Free Bakery Kitchen Safety SOP Layout

I. Introduction

A. Purpose

(Write about the purpose of the SOP. Explain that this document aims to ensure a safe working environment in the bakery kitchen. Mention the importance of safety protocols to prevent accidents and injuries, and to ensure compliance with health and safety regulations.)

B. Scope

(Detail the scope of the SOP. Indicate that it applies to all employees, contractors, and visitors in the bakery kitchen. Highlight that the SOP covers safety procedures for equipment usage, handling ingredients, personal protective equipment (PPE), and emergency procedures.)

C. Responsibility

(Describe the responsibilities of different roles within the bakery. For example, specify that kitchen managers are responsible for enforcing safety procedures, employees must adhere to safety protocols, and safety officers must conduct regular inspections and training sessions.)

II. Safety Procedures

A. Personal Protective Equipment (PPE)

(Detail the types of PPE required in the bakery kitchen. Mention items like gloves, aprons, hairnets, and safety shoes. Explain the importance of wearing PPE and the consequences of non-compliance.)

Gloves (Describe when and how to wear gloves, emphasizing their use when handling food and cleaning. Provide instructions on proper disposal and replacement of gloves.)

Aprons (Explain the necessity of wearing aprons to protect clothing and skin from hot substances and chemicals. Describe how to properly tie and wear aprons.)

Hairnets and Beard Nets (Detail the use of hairnets and beard nets to prevent hair from contaminating food. Specify that all kitchen staff must wear them at all times.)

Safety Shoes (Highlight the importance of wearing non-slip safety shoes to prevent falls and protect feet from hot spills or falling objects.)

B. Equipment Safety

(Provide comprehensive instructions on safely operating kitchen equipment. Emphasize the importance of following manufacturer guidelines and regular maintenance checks.)

Ovens and Stoves (Explain the correct procedures for operating ovens and stoves. Mention the importance of using oven mitts, checking for gas leaks, and never leaving them unattended while in use.)

Mixers and Blenders (Detail the safe operation of mixers and blenders. Include instructions on securing the mixing bowl, using the correct attachments, and never inserting hands while the machine is running.)

Slicers and Choppers (Describe how to safely use slicers and choppers. Emphasize the importance of using guards, keeping hands clear of blades, and properly cleaning equipment after use.)

Dishwashers (Provide instructions for safely using dishwashers. Highlight the importance of loading dishes properly, using the correct detergents, and regularly cleaning the machine.)

C. Handling Ingredients

(Explain the procedures for safely handling ingredients to prevent contamination and ensure food safety.)

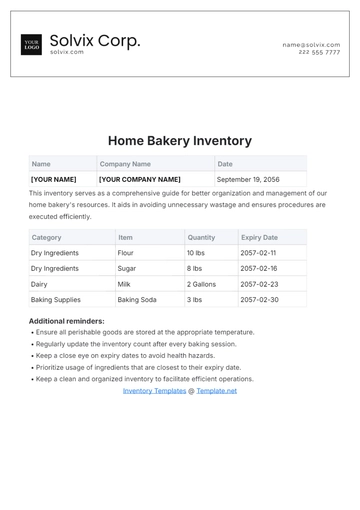

Receiving Ingredients (Detail the steps for receiving and inspecting ingredients. Emphasize checking expiration dates, ensuring proper storage temperatures, and rejecting damaged or contaminated items.)

Storage (Provide guidelines for storing ingredients safely. Include instructions on proper labeling, rotating stock (FIFO method), and maintaining cleanliness in storage areas.)

Preparation (Describe the safe methods for preparing ingredients. Highlight the importance of washing hands, using separate cutting boards for different food types, and avoiding cross-contamination.)

Allergen Management (Explain the procedures for managing allergens in the kitchen. Detail the importance of clearly labeling allergens, avoiding cross-contact, and training staff on allergen awareness.)

