Bakery Quality Control Guideline

I. Introduction

The purpose of this Bakery Quality Control Guideline is to ensure that [Your Company Name] maintains the highest standards of quality in all bakery items. This document outlines the procedures and standards necessary to achieve this goal.

A. Purpose

Quality Assurance: To provide clear guidelines for maintaining the quality of our bakery products. Ensuring consistent quality helps build customer trust and satisfaction.

Standardization: To establish standardized procedures for production, packaging, and delivery. Standardization reduces variability and enhances product reliability.

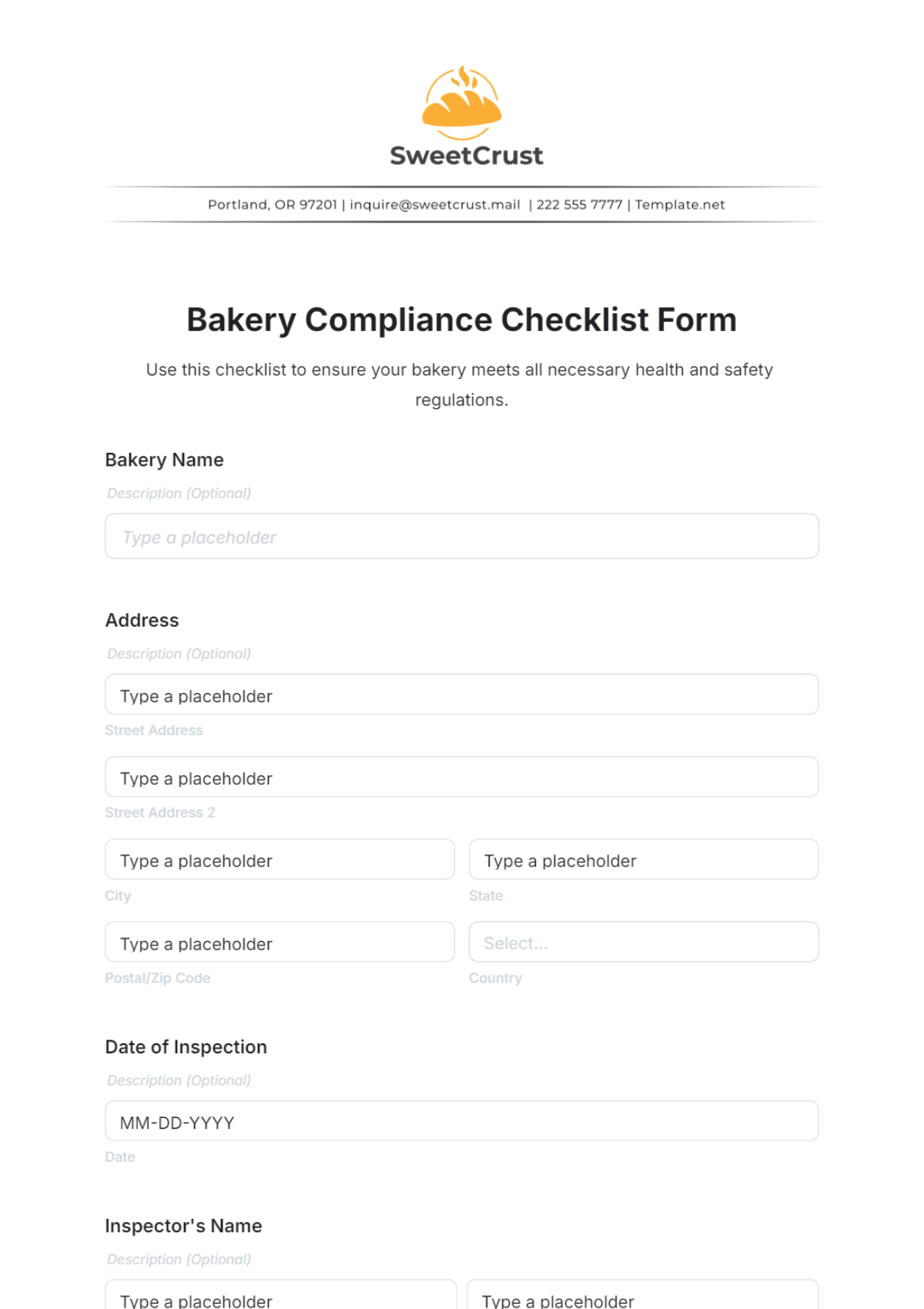

Compliance: To ensure compliance with health and safety regulations. Adherence to regulations protects both customers and staff from potential hazards.

