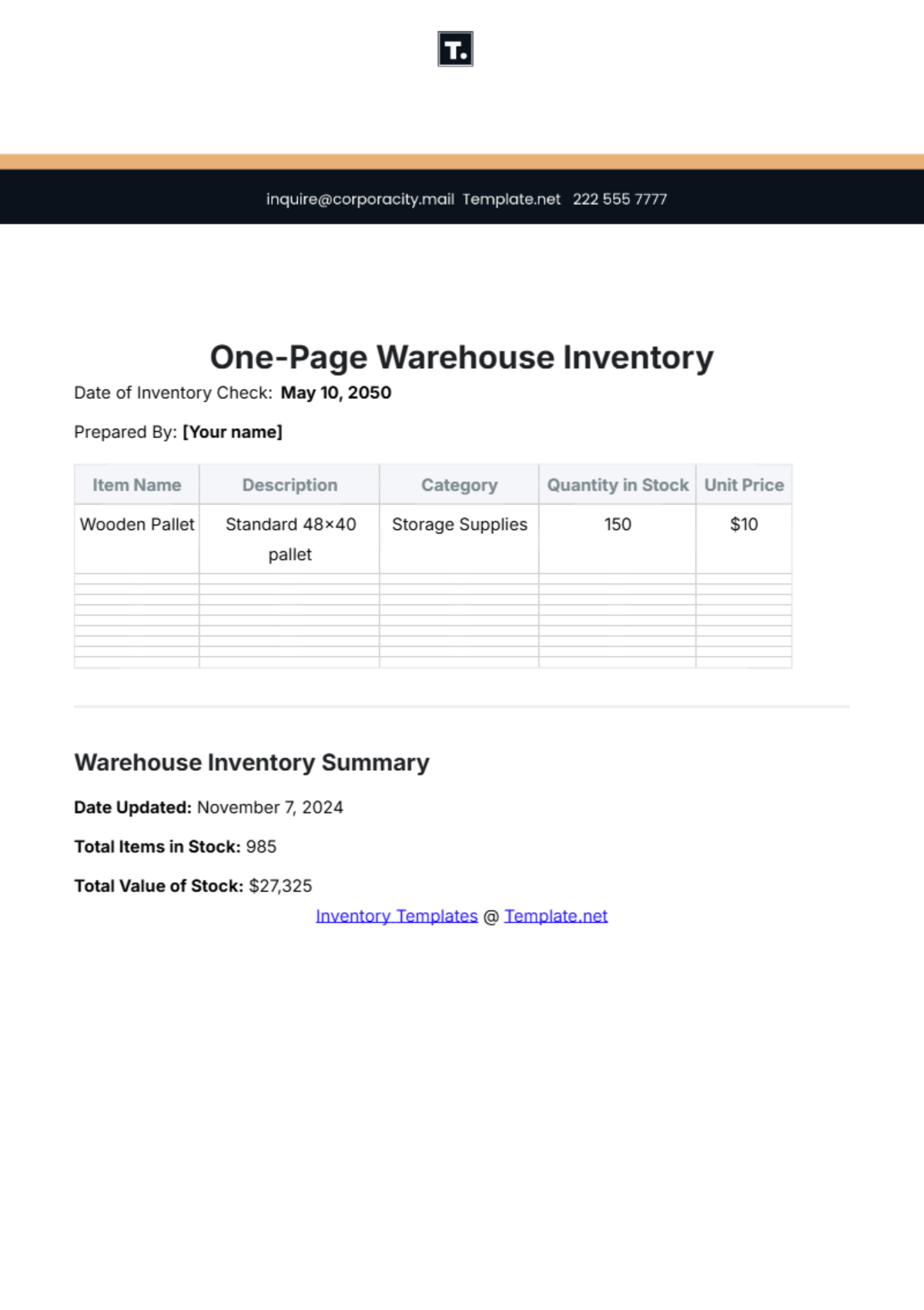

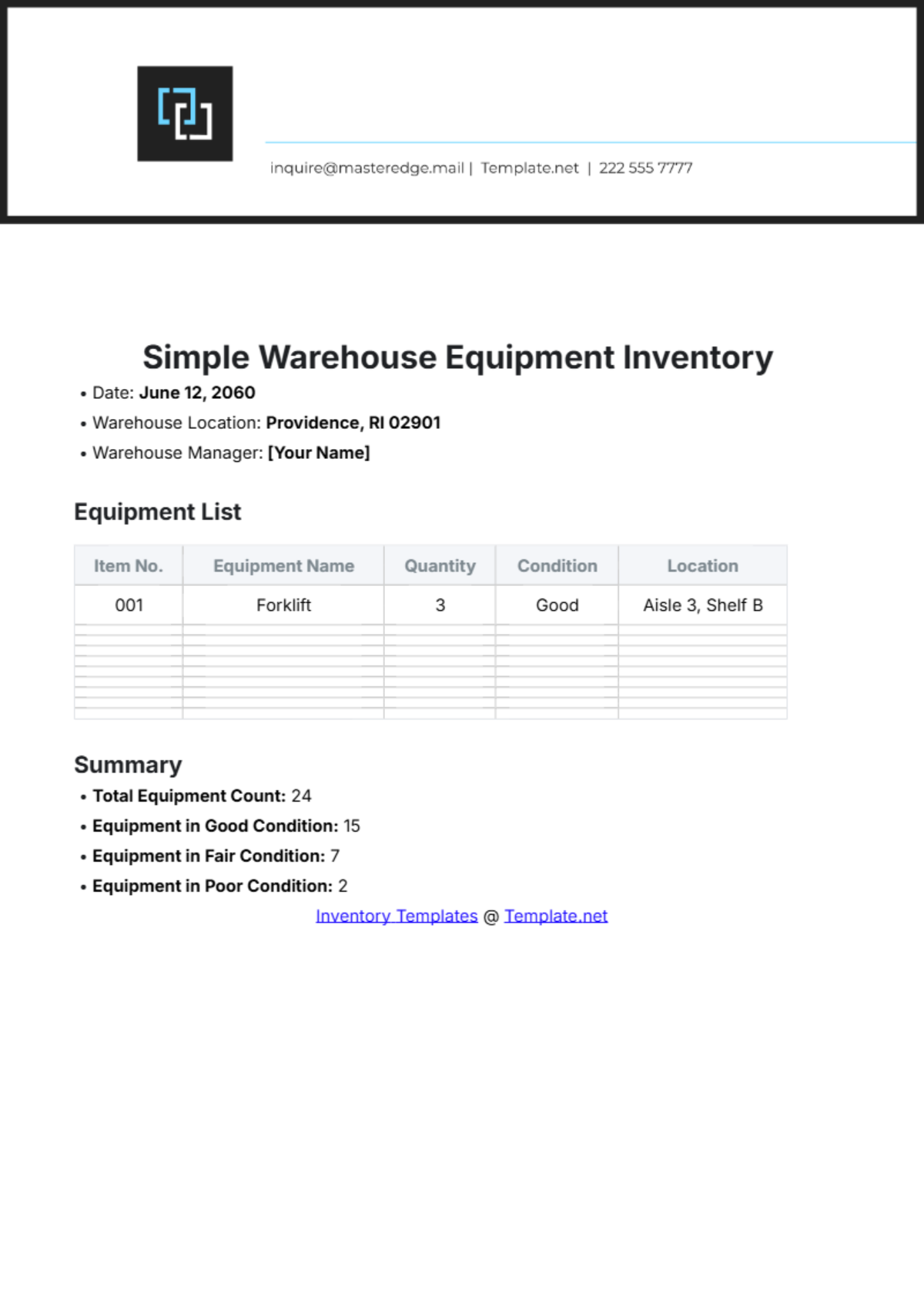

Inventory Tracking

Accurate inventory tracking is essential for effective warehouse management. Utilize modern inventory management systems to keep track of stock levels, movements, and locations.