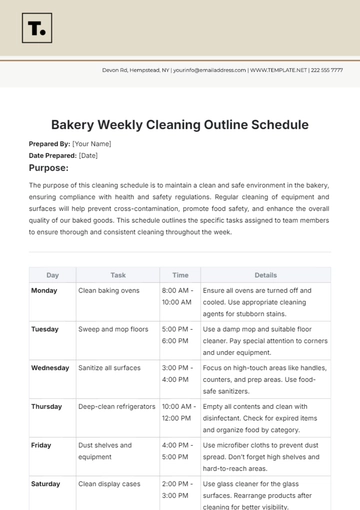

D. Cleaning and Sanitation

(Detail the cleaning and sanitation procedures to maintain a hygienic kitchen environment.)

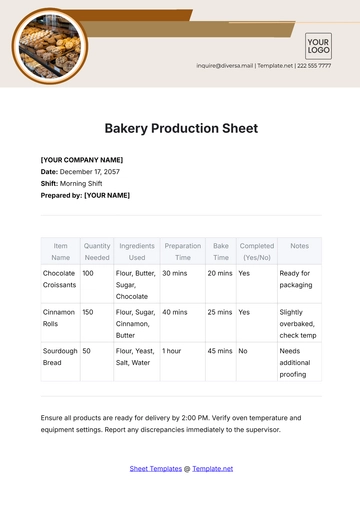

Daily Cleaning (Provide a checklist for daily cleaning tasks. Include wiping down surfaces, sweeping and mopping floors, and sanitizing high-touch areas.)

Deep Cleaning (Describe the deep cleaning procedures that should be done weekly or monthly. Mention tasks like cleaning ovens, descaling dishwashers, and scrubbing walls and ceilings.)

Waste Management (Explain the proper methods for disposing of kitchen waste. Include instructions on separating recyclables, composting food waste, and safely disposing of hazardous materials.)

Pest Control (Detail the procedures for preventing and managing pests in the kitchen. Emphasize regular inspections, sealing entry points, and keeping the kitchen clean and clutter-free.)

III. Emergency Procedures

A. Fire Safety

(Provide instructions on fire safety protocols to prevent and respond to fires in the bakery kitchen.)

Fire Extinguishers (Describe the locations and types of fire extinguishers available. Provide instructions on how to use them and ensure staff is trained in their operation.)

Fire Exits (Detail the locations of fire exits and the importance of keeping them clear. Provide instructions on the evacuation procedure and conducting regular fire drills.)

Emergency Contacts (List emergency contact numbers, including fire department, police, and medical services. Explain the procedure for reporting a fire or other emergencies.)

B. First Aid

(Explain the first aid procedures and the importance of having trained personnel available.)

First Aid Kits (Detail the locations of first aid kits and the importance of keeping them stocked. Provide a checklist of essential first aid supplies.)

Injury Reporting (Describe the process for reporting injuries. Emphasize the importance of immediate reporting and documenting all incidents.)

Medical Emergencies (Provide instructions for handling medical emergencies, such as severe cuts, burns, or allergic reactions. Include steps for administering first aid and calling for professional medical help.)

C. Chemical Safety

(Detail the procedures for handling and storing chemicals safely to prevent accidents and injuries.)

Chemical Storage (Explain the importance of proper chemical storage. Include instructions on labeling, keeping chemicals in original containers, and storing them away from food.)

Spill Management (Provide steps for managing chemical spills. Emphasize using proper PPE, containing the spill, and cleaning it up according to safety guidelines.)

Material Safety Data Sheets (MSDS) (Detail the importance of MSDS for all chemicals used in the kitchen. Explain how to access and interpret MSDS, and ensure staff is familiar with this information.)

IV. Training and Compliance

A. Employee Training

(Explain the importance of training employees on safety procedures. Detail the training schedule and topics covered.)

Orientation (Describe the safety training provided during new employee orientation. Include topics like PPE usage, equipment operation, and emergency procedures.)

Ongoing Training (Detail the schedule for ongoing safety training sessions. Include refresher courses, updates on new safety protocols, and hands-on training.)

