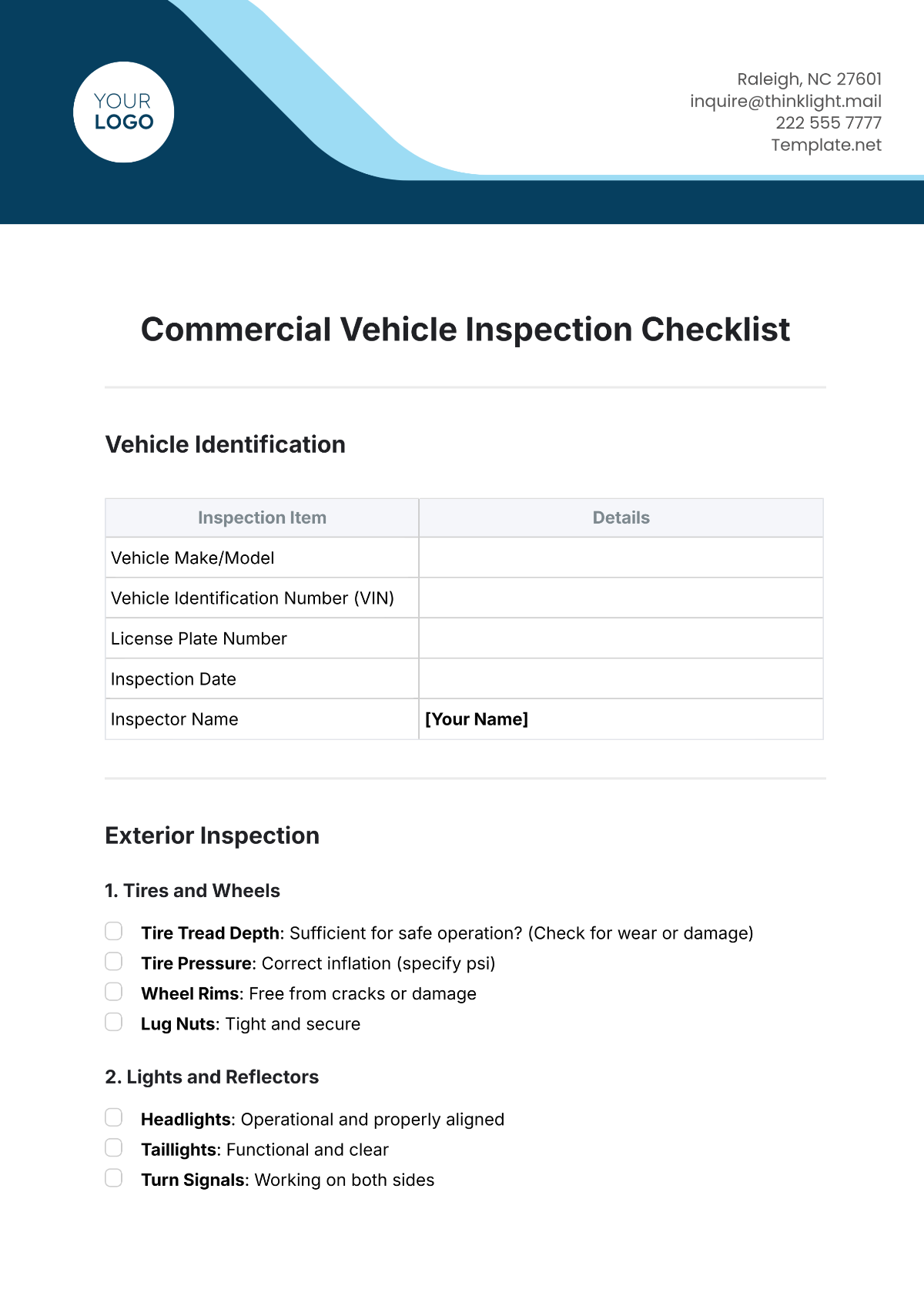

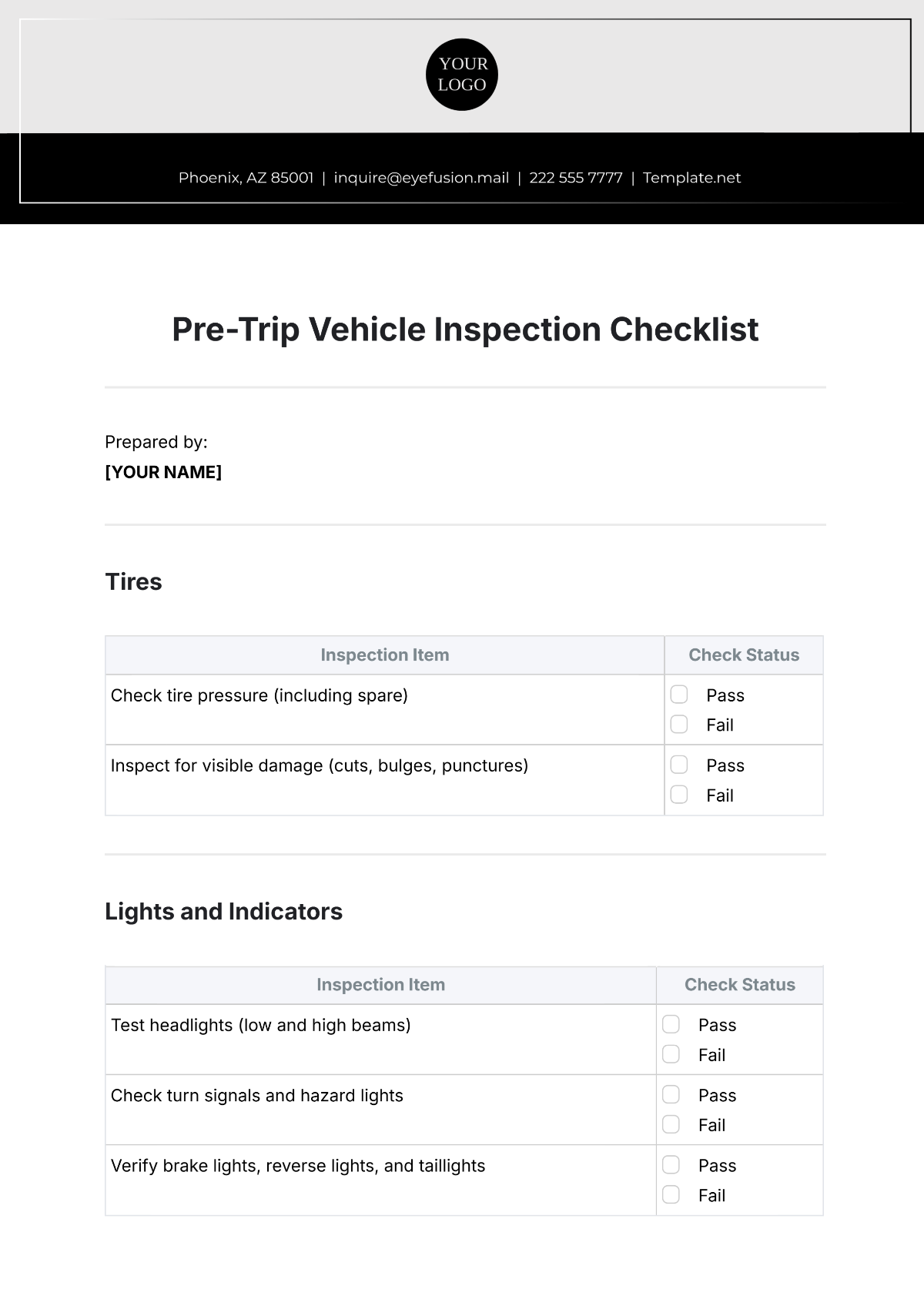

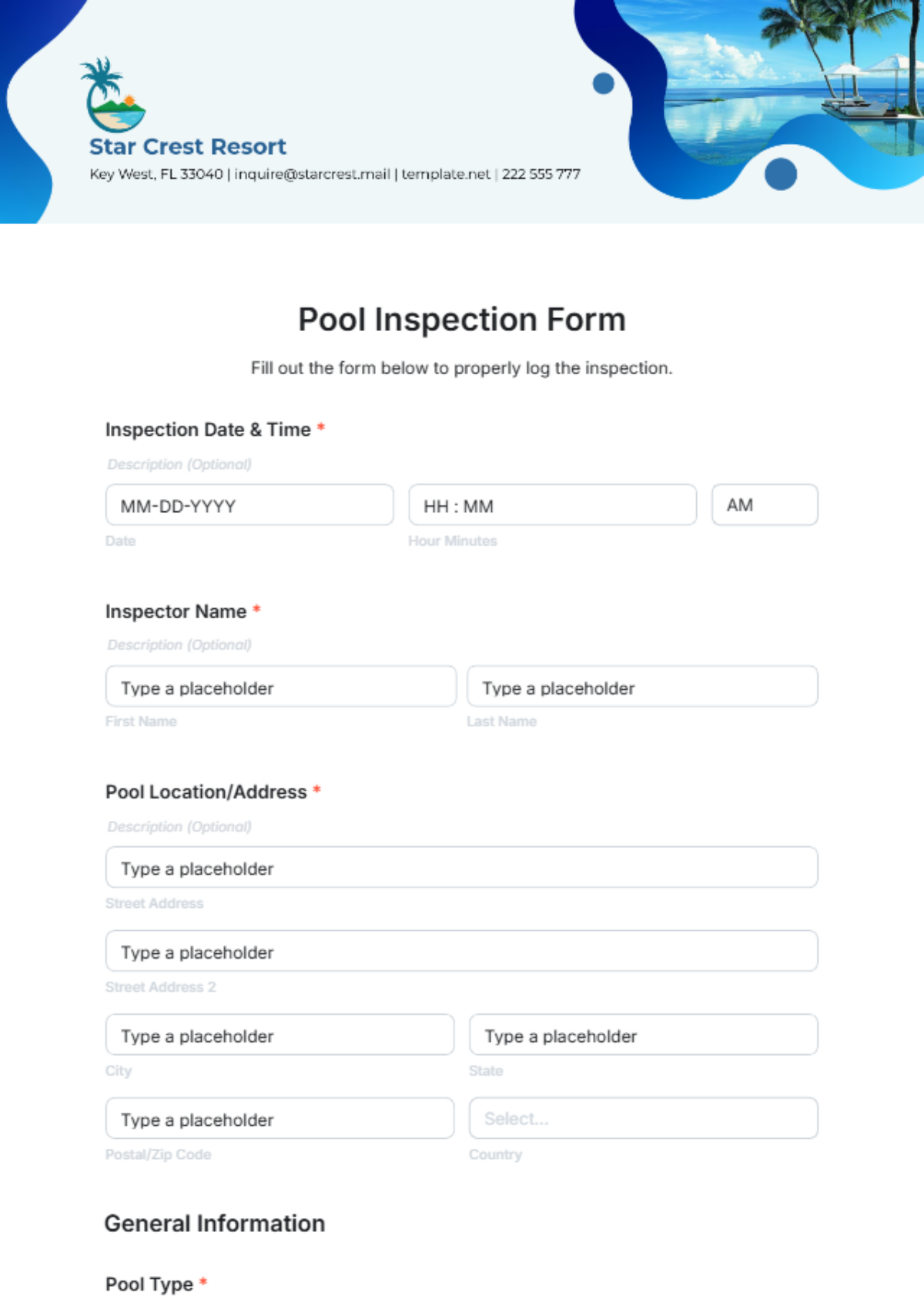

