Production Survey Descriptive Research

Prepared By: [Your Name]

Company Name: [Your Company Name]

1. Introduction

The Production Survey Descriptive Research provides an extensive analysis of production processes across different industries. Its primary purpose is to deliver a detailed description of manufacturing techniques, equipment used, and production volumes. By examining these factors, the research aims to uncover production trends, identify areas for improvement, and facilitate comparisons between various production practices. This research serves as a valuable tool for industry professionals, managers, and stakeholders seeking to enhance production efficiency and effectiveness.

2. Methodology

2.1 Survey Design

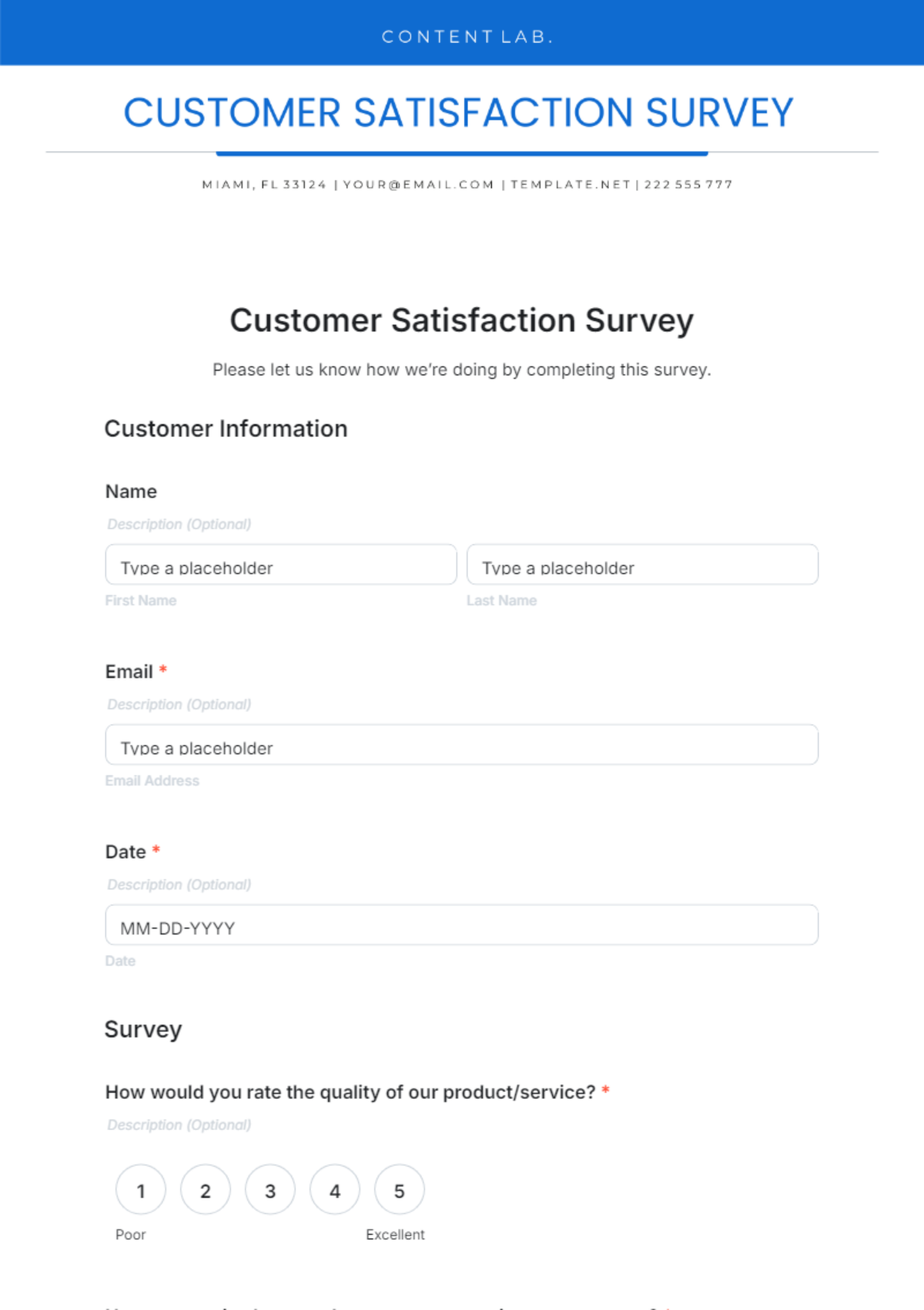

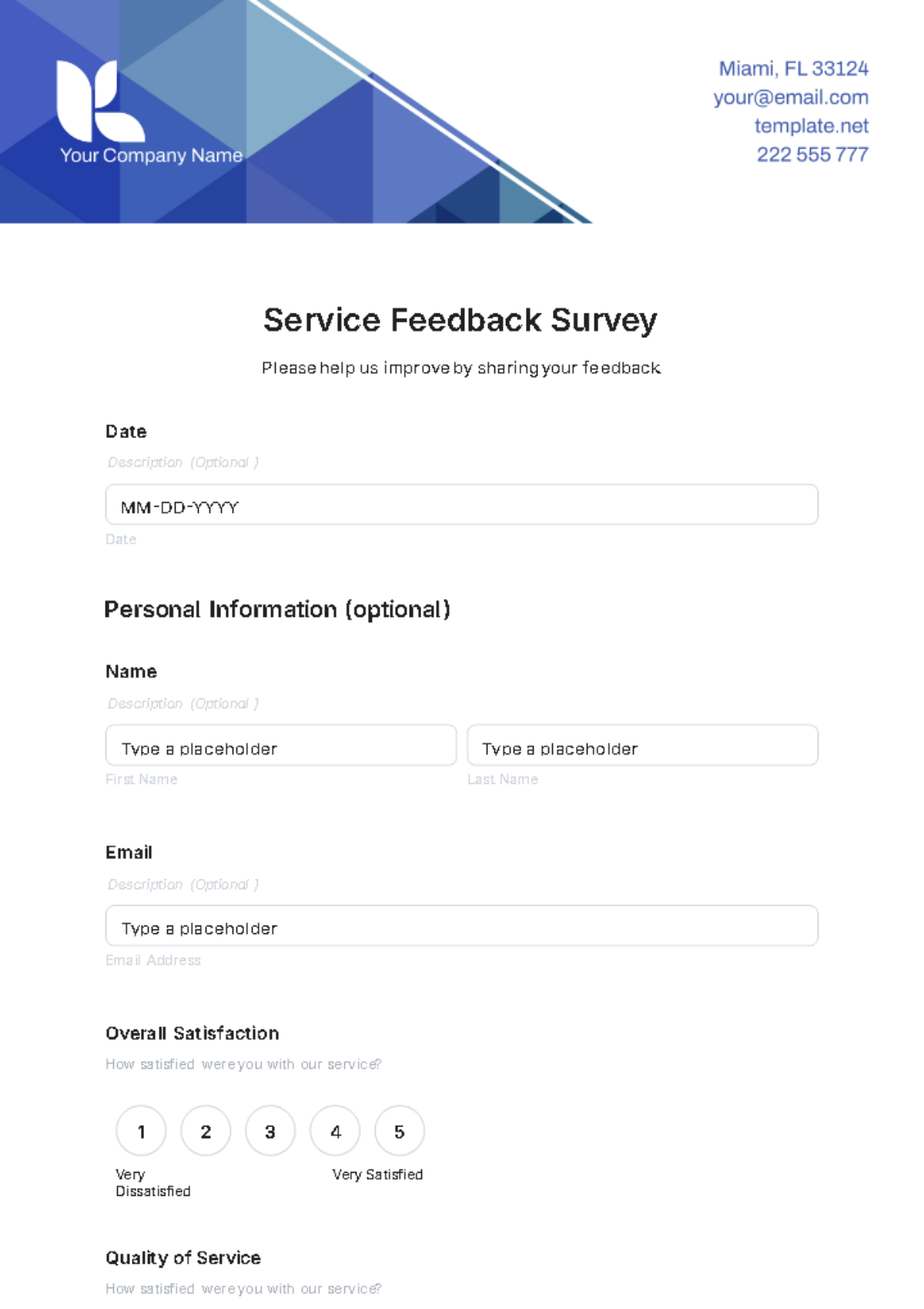

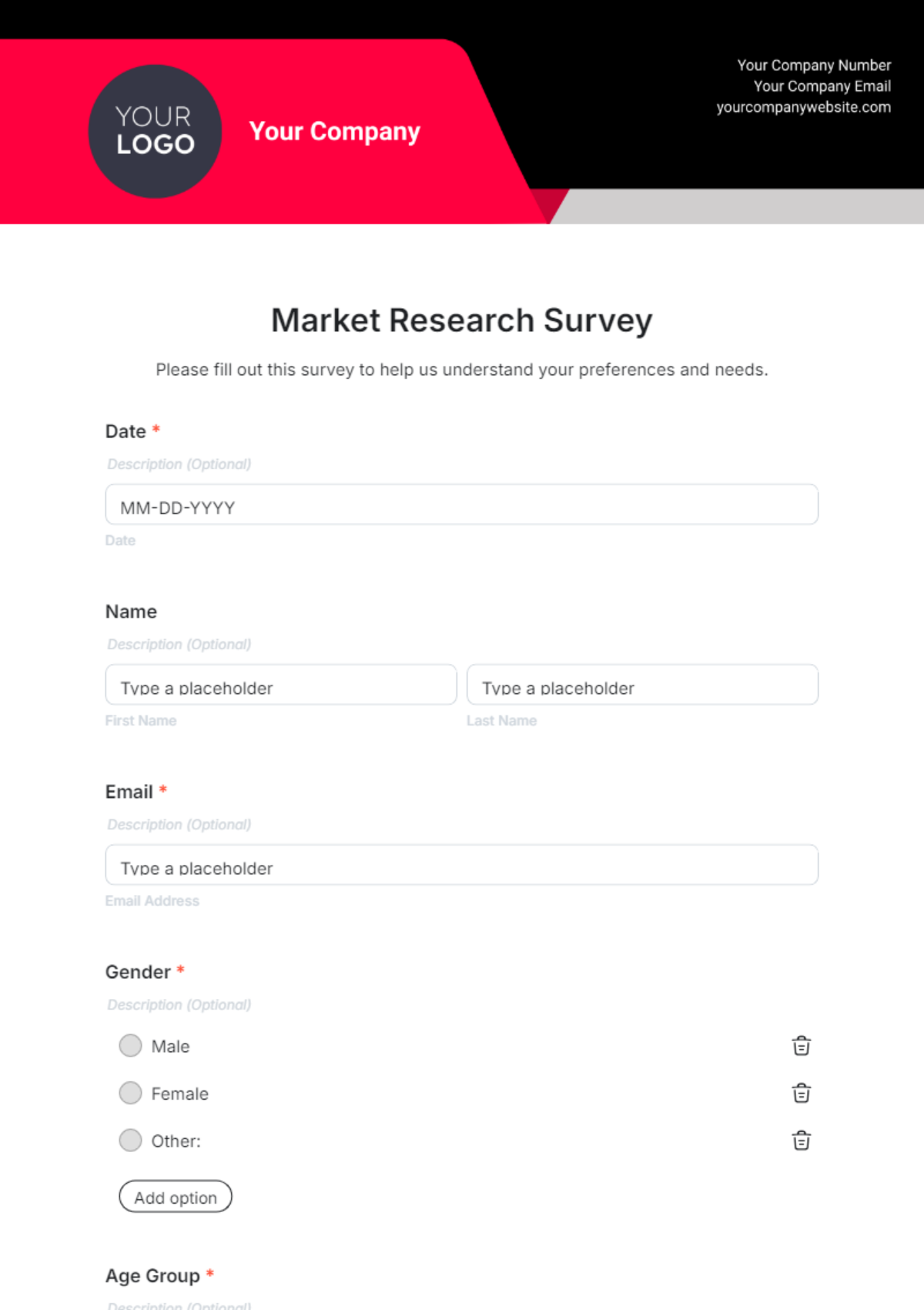

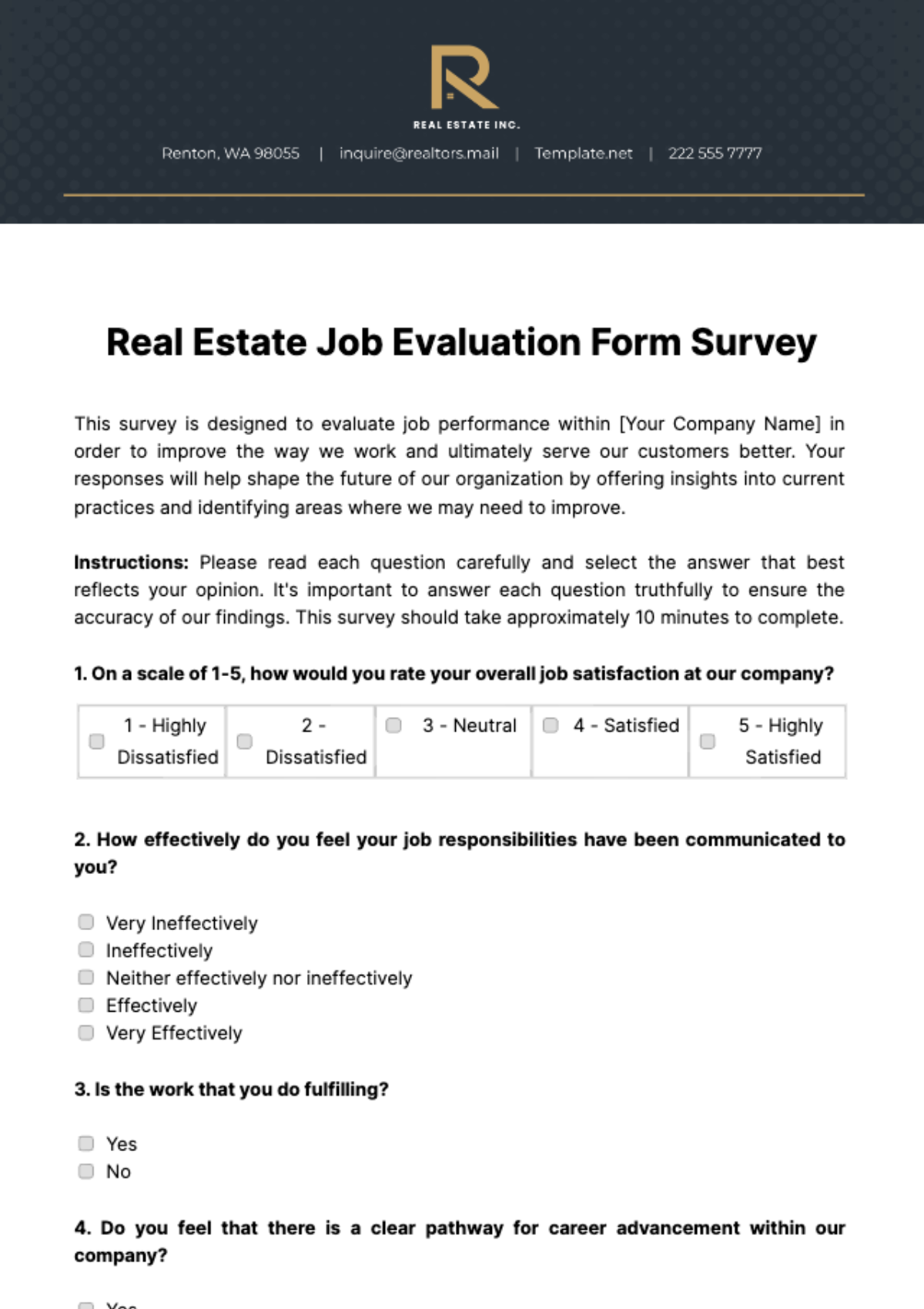

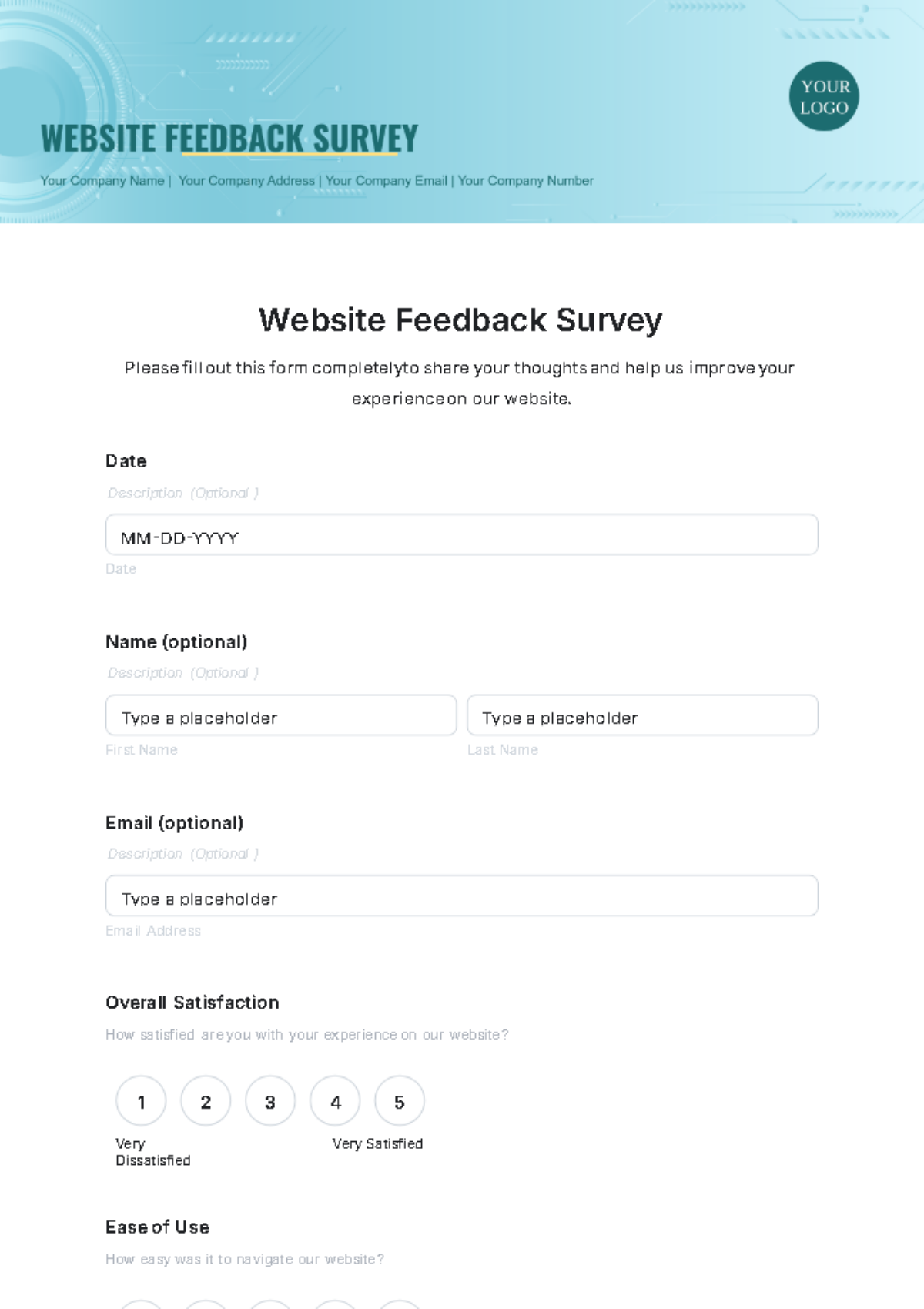

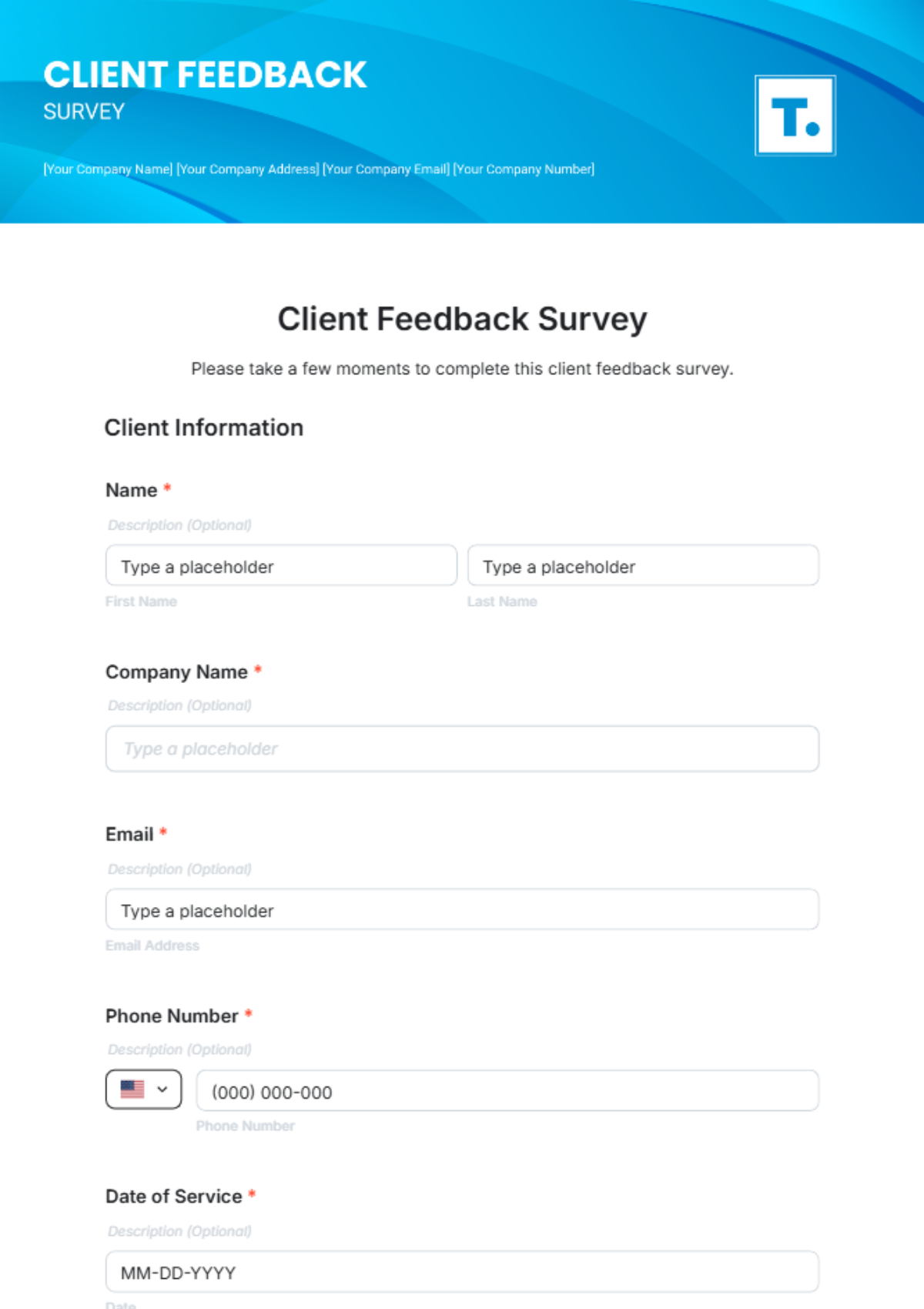

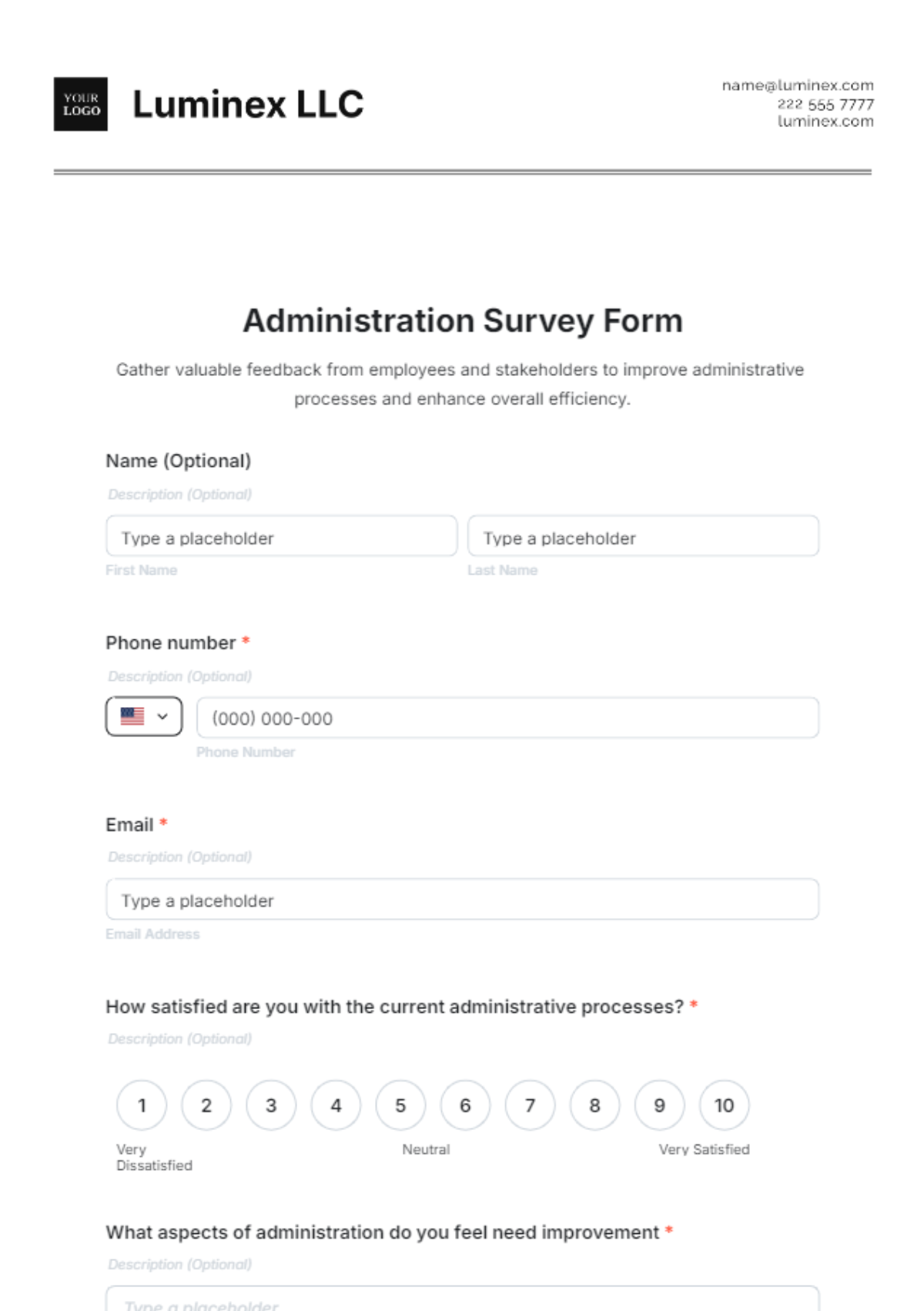