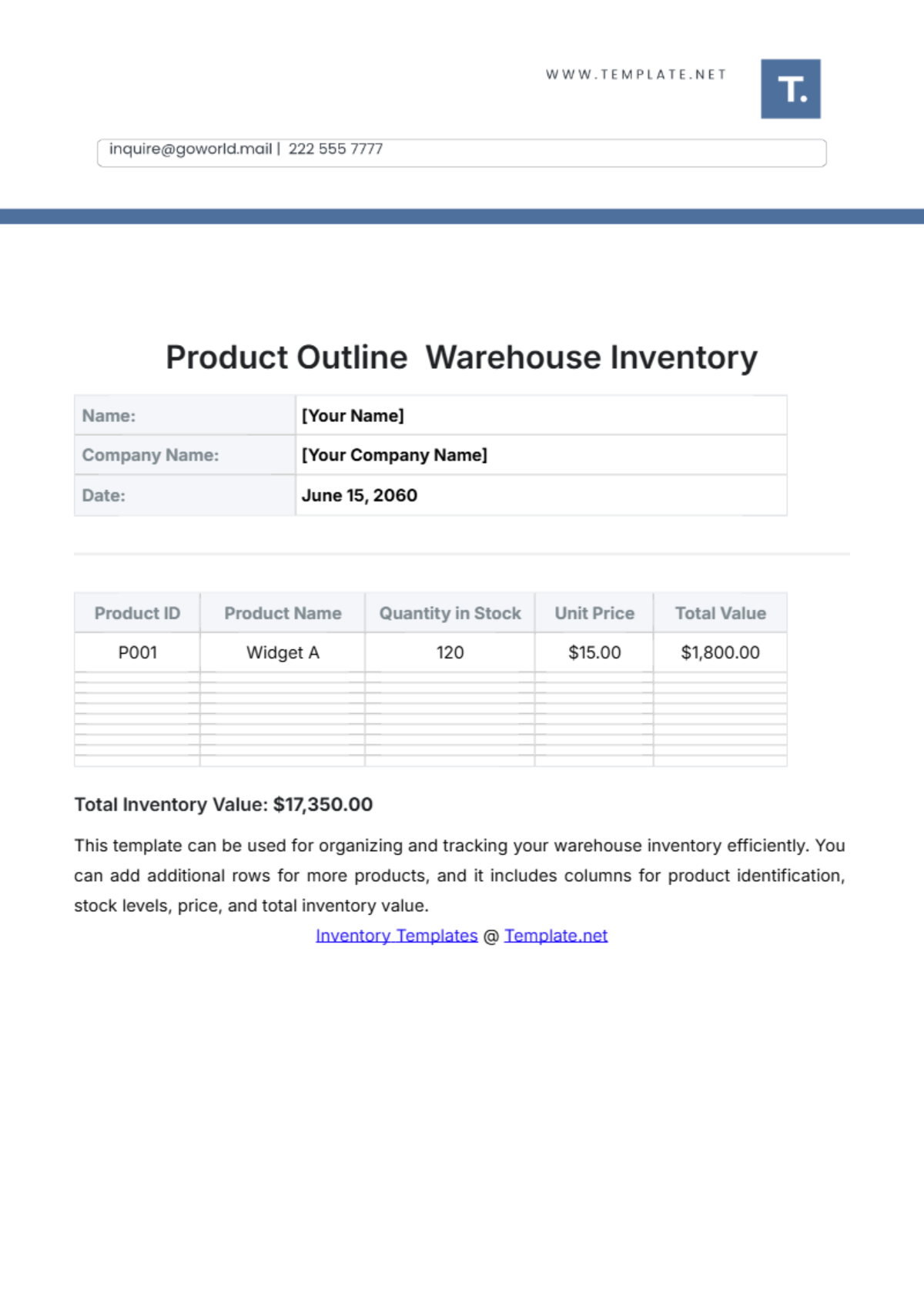

Stock Replenishment

Develop a replenishment strategy to ensure that stock levels remain optimal and to avoid overstocking or stockouts.