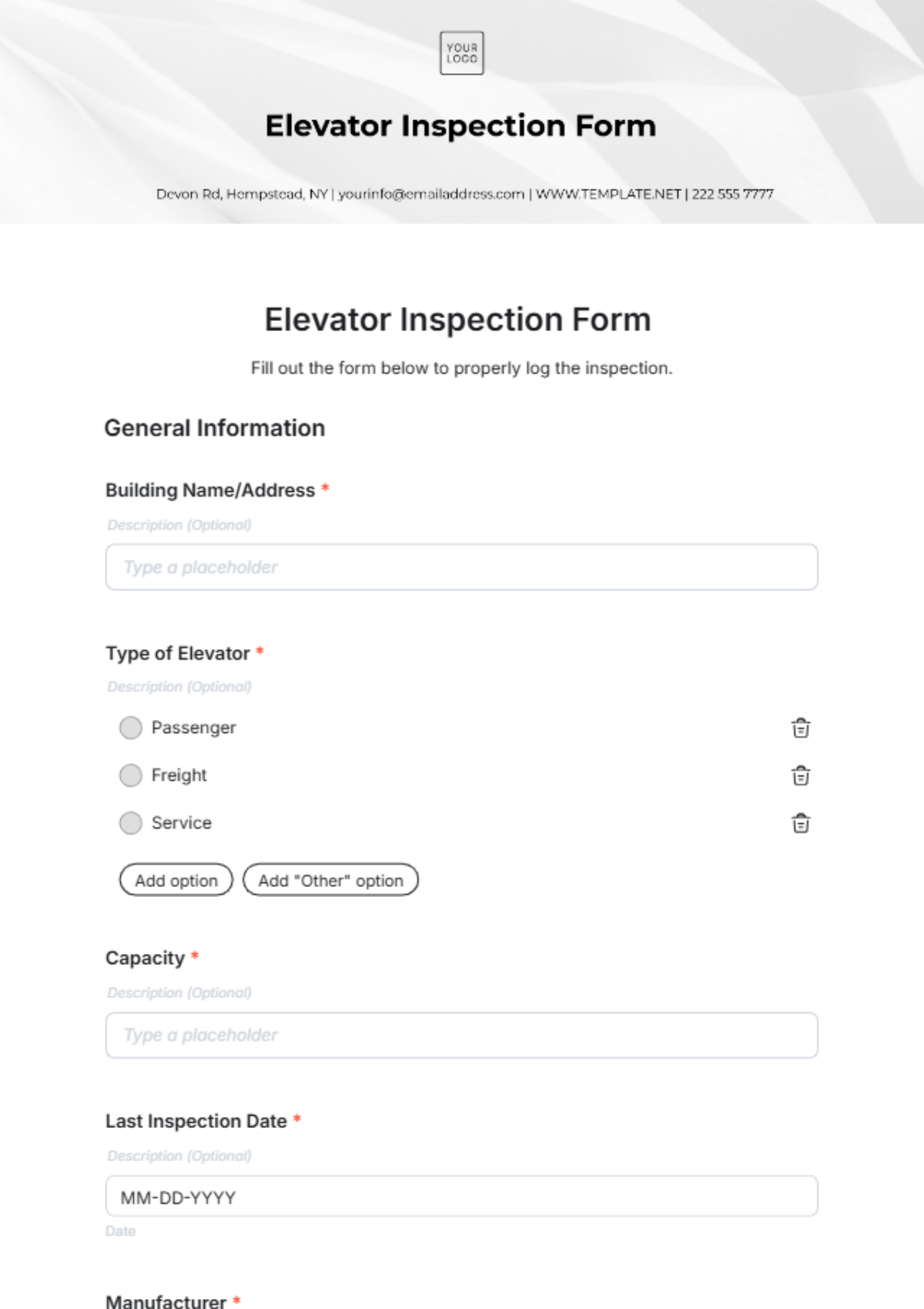

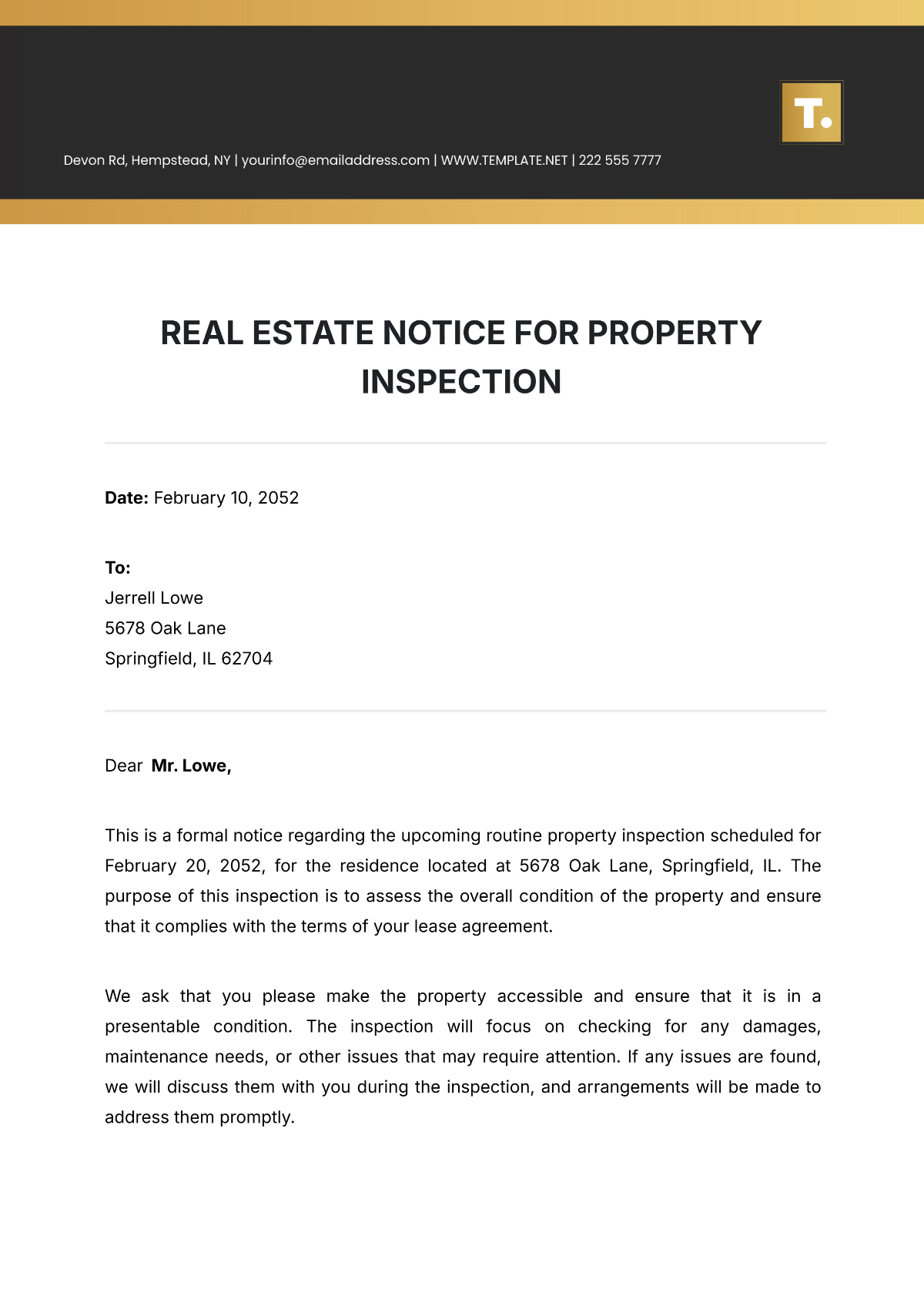

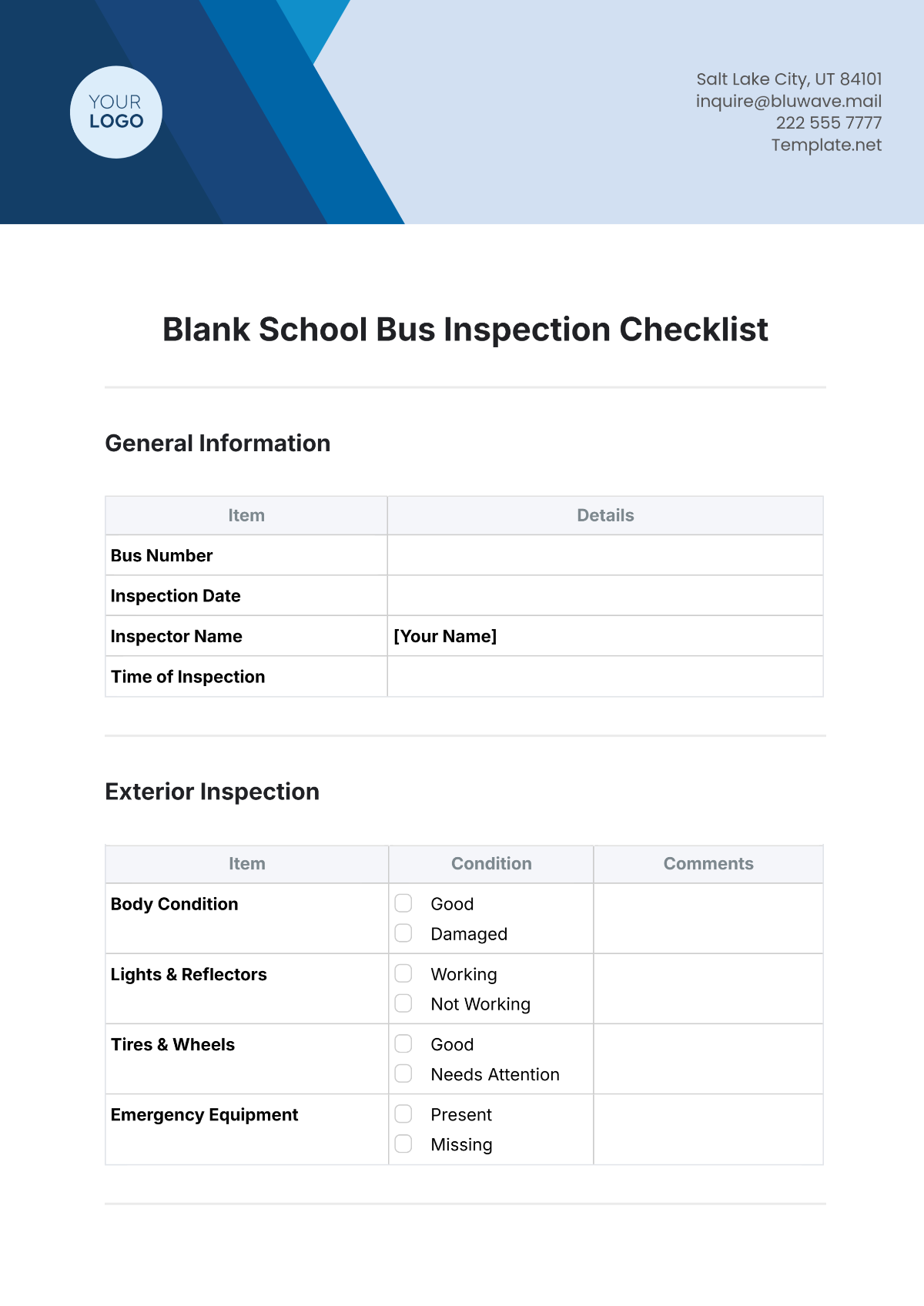

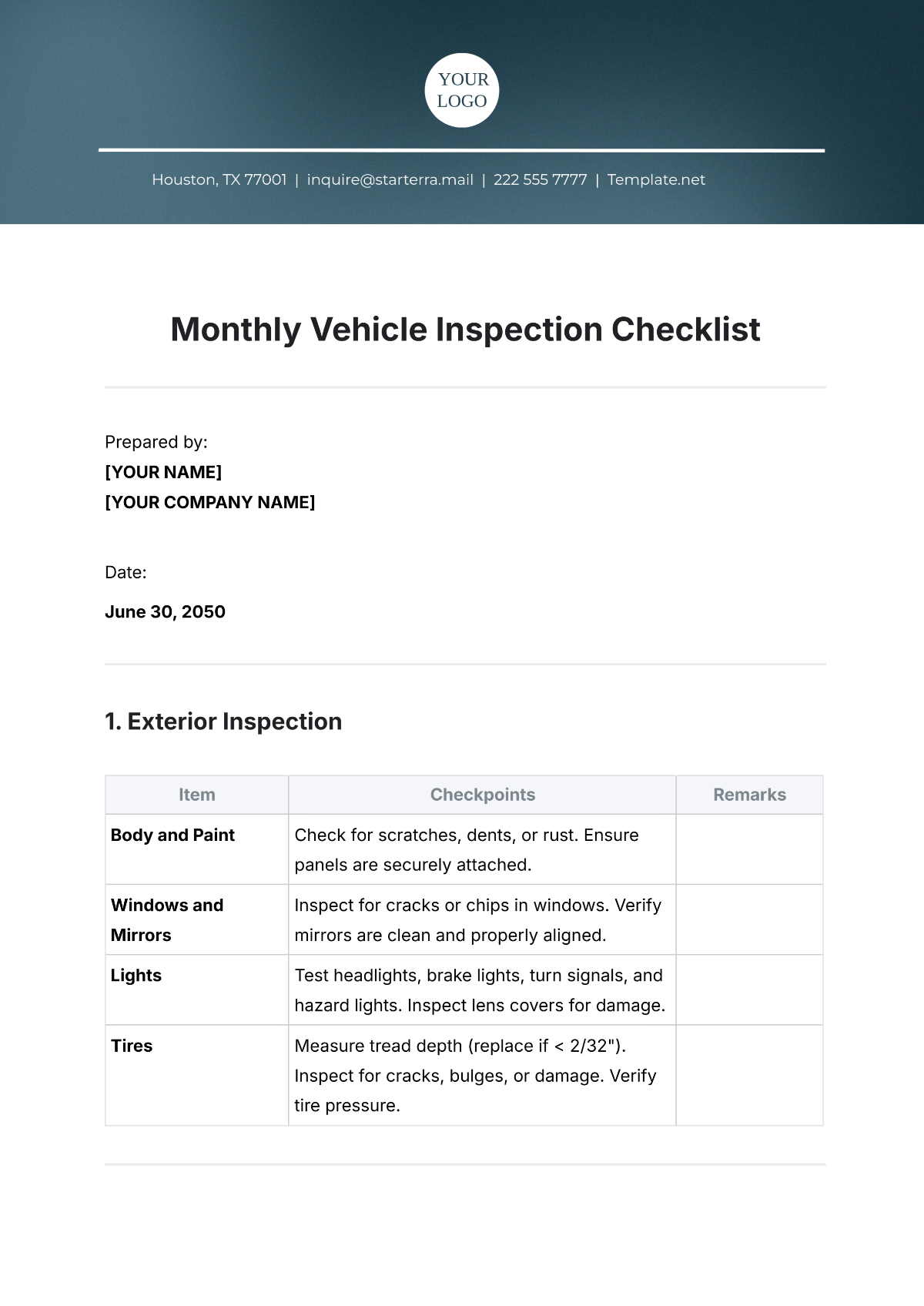

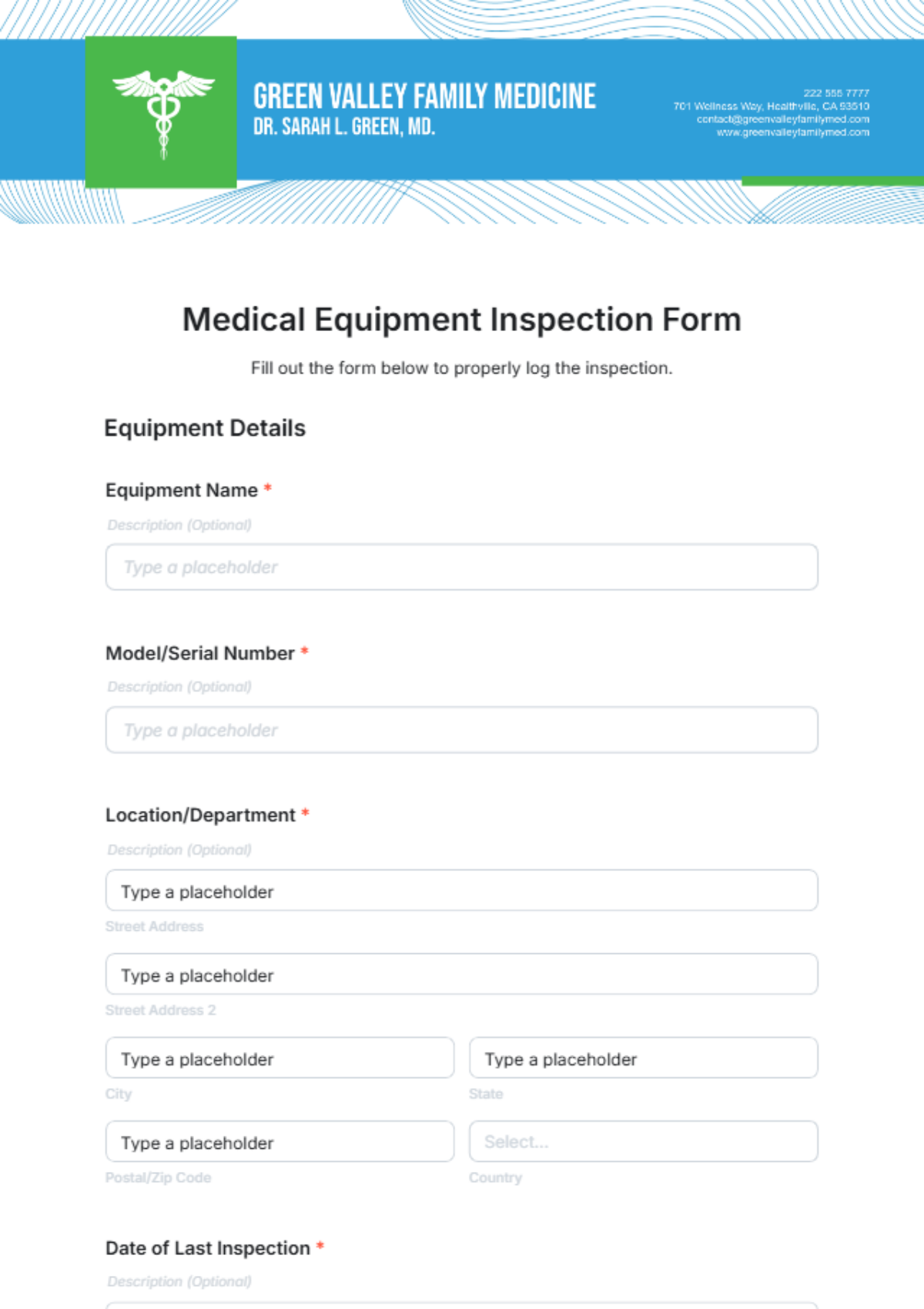

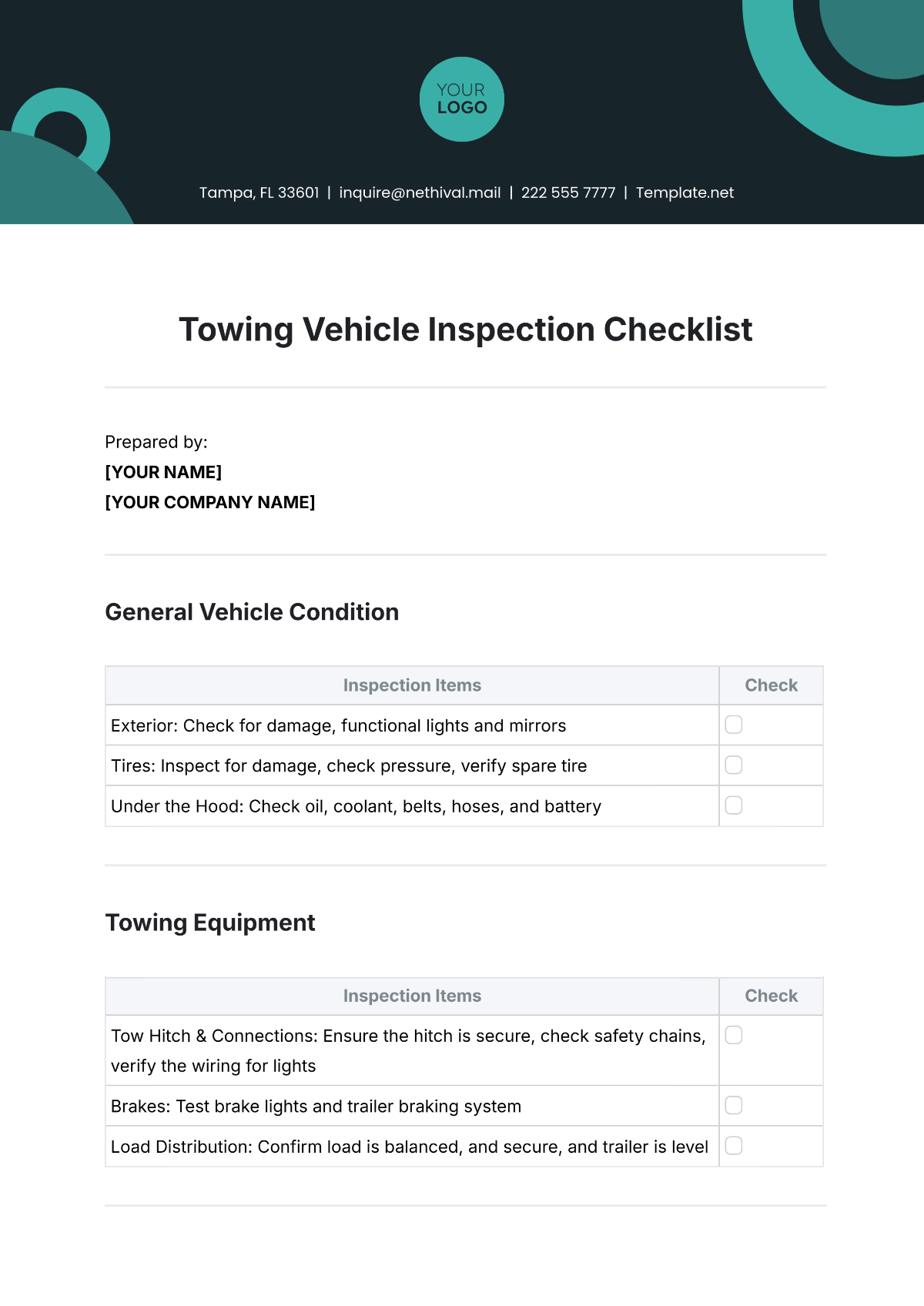

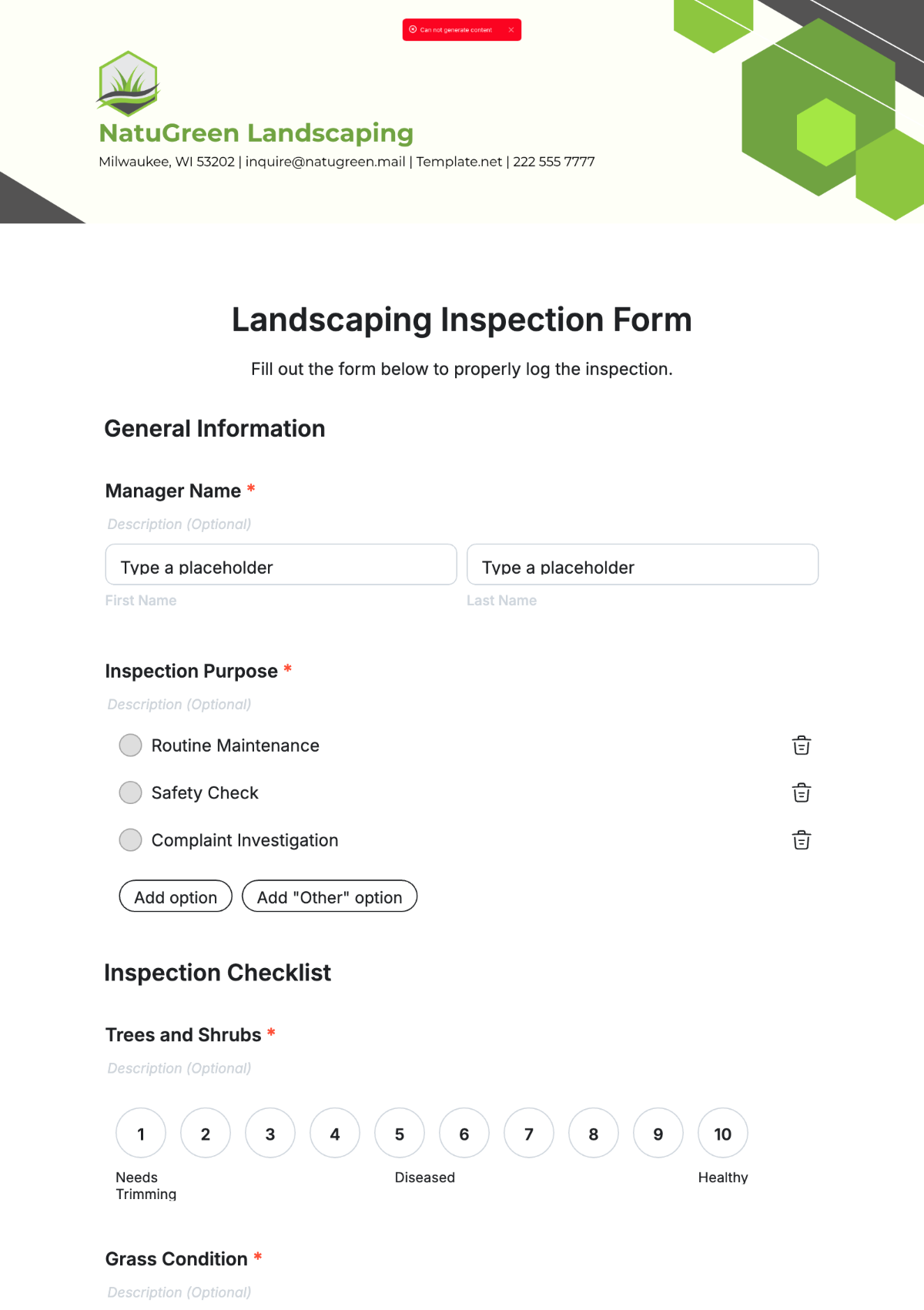

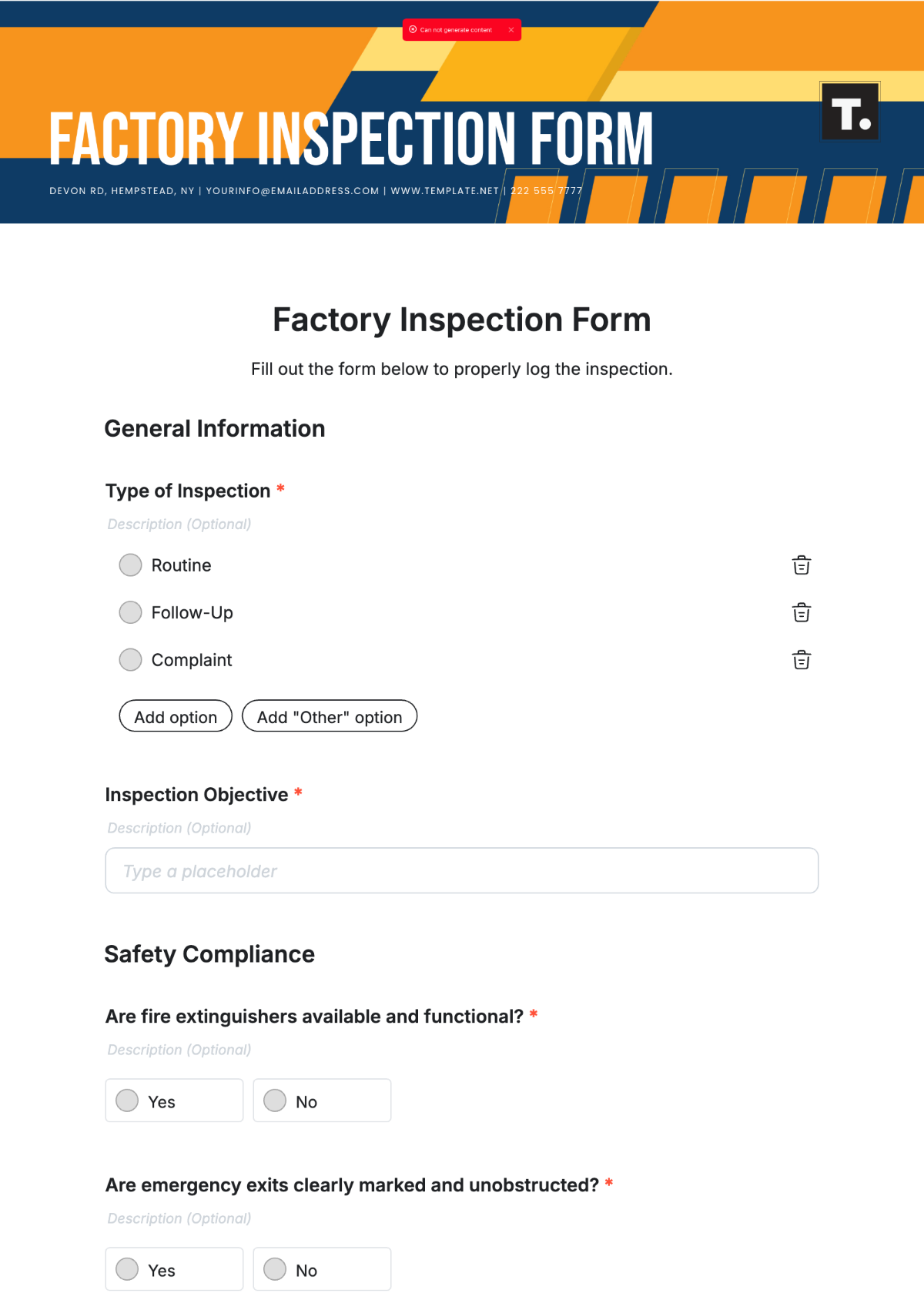

Free Inspection Requirements

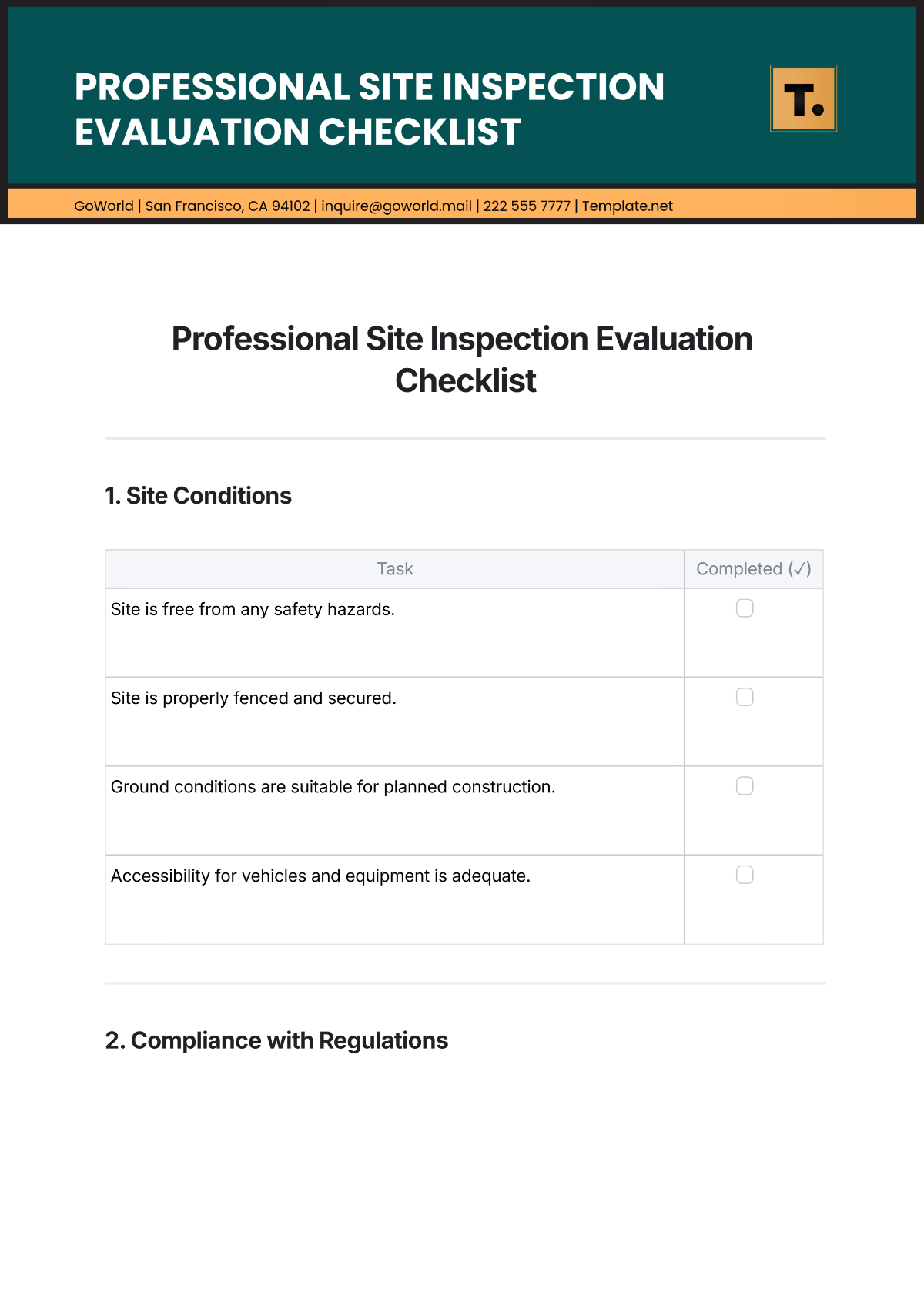

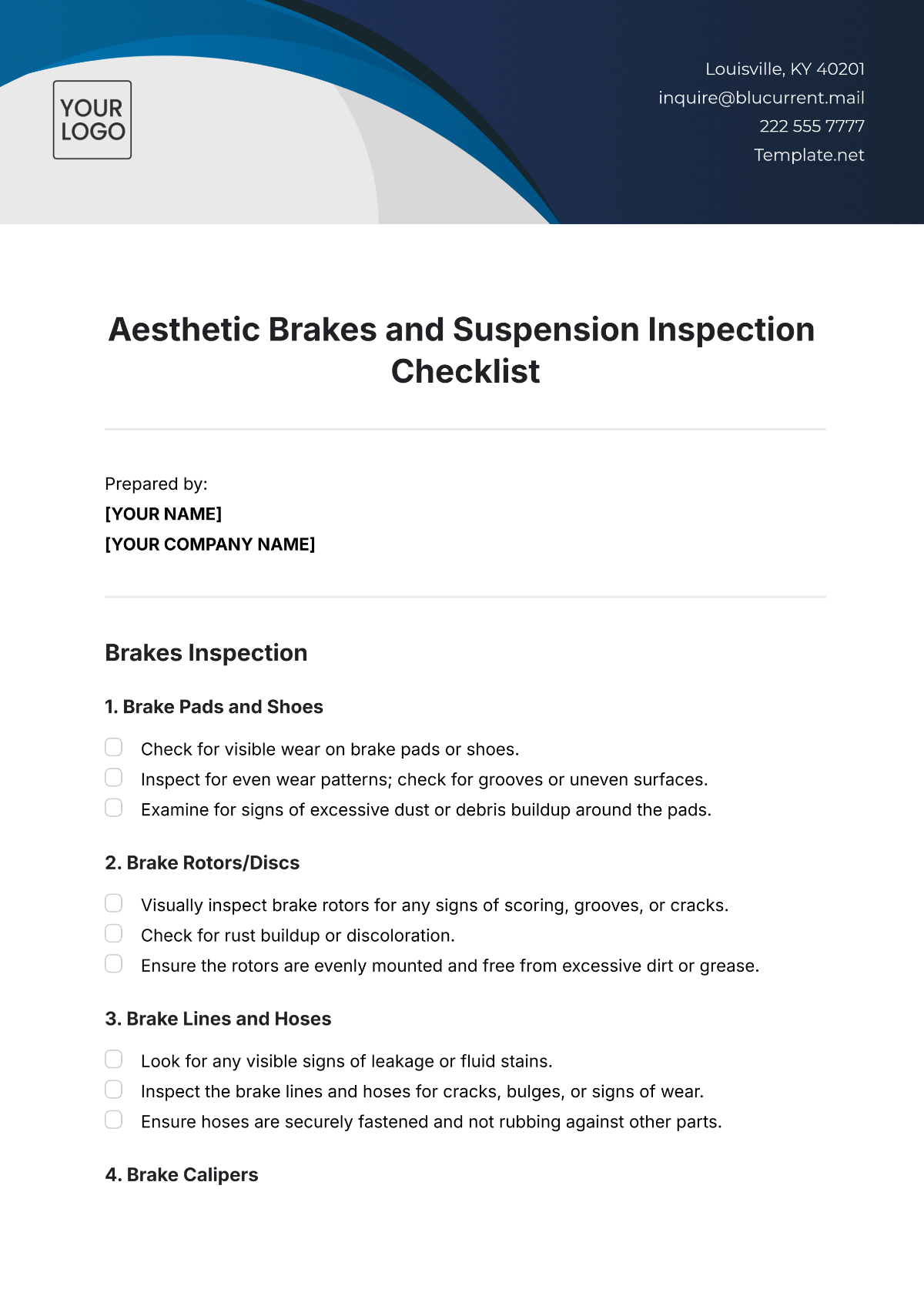