B. Scope

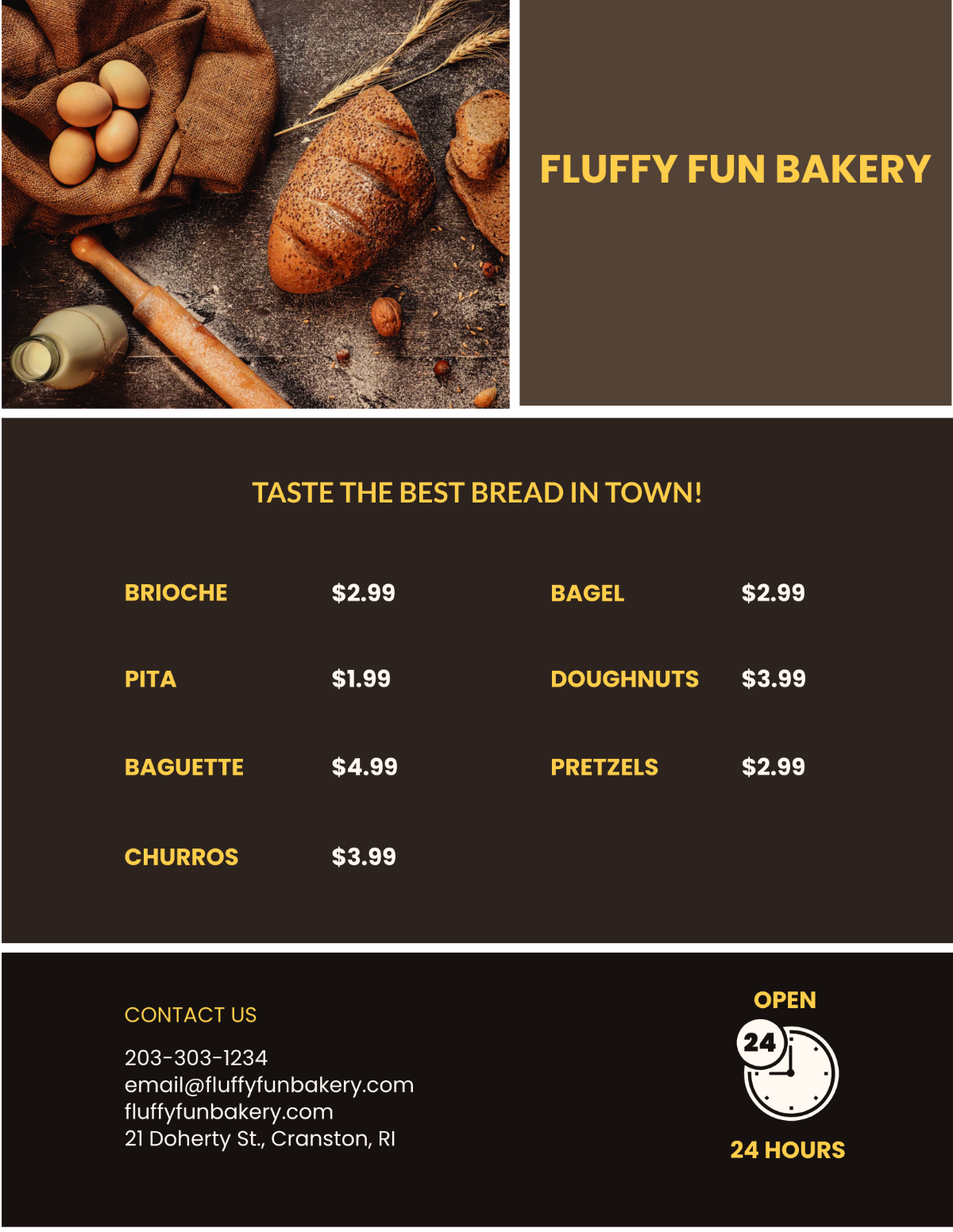

Product Range: This guideline applies to all bakery items produced at [Your Company Name], including bread, pastries, cakes, and other baked goods. A comprehensive approach ensures quality across the product range.

Production Stages: It covers all stages of production, from ingredient sourcing to final delivery. Addressing every stage helps maintain quality throughout the process.

Staff Involvement: This guideline is intended for all staff involved in production, packaging, and delivery. Involving all relevant staff ensures thorough implementation.

C. Target Audience

Bakers: This guideline is primarily for bakers who are responsible for producing high-quality baked goods. Clear instructions help bakers maintain quality standards.

Quality Control Personnel: Staff responsible for quality control must follow these guidelines to ensure product consistency and safety. Their role is crucial in identifying and addressing quality issues.

Management: Management should use this guideline to oversee operations and ensure adherence to quality standards. Effective oversight supports overall quality objectives.

