Optimization Techniques Action Research

Prepared by: [YOUR NAME]

Date: [DATE]

I. Introduction

In today's fast-paced and ever-evolving landscape, organizations must continuously refine and improve their processes, strategies, and systems to maintain a competitive edge. This comprehensive research delves into a structured approach aimed at optimizing these elements through iterative cycles of planning, action, and evaluation. This method involves identifying optimization problems, implementing effective techniques to address these issues, and assessing the outcomes to ensure enhanced performance.

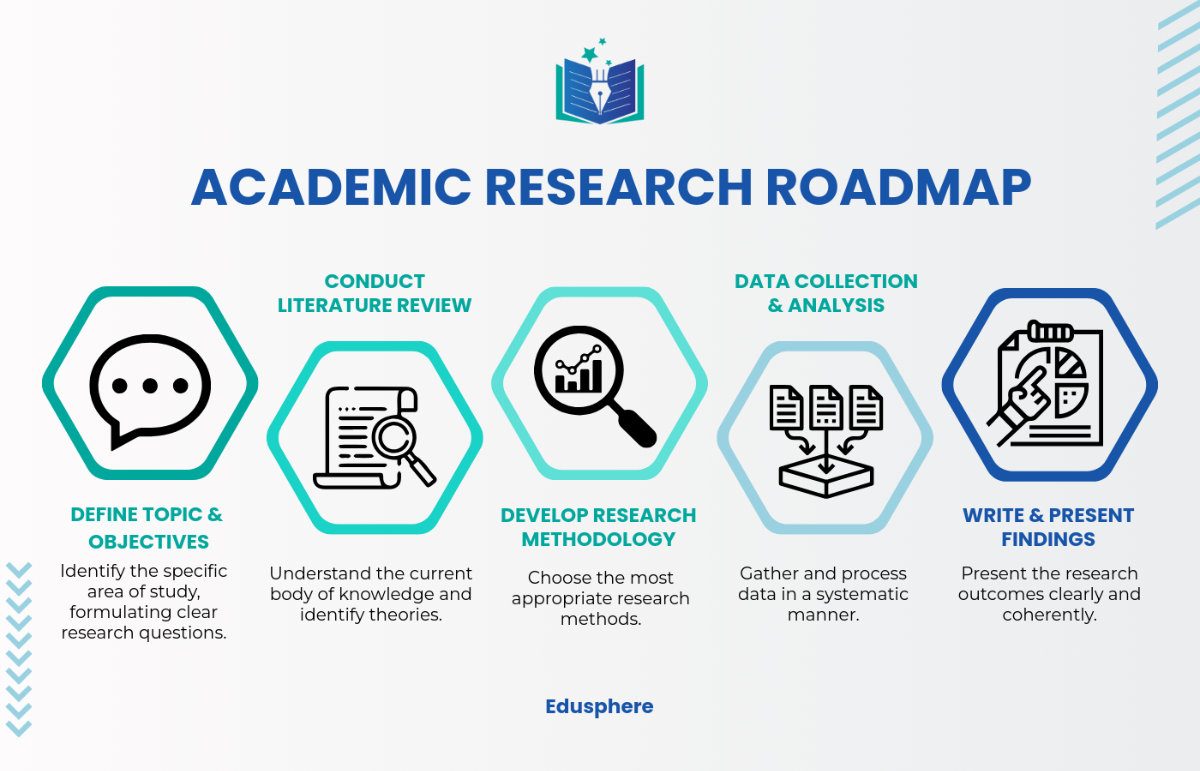

II. Overview of the Structured Approach

A. Planning

The first phase involves meticulous planning, where the current state of the process or system is analyzed, and objectives are set. This phase includes:

Identifying areas for improvement

Setting clear, measurable goals

Developing a detailed action plan

Allocating necessary resources

B. Action

In the action phase, the plans are put into practice. This phase includes:

Implementing the proposed changes

Ensuring all stakeholders are informed and on board

Monitoring the implementation process

Addressing any issues that arise

C. Evaluation

Evaluation is the final phase, where the outcomes of the implemented actions are assessed. This phase encompasses:

Collecting and analyzing data

Comparing results against the set objectives

Identifying any remaining gaps or new issues

Adjusting the plan for continuous improvement

III. Identifying Optimization Problems

Optimization problems can arise due to various reasons, including inefficiencies, outdated strategies, or inadequate resources. Identifying these problems is crucial to targeting the right areas for improvement. Common techniques to identify optimization problems include:

Technique | Description |

|---|---|

SWOT Analysis | Assessing strengths, weaknesses, opportunities, and threats to pinpoint areas needing improvement |

Root Cause Analysis | Identifying the underlying causes of problems by examining symptoms and tracing them back to their origins |

Benchmarking | Comparing current processes and outcomes with industry standards or best practices |

IV. Implementing Optimization Techniques

Once optimization problems are identified, various techniques can be employed to address them effectively. Some common approaches include:

Lean Methodology: Aiming to reduce waste and enhance productivity

Six Sigma: Using statistical tools to minimize variability and defects

Agile Practices: Focusing on flexibility and rapid iterations to improve processes

Continuous Improvement (Kaizen): Encouraging ongoing, incremental changes for long-term success

Business Process Reengineering: Redesigning processes from scratch to achieve significant improvements

V. Assessing Effectiveness

Evaluating the success of the implemented changes is essential to ensure that the desired outcomes are achieved. Methods for assessing effectiveness include:

Key Performance Indicators (KPIs): Metrics that provide insights into the performance of the process or system

Balanced Scorecards: A strategic planning tool that measures performance from multiple perspectives

Feedback Mechanisms: Gathering input from stakeholders to gauge satisfaction and identify areas for further improvement

Periodic Audits: Regular evaluations to ensure that processes remain aligned with the set goals and objectives

VI. Conclusion

Adopting a structured approach to process and system optimization through iterative cycles of planning, action, and evaluation can significantly enhance organizational performance. By continually identifying optimization problems, implementing effective techniques, and assessing results, organizations can sustain continuous improvement and maintain a competitive advantage in their respective fields.

VII. References

Smith, J. (2050). Process Improvement and Quality Management. New York: McGraw-Hill.

Johnson, L. & Brown, K. (2051). Continuous Improvement Strategies: An Introduction. Boston: Harvard Business Review Press.

Doe, A. (2052). Lean Six Sigma: A Practical Guide for Implementation. Chicago: Quality Press.