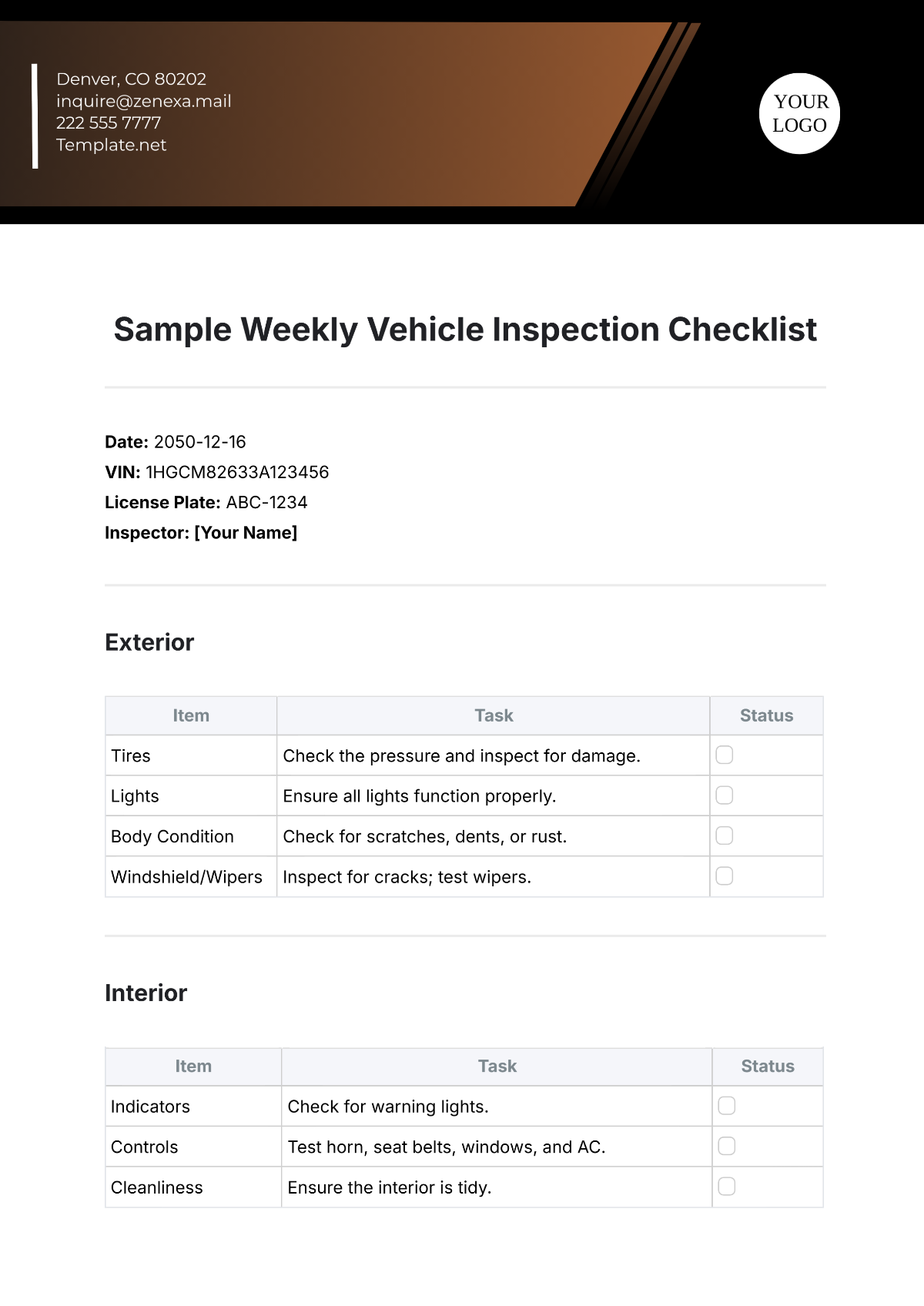

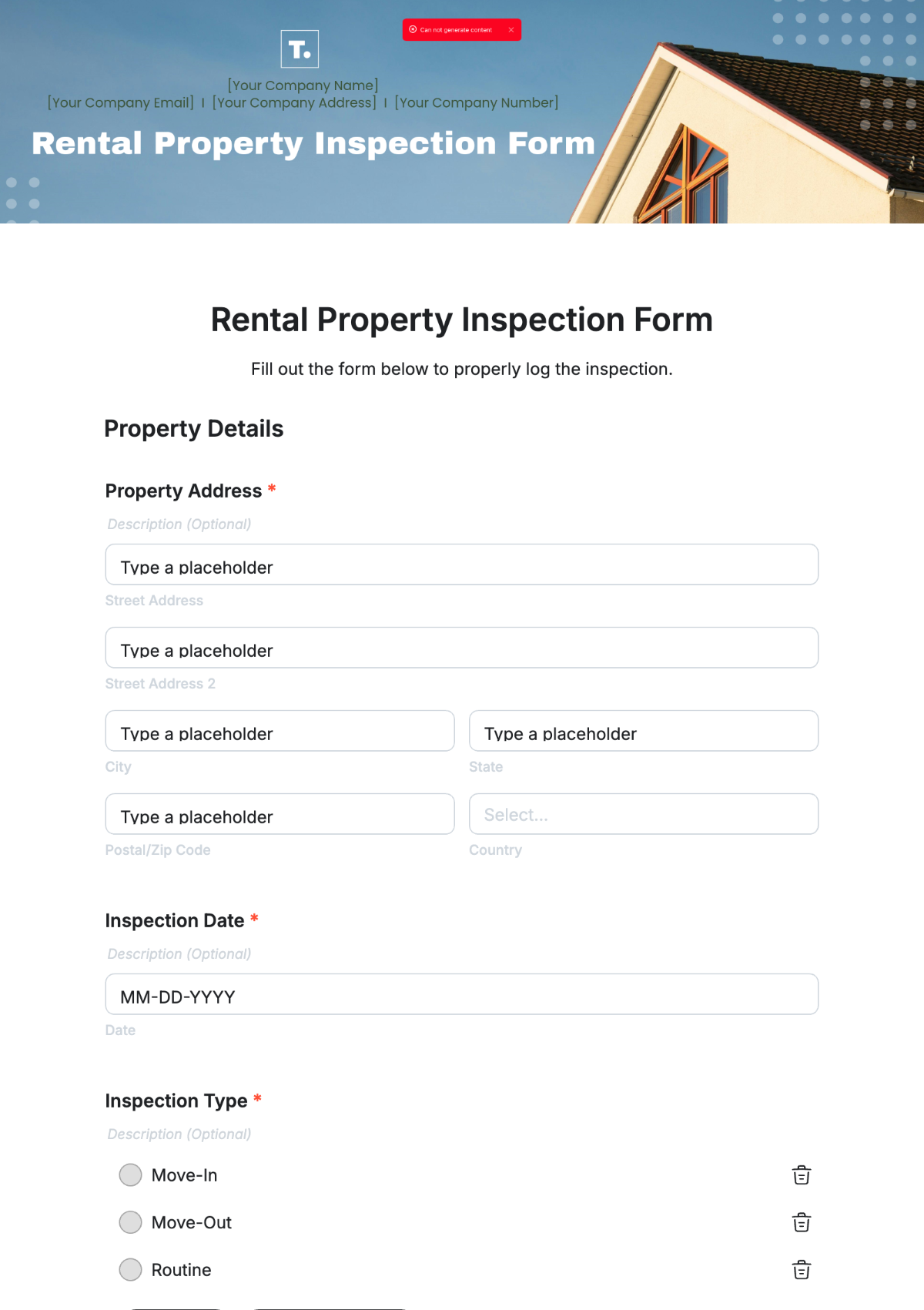

Elevate your inspection processes with the Inspection Requirements Template, offered by Template.net. This highly customizable template is designed to streamline your inspection tasks, making it easy to tailor to your specific needs. Downloadable and printable, it provides flexibility in how you manage your inspections. Plus, with the option to be edited in our AI Editor Tool, you can effortlessly adjust and update the template as needed. Optimize your workflow today with this versatile solution.