Item | Reorder Point | Replenishment Method |

|---|---|---|

Product A | 100 units | Automated reorder system |

Product B | 50 units | Manual reorder process |

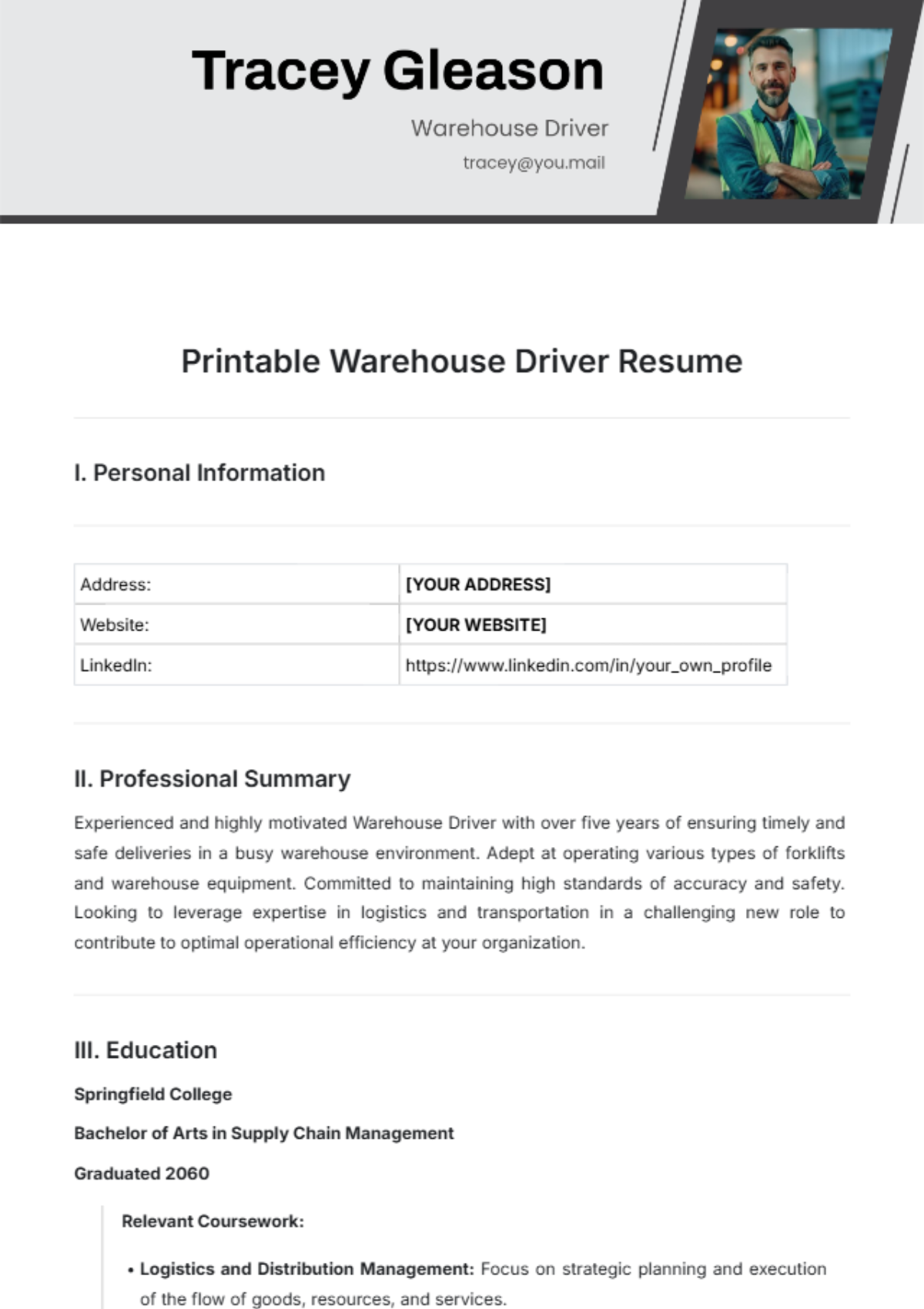

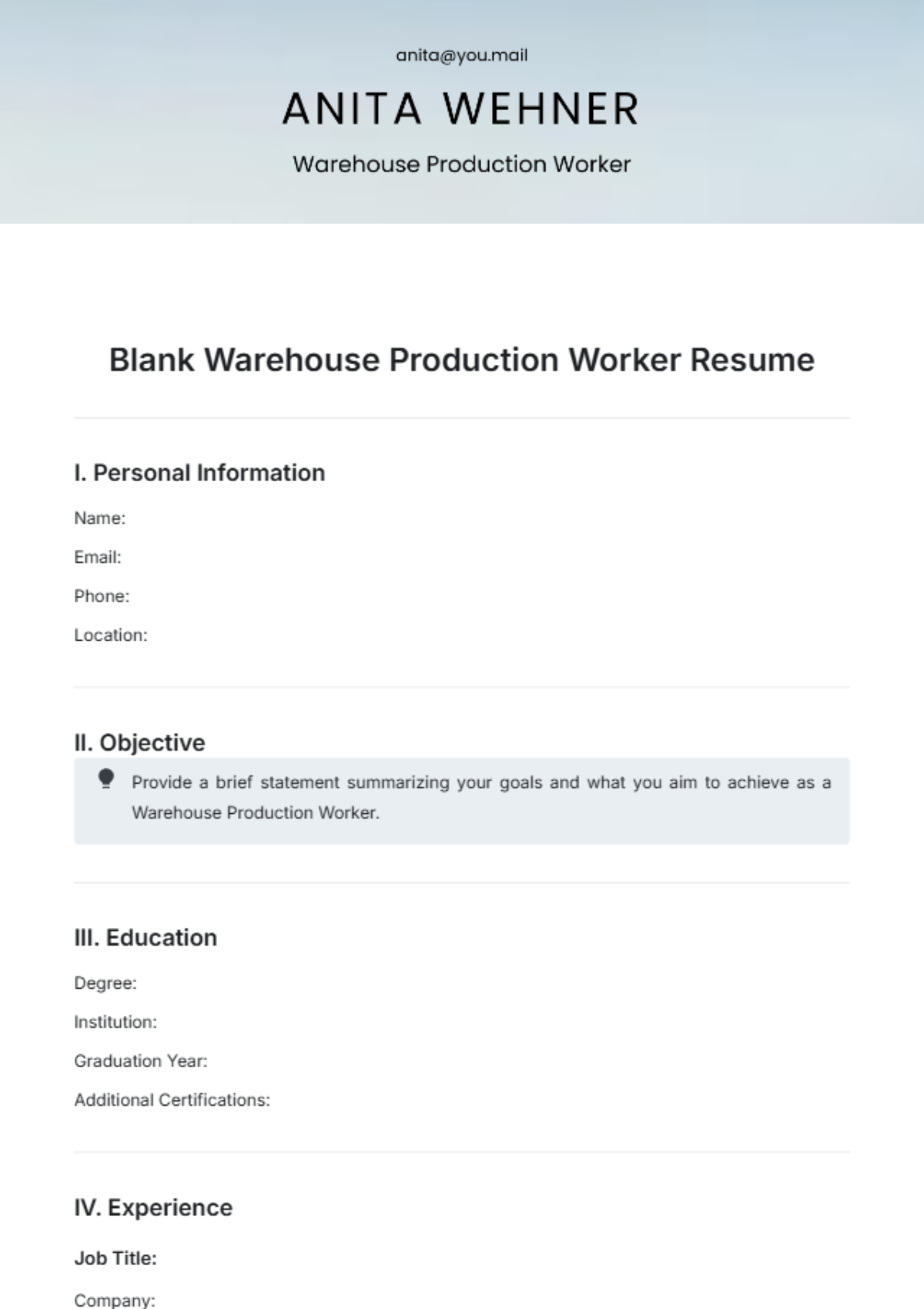

4. Human Resources

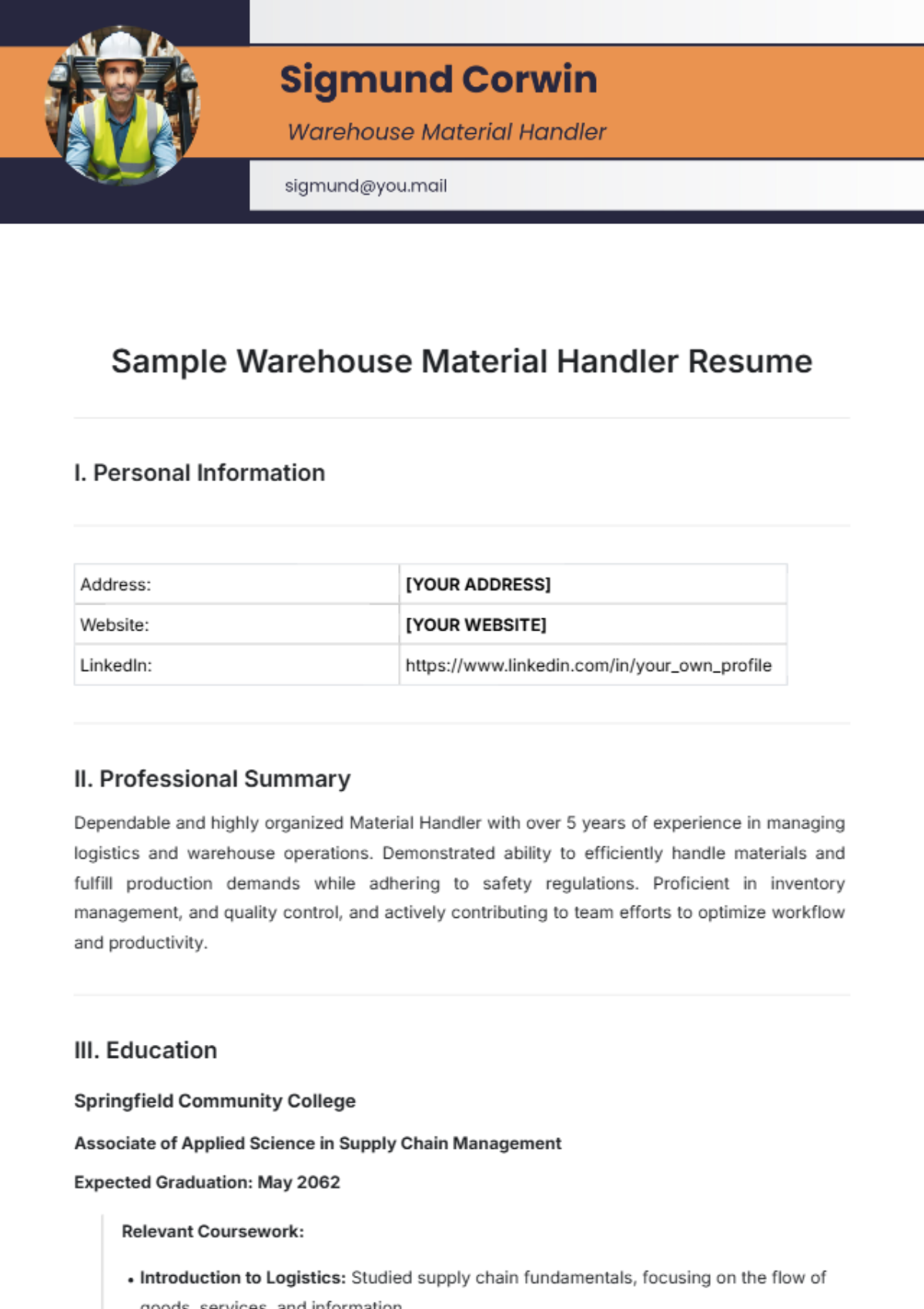

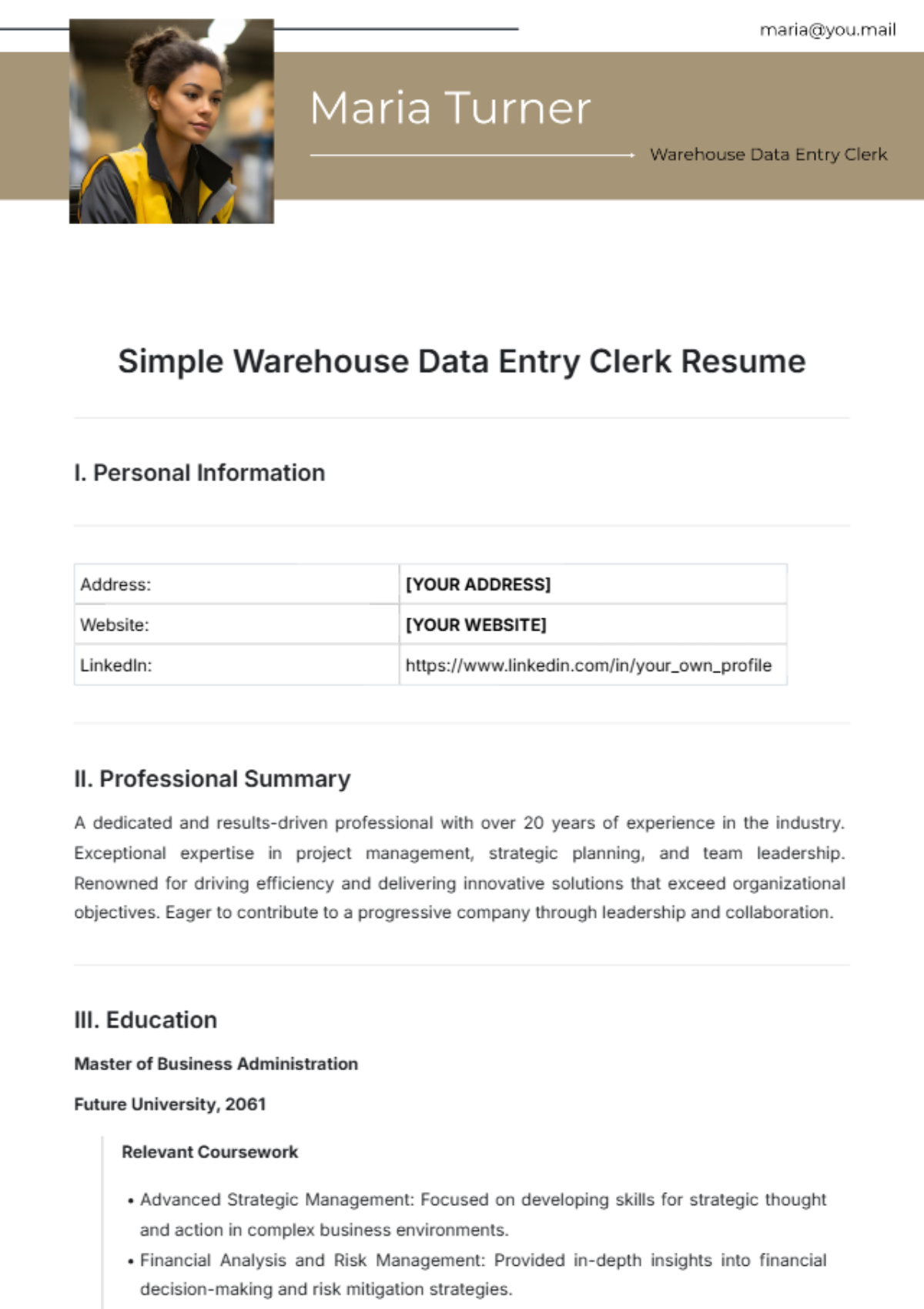

Staff Training

Invest in continuous staff training to enhance productivity and ensure that all procedures are followed correctly.

Provide orientation for new hires: Comprehensive warehouse operations and safety protocols introduction.

Offer regular workshops on warehouse management best practices: Ongoing training sessions to keep staff updated.

Implement a mentorship program for on-the-job learning: Pair new hires with experienced staff for hands-on training.

Staff Scheduling

Effective scheduling ensures that the warehouse is sufficiently staffed to meet operational demands while avoiding overstaffing.

5. Technology and Equipment

Warehouse Management System (WMS)

A robust WMS is crucial for efficient warehouse operations. Ensure that the system is updated regularly and that staff are trained to use it effectively.

Equipment Maintenance

Regular maintenance of equipment such as forklifts, conveyor belts, and shelving units is necessary to prevent downtime and accidents.

Schedule routine inspections and servicing: Regular checks to ensure equipment is in good working condition.

Keep a record of all maintenance activities: Detailed logs of maintenance work performed.

Train staff on proper equipment usage and safety protocols: Comprehensive equipment operation and safety training.

6. Quality Control

Incoming Goods Inspection

Introduce a rigorous inspection process for all incoming goods to ensure they meet quality standards before being stored.

Periodic Audits

Conduct periodic audits to review inventory accuracy, operational efficiency, and compliance with established procedures.