Documentation (Explain the importance of documenting all training sessions. Include procedures for maintaining training records and ensuring compliance.)

B. Inspections and Audits

(Provide instructions on conducting regular safety inspections and audits to ensure compliance with safety protocols.)

Routine Inspections (Detail the procedures for routine safety inspections. Include checklists for inspecting equipment, PPE, and overall kitchen cleanliness.)

External Audits (Explain the process for external safety audits. Detail the preparation required, the audit process, and how to address any findings.)

Corrective Actions (Describe the procedures for implementing corrective actions based on inspection and audit findings. Emphasize the importance of timely and effective responses to identified issues.)

V. Recordkeeping and Documentation

A. Safety Records

(Explain the types of safety records that must be maintained and their importance.)

Incident Reports (Detail the process for creating and maintaining incident reports. Emphasize the importance of thorough documentation and regular review of these reports.)

Training Records (Describe the procedures for maintaining training records. Include instructions on recording attendance, topics covered, and employee assessments.)

Inspection Reports (Provide guidelines for documenting inspection reports. Include details on the frequency of inspections, findings, and corrective actions taken.)

B. Regulatory Compliance

(Detail the importance of complying with local, state, and federal regulations. Provide instructions on staying updated with regulatory changes and maintaining compliance.)

Health and Safety Regulations (Explain the key health and safety regulations applicable to bakery kitchens. Provide a summary of the main requirements and how to comply with them.)

Food Safety Standards (Detail the food safety standards that must be followed. Include information on Hazard Analysis and Critical Control Points (HACCP) and other relevant guidelines.)

Record Retention (Describe the procedures for retaining safety records. Include the required retention periods and the importance of secure storage.)

VI. Continuous Improvement

A. Feedback and Reporting

(Explain the importance of continuous improvement in kitchen safety. Provide instructions on how to gather and act on feedback from employees.)

Employee Feedback (Detail the procedures for collecting feedback from employees. Include methods like suggestion boxes, regular meetings, and anonymous surveys.)

Safety Committees (Describe the role of safety committees in continuous improvement. Include instructions on forming committees, meeting schedules, and their responsibilities.)

Reporting Mechanisms (Provide guidelines for reporting safety concerns. Emphasize the importance of a no-blame culture and encourage employees to report issues promptly.)

B. Performance Metrics

(Detail the performance metrics used to measure safety performance. Explain how to track and analyze these metrics.)

Incident Rates (Describe how to calculate and monitor incident rates. Include information on tracking near misses, injuries, and other safety incidents.)

Training Completion (Provide guidelines for tracking training completion rates. Emphasize the importance of ensuring all employees complete required safety training.)

Audit Scores (Explain how to use audit scores to measure safety performance. Include information on setting benchmarks and using audit results for continuous improvement.)

C. Action Plans

(Detail the procedures for developing and implementing action plans based on performance metrics and feedback.)

Setting Goals (Explain how to set achievable safety goals. Include guidelines for creating SMART (Specific, Measurable, Achievable, Relevant, Time-bound) goals.)

Implementation (Provide instructions on implementing action plans. Include steps for assigning responsibilities, setting deadlines, and monitoring progress.)

Review and Adjust (Detail the process for reviewing and adjusting action plans. Emphasize the importance of regular review meetings and being adaptable to change.)

VII. Conclusion

A. Summary

(Summarize the key points covered in the SOP. Reiterate the importance of safety in the bakery kitchen and the commitment of [Your Company Name] to maintaining a safe working environment.)

B. Acknowledgment

(Provide a section for employees to acknowledge that they have read and understood the SOP. Include spaces for signatures and dates.)

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Ensure safety in the kitchen with the Bakery Kitchen Safety SOP Layout Template from Template.net. This customizable and editable tool offers a structured format for safety procedures. Use our Ai Editor Tool to draft SOPs covering hygiene practices, equipment safety, and emergency protocols, promoting a safe working environment in your bakery.