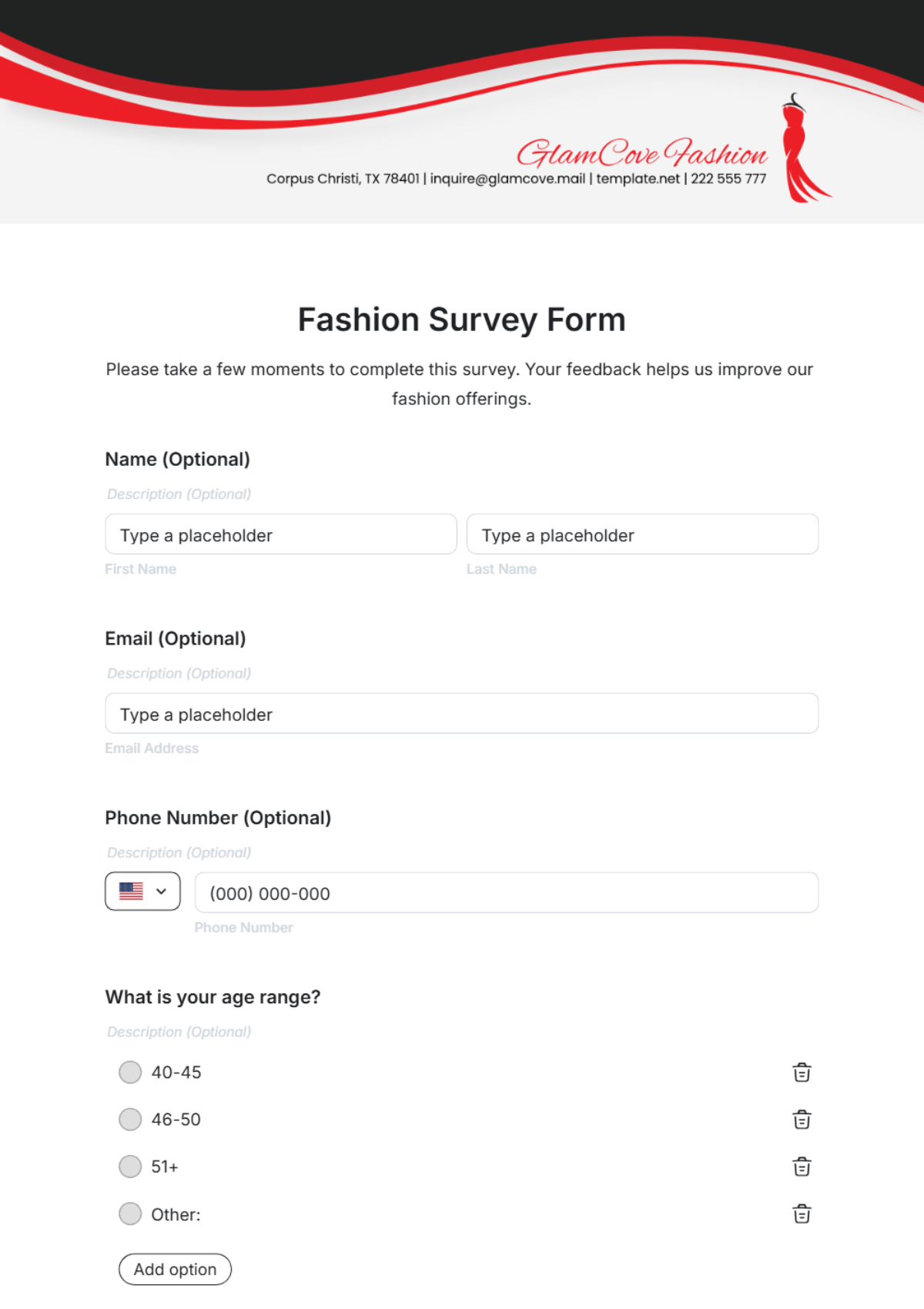

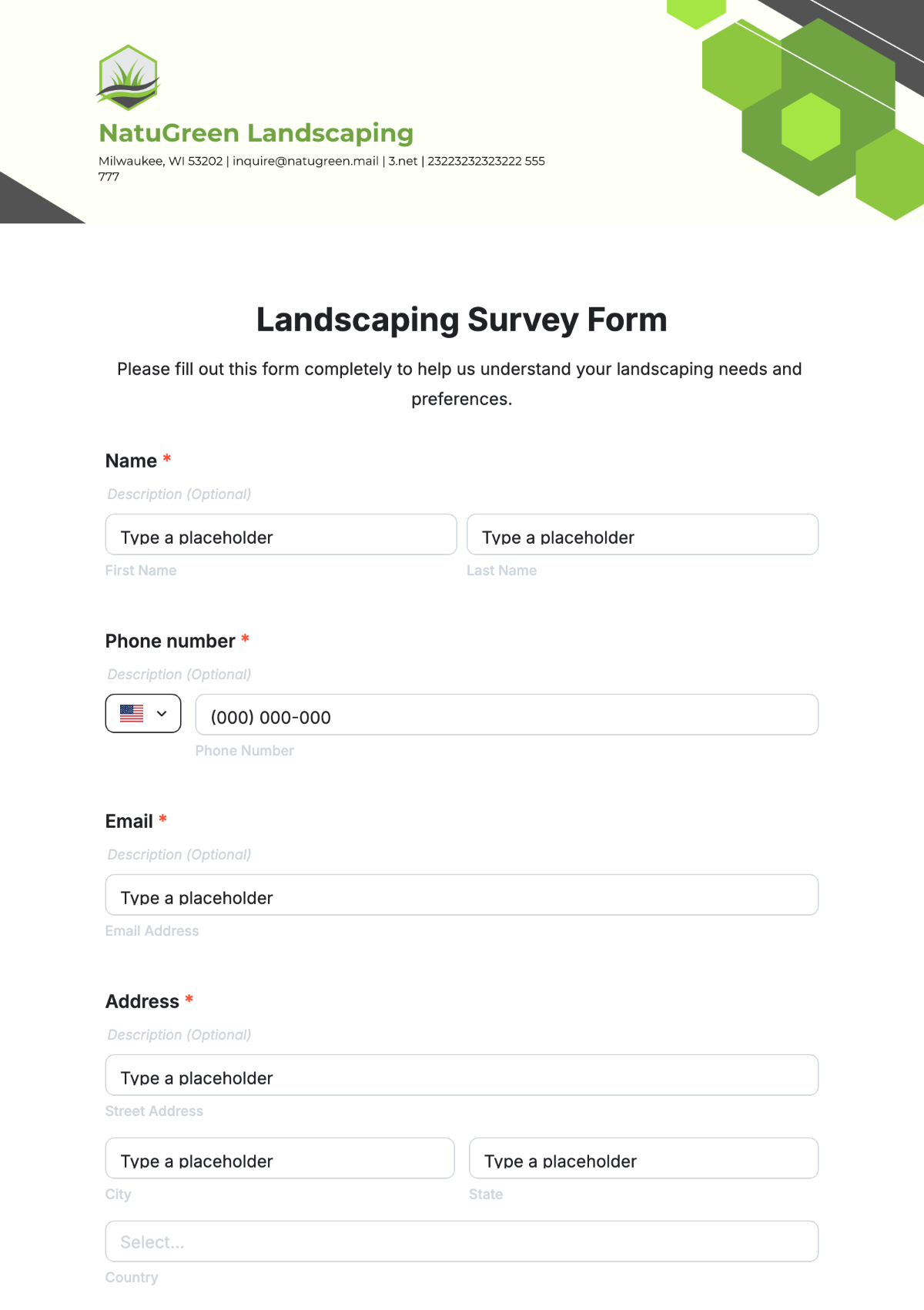

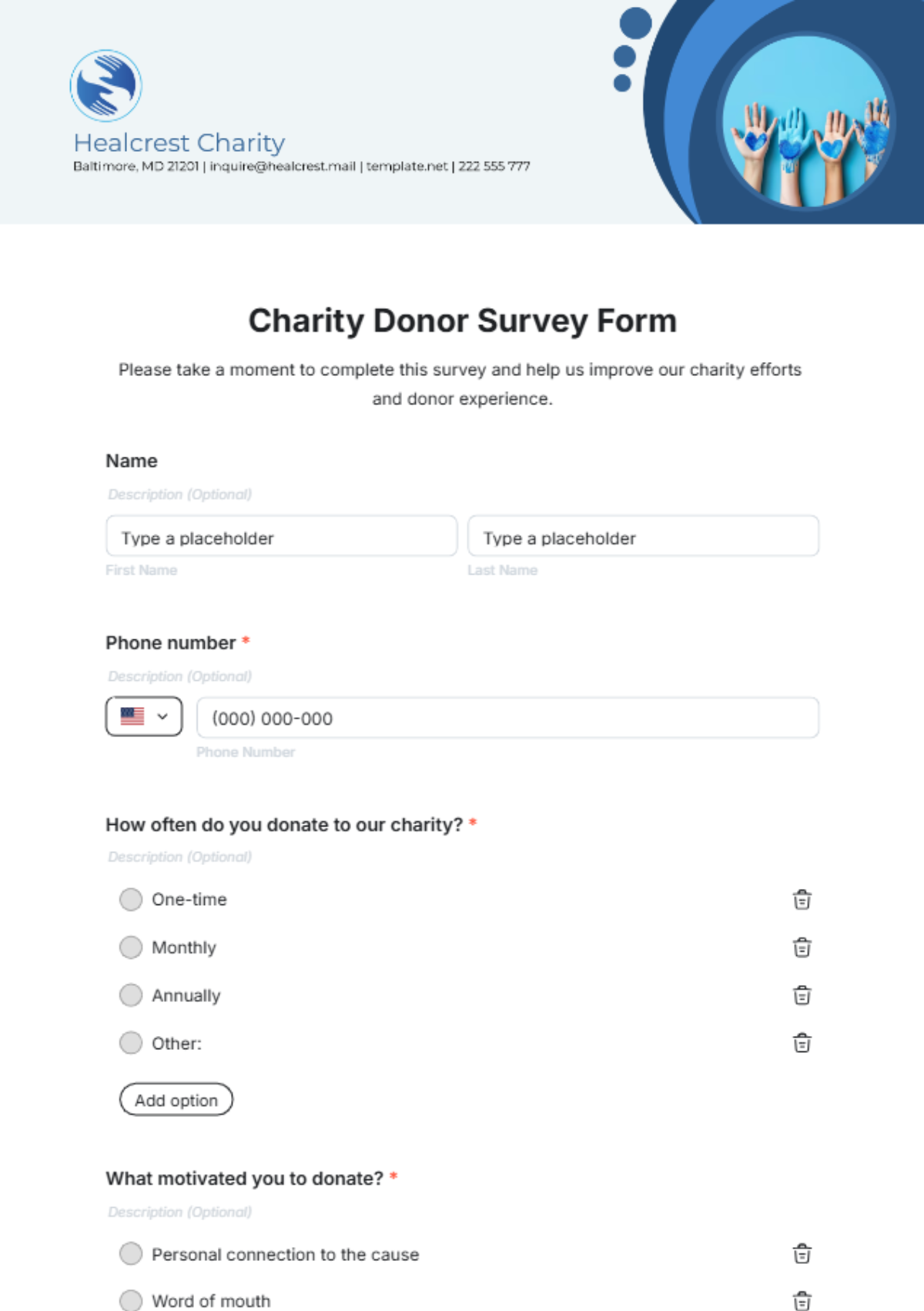

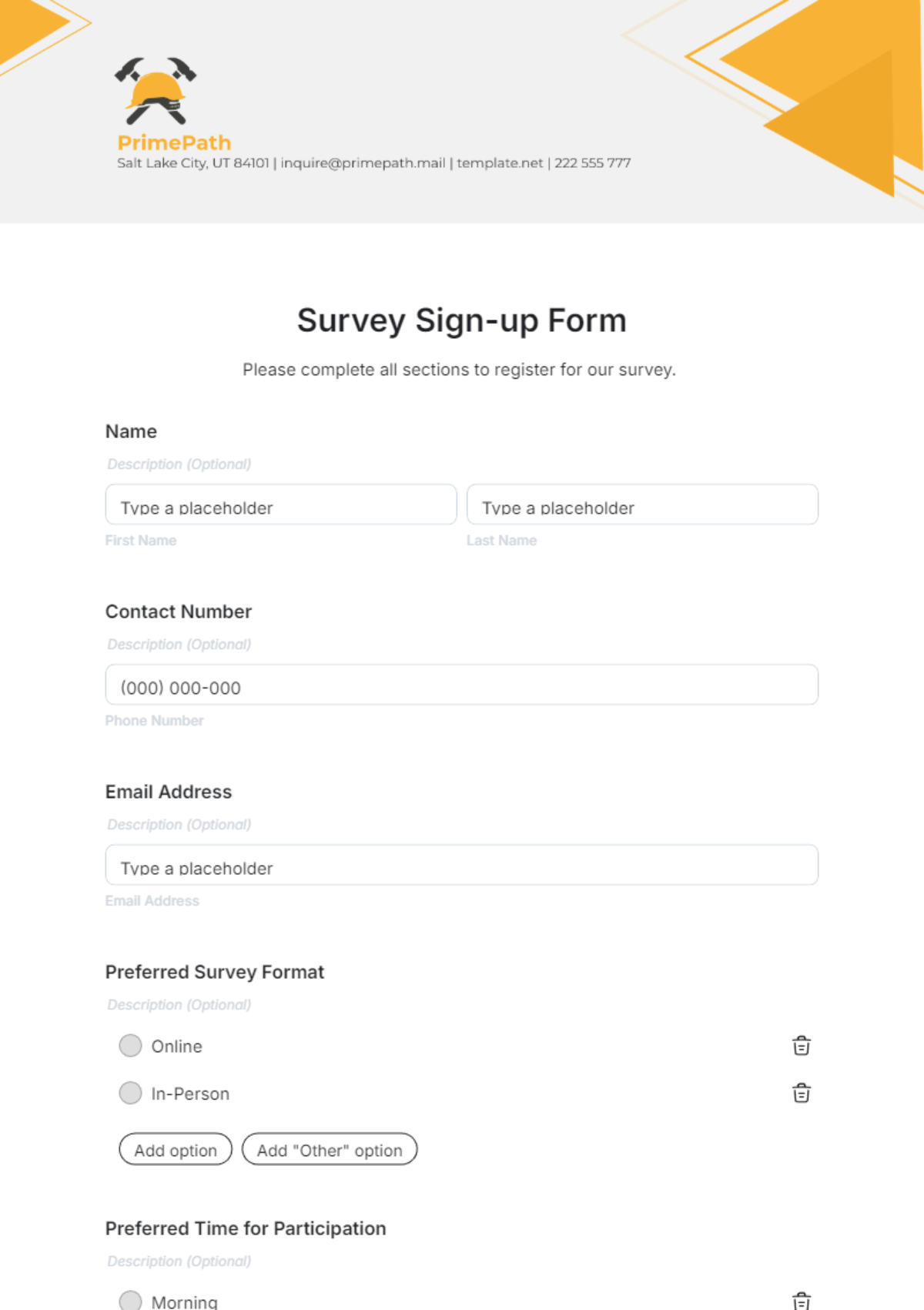

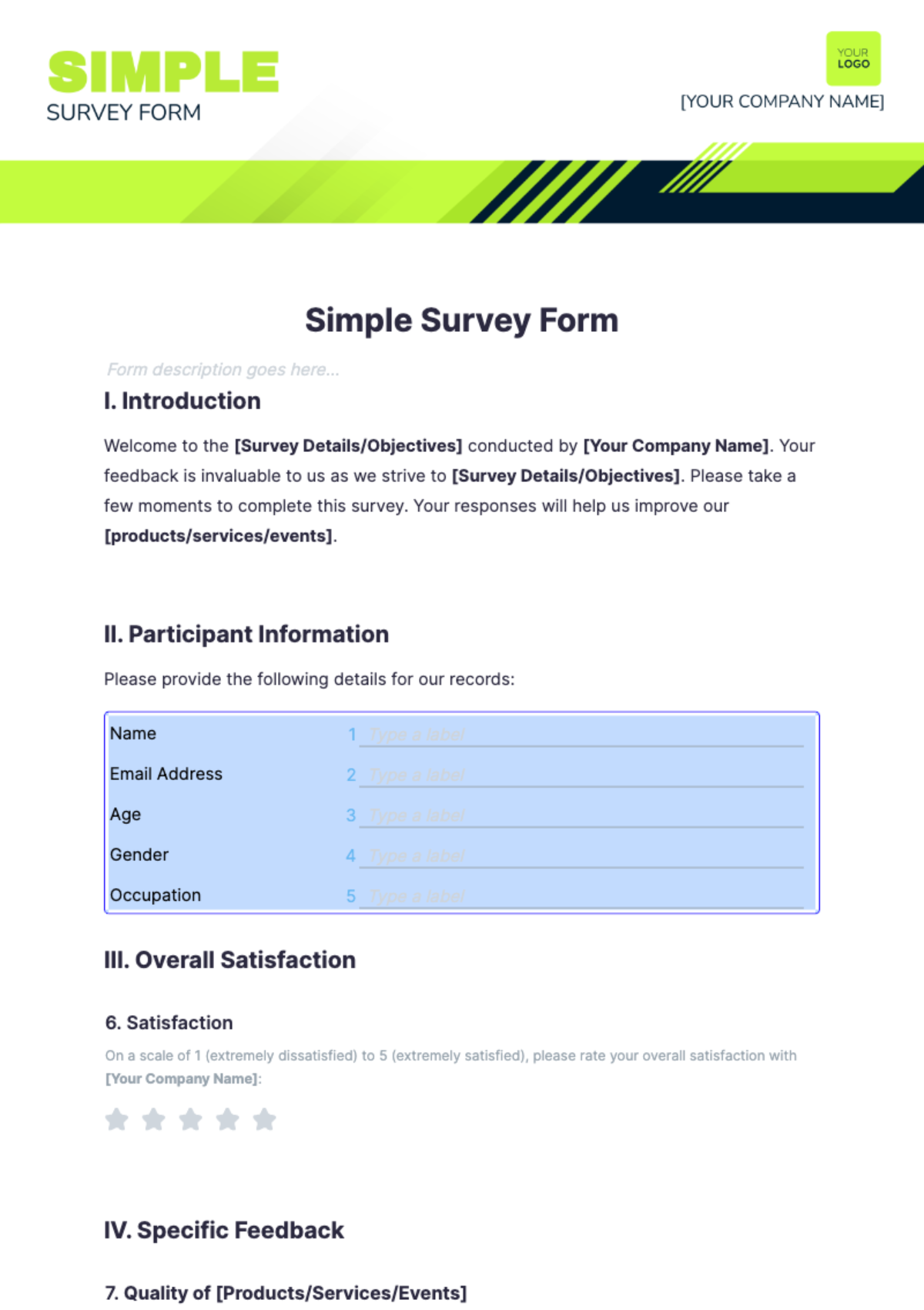

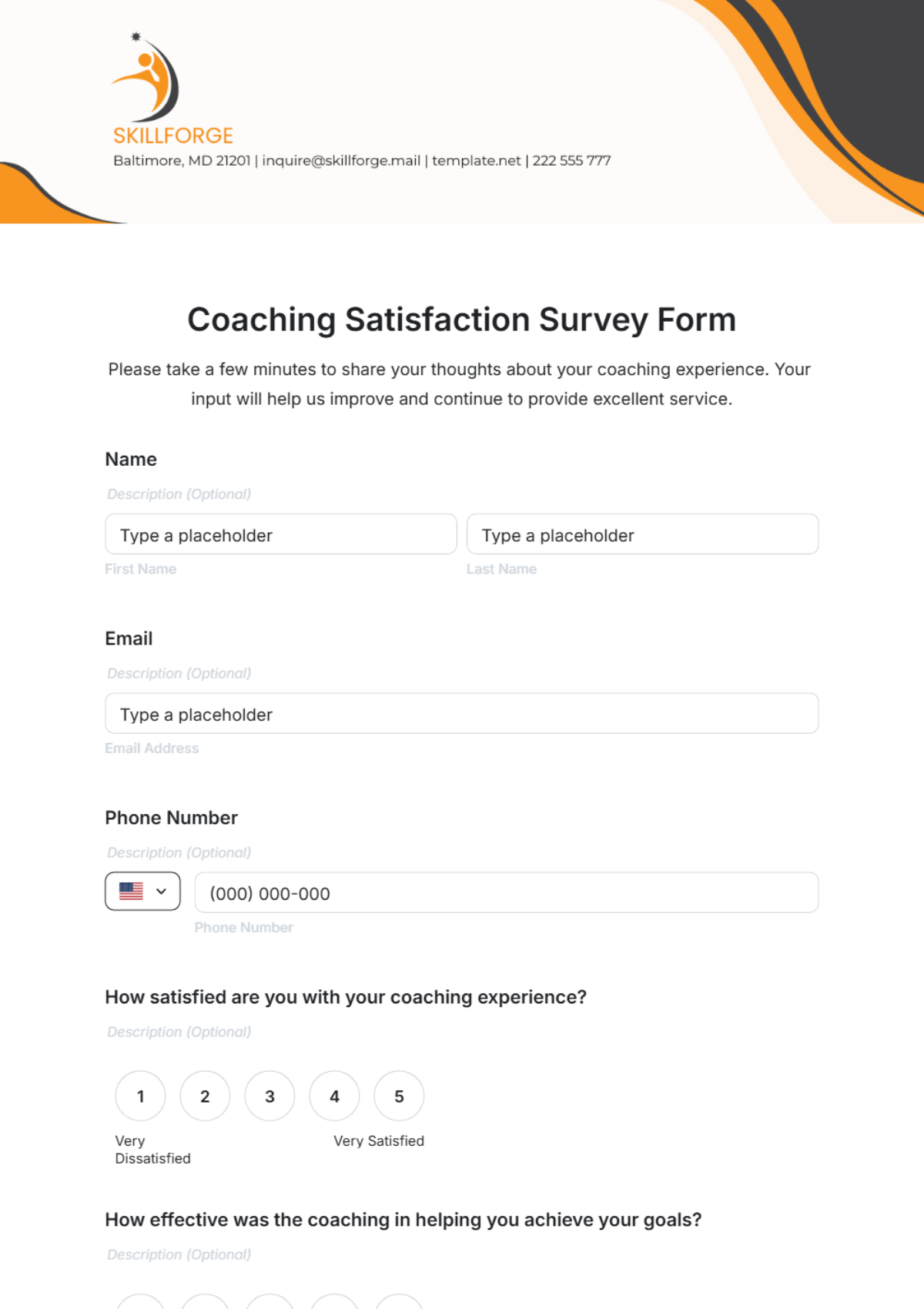

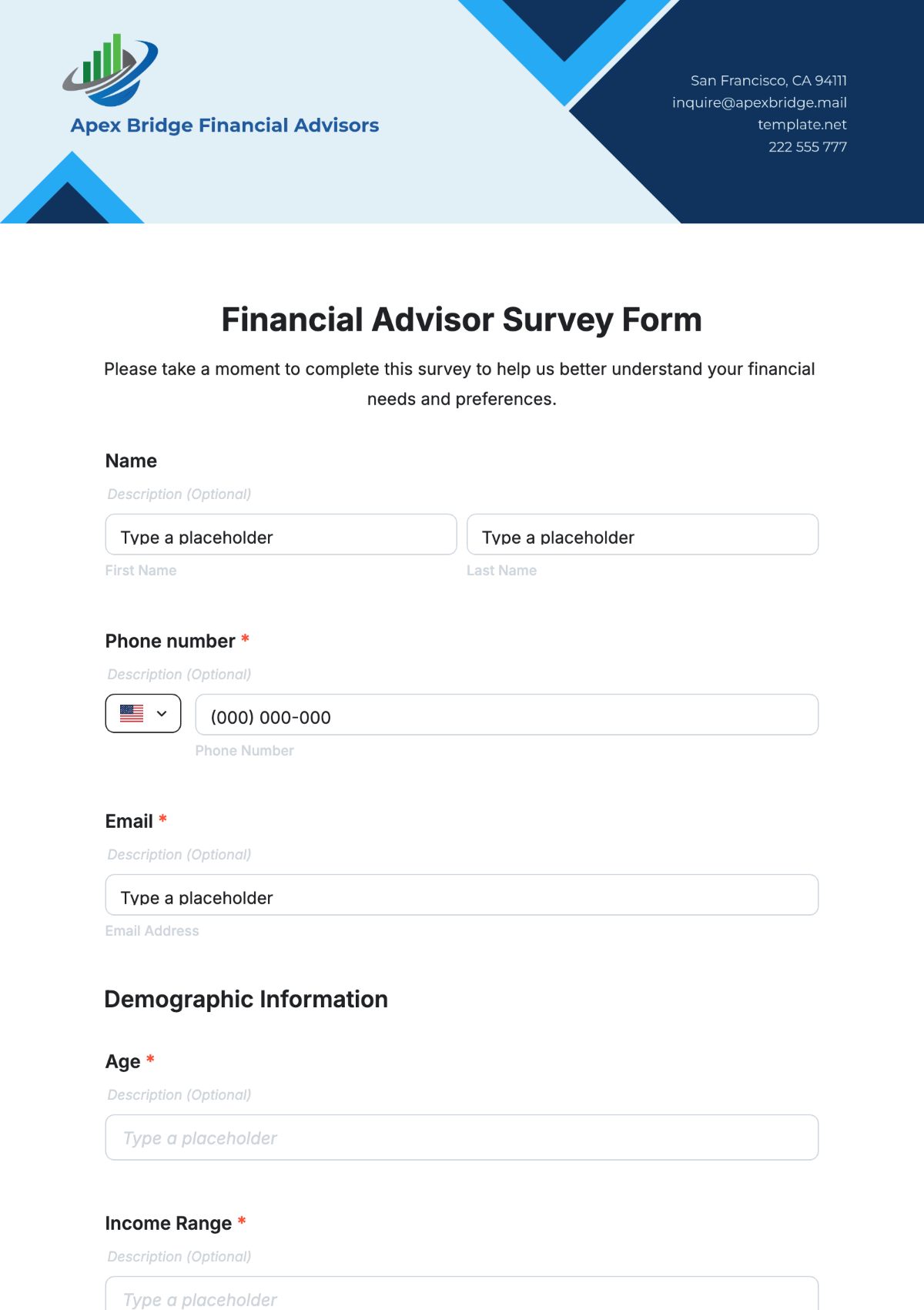

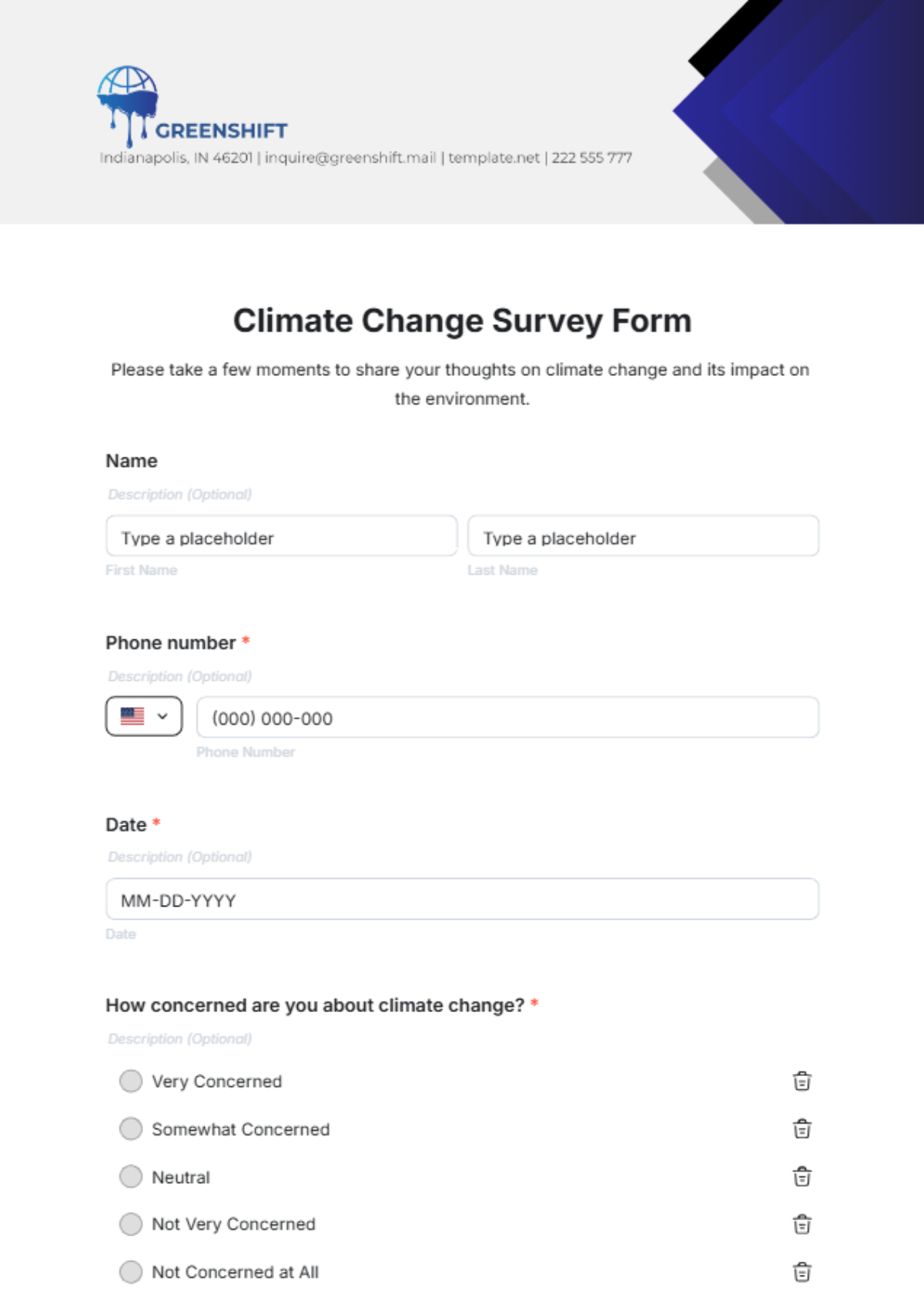

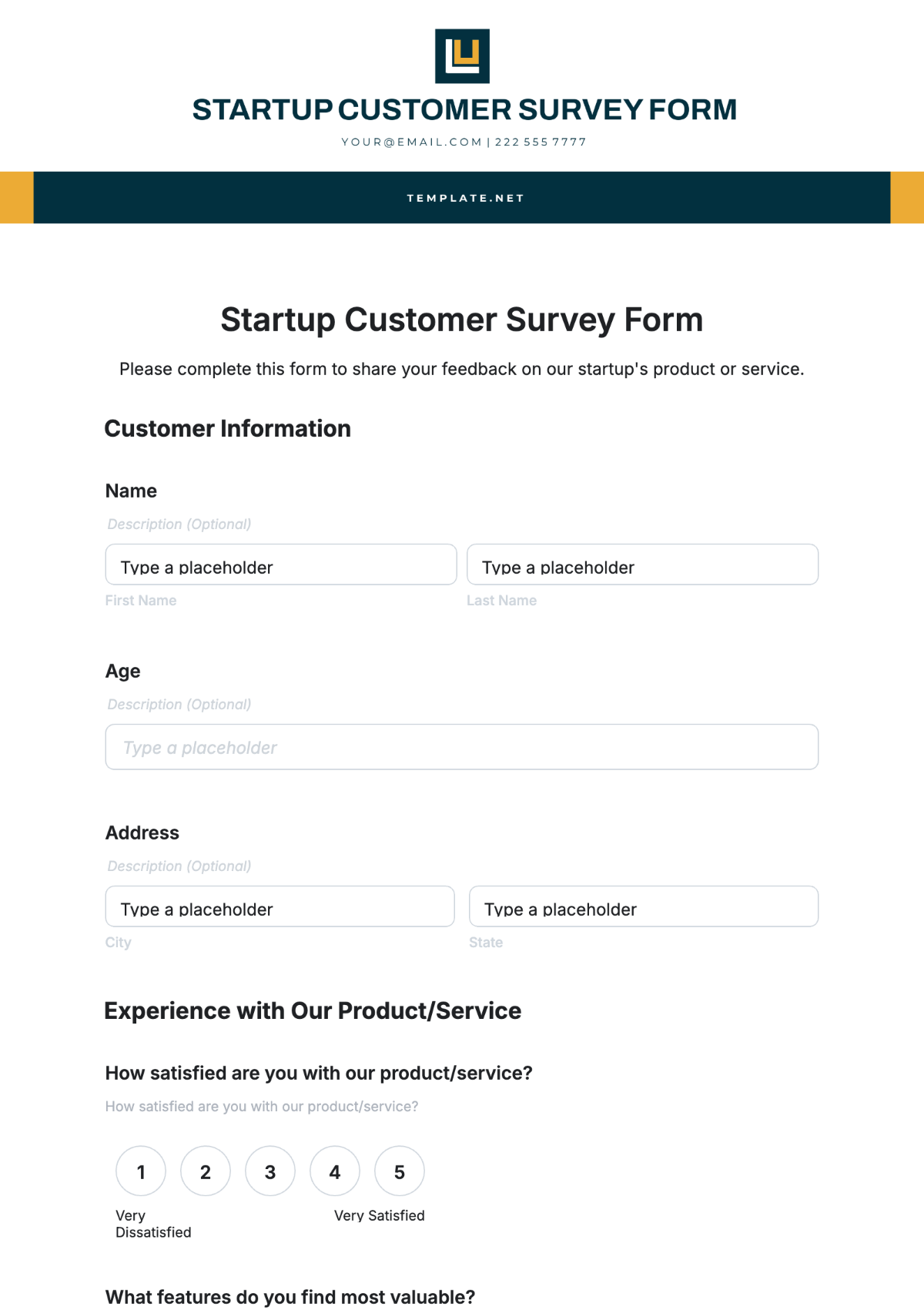

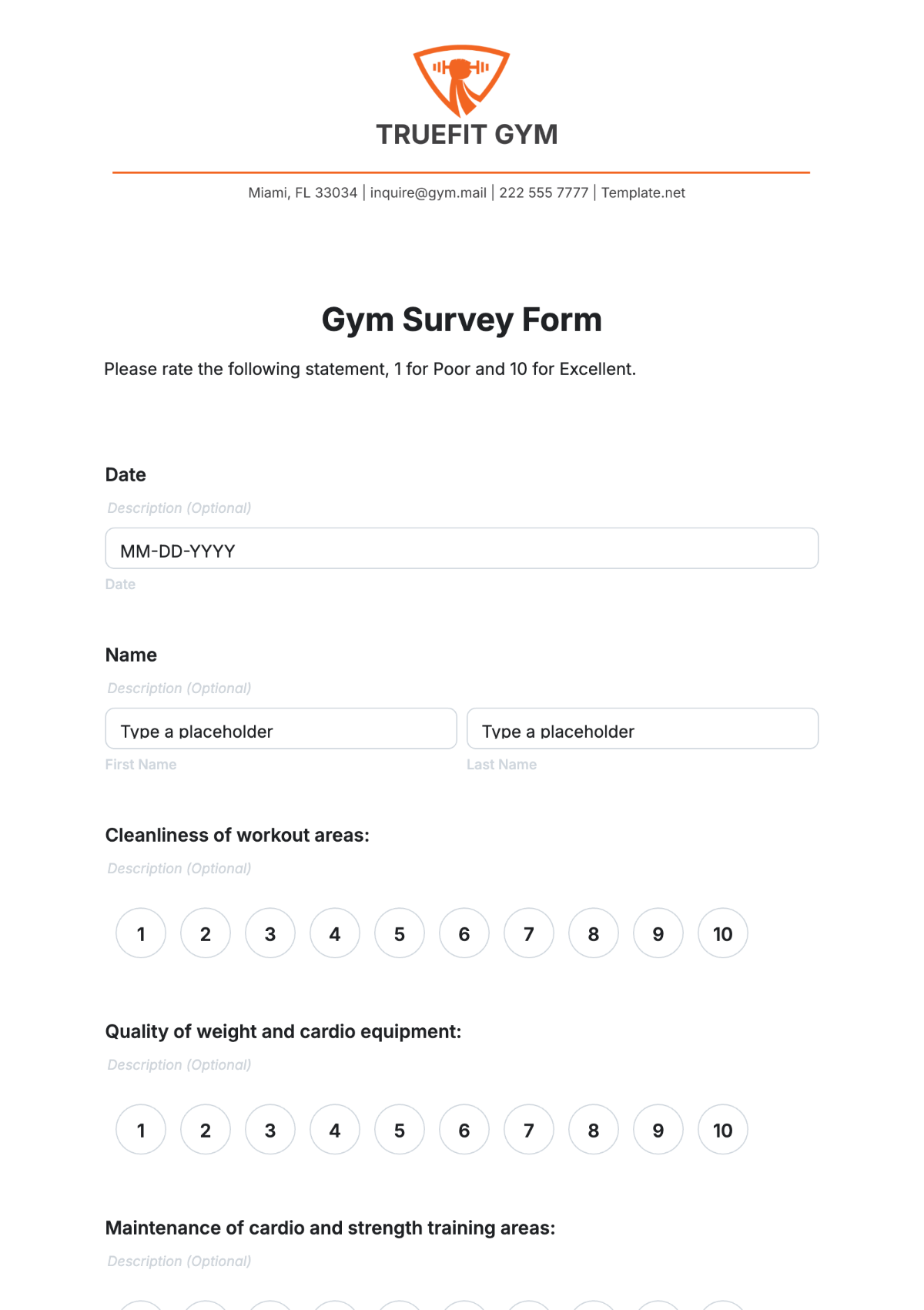

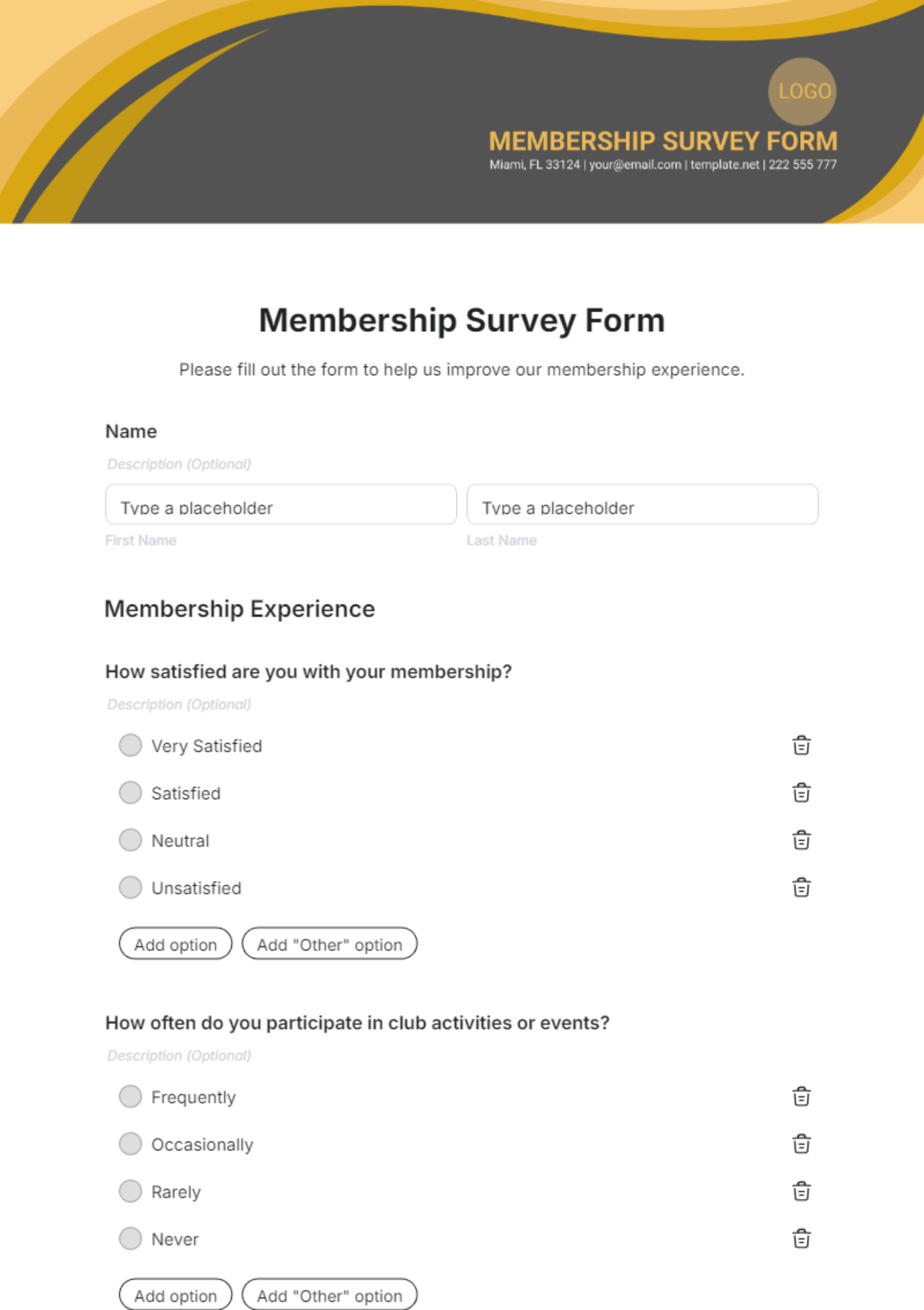

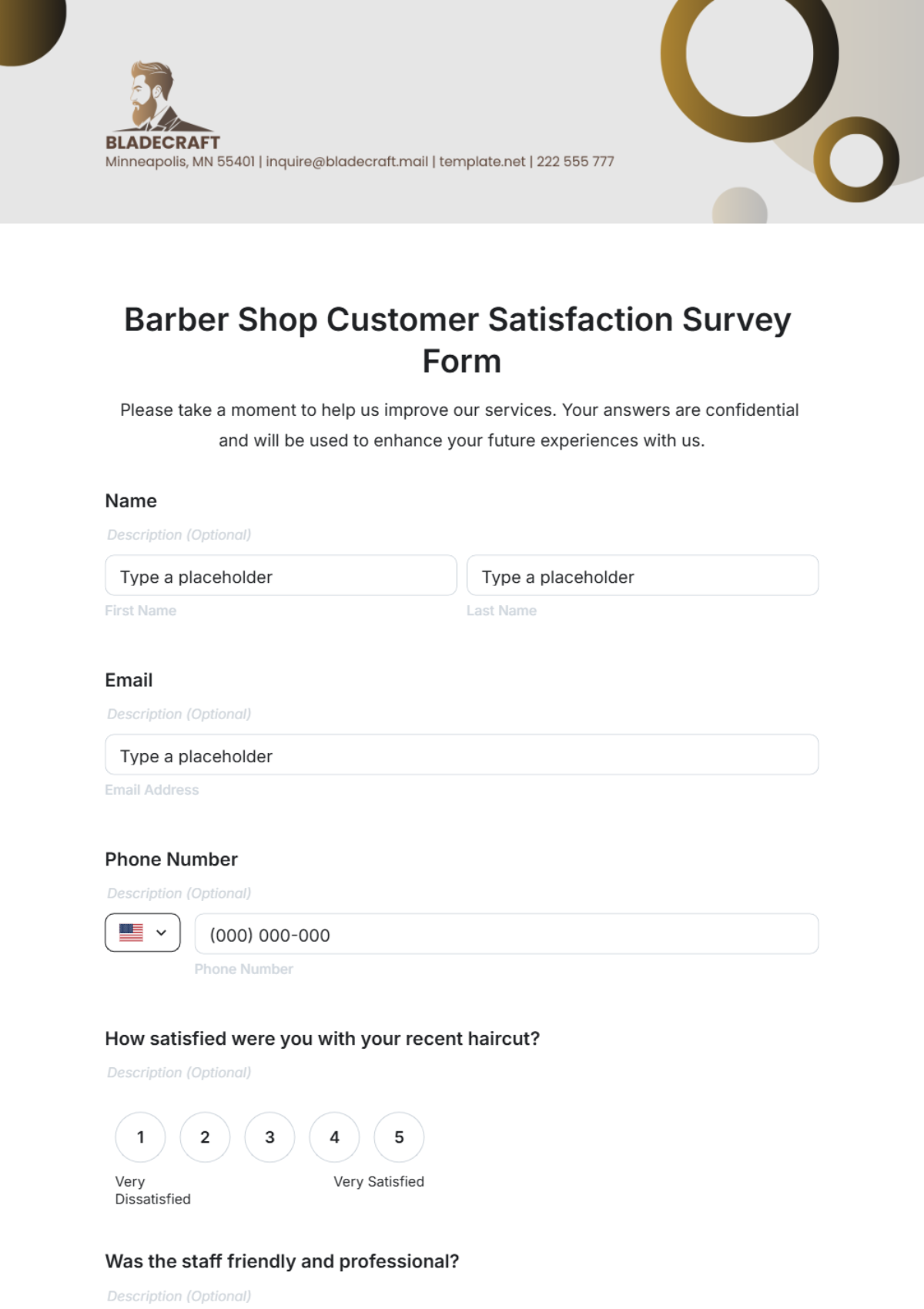

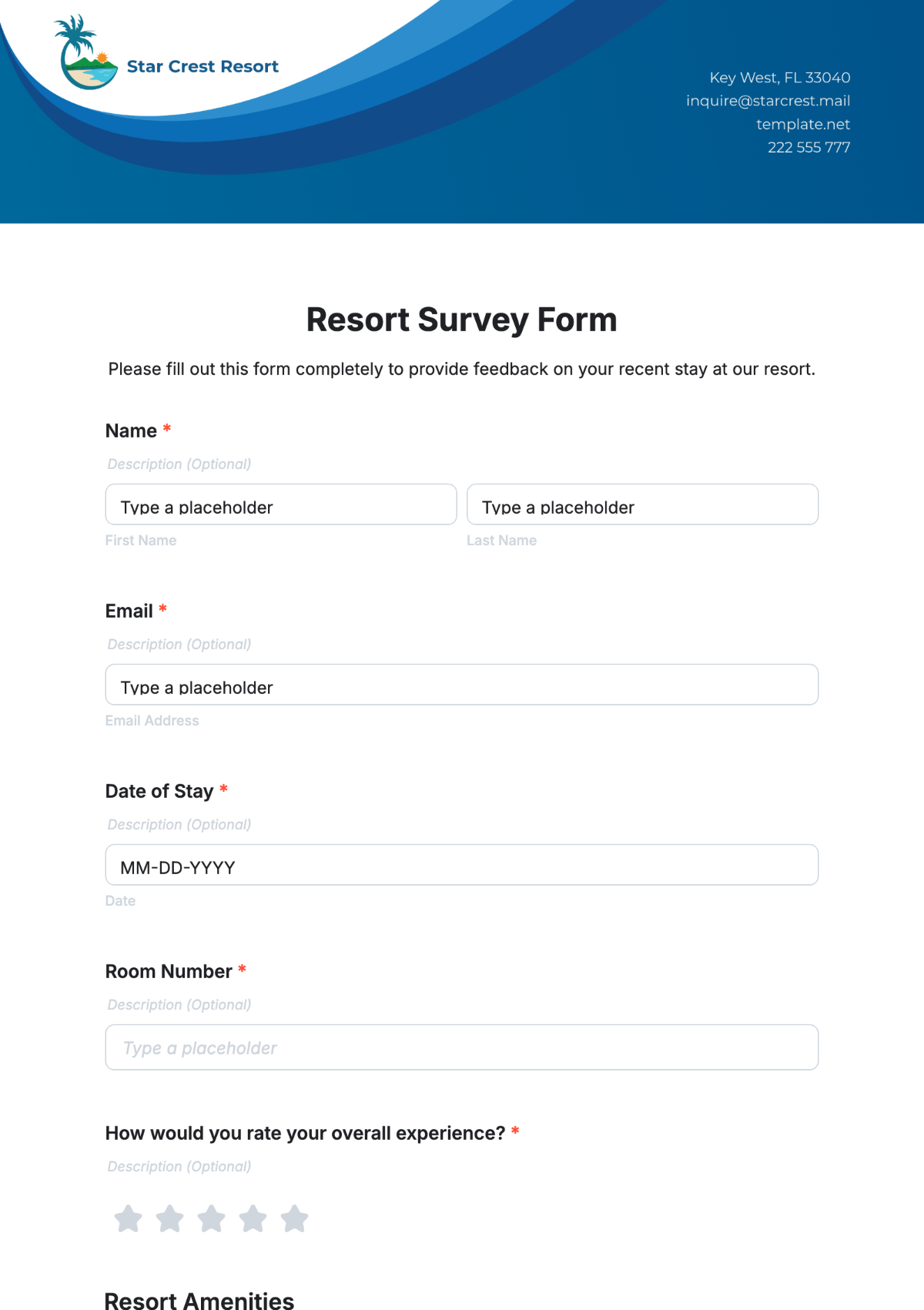

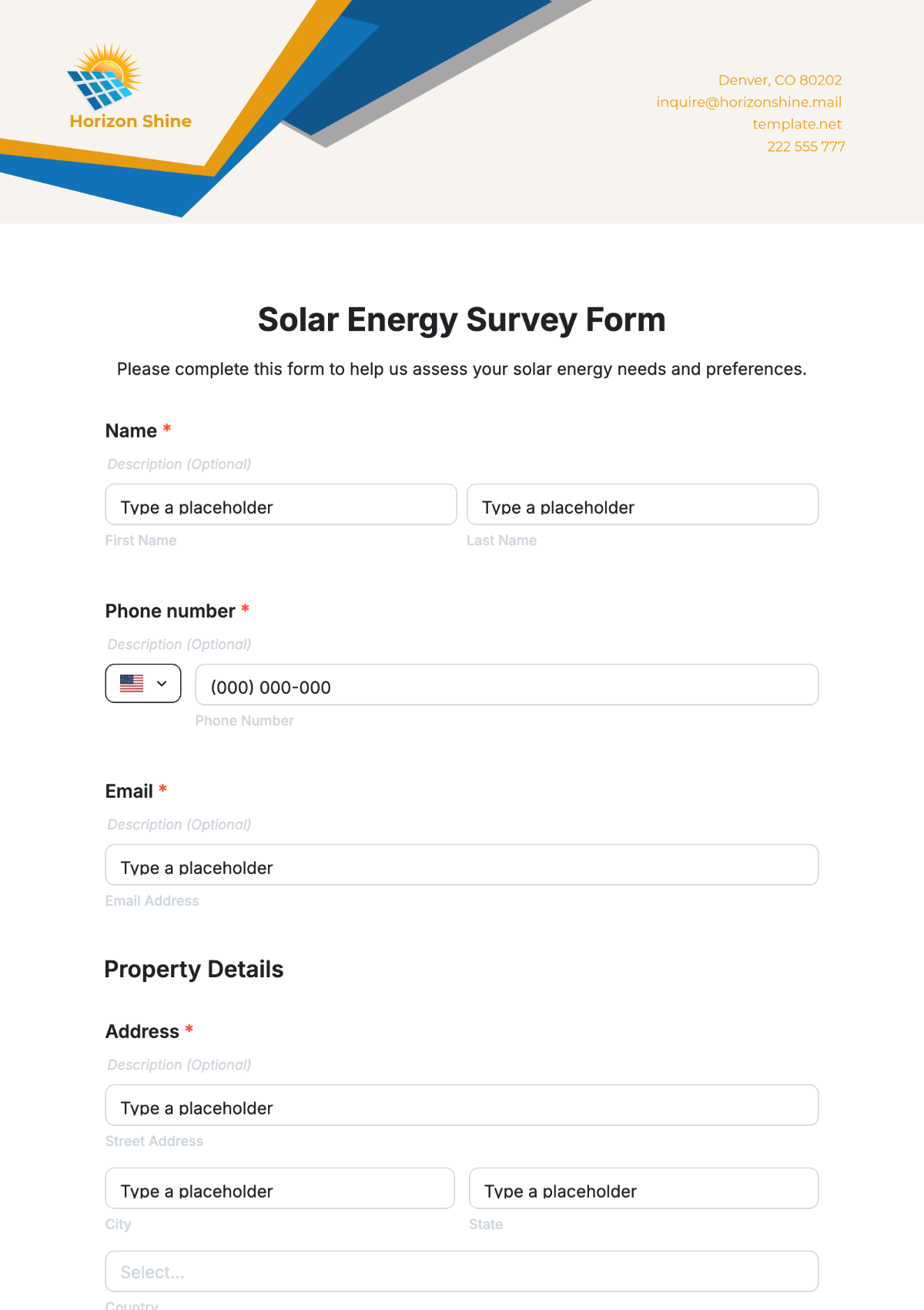

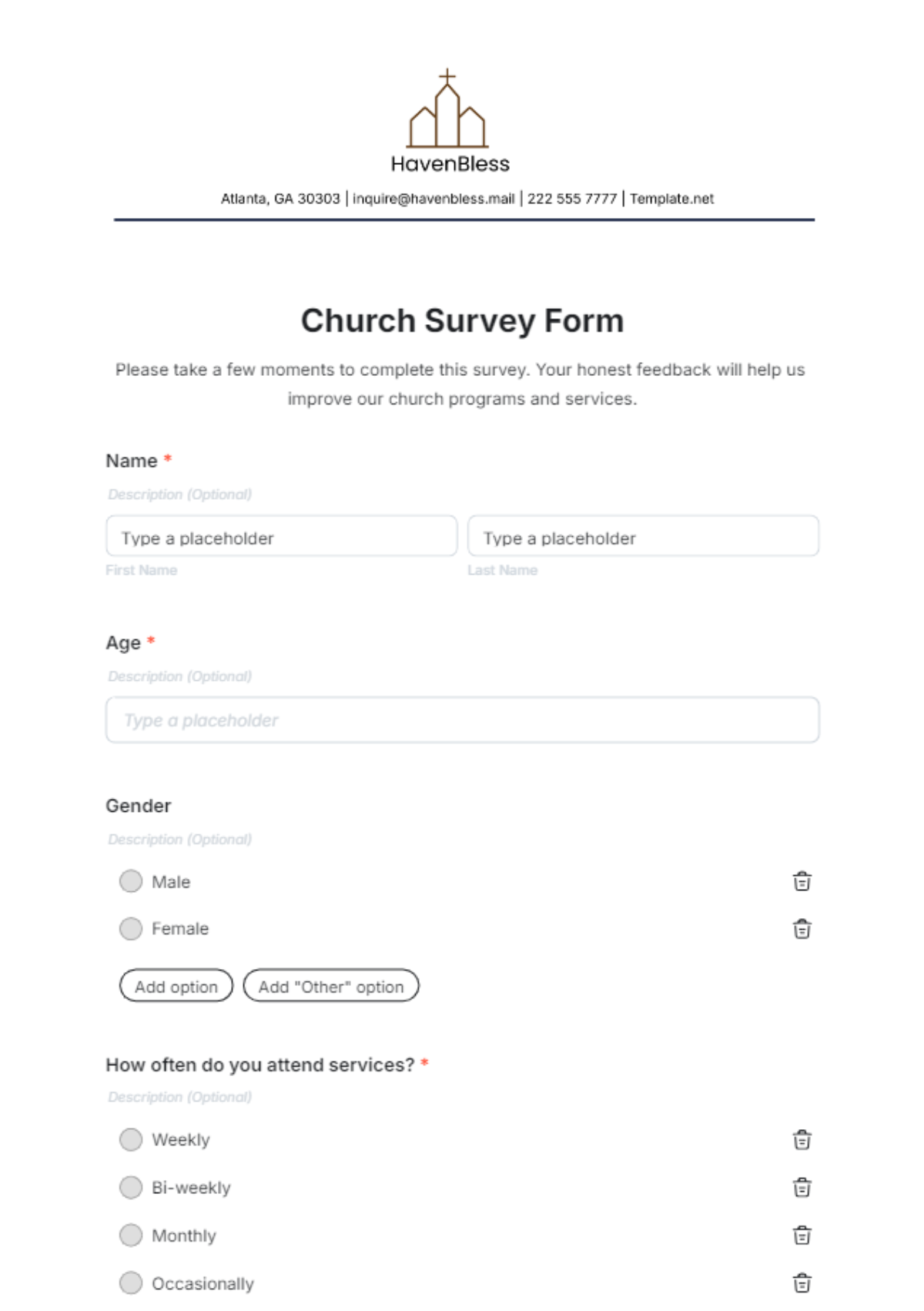

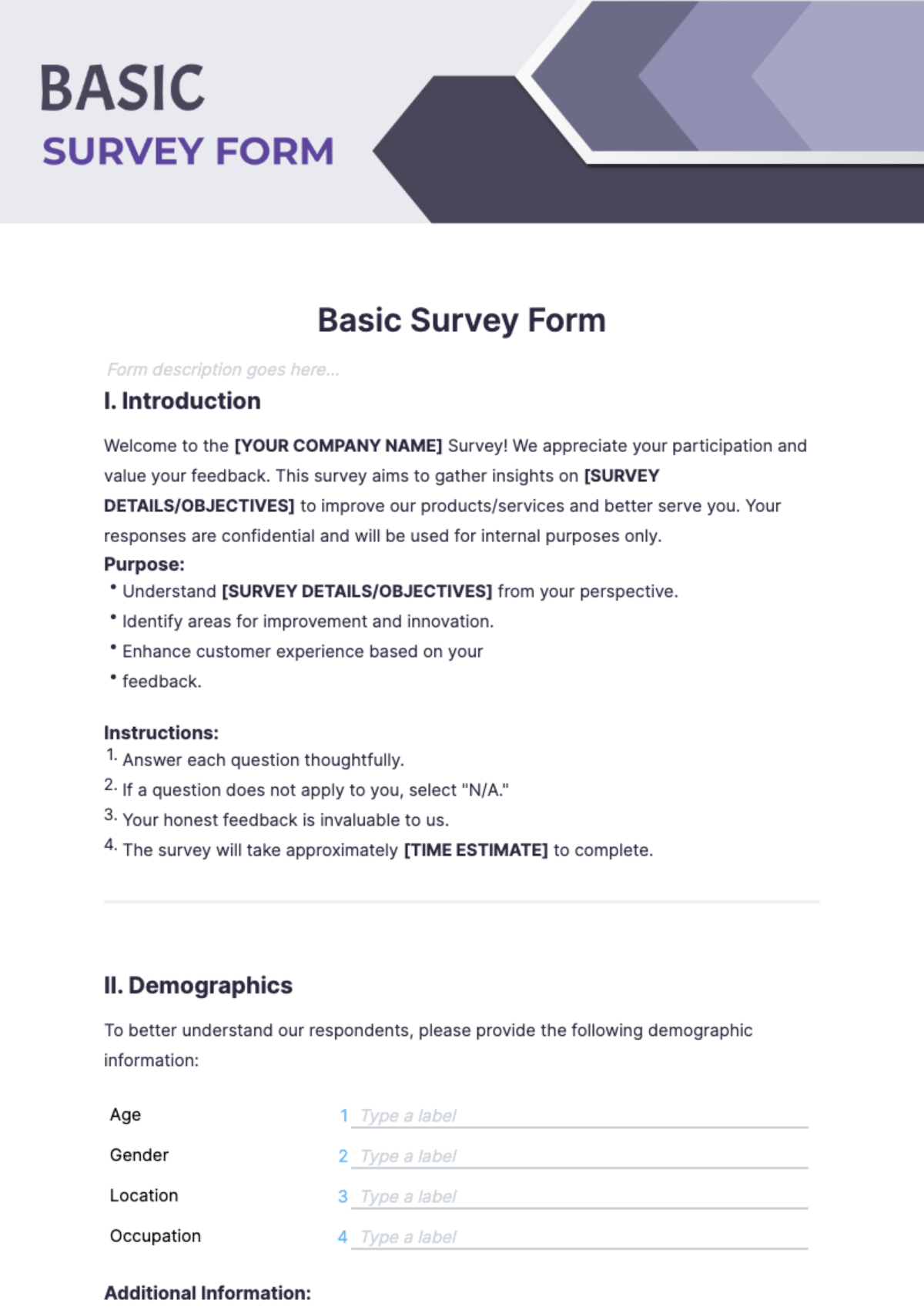

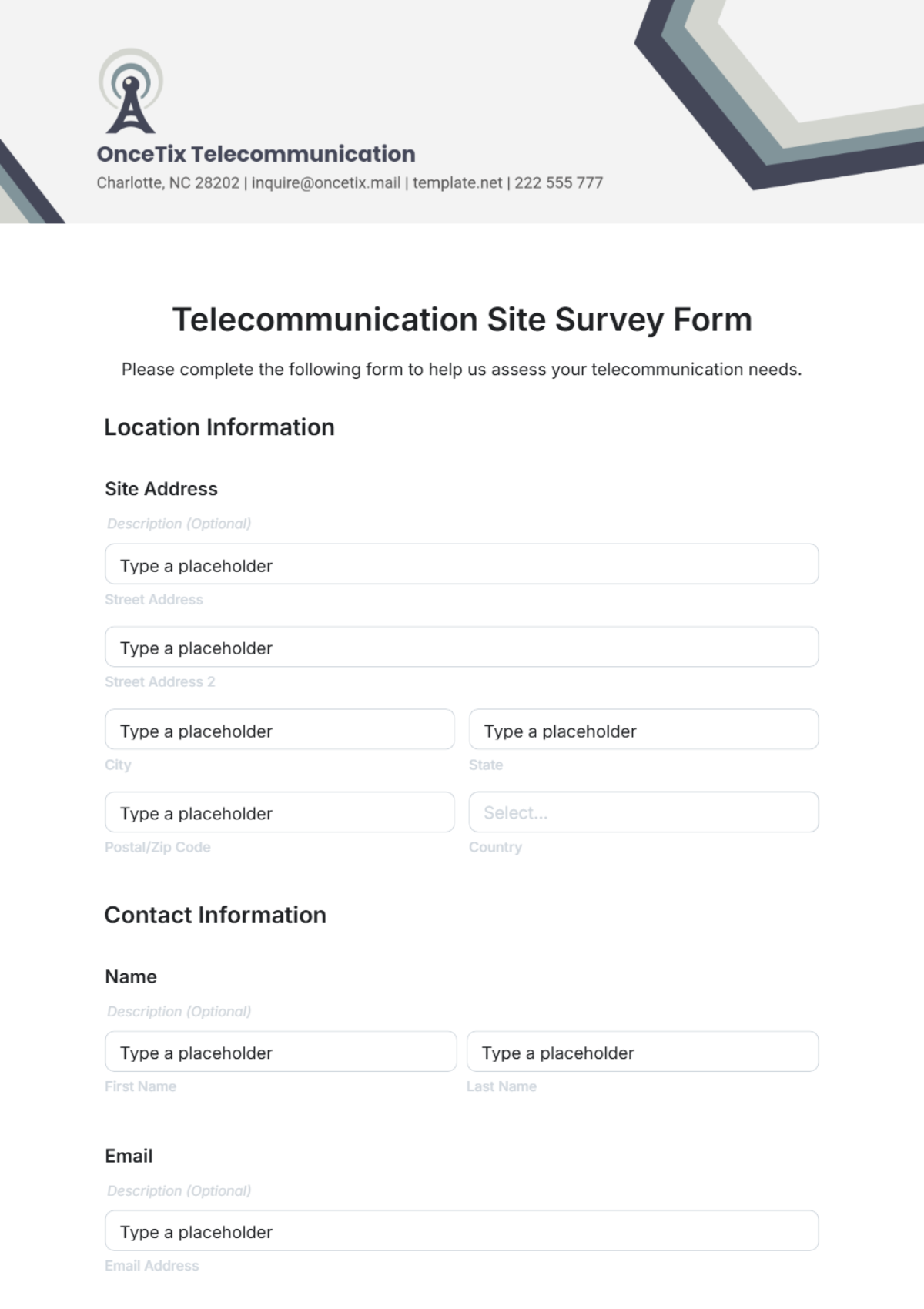

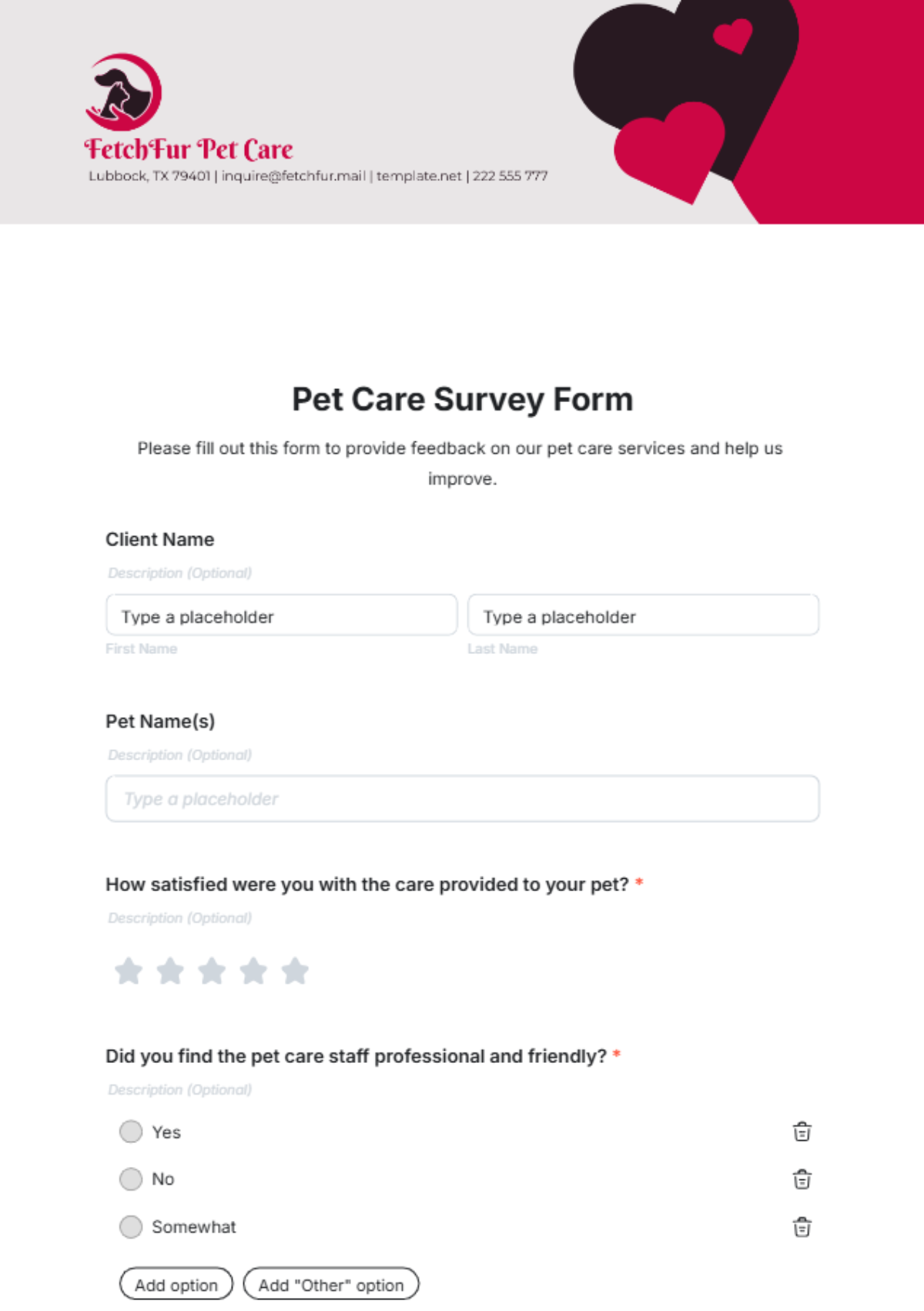

The research survey was meticulously designed to capture a broad spectrum of data related to production processes. It consisted of structured questionnaires that included both quantitative and qualitative questions. The quantitative questions focused on numerical data such as production volumes, equipment types, and method efficiencies. Qualitative questions aimed to gather insights on challenges, best practices, and innovation in production processes.

2.2 Data Collection Methods

Data was collected through multiple channels to ensure a comprehensive understanding of production practices:

Online Surveys: Distributed to a wide range of industry professionals.

Interviews: Conducted with key stakeholders such as production managers, engineers, and operational leaders.

Site Visits: Observational visits to manufacturing facilities for direct data collection and process analysis.

2.3 Analysis Techniques

The collected data underwent rigorous analysis using various statistical and analytical methods:

Descriptive Statistics: Used to summarize and describe the features of the data set, such as average production volumes and common equipment types.

Comparative Analysis: Employed to identify differences and similarities in production practices across industries.

Trend Analysis: Focused on identifying patterns and trends in production methods over time.

3. Industry Overview

3.1 Manufacturing Sector

The manufacturing sector encompasses a variety of industries including automotive, electronics, textiles, and consumer goods, each utilizing specific production techniques and equipment tailored to their products.

3.2 Energy Sector

Production processes in the energy sector vary significantly between renewable sources like solar and wind, and traditional fossil fuels such as oil and coal, reflecting the diverse technologies and methods used.

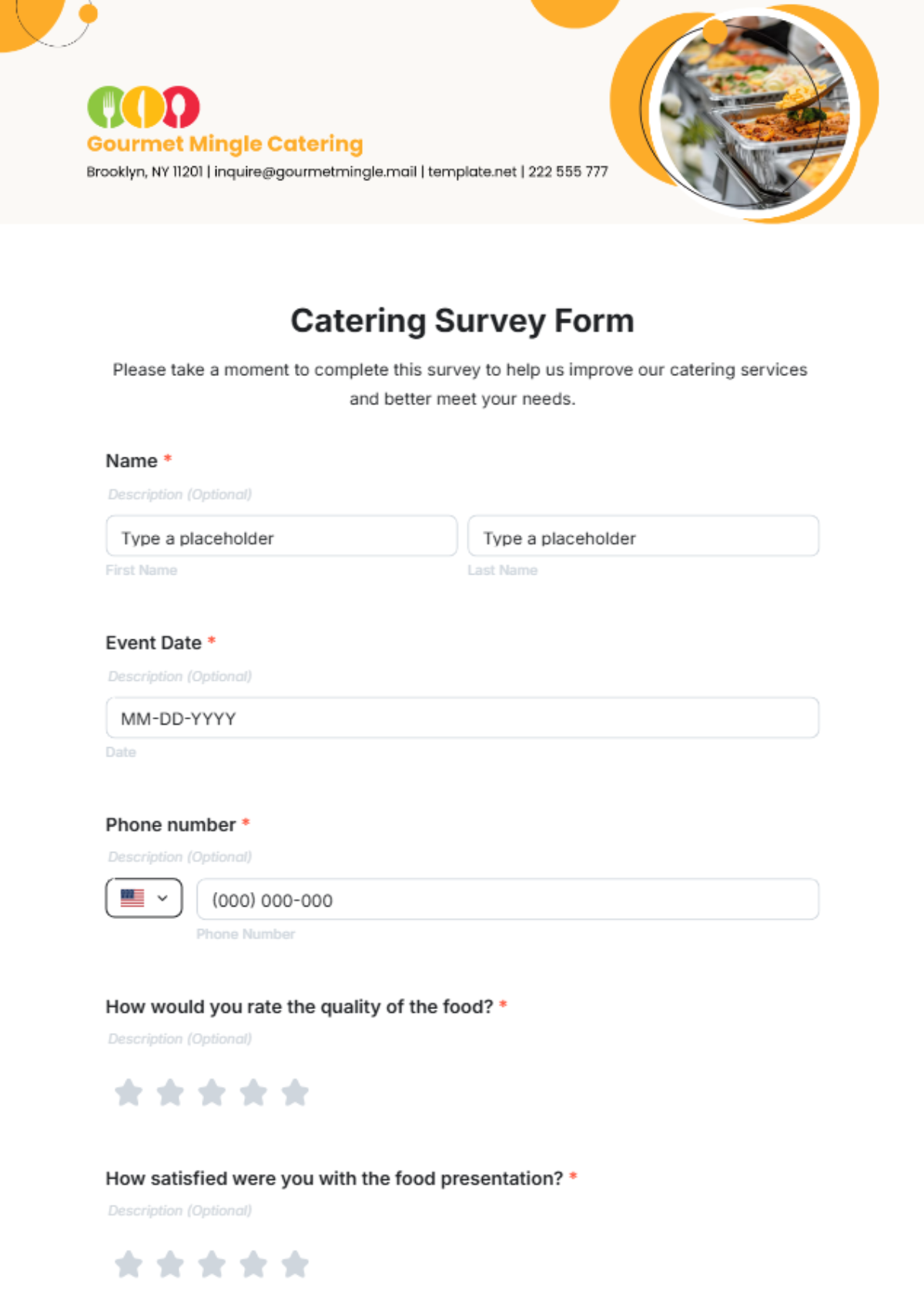

3.3 Food and Beverage Sector

The food and beverage sector involves production methods such as mixing, cooking, and packaging, with practices and equipment varying depending on whether the focus is on processed foods or beverages.

4. Production Processes

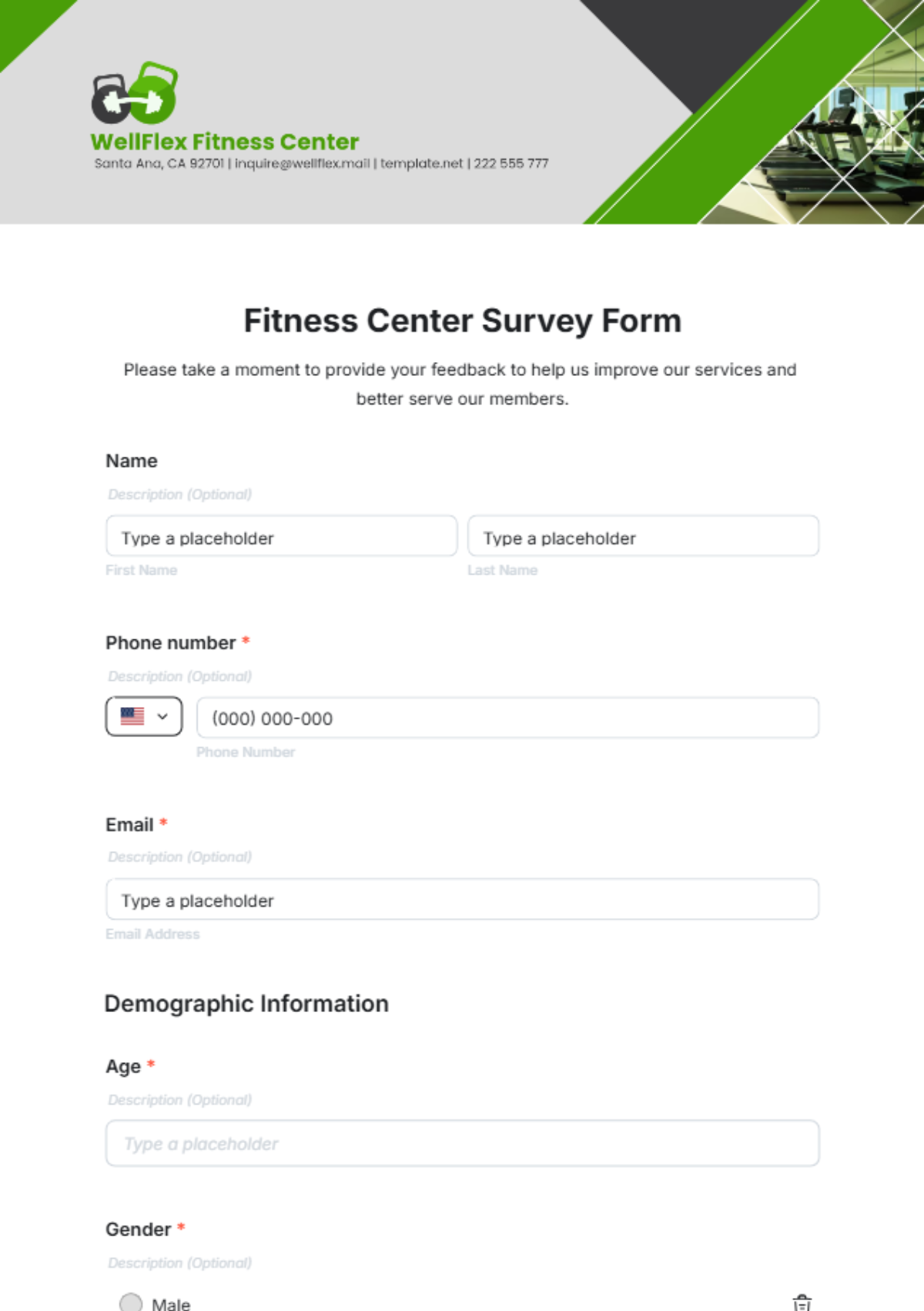

4.1 Automotive Production

Automotive production involves assembly lines and robotic automation for efficient and precise manufacturing of vehicles, with equipment such as robotic arms and CNC machines facilitating high and low-volume production.

4.2 Electronics Production

Electronics production utilizes surface-mount technology and soldering techniques, with equipment like pick-and-place machines and reflow ovens ensuring precision and quality in high-volume manufacturing.

4.3 Food Processing

Food processing includes methods like mixing, cooking, and packaging, with equipment such as mixers and ovens designed to handle both artisanal and large-scale industrial production.

5. Data Analysis

5.1 Trends and Patterns

The analysis revealed several key trends in production processes:

Increased Automation: Adoption of advanced robotics and automated systems across various industries.

Efficiency Improvements: Enhanced production efficiency through advanced equipment and optimized processes.

Sustainability Focus: Growing emphasis on sustainable practices and energy-efficient technologies.

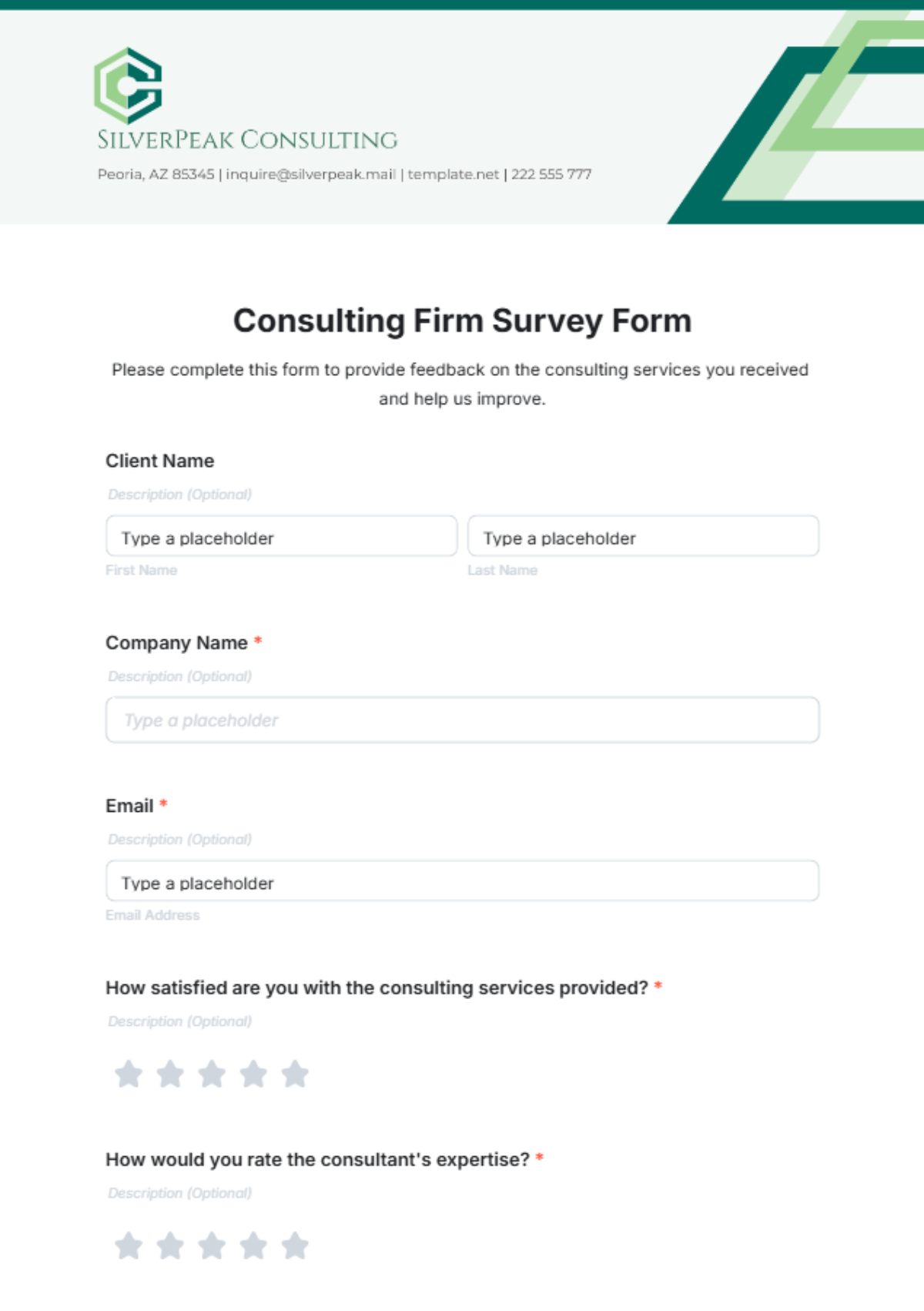

5.2 Comparative Insights

The comparative analysis highlighted:

Robotics vs. Manual Labor: Higher levels of automation in automotive and electronics compared to traditional methods in food processing.

Production Volumes: Significant differences in production volumes, with high-volume manufacturing in electronics and automotive sectors compared to more variable volumes in food processing.

6. Findings

6.1 Key Observations

Automation Benefits: Automation has led to increased efficiency, reduced labor costs, and improved precision.

Process Optimization: Industries that continually refine their processes achieve better performance and higher quality products.

Challenges: Common challenges include equipment maintenance, supply chain issues, and adapting to technological advancements.

6.2 Implications

The findings suggest that industries investing in modern technology and process improvements are likely to gain a competitive edge and achieve better production outcomes.

7. Recommendations

7.1 For Automotive Manufacturers

Investing in advanced robotics will boost precision and efficiency while optimizing supply chains will minimize disruptions and enhance production continuity.

7.2 For Electronics Producers

Improving testing procedures will ensure product quality and reliability, and adopting new technologies will help stay competitive and meet market demands.

7.3 For Food Processors

Advanced packaging can extend shelf life and reduce waste, while better quality control will ensure product consistency and compliance with health standards.

8. Conclusion

This Production Survey Descriptive Research provides a thorough overview of production processes across various industries. By offering insights into current practices, trends, and challenges, this research helps stakeholders make informed decisions to optimize production efficiency and maintain competitive advantage.