OHS Safety Program Manual

I. Introduction

Occupational Health and Safety (OHS) is a critical aspect of our operations at [Your Company Name]. This OHS Safety Program Manual is designed to ensure that all employees, contractors, and visitors are aware of and adhere to the safety practices that protect everyone from potential hazards in the workplace. We are committed to providing a safe and healthy work environment that complies with all applicable federal, state, and local regulations, including the Occupational Safety and Health Administration (OSHA) standards. By implementing these guidelines, we aim to prevent workplace injuries, illnesses, and incidents that could result in harm to our team members and our business operations.

This manual outlines the key safety procedures and responsibilities that everyone in our organization must follow. It includes information on hazard identification, risk assessment, emergency procedures, and incident reporting. We expect all employees to take an active role in maintaining a safe work environment by following the procedures outlined in this manual and participating in ongoing safety training. Safety is a shared responsibility, and together, we can create a workplace where everyone feels secure and confident in their well-being.

II. Safety Policies

At [Your Company Name], our safety policies are the cornerstone of maintaining a secure and healthy work environment. These guidelines are designed to protect our employees from potential hazards, ensuring that everyone can work safely and confidently. We emphasize the importance of compliance with all Occupational Health and Safety (OHS) laws and regulations, understanding that strict adherence to these standards is crucial for a safe workplace. Regular reviews and updates of our safety policies help us stay proactive in addressing new risks and enhancing our safety measures.

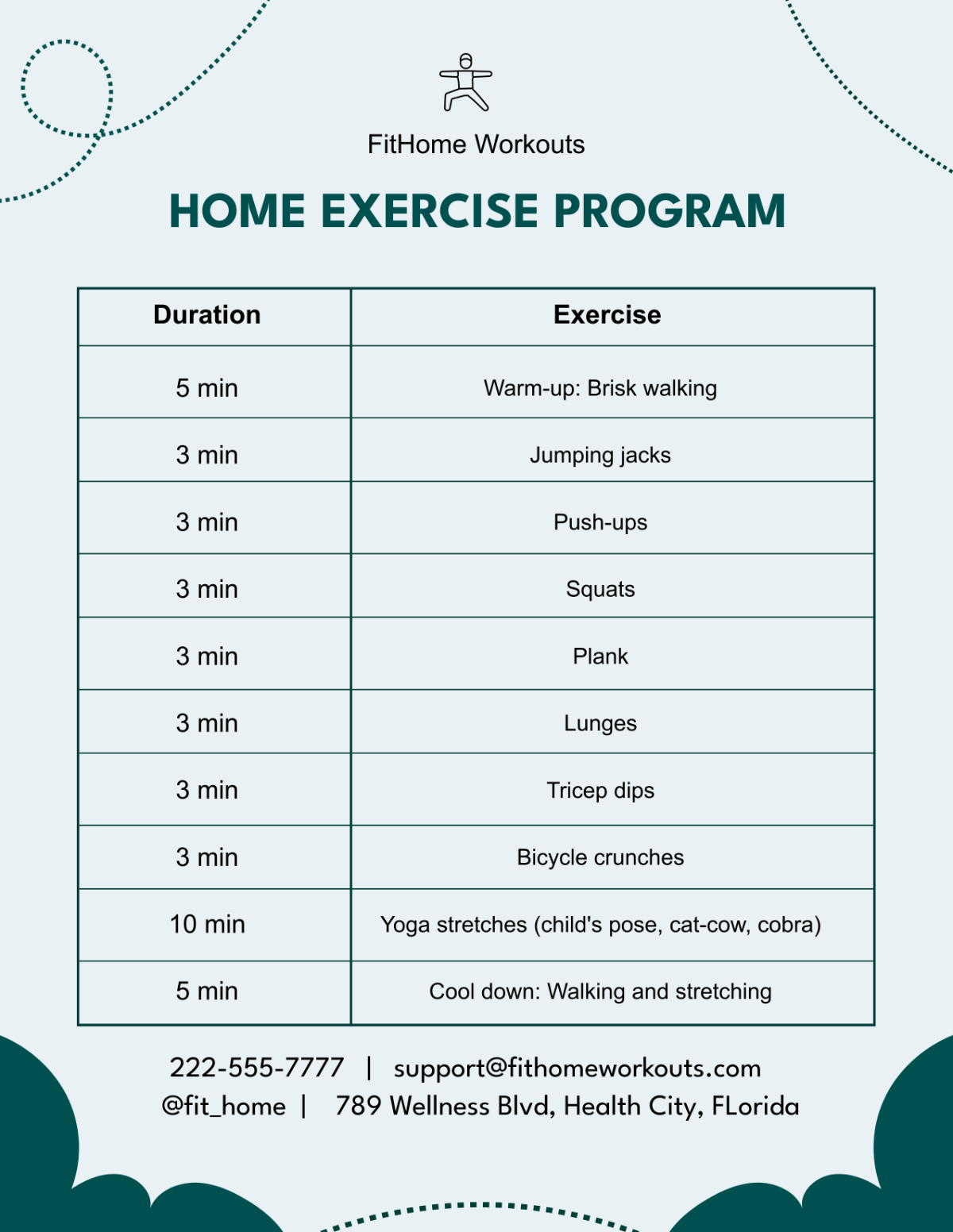

The policies outlined here include key aspects such as the proper use of Personal Protective Equipment (PPE). PPE plays a vital role in our overall safety strategy, and we are dedicated to providing the necessary equipment for all job tasks. Additionally, we focus on thorough training to ensure employees know how to use and maintain their PPE effectively, reducing the risk of injury. These practices foster a safety-conscious culture that supports the well-being of every team member.

General Safety Policies

Promote a safe and healthy work environment for all employees.

Ensure compliance with all applicable OHS laws and regulations.

Regularly review and update safety policy documentation.

Personal Protective Equipment (PPE)

Identify necessary PPE for various job tasks.

Provide appropriate PPE to all employees.

Ensure employees are trained in the proper use and maintenance of PPE.

III. Responsibilities

A successful Occupational Health and Safety (OHS) program depends on the active participation of both employers and employees. At [Your Company Name], we believe that safety is a shared responsibility, with everyone playing a vital role in maintaining a secure work environment. To achieve this, it is crucial that both management and staff understand and fulfill their specific duties related to workplace safety. Clear expectations and responsibilities ensure that safety measures are consistently applied and that potential hazards are promptly addressed.

The table below outlines the key responsibilities of both the employer and employees. By adhering to these guidelines, we can create a cohesive safety culture where everyone is committed to reducing risks and ensuring a safe workplace for all.

Responsibilities | Employer | Employee |

|---|---|---|

OHS Program Implementation | Implement and maintain the OHS program. | Comply with all safety policies and procedures. |

Safety Training & Resources | Provide necessary resources for safety training and PPE. | Attend and participate in safety training sessions. |

Safety Inspections | Conduct regular workplace safety inspections. | Report unsafe conditions and incidents immediately. |

IV. Training and Education

Training and education are fundamental components of our Occupational Health and Safety (OHS) program at [Your Company Name]. Providing comprehensive safety training ensures that all employees are equipped with the knowledge and skills necessary to recognize and mitigate workplace hazards. This commitment to ongoing education fosters a culture of safety and empowers employees to make informed decisions that protect their well-being and that of their colleagues.

Safety Training Programs

Our safety training programs are designed to cover a broad range of topics relevant to our operations. These programs include:

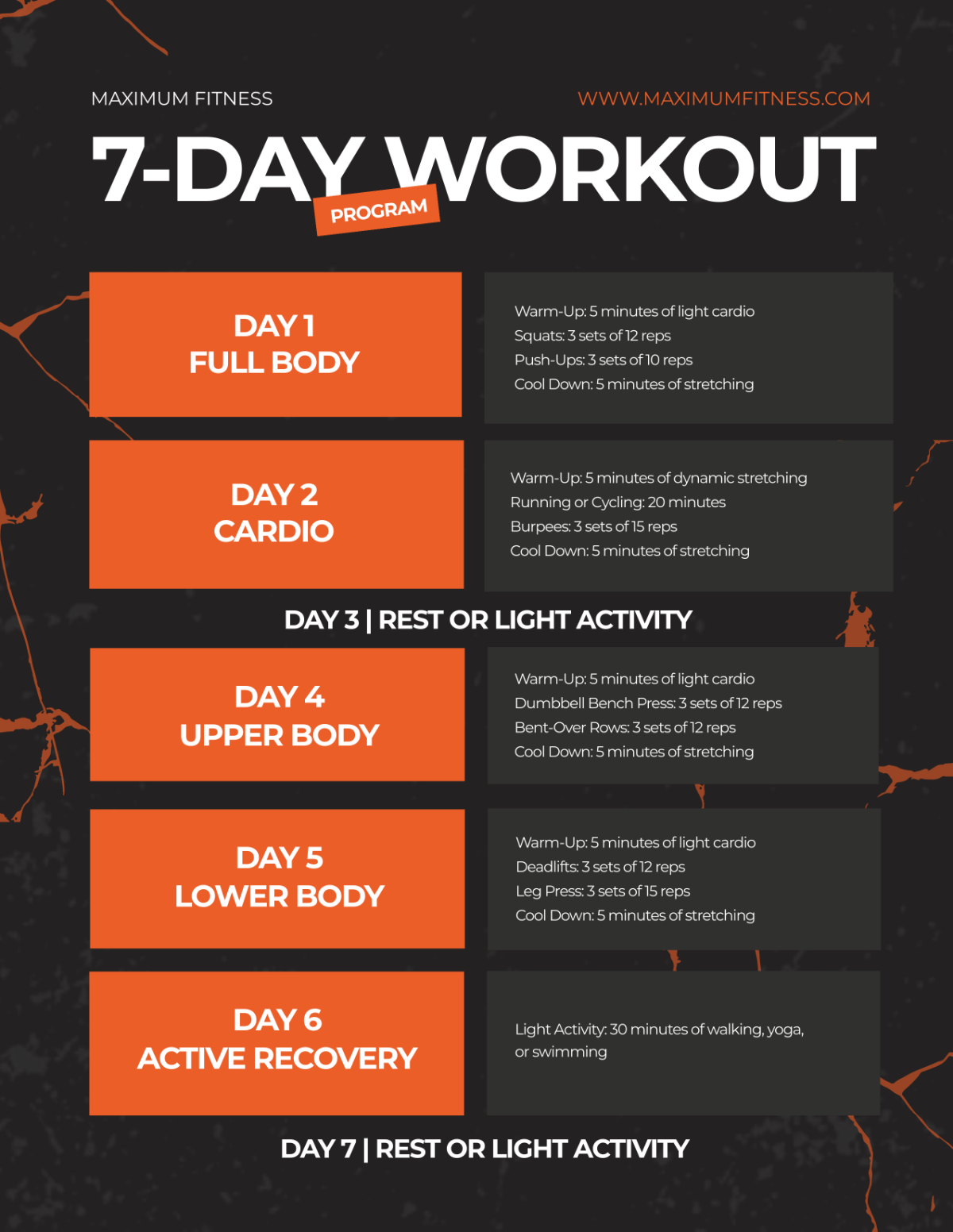

General Safety Orientation: All new employees undergo a mandatory safety orientation that introduces them to our safety policies, procedures, and the importance of compliance with OHS regulations. This orientation provides a foundation for understanding workplace safety standards and expectations.

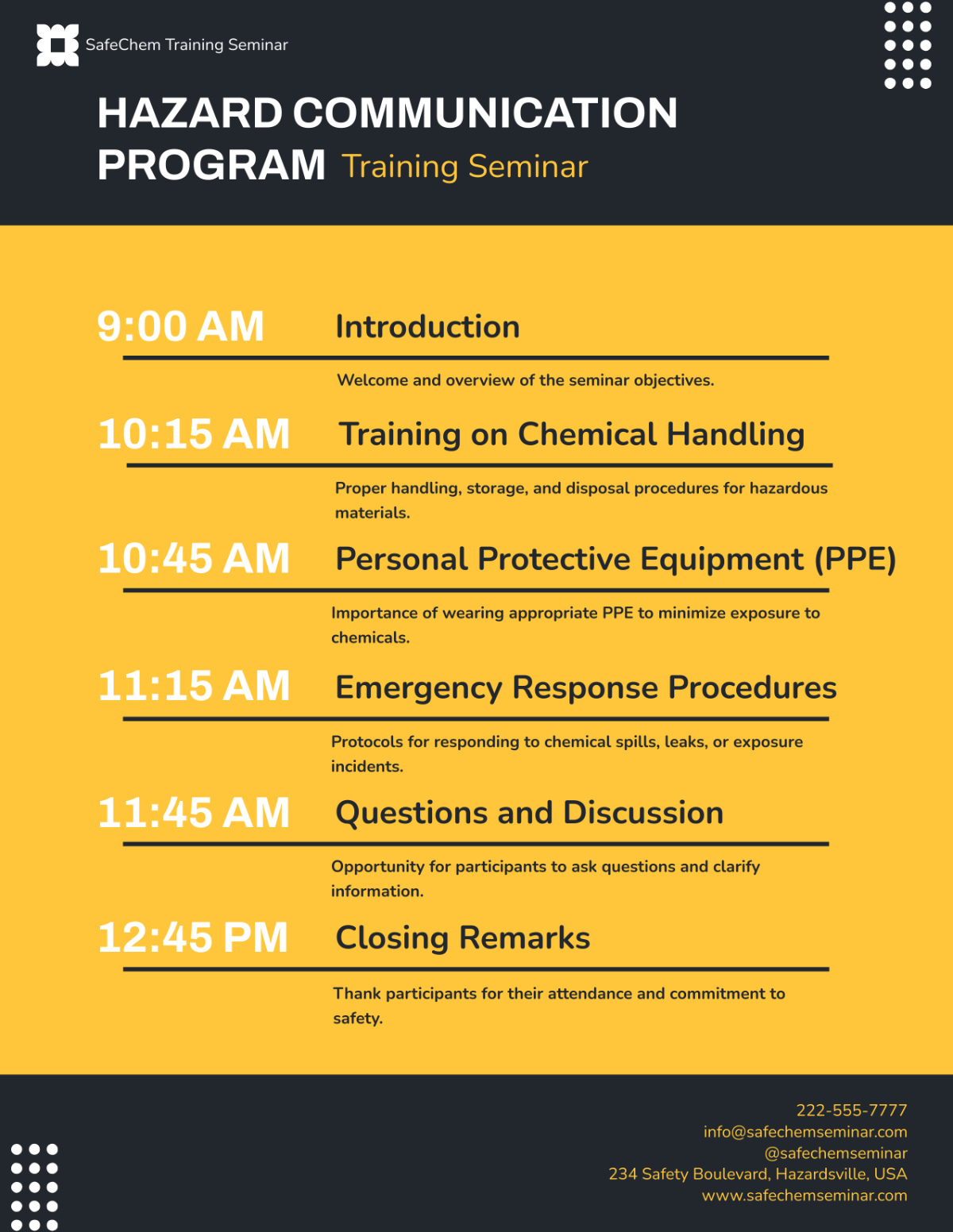

Job-Specific Training: Employees receive specialized training tailored to their specific job roles. This includes instruction on the safe operation of machinery, handling hazardous materials, and other tasks that pose potential risks. By focusing on the particular hazards associated with each job, we ensure that employees are prepared to perform their duties safely.

Emergency Response Training: In the event of an emergency, quick and effective action is crucial. We provide training on emergency procedures, including evacuation routes, the use of fire extinguishers, and first aid. This training is designed to equip employees with the skills needed to respond confidently and efficiently during emergencies.

Continuous Education and Refresher Courses

Safety training at [Your Company Name] does not end with the initial orientation. We are committed to continuous education, offering regular refresher courses to keep safety knowledge up to date. These sessions help reinforce critical safety practices and introduce new information as regulations and technologies evolve. Employees are encouraged to actively participate in these refresher courses to stay current on best practices.

Documentation and Record-Keeping

To ensure accountability and compliance, we maintain detailed records of all safety training sessions. These records include the date of training, the topics covered, and the names of participants. Keeping accurate documentation helps us monitor training progress, identify areas for improvement, and demonstrate our commitment to safety in audits and inspections.

V. Emergency Procedures

Effective emergency procedures are essential to ensuring the safety of all employees, visitors, and contractors at [Your Company Name]. Being prepared for emergencies such as fires, medical incidents, or natural disasters can significantly reduce the risk of injury and damage. Our emergency procedures outline clear steps for responding to various situations, ensuring that everyone knows how to act quickly and appropriately in the event of an emergency.

Emergency Procedures

Emergency Situation | Action Steps |

|---|---|

Fire Emergency |

|

Medical Emergency |

|

Severe Weather/Natural Disaster |

|

Workplace Violence |

|

Hazardous Material Spill |

|

VI. Incident Reporting and Investigation

Timely and accurate reporting of workplace incidents is essential for maintaining a safe work environment at [Your Company Name]. Incident reporting allows us to promptly address hazards, prevent future occurrences, and ensure compliance with Occupational Health and Safety (OHS) regulations. All employees are encouraged to report any unsafe conditions, near misses, or actual incidents, no matter how minor they may seem. This proactive approach helps us identify and mitigate risks before they lead to serious harm.

Incident Reporting Procedures

Immediate Reporting: Employees must report any incident, injury, or near miss to their supervisor or safety officer as soon as possible, preferably within the same work shift. This includes any unsafe conditions that could lead to an incident.

Documentation: An Incident Report Form must be completed by the employee involved or a witness. The form should include details such as the date, time, location, and a description of the incident, as well as any immediate corrective actions taken.

Confidentiality: Incident reports are handled with confidentiality to encourage honest and open reporting without fear of retaliation.

Incident Investigation Procedures

Initial Assessment: Once an incