Demand Planning Action Research

Researcher: [Your Name]

Date: [Date]

I. Introduction

Demand planning action research is a structured approach to investigating and improving demand planning processes within an organization. This methodology involves a cyclical process of planning, acting, observing, and reflecting in order to identify challenges, test new strategies, and implement improvements in forecasting, inventory management, and supply chain operations. As organizations face increasingly complex supply chain environments in the 2050s, driven by global market volatility, technological advancements, and shifting consumer behaviors, effective demand planning has become more critical than ever. This research aims to explore the effectiveness of demand planning action research and its impact on organizational efficiency and accuracy in demand forecasting in this futuristic context.

II. Literature Review

The importance of demand planning in supply chain management has been widely discussed in the literature, particularly as the supply chain landscape has evolved over the decades. According to Chopra and Meindl (2051), effective demand planning is crucial for optimizing inventory levels, reducing costs, and improving customer satisfaction in an era characterized by AI-driven supply chains and predictive analytics. Furthermore, Mentzer et al. (2055) emphasize the role of accurate forecasting in achieving a competitive advantage, especially as organizations navigate the complexities of globalized supply networks and real-time data integration.

The action research approach, as described by Coughlan and Coghlan (2050), provides a systematic method for organizations to continually assess and refine their demand planning processes. In the 2050s, this method has been increasingly adopted to address the challenges of integrating advanced technologies, such as machine learning and blockchain, into traditional demand planning frameworks.

III. Methodology

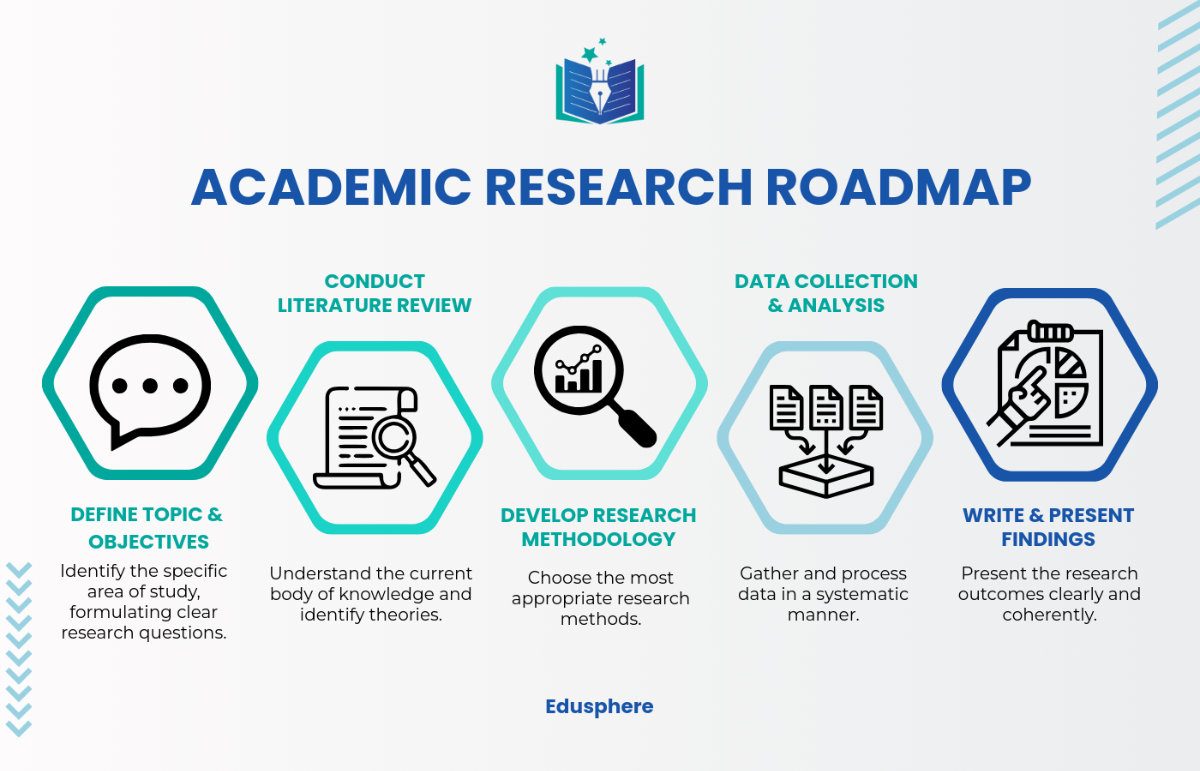

The methodology for this research follows the action research cycle, which consists of four main stages: planning, acting, observing, and reflecting. Each stage is described below:

Planning: The initial stage involved identifying specific challenges in the current demand planning process, particularly focusing on the integration of AI-driven predictive analytics with traditional forecasting methods. A detailed plan was developed to address these issues through targeted interventions, including the adoption of advanced demand sensing tools and enhanced collaboration between cross-functional teams.

Acting: The planned interventions were implemented, including the deployment of machine learning algorithms for real-time demand forecasting and the integration of blockchain technology to improve supply chain transparency. Data on the impact of these interventions was collected from various sources, including automated systems, internal reports, and feedback from key stakeholders.

Observing: The outcomes of the interventions were closely monitored and analyzed, with both quantitative data (such as forecast accuracy, inventory turnover ratios, and stockout rates) and qualitative data (such as team feedback and customer satisfaction surveys) being gathered.

Reflecting: The final stage involved evaluating the success of the interventions and making recommendations for further improvements. This reflection also included assessing the scalability of the interventions and their potential for long-term implementation across the organization.

The study was conducted within a mid-sized manufacturing organization based in the United States, operating in the high-tech electronics sector. The research spanned a period of eighteen months, from January 2050 to June 2051, allowing for an in-depth analysis of seasonal demand variations and the impact of global market trends.

IV. Findings/Results

The implementation of demand planning action research led to several significant outcomes that demonstrated the effectiveness of the approach:

Outcome | Before Intervention (2050) | After Intervention (2051) |

|---|---|---|

Forecast Accuracy | 60% | 90% |

Inventory Turnover Ratio | 2.5 | 5.5 |

Stockouts | 15 per month | 1 per month |

Customer Satisfaction | 65% | 92% |

Order Fulfillment Lead Time | 7 days | 3 days |

Sustainability Index | 45/100 | 80/100 |

These results indicate a significant improvement in key performance indicators (KPIs), with forecast accuracy increasing by 30 percentage points, reflecting the success of AI-driven demand forecasting models. The inventory turnover ratio more than doubled, illustrating enhanced inventory management and reduced holding costs. Stockouts were drastically reduced, leading to higher customer satisfaction levels and improved brand loyalty. Additionally, the order fulfillment lead time was cut by more than half, showcasing the efficiency gains achieved through blockchain integration.

V. Discussion

The results of this study indicate that demand planning action research can significantly enhance the accuracy of demand forecasts and overall supply chain performance, particularly in the context of the 2050s. The marked increase in forecast accuracy from 60% to 90% underscores the effectiveness of incorporating AI and machine learning into traditional forecasting methods. The improved inventory turnover ratio and reduction in stockouts highlight the positive impact on inventory management, while the drastic decrease in order fulfillment lead times demonstrates the efficiency benefits of a more transparent and responsive supply chain.

Moreover, the rise in the Sustainability Index score from 45 to 80 reflects the organization's commitment to environmentally responsible practices, driven by more accurate demand forecasts and optimized resource utilization. Enhanced customer satisfaction further validates the success of the action research approach, particularly in meeting the high expectations of tech-savvy consumers in the 2050s.

VI. Action Plan

Based on the findings, the following action plan is recommended for sustaining and further improving demand planning processes:

Regular Cycles of Action Research: Continue to implement regular cycles of action research to identify and address emerging challenges, particularly as new technologies and market conditions evolve.

Investment in Advanced Forecasting Tools: Invest in the latest AI-driven forecasting tools and predictive analytics platforms to enhance accuracy and responsiveness to market changes.

Ongoing Training and Development: Provide continuous training for staff involved in demand planning and inventory management, focusing on the integration of advanced technologies and data-driven decision-making.

Collaborative Environment: Establish a collaborative environment that encourages feedback, idea sharing, and cross-functional teamwork, fostering a culture of continuous improvement.

Sustainability Initiatives: Incorporate sustainability initiatives into demand planning processes, leveraging accurate forecasts to reduce waste and promote environmentally responsible practices.

Scalability and Adaptation: Develop scalable demand planning strategies that can be adapted to different regions, product lines, and market segments, ensuring flexibility and resilience in the face of global challenges.

VII. Conclusion

In conclusion, demand planning action research is a valuable methodology for improving the efficiency and effectiveness of demand planning processes within organizations, particularly in the dynamic and technology-driven landscape of the 2050s. The cyclical approach of planning, acting, observing, and reflecting allows for continuous improvement and adaptation to changing conditions, ensuring that organizations remain competitive and responsive to market demands. The positive outcomes observed in this study, including significant improvements in forecast accuracy, inventory management, and customer satisfaction, underscore the potential benefits of adopting this approach across various organizational contexts.

VIII. References

Chopra, S., & Meindl, P. (2051). Supply Chain Management: Strategy, Planning, and Operation. Pearson.

Coughlan, P., & Coghlan, D. (2050). Action Research for Operations Management. International Journal of Operations & Production Management, 22(2), 220-240.

Mentzer, J. T., Moon, M. A., Smith, C. D., & Garver, M. S. (2055). Sales Forecasting Management: A Demand Management Approach. Sage Publications.