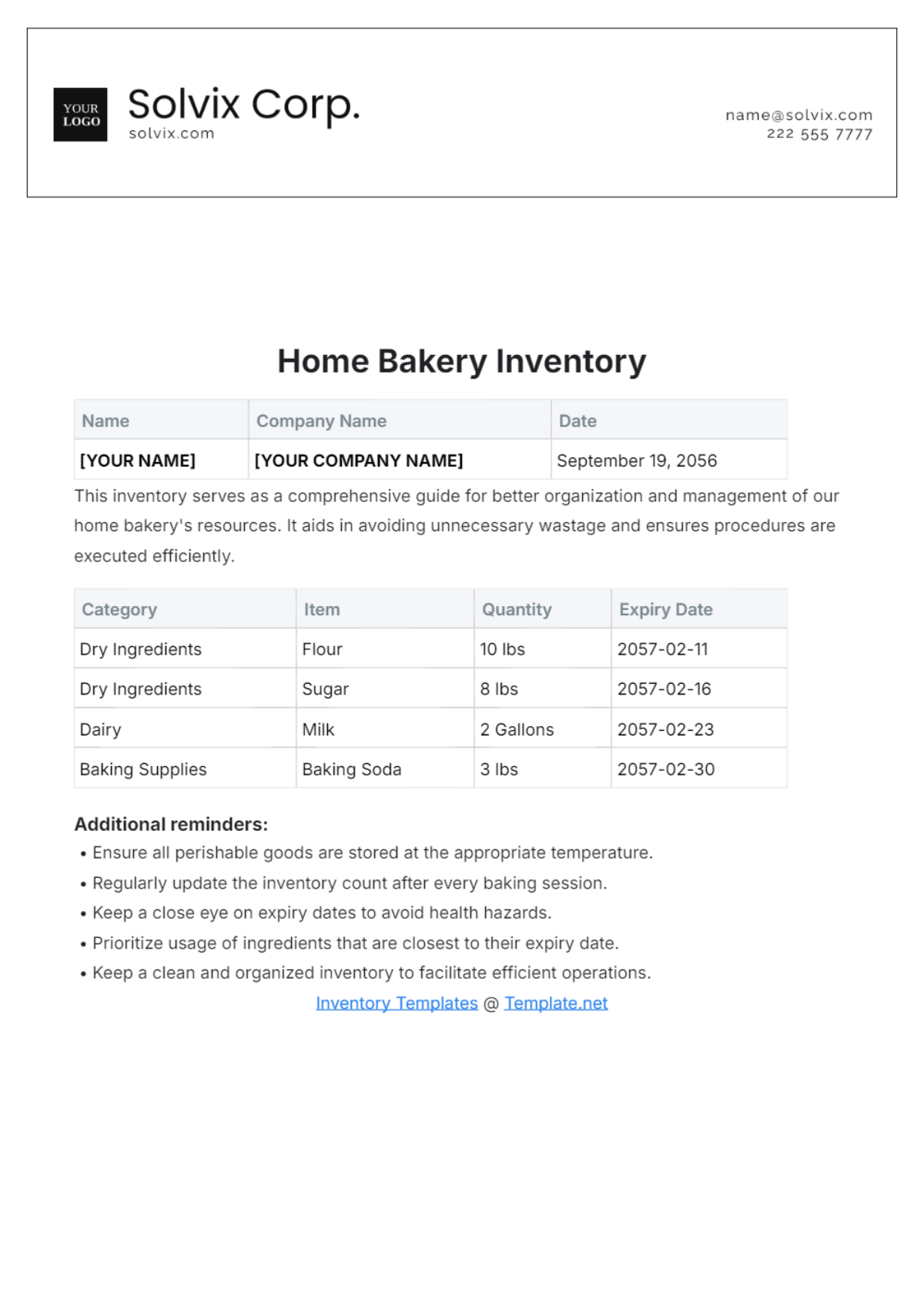

II. Ingredient Sourcing and Handling

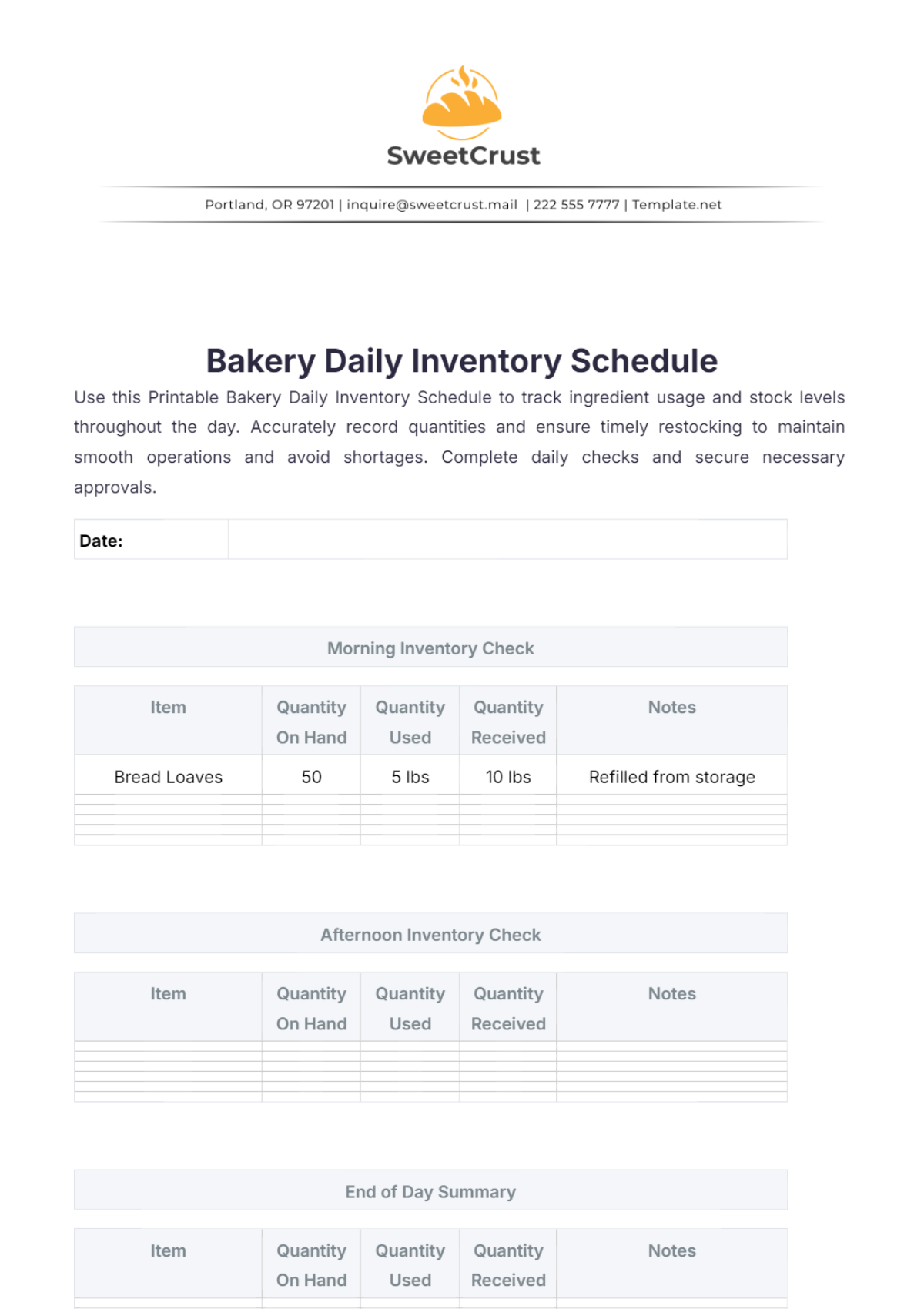

The following table provides an overview of the key processes involved in sourcing and handling ingredients to ensure quality:

No. | Process | Description |

|---|---|---|

1 | Supplier Selection | Choose suppliers based on quality and reliability. |

2 | Ingredient Inspection | Inspect all ingredients upon arrival for freshness and quality. |

3 | Storage Conditions | Store ingredients under appropriate conditions to maintain their quality. |

4 | Rotation System | Implement a first-in, first-out (FIFO) system to use older stock first. |

5 | Handling Procedures | Follow proper handling procedures to prevent contamination and spoilage. |

A. Supplier Selection

Criteria: Select suppliers based on their ability to consistently provide high-quality ingredients. Reliability and consistency are key factors in supplier selection.

