Bakery Hygiene Guideline Sample

I. Introduction

Maintaining a rigorous standard of hygiene in a bakery is vital for ensuring the quality, safety, and freshness of baked goods. This comprehensive guideline is designed to provide clear and actionable instructions for [Your Company Name] to uphold exceptional cleanliness and sanitation practices. Proper hygiene not only helps in preventing contamination and the spread of foodborne illnesses but also contributes to the overall success and reputation of the bakery. By adhering to these practices, we ensure that our bakery products are safe for consumption and meet the highest standards of quality. This document serves as a critical resource for all employees, helping them understand their responsibilities and the procedures necessary to maintain a hygienic environment.

II. Personal Hygiene for Bakery Staff

A. General Hygiene Practices

Hand Washing

Employees must perform hand washing with soap and water for a minimum of 20 seconds before commencing work, after handling raw ingredients, after visiting the restroom, and following any other activity that may result in contamination. Effective hand washing involves scrubbing all surfaces of the hands, including the backs, between fingers, and under nails. Hands should be thoroughly dried using single-use paper towels or a high-speed air dryer to eliminate moisture that could harbor bacteria.

In addition to regular hand washing, staff should use hand sanitizers containing at least 60% alcohol when soap and water are not available. This practice is especially important after handling money or touching shared equipment.

Use of Gloves and Hairnets

Disposable gloves should be worn when handling ready-to-eat foods and changed frequently to prevent cross-contamination. Gloves must be changed whenever they become soiled, torn, or after handling raw ingredients. It is essential to remember that gloves are not a substitute for hand washing.

Hairnets or caps must be worn at all times in the production area to prevent hair from contaminating the food. Hair restraints should fit snugly to cover all hair, including beards and mustaches if applicable. Staff with longer hair should secure their hair in a bun or ponytail to further reduce the risk of contamination.

Personal Cleanliness

All bakery staff are required to arrive in clean uniforms, which should include aprons and non-slip shoes to prevent accidents and maintain hygiene. Uniforms should be changed regularly, and any uniforms showing signs of wear or damage should be replaced to ensure continued effectiveness in maintaining cleanliness.

Jewelry, with the exception of plain wedding bands, should not be worn in the food preparation areas. Rings, bracelets, and necklaces can harbor bacteria and pose a risk of contamination. Staff should be encouraged to leave personal items, such as watches and jewelry, in a designated area away from food preparation zones.

B. Health and Wellness

Illness Policy

Employees exhibiting symptoms of illness, particularly those involving gastrointestinal distress such as vomiting, diarrhea, or fever, must refrain from working until they are symptom-free for a minimum of 48 hours. This policy helps prevent the spread of contagious illnesses that can compromise food safety and employee health.

Regular health screenings should be conducted to ensure staff members are fit for food handling duties. This includes monitoring for symptoms of communicable diseases and ensuring that any underlying health conditions are managed appropriately.

Reporting Injuries

Any injuries sustained while working, particularly those involving cuts, abrasions, or burns, must be reported to a supervisor immediately. Proper procedures must be followed to treat and cover wounds to prevent contamination. Employees should use waterproof bandages and wear gloves when handling food if they have an open wound.

An incident report should be completed for all injuries, detailing the nature of the injury, the circumstances under which it occurred, and the steps taken to address it. This report helps in tracking incidents and ensuring that appropriate corrective measures are implemented.

III. Cleaning and Sanitation Procedures

A. Daily Cleaning Tasks

Surface Cleaning

All food preparation surfaces must be cleaned and sanitized before and after use with approved cleaning agents. This includes countertops, cutting boards, and other surfaces that come into direct contact with food. Cleaning agents should be chosen based on their effectiveness in removing contaminants and their suitability for food contact surfaces.

Special attention should be given to frequently touched surfaces, such as doorknobs, handles, and light switches, as these can harbor significant amounts of bacteria. Regular cleaning of these high-touch areas helps in reducing the risk of spreading germs throughout the bakery.

Equipment Cleaning

Equipment, including mixers, ovens, and baking tools, must be disassembled and thoroughly cleaned and sanitized at the end of each day. Equipment should be inspected for any signs of residue or buildup that could affect its performance or safety.

Small utensils, such as whisks, spatulas, and measuring cups, should be washed in a commercial dishwasher to ensure they are free from contaminants. Dishwashers should be regularly maintained and checked for proper functioning to ensure thorough cleaning.

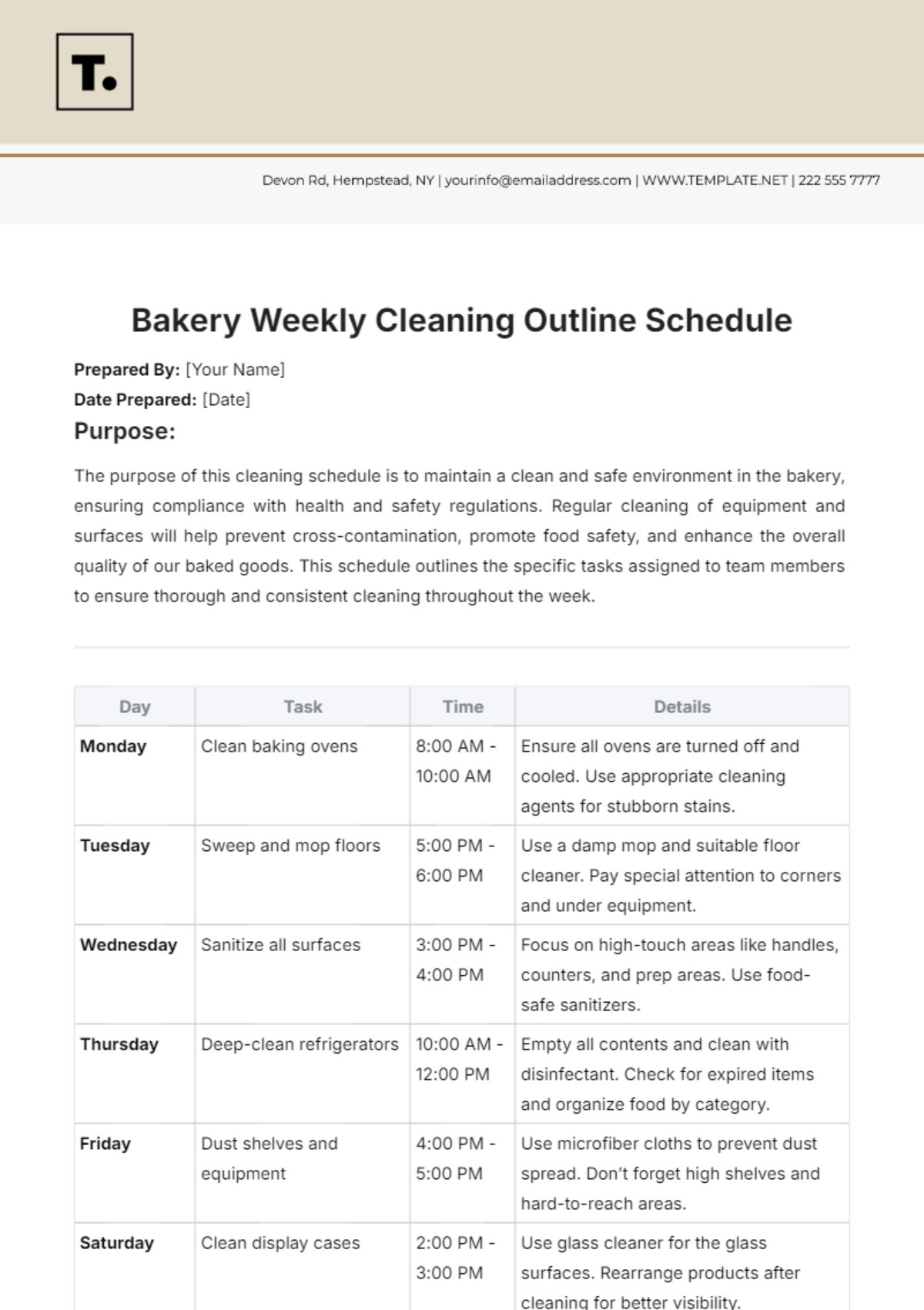

B. Weekly Deep Cleaning Tasks

Floor Cleaning

Floors should be swept and mopped thoroughly using a disinfectant solution to remove any residue, spills, or accumulated dirt that may have occurred throughout the week. Special attention should be given to areas where spills are likely to occur, such as around sinks and prep stations.

Areas under equipment and in the corners of the bakery should be cleaned meticulously to prevent the buildup of dirt and grime, which can attract pests and create unsanitary conditions.

Refrigeration Units

Refrigeration units, including walk-in coolers and display cases, should be emptied, cleaned, and sanitized. This includes removing shelves and drawers, washing them with hot, soapy water, and sanitizing the interior surfaces.

Temperature logs should be maintained and reviewed regularly to ensure all refrigeration units are operating at safe temperatures, typically at or below 40°F (4°C) for refrigeration and 0°F (-18°C) for freezers.

C. Monthly and Annual Cleaning Tasks

Ventilation and Duct Cleaning

Ventilation systems and ducts should be cleaned monthly to ensure proper airflow and to prevent dust and grease accumulation. Accumulated dust can reduce the efficiency of the ventilation system and pose a fire hazard.

Annual professional cleaning of ventilation systems is recommended to ensure thorough maintenance. Professional services can address areas that are difficult to reach with standard cleaning procedures.

Pest Control Measures

Regular pest control inspections should be conducted to identify and address any potential infestations. This includes checking for signs of pests such as droppings, nests, and damage to packaging or structural elements.

Preventative measures, such as sealing cracks, using traps, and maintaining a clean environment, should be followed strictly to deter pests from entering the bakery. Pest control records should be kept to document inspections and actions taken.

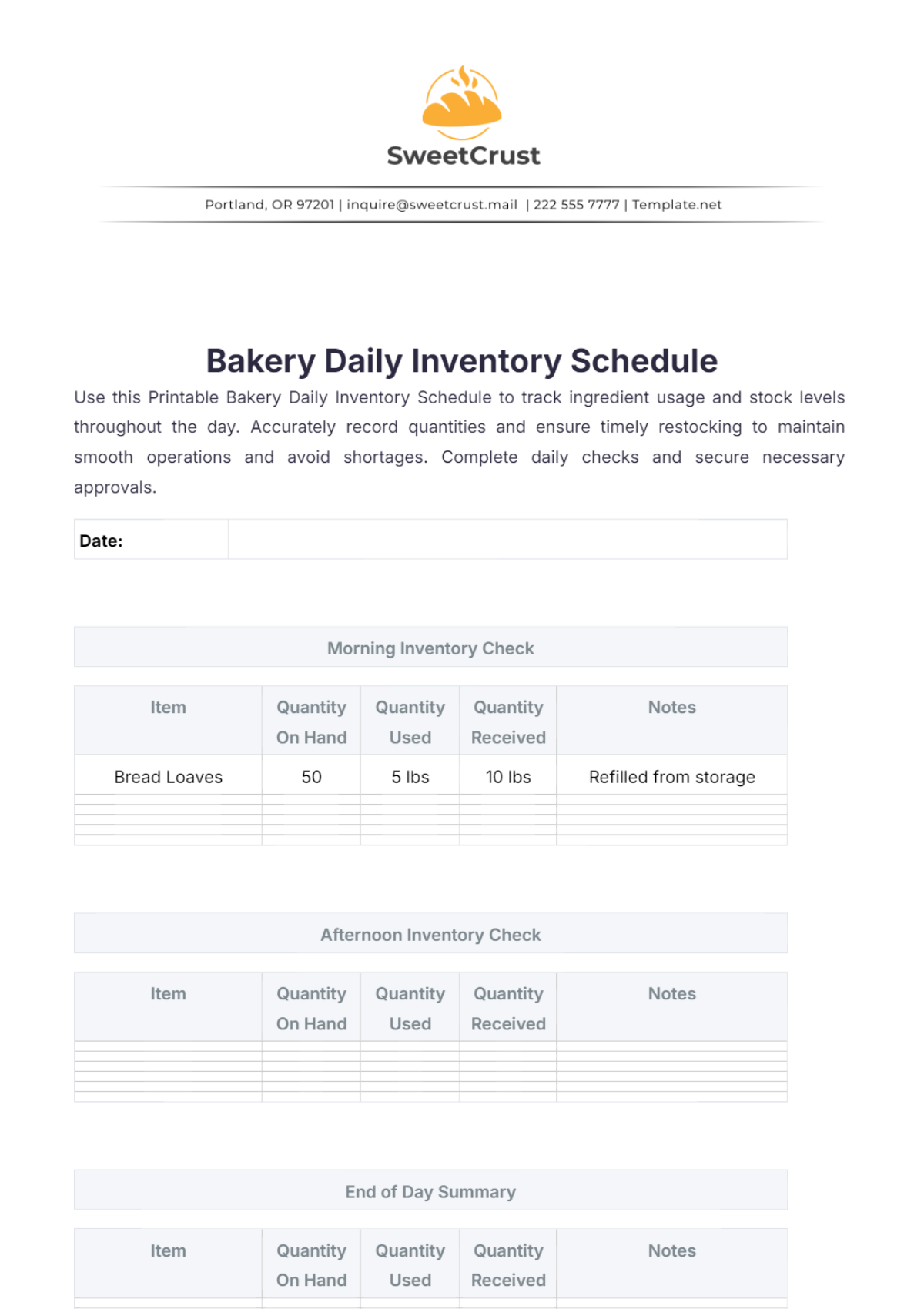

IV. Handling Ingredients and Raw Materials

A. Receiving and Storage

Inspection of Deliveries

All deliveries should be inspected upon arrival for signs of contamination, damage, or spoilage. Items such as packaging integrity, temperature, and expiration dates should be checked to ensure they meet [Your Company Name]’s quality and safety standards.

Any compromised or suspicious items should be rejected and returned to the supplier. Documentation of rejected items and reasons for rejection should be maintained for record-keeping and quality control purposes.

Proper Storage Practices

Ingredients should be stored off the floor and away from walls in a clean, dry area to prevent contamination and to allow for proper air circulation. Storage areas should be organized to prevent cross-contamination, with raw materials stored separately from finished products.

Temperature-sensitive items, such as dairy products and meats, must be stored in refrigeration units at appropriate temperatures. Dry goods should be kept in sealed containers to protect them from pests and moisture.

B. Ingredient Handling

FIFO Method

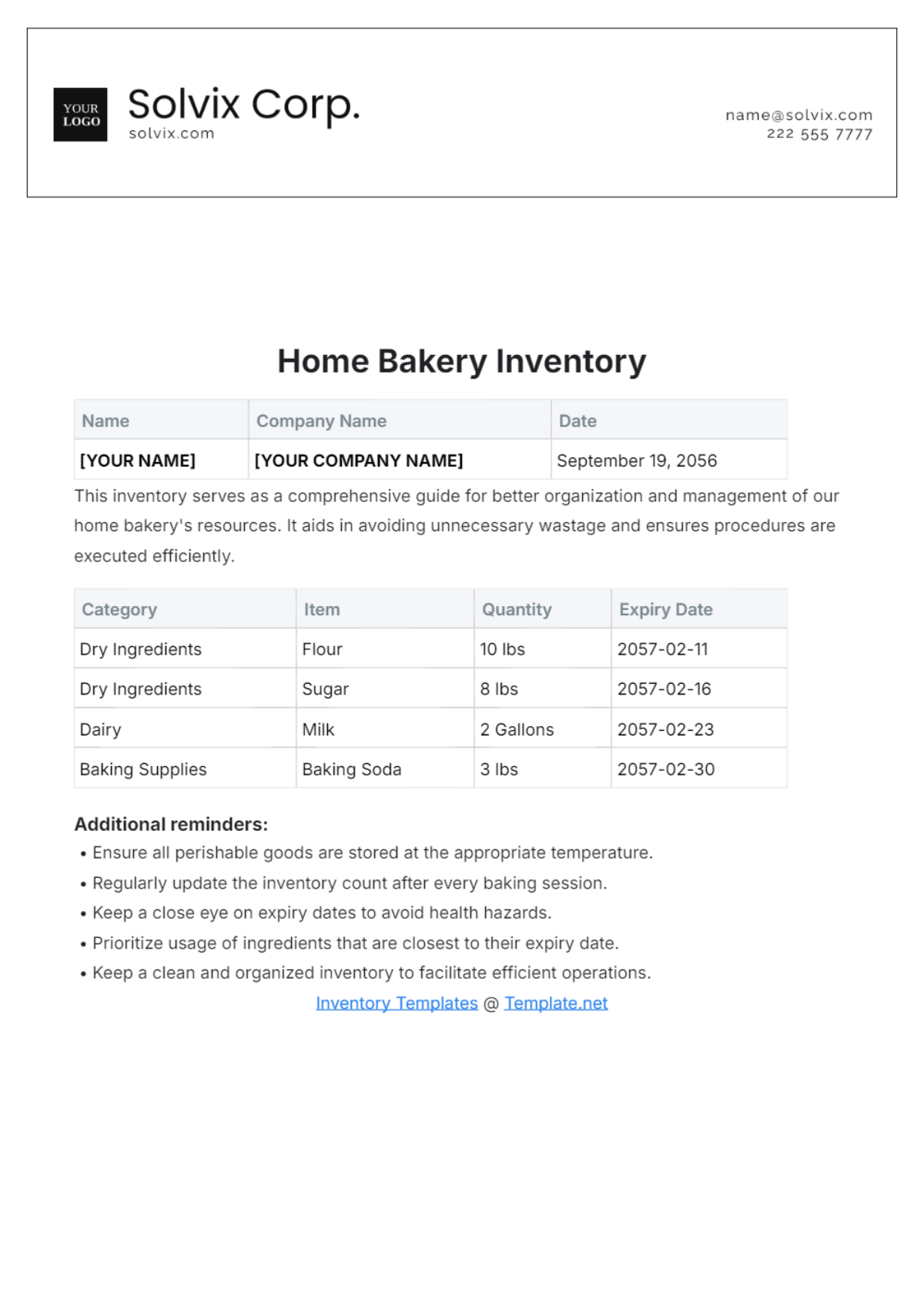

The First-In, First-Out (FIFO) method should be employed to ensure that older stock is used before newer stock, thus reducing the risk of using expired ingredients. This method helps in maintaining product freshness and minimizing waste.

Regular inventory checks should be conducted to monitor expiration dates and stock levels. Items that are nearing their expiration dates should be used promptly to avoid waste.

Cross-Contamination Prevention

Separate utensils and equipment should be used for handling raw and cooked ingredients to prevent cross-contamination. For example, use different cutting boards for raw meats and vegetables.

Workstations should be cleaned and sanitized thoroughly between tasks involving different types of ingredients. This practice helps in preventing the transfer of pathogens from one ingredient to another.

V. Baking Process Hygiene

A. Preparation and Mixing

Clean Workstations

Workstations must be cleaned and sanitized before beginning the preparation of any dough or batter. This includes wiping down surfaces, removing any debris, and ensuring that all utensils and equipment are clean.

All ingredients should be measured and prepared in a hygienic manner to avoid contamination. Ingredients should be kept covered and stored properly to prevent exposure to airborne contaminants.

Equipment Usage

Equipment should be checked for cleanliness and functionality before use. Any equipment found to be dirty or malfunctioning must be cleaned or repaired immediately to avoid contamination of the products.

Mixing bowls, spoons, and other utensils should be sanitized between uses. Proper cleaning and sanitizing procedures should be followed to ensure that all equipment is free from contaminants.

B. Baking and Cooling

Oven Hygiene

Ovens should be preheated to the required temperature before baking to ensure even cooking and to prevent undercooked products. Ovens should be cleaned regularly to remove any residue from previous bakes, which can affect the taste and quality of new products.

Baking trays and molds should be lined with parchment paper or silicone mats to minimize direct contact with surfaces. This practice helps in reducing the risk of contamination and ensures easy removal of baked goods.

Cooling Racks and Storage

Cooling racks should be cleaned and sanitized before use to prevent contamination of baked goods. Baked goods should be placed on these racks in a manner that allows for proper airflow and cooling.

Once cooled, baked goods should be transferred to clean, covered containers or packaging to protect them from dust, contaminants, and pests. Proper storage helps in maintaining the freshness and quality of the products.

VI. Packaging and Display Hygiene

A. Packaging Procedures

Sanitized Packaging Areas

The packaging area must be kept clean and free from contaminants. All surfaces, including countertops and packaging stations, should be sanitized before use to ensure that no harmful bacteria or residues come into contact with the baked goods.

Packaging materials, such as boxes and bags, should be stored in a clean, dry area and protected from dust, pests, and moisture. Proper storage of packaging materials helps in maintaining their integrity and safety.

Safe Handling Practices

Employees must wear gloves when handling baked goods during packaging to prevent direct contact with the products. Gloves should be changed regularly, especially when switching between different types of products or after handling contaminated materials.

Each item should be inspected for quality and cleanliness before being packaged. Any items that do not meet the quality standards should be removed and disposed of appropriately.

B. Display and Sales Area Hygiene

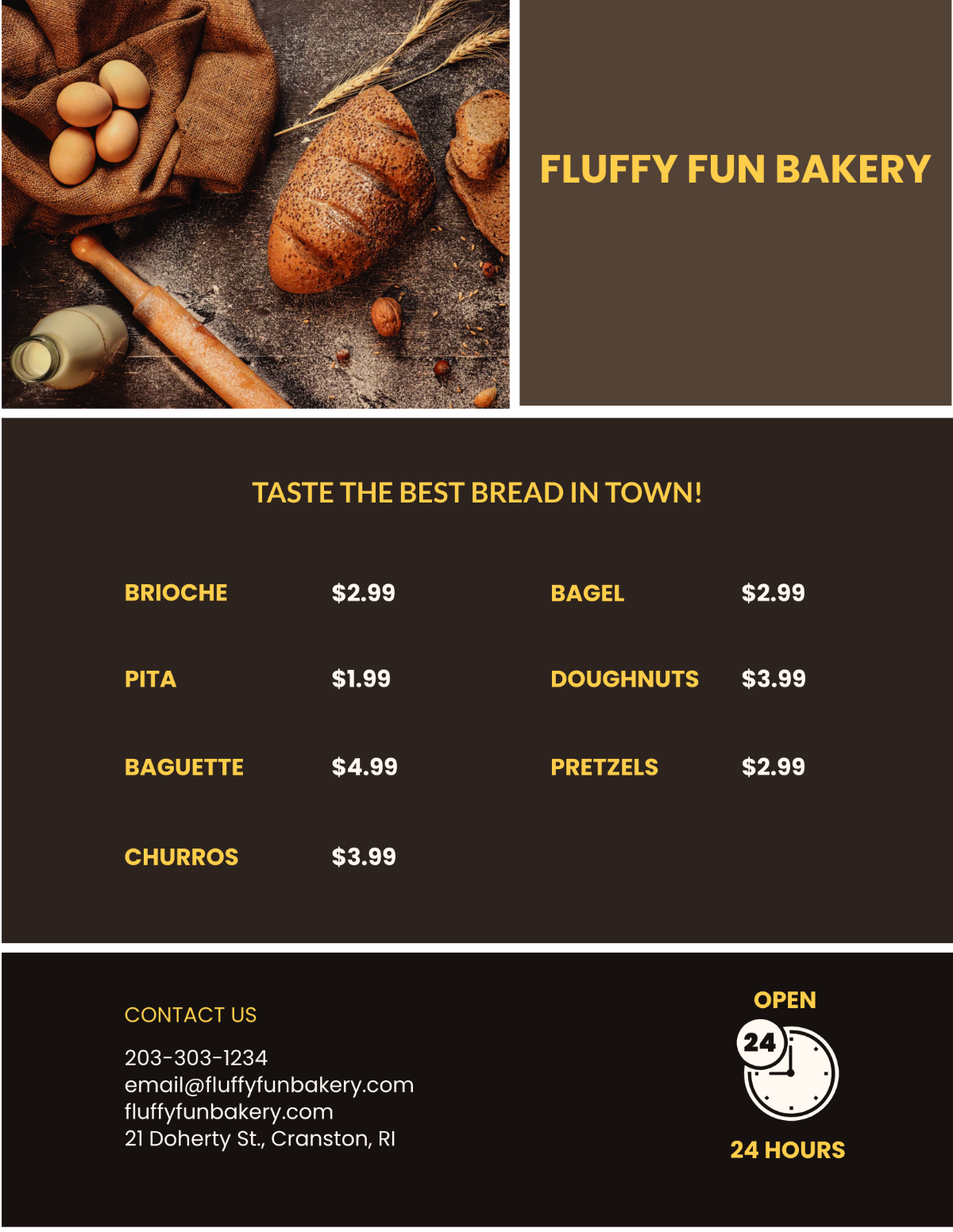

Display Case Cleanliness

Display cases should be cleaned daily to remove any debris, spills, or fingerprints. This includes wiping down shelves, glass surfaces, and any other areas that come into contact with customers or products.

Temperature-controlled display units should be monitored regularly to ensure they are operating at safe temperatures. This includes checking the temperature settings and ensuring that cooling units are functioning properly.

Customer Interaction

Employees should use tongs or gloves when handling items for customers to avoid direct contact and minimize the risk of contamination. Tongs and gloves should be sanitized regularly to maintain hygiene.

Hand sanitizers should be available for both staff and customers. Staff should use hand sanitizers between interactions with customers and after handling money, while customers should be encouraged to use hand sanitizers before touching the products.

VII. Waste Management

A. Daily Waste Disposal

Proper Waste Segregation

Waste should be segregated into recyclable, non-recyclable, and organic waste categories. Clearly labeled bins should be provided for each type of waste, and staff should be trained on proper waste segregation practices.

Bins should be emptied regularly throughout the day to prevent overflow and reduce the risk of odors and pests. Waste bins should be placed in convenient locations to encourage proper disposal by employees and customers.

Timely Removal

Waste should be removed from the bakery premises at regular intervals to prevent the buildup of odors and pests. This includes disposing of waste generated during food preparation, packaging, and customer interactions.

All waste bins should be cleaned and sanitized daily to maintain hygiene and prevent contamination. Proper waste management practices help in maintaining a clean and sanitary environment.

B. Sustainable Practices

Minimizing Waste

Efforts should be made to minimize waste by accurately measuring ingredients and planning production schedules to match customer demand. This includes adjusting recipes and production quantities to reduce excess.

Surplus food that is safe to consume can be donated to local charities or food banks. This not only helps in reducing waste but also supports the community and contributes to social responsibility.

Eco-friendly Packaging

Use recyclable or biodegradable packaging materials to reduce environmental impact. Packaging materials should be chosen based on their sustainability and environmental impact, with a focus on minimizing waste.

Encourage customers to bring their own containers or bags when purchasing products. This practice helps in reducing the use of single-use packaging and promotes environmentally friendly behavior.

VIII. Training and Compliance

A. Staff Training

Initial Training

New employees should undergo comprehensive training on bakery hygiene practices before starting work. This training should cover all aspects of personal hygiene, cleaning procedures, ingredient handling, and waste management.

Training sessions should include practical demonstrations and hands-on activities to ensure employees understand and can apply the hygiene practices effectively.

Ongoing Education

Regular refresher courses should be conducted to keep staff updated on the latest hygiene practices, regulations, and industry standards. This includes reviewing any changes in health regulations and incorporating new hygiene techniques.

Training sessions should include assessments and evaluations to ensure that staff are knowledgeable and compliant with hygiene standards. Feedback should be provided to employees to address any areas needing improvement.

B. Compliance and Monitoring

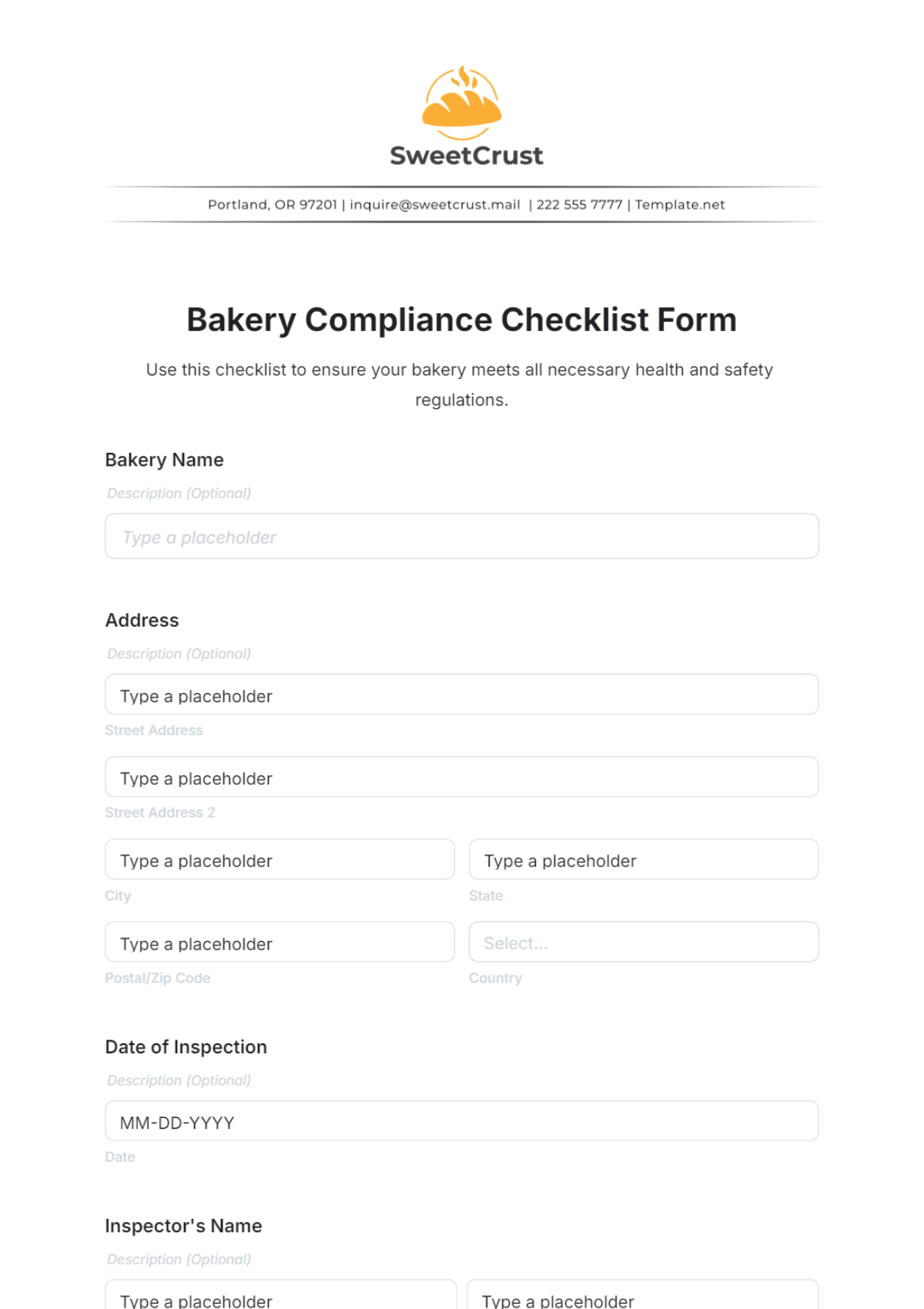

Regular Inspections

Internal audits should be conducted regularly to ensure compliance with hygiene guidelines. These inspections should cover all areas of the bakery, including food preparation, storage, and waste management.

Any non-compliance issues identified during inspections should be addressed immediately with corrective actions. Follow-up inspections should be conducted to verify that corrective measures have been implemented effectively.

Record Keeping

Detailed records of cleaning schedules, equipment maintenance, temperature logs, and staff training should be maintained. These records help in tracking adherence to hygiene practices and identifying areas for improvement.

Records should be reviewed regularly to ensure that all procedures are being followed correctly. Documentation should be kept organized and accessible for review during inspections and audits.

IX. Appendices

Appendix A: Additional Resources

This section provides supplementary materials and references that support the main content of the Bakery Hygiene Guidelines. It includes industry standards, regulatory documents, and other helpful resources.

1. Industry Standards

Food Safety and Hygiene Regulations:

Comprehensive regulations covering all aspects of food safety and hygiene, including requirements for bakeries.

FDA Guidelines for Bakeries:

Specific guidelines tailored for bakeries to ensure compliance with federal standards.

ISO 22000:2018 Food Safety Management Systems:

An international standard that specifies requirements for a food safety management system, applicable to all organizations in the food chain.

Appendix B: Glossary of Terms

This section defines key terms used throughout the Bakery Hygiene Guidelines. Understanding these terms is crucial for ensuring compliance and effective implementation of hygiene practices.

1. Sanitation

The process of maintaining a clean and hygienic environment to prevent contamination and ensure safety. Includes both cleaning and disinfecting practices.

2. Cross-Contamination

The transfer of harmful microorganisms from one surface or food item to another, often due to improper handling or inadequate cleaning. This can occur via utensils, hands, or surfaces.

3. HACCP (Hazard Analysis and Critical Control Points)

A systematic approach to food safety that identifies, evaluates, and controls hazards at critical points in the food production process. This methodology helps ensure the safety of food products.

4. PPE (Personal Protective Equipment)

Gear worn by employees to protect against health and safety risks. This includes items such as gloves, masks, aprons, and hairnets, which help maintain hygiene and prevent contamination.

5. Compliance

Adhering to regulatory requirements, industry standards, and internal policies to ensure safe and hygienic practices in the bakery.

Appendix C: Frequently Asked Questions (FAQs)

This section addresses common questions related to bakery hygiene practices, providing clarity and additional information for bakery staff and management.

1. What are the key hygiene practices for bakery staff?

Key practices include regular hand washing, wearing appropriate PPE, and maintaining clean work surfaces and equipment. Staff should also follow strict protocols for handling food and cleaning procedures.

2. How often should cleaning and sanitization be performed?

Cleaning should be done frequently throughout the day, especially after handling raw ingredients or cleaning spills. Sanitization should be performed at least once daily or more often if necessary, especially on high-touch surfaces.

3. What steps should be taken in the event of a contamination incident?

Immediate actions include isolating the affected area, informing management, conducting a thorough cleaning and sanitization, and investigating the cause of contamination. Document the incident and review procedures to prevent recurrence.

4. Are there specific guidelines for handling allergens?

Yes, allergen management includes proper labeling of allergen-containing products, segregating these products to avoid cross-contact, and thorough cleaning of surfaces and equipment to prevent cross-contamination.

5. How can staff be trained on hygiene practices?

Staff training can be conducted through formal training programs, workshops, and regular refresher courses. Training should cover hygiene standards, proper use of PPE, and procedures for cleaning and sanitizing.