Evaluation: Regularly evaluate suppliers to ensure they meet quality standards. Continuous evaluation helps maintain high-quality supplies.

Contracts: Establish contracts that specify quality requirements and delivery schedules. Clear contracts set expectations and prevent misunderstandings.

B. Ingredient Inspection

Arrival Checks: Inspect ingredients upon arrival for freshness, appearance, and any signs of damage. Immediate checks help identify issues before use.

Testing: Perform quality tests on critical ingredients to ensure they meet standards. Testing adds an additional layer of quality assurance.

Documentation: Record inspection results to maintain a traceable quality history. Documentation supports accountability and traceability.

C. Storage Conditions

Temperature Control: Store perishable ingredients at appropriate temperatures to prevent spoilage. Proper temperature control extends shelf life and maintains quality.

Humidity Control: Ensure storage areas have appropriate humidity levels to prevent ingredient degradation. Humidity control helps maintain ingredient integrity.

Organized Storage: Keep storage areas organized to facilitate easy access and inventory management. Organization supports efficient operations and quality maintenance.

D. Rotation System

FIFO Method: Implement a first-in, first-out (FIFO) system to use older stock first. FIFO helps minimize waste and ensures ingredient freshness.

Labeling: Clearly label all ingredients with arrival dates to support the FIFO system. Labeling aids in quick and accurate stock rotation.

Monitoring: Regularly monitor stock levels and rotation to ensure compliance with the FIFO system. Monitoring helps maintain consistency and quality.

E. Handling Procedures

Hygiene: Follow strict hygiene procedures when handling ingredients to prevent contamination. Hygiene practices are crucial for food safety.

Cross-Contamination Prevention: Use separate tools and equipment for different ingredients to avoid cross-contamination. Prevention measures protect product integrity.

Training: Provide regular training on handling procedures to all relevant staff. Training ensures that all staff are knowledgeable about quality practices.

Proper ingredient sourcing and handling are critical to maintaining the quality of bakery products. By ensuring that all ingredients meet high standards and are handled correctly, [Your Company Name] can produce consistently excellent baked goods that meet customer expectations.

III. Production Process

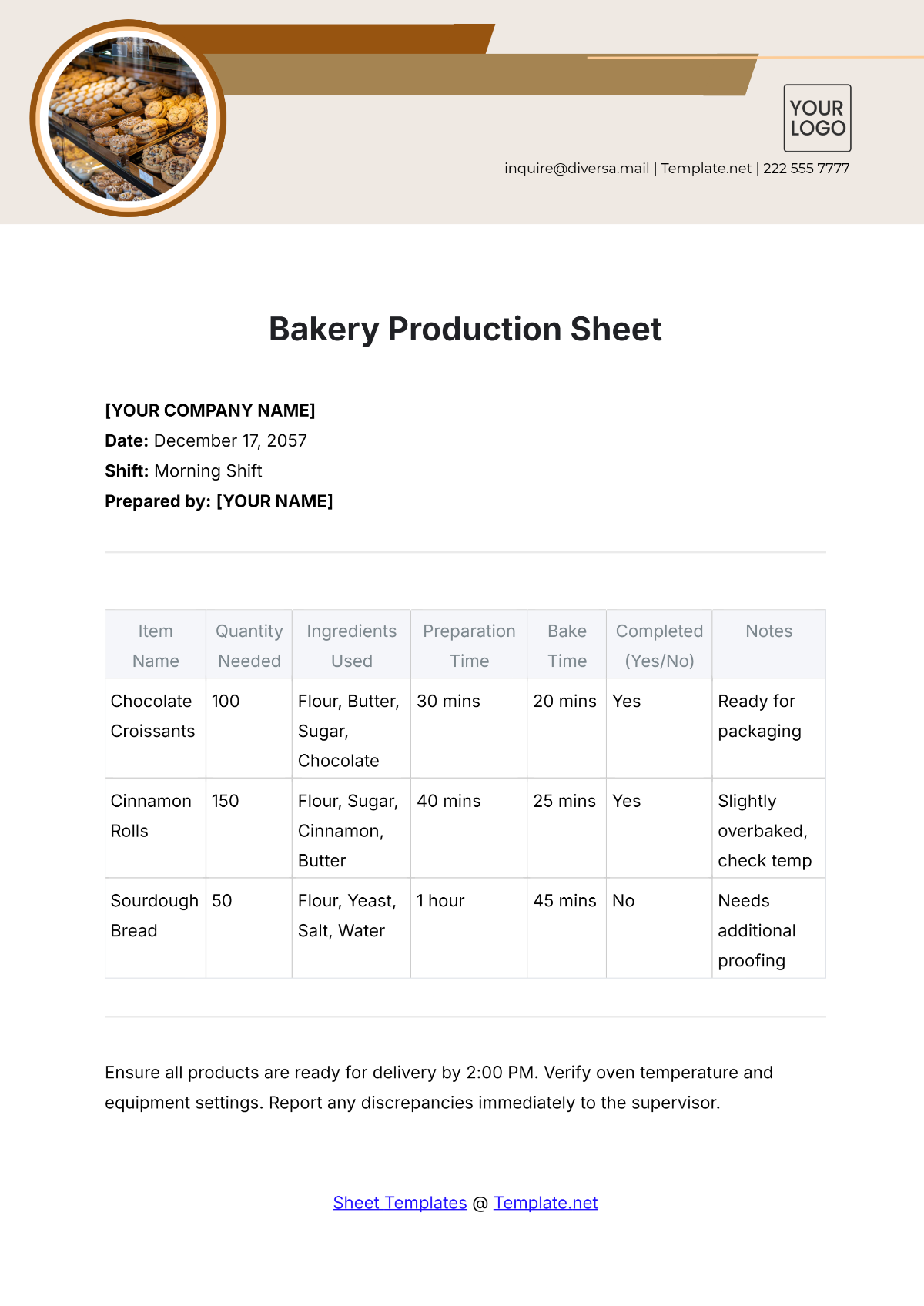

The following table outlines the key steps in the production process to ensure consistent quality in our bakery items:

No. | Step | Description |

|---|---|---|

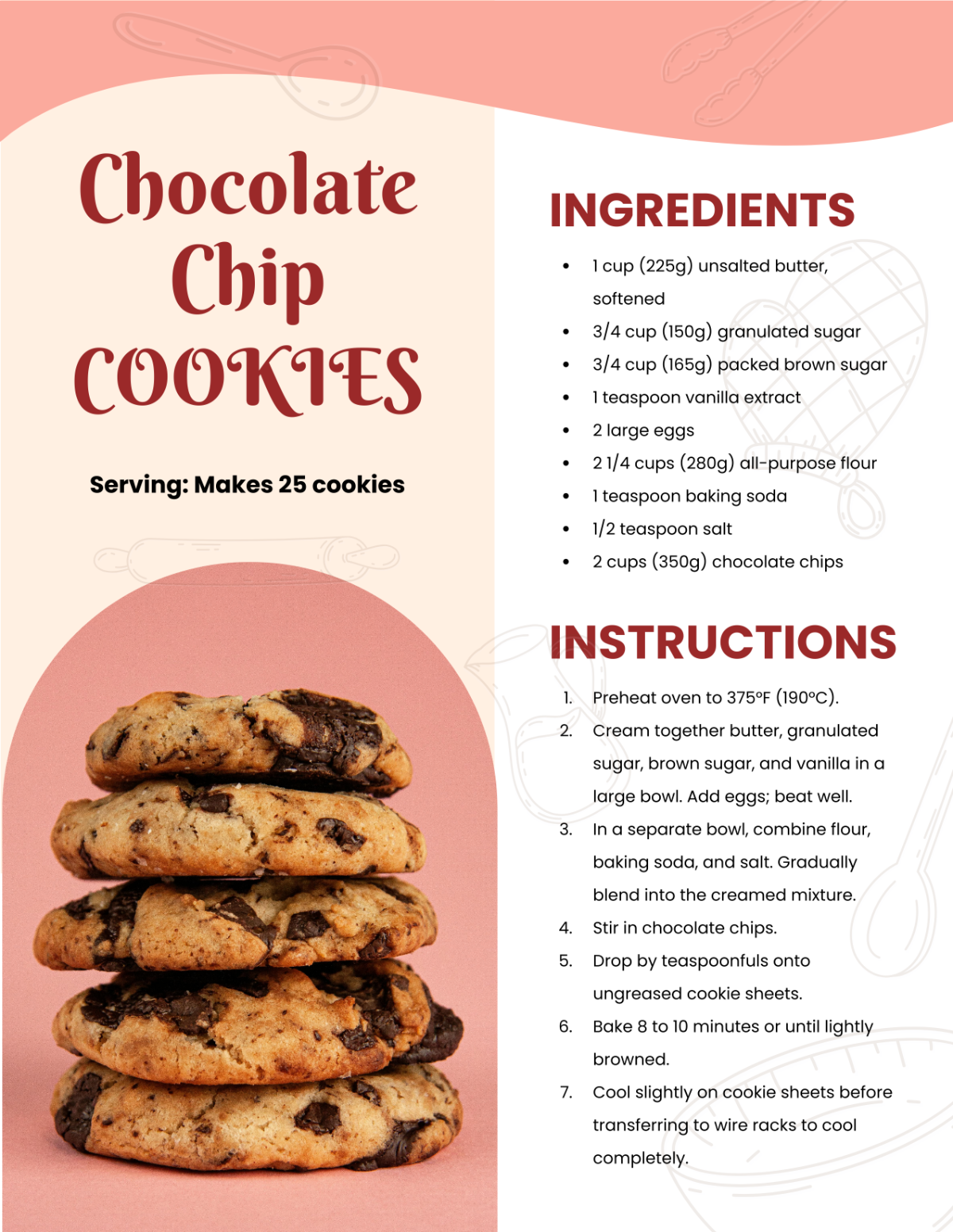

1 | Recipe Standardization | Use standardized recipes to ensure consistency. |

2 | Equipment Calibration | Regularly calibrate equipment to maintain accuracy. |

3 | Mixing and Preparation | Follow precise mixing and preparation procedures. |

4 | Baking Conditions | Ensure proper baking conditions (temperature, time) for each product. |

5 | Cooling and Storage | Properly cool and store baked goods to maintain quality. |

A. Recipe Standardization

Consistency: Standardize recipes to ensure each product batch is consistent in taste and quality. Consistency is crucial for customer satisfaction.

Documentation: Document all recipes and ensure they are accessible to relevant staff. Proper documentation supports accurate and repeatable production.

Regular Reviews: Regularly review and update recipes as needed to maintain quality. Reviews help identify and correct any inconsistencies.

B. Equipment Calibration

Accuracy: Calibrate equipment regularly to ensure it operates within the required specifications. Accurate equipment is essential for consistent results.

Schedule: Establish a calibration schedule and adhere to it strictly. Regular maintenance prevents unexpected issues and downtime.

Record Keeping: Keep detailed records of all calibration activities. Records provide a history of equipment performance and maintenance.

C. Mixing and Preparation

Procedure Adherence: Follow precise mixing and preparation procedures to ensure uniformity. Adherence to procedures minimizes variability.

Ingredient Measurement: Measure ingredients accurately to maintain consistency. Proper measurement is key to achieving the desired outcome.

Mixing Time: Ensure mixing times are consistent with the recipe requirements. Correct mixing times affect texture and quality.

D. Baking Conditions

Temperature Control: Maintain proper baking temperatures for each product to achieve the desired texture and flavor. Temperature control is critical for quality.

Timing: Follow specified baking times to avoid under- or over-baking. Accurate timing ensures the best possible product.

Oven Maintenance: Regularly maintain and clean ovens to ensure even baking. Proper maintenance prevents quality issues related to equipment.

E. Cooling and Storage

Cooling Procedures: Follow proper cooling procedures to prevent condensation and sogginess. Correct cooling preserves texture and quality.

Storage Conditions: Store baked goods in appropriate conditions to maintain freshness and prevent spoilage. Proper storage extends shelf life.

Packaging: Package products appropriately to protect them during storage and transport. Good packaging practices maintain product integrity.

The production process is a critical phase where quality can be ensured or compromised. By following standardized recipes, maintaining equipment, and adhering to precise procedures, [Your Company Name] ensures that all bakery items meet the highest standards of quality and consistency.

IV. Quality Control Inspections

The following table provides an overview of the key steps involved in quality control inspections to ensure that our bakery items meet the required standards:

No. | Step | Description |

|---|---|---|

1 | In-Process Inspections | Conduct inspections during production to catch issues early. |

2 | Final Product Inspections | Inspect finished products for quality and consistency. |

3 | Sensory Evaluation | Perform sensory evaluations (taste, texture, appearance) on finished products. |

4 | Record Keeping | Maintain detailed records of all inspections and evaluations. |

5 | Feedback and Improvement | Use inspection results to provide feedback and drive continuous improvement. |

A. In-Process Inspections

Regular Checks: Conduct regular checks during production to identify and address issues promptly. Early detection prevents defects from reaching the final product.

Critical Control Points: Focus on critical control points where quality issues are most likely to occur. Targeted inspections help ensure thorough quality control.

Immediate Actions: Take immediate corrective actions if any issues are found during in-process inspections. Prompt action helps maintain production quality.

B. Final Product Inspections

Comprehensive Evaluation: Perform comprehensive evaluations of finished products to ensure they meet quality standards. Thorough evaluations prevent substandard products from reaching customers.

Criteria: Assess products based on specific criteria such as appearance, taste, texture, and packaging. Clear criteria guide consistent evaluations.

Documentation: Record inspection results for future reference and analysis. Documentation supports traceability and accountability.

C. Sensory Evaluation

Taste Testing: Conduct taste tests to ensure products meet flavor expectations. Taste testing is essential for customer satisfaction.

Texture Assessment: Evaluate the texture of products to ensure they have the desired consistency. Texture affects the overall eating experience.

Visual Inspection: Perform visual inspections to check for appearance and presentation. Aesthetic appeal is important for attracting customers.

D. Record Keeping

Detailed Records: Maintain detailed records of all quality control inspections and evaluations. Comprehensive records support ongoing quality assurance.

Traceability: Ensure records are organized and accessible for traceability purposes. Traceability helps identify and resolve issues quickly.

Trend Analysis: Use records to analyze trends and identify areas for improvement. Trend analysis supports continuous improvement efforts.

E. Feedback and Improvement

Internal Feedback: Provide feedback to production staff based on inspection results. Constructive feedback helps staff improve their performance.

Continuous Improvement: Use inspection results to drive continuous improvement initiatives. Ongoing improvement efforts enhance overall quality.

Customer Feedback: Incorporate customer feedback into quality control processes. Customer insights help refine and improve products.

Quality control inspections are essential for ensuring that [Your Company Name] consistently delivers high-quality bakery products. By conducting thorough inspections and evaluations, maintaining detailed records, and using feedback for improvement, we can uphold our commitment to quality and customer satisfaction.

V. Packaging and Labeling

The following table outlines the key steps in the packaging and labeling process to ensure that our bakery items are properly presented and protected:

No. | Step | Description |

|---|---|---|

1 | Packaging Materials | Select appropriate packaging materials to protect products. |

2 | Labeling Requirements | Ensure labels include all necessary information (ingredients, allergens, etc.). |

3 | Packaging Procedures | Follow standardized packaging procedures to ensure consistency. |

4 | Storage of Packaged Goods | Store packaged goods in appropriate conditions to maintain quality. |

A. Packaging Materials

Material Selection: Choose packaging materials that provide adequate protection and maintain product freshness. Proper materials prevent damage and spoilage.

Quality: Ensure packaging materials are of high quality to withstand handling and transport. High-quality materials support product integrity.

Sustainability: Consider using sustainable packaging materials to reduce environmental impact. Sustainability aligns with our values and customer preferences.

B. Labeling Requirements

Ingredients: Clearly list all ingredients on the labels to inform customers. Transparency about ingredients helps customers make informed choices.

Allergen Information: Include allergen information on labels to protect customers with allergies. Accurate allergen labeling is crucial for customer safety.

Date Codes: Ensure labels have production and expiration dates for traceability and freshness. Date codes help customers know the shelf life of products.

C. Packaging Procedures

Consistency: Follow standardized packaging procedures to ensure each product is packaged uniformly. Consistency in packaging supports brand image and customer expectations.

Hygiene: Maintain strict hygiene standards during packaging to prevent contamination. Hygiene practices protect product safety.

Inspection: Inspect packaged products to ensure they are correctly labeled and sealed. Inspections catch any packaging errors before distribution.

D. Storage of Packaged Goods

Temperature Control: Store packaged goods at appropriate temperatures to maintain quality. Proper storage conditions extend product shelf life.

Organization: Keep storage areas organized to facilitate easy access and inventory management. Organization supports efficient operations.

Regular Checks: Perform regular checks of stored goods to ensure they remain in good condition. Regular monitoring helps identify any issues early.

Packaging and labeling are critical components of the quality control process. By selecting the right materials, adhering to labeling requirements, following standardized procedures, and ensuring proper storage, [Your Company Name] can deliver products that are not only high in quality but also safe and appealing to customers.

VI. Customer Feedback and Complaint Handling

The following table provides an overview of the key steps involved in collecting and handling customer feedback and complaints to improve our bakery products:

No. | Step | Description |

|---|---|---|

1 | Feedback Collection | Gather customer feedback through various channels. |

2 | Complaint Logging | Record and log all customer complaints systematically. |

3 | Investigation | Investigate the root causes of complaints to identify and address issues. |

4 | Resolution | Implement solutions to resolve complaints and improve customer satisfaction. |

A. Feedback Collection

Multiple Channels: Collect feedback through surveys, online reviews, social media, and in-person interactions. Multiple channels ensure a comprehensive understanding of customer opinions.

Regular Collection: Regularly gather feedback to stay updated on customer experiences. Ongoing collection helps identify trends and areas for improvement.

Incentives: Offer incentives for customers to provide feedback. Incentives encourage more customers to share their opinions.

B. Complaint Logging

Systematic Recording: Log all complaints systematically to ensure they are addressed promptly. Systematic logging helps track and manage complaints effectively.

Detail Capture: Record detailed information about each complaint, including customer contact details, nature of the complaint, and product involved. Detailed records support thorough investigations.

Priority Handling: Prioritize complaints based on severity and impact. Prioritization ensures that critical issues are resolved quickly.

C. Investigation

Root Cause Analysis: Conduct thorough investigations to determine the root causes of complaints. Root cause analysis helps identify and eliminate underlying issues.

Cross-Departmental Collaboration: Collaborate with relevant departments to investigate complaints. Cross-departmental efforts ensure comprehensive investigations.

Documentation: Document findings from investigations for future reference and accountability. Documentation supports continuous improvement efforts.

D. Resolution

Timely Solutions: Implement solutions promptly to resolve complaints and satisfy customers. Timely resolutions demonstrate our commitment to customer satisfaction.

Follow-Up: Follow up with customers to ensure they are satisfied with the resolution. Follow-ups help build trust and loyalty.

Continuous Improvement: Use complaint data to drive continuous improvement initiatives. Analyzing complaint trends helps identify areas for systemic improvement.

Customer feedback and complaint handling are essential for maintaining and improving the quality of our bakery products. By actively collecting feedback, systematically logging complaints, conducting thorough investigations, and implementing effective resolutions, [Your Company Name] can enhance customer satisfaction and loyalty.

VII. Staff Training and Development

A. Training Programs

Comprehensive Content: Develop training programs that cover all aspects of bakery operations, including production, hygiene, and customer service. Comprehensive programs ensure staff are well-rounded.

Practical Training: Include practical training sessions to reinforce theoretical knowledge. Hands-on experience helps staff apply what they learn.

Regular Updates: Regularly update training programs to reflect new procedures and standards. Updates keep training relevant and effective.

B. Skill Assessments

Initial Assessments: Conduct initial skill assessments for new staff to identify their training needs. Initial assessments help tailor training programs.

Ongoing Assessments: Regularly assess staff skills to ensure they meet quality standards. Ongoing assessments identify areas for improvement.

Feedback: Provide feedback based on assessment results to help staff improve. Constructive feedback supports skill development.

C. Continuous Learning

Encouragement: Encourage staff to pursue continuous learning opportunities, such as workshops and courses. Continuous learning helps staff stay updated and skilled.

Resources: Provide access to learning resources, such as books, online courses, and seminars. Resources support self-directed learning.

Recognition: Recognize and reward staff who actively engage in continuous learning. Recognition motivates staff to keep improving.

D. Performance Reviews

Regular Reviews: Conduct regular performance reviews to evaluate staff performance and set improvement goals. Regular reviews provide structured feedback.

Objective Criteria: Use objective criteria to assess performance and provide fair evaluations. Objective criteria ensure transparency and fairness.

Development Plans: Create development plans based on review results to help staff improve. Development plans provide a roadmap for growth.

Staff training and development are vital for maintaining quality standards at [Your Company Name]. By providing comprehensive training programs, regularly assessing skills, encouraging continuous learning, and conducting performance reviews, we can ensure that our staff are well-equipped to deliver high-quality bakery products.

VIII. Health and Safety Compliance

A. Health and Safety Training

Comprehensive Coverage: Provide training that covers all aspects of health and safety relevant to bakery operations. Comprehensive training ensures staff are aware of all safety protocols.

Regular Updates: Update training materials regularly to reflect changes in regulations and best practices. Keeping training materials current ensures compliance with the latest standards.

Assessment: Assess staff understanding of health and safety procedures regularly. Assessments help ensure staff are knowledgeable and capable of maintaining a safe work environment.

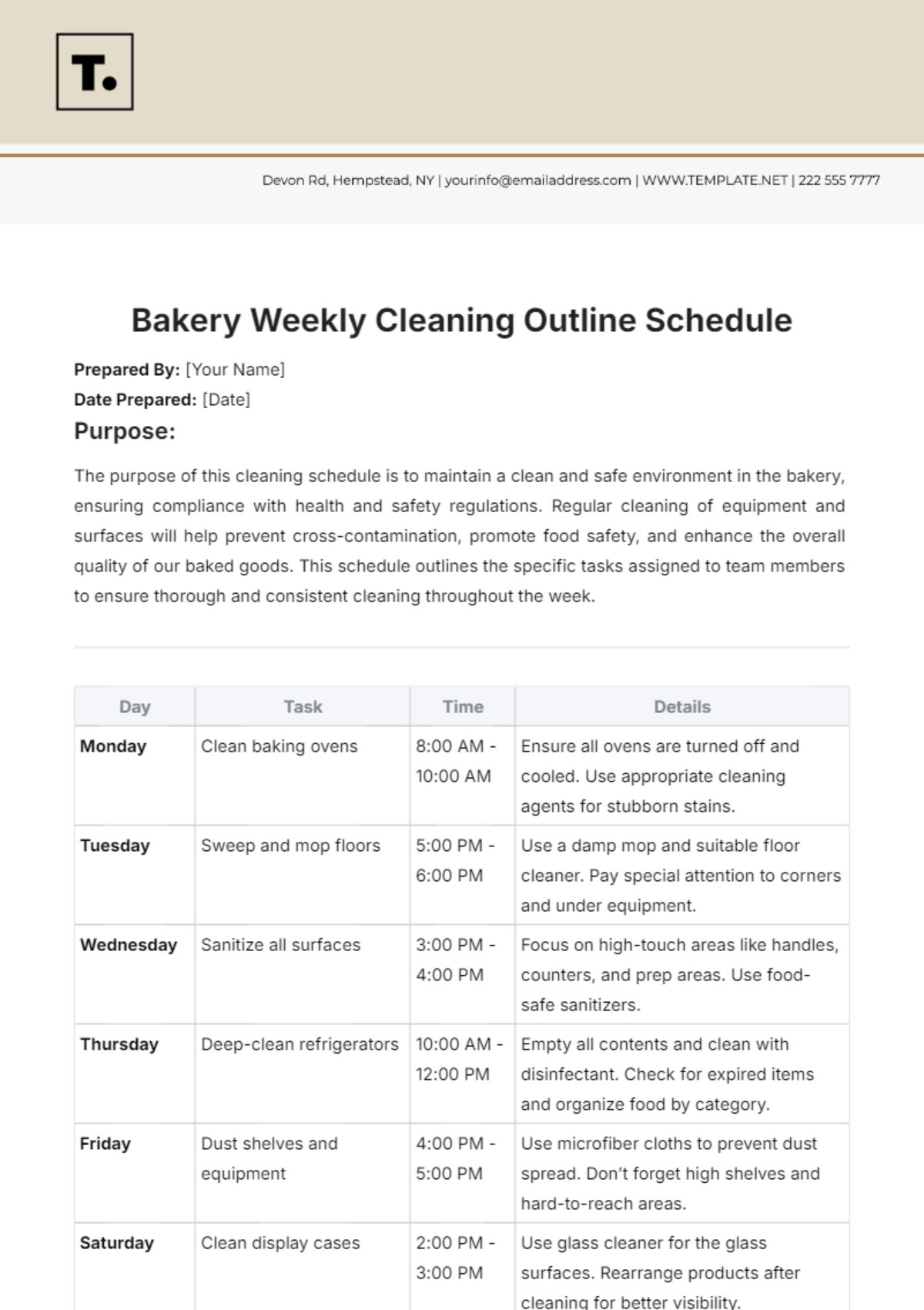

B. Hygiene Standards

Strict Enforcement: Establish and strictly enforce hygiene standards to prevent contamination. Strict hygiene practices are essential for food safety.

Cleaning Schedules: Implement regular cleaning schedules for all areas and equipment. Regular cleaning helps maintain a hygienic environment.

Monitoring: Monitor adherence to hygiene standards and take corrective action when necessary. Continuous monitoring ensures compliance.

C. Equipment Safety

Safe Usage: Train staff on the safe use of all equipment to prevent accidents. Proper training helps avoid injuries and equipment damage.

Regular Maintenance: Schedule regular maintenance for all equipment to ensure it operates safely and efficiently. Maintenance prevents malfunctions and extends equipment lifespan.

Safety Inspections: Conduct regular safety inspections to identify and address potential hazards. Inspections help maintain a safe working environment.

D. Emergency Procedures

Procedure Development: Develop comprehensive emergency procedures for various scenarios, such as fires, medical emergencies, and natural disasters. Thorough procedures ensure preparedness.

Staff Training: Train staff on emergency procedures to ensure they know how to respond appropriately. Training helps minimize panic and ensure effective responses.

Regular Drills: Conduct regular emergency drills to practice and refine procedures. Drills help staff stay prepared and confident in their responses.

Health and safety compliance is crucial for protecting both staff and customers. By providing thorough training, enforcing hygiene standards, ensuring equipment safety, and developing emergency procedures, [Your Company Name] can create a safe and compliant working environment.

IX. Continuous Improvement

The following table outlines the key steps in our continuous improvement process to ensure we consistently enhance the quality of our bakery products and operations:

No. | Step | Description |

|---|---|---|

1 | Data Collection | Collect data on all aspects of bakery operations. |

2 | Analysis | Analyze data to identify areas for improvement. |

3 | Action Planning | Develop action plans based on analysis results. |

4 | Implementation | Implement improvement actions. |

A. Data Collection

Comprehensive Coverage: Collect data on production, quality control, customer feedback, and other relevant areas. Comprehensive data collection provides a complete picture of operations.

Regular Updates: Ensure data is collected regularly to track trends and measure progress. Regular updates help identify patterns and areas for improvement.

Accuracy: Maintain high standards of accuracy in data collection to ensure reliable analysis. Accurate data supports effective decision-making.

B. Analysis

Trend Identification: Analyze data to identify trends and recurring issues. Identifying trends helps focus improvement efforts on the most significant areas.

Root Cause Analysis: Conduct root cause analysis to understand the underlying causes of issues. Root cause analysis provides insights for effective solutions.

Benchmarking: Compare performance against industry benchmarks to identify gaps and opportunities. Benchmarking helps set realistic improvement goals.

C. Action Planning

Goal Setting: Set clear and achievable goals based on analysis results. Clear goals guide focused improvement efforts.

Resource Allocation: Allocate necessary resources, including time, staff, and budget, to support improvement actions. Adequate resources are essential for successful implementation.

Timeline Development: Develop a realistic timeline for implementing improvement actions. A clear timeline ensures timely execution and progress tracking.

D. Implementation

Execution: Execute improvement actions according to the plan. Effective execution is crucial for achieving desired outcomes.

Monitoring: Monitor the implementation process to ensure it stays on track and addresses identified issues. Continuous monitoring helps catch and correct any deviations.

Evaluation: Evaluate the effectiveness of improvement actions and make adjustments as needed. Evaluation ensures that improvements are achieving the desired impact.

Continuous improvement is a core principle at [Your Company Name]. By systematically collecting and analyzing data, developing and implementing action plans, and continuously monitoring progress, we can ensure that our bakery products and operations are always evolving to meet the highest standards of quality and customer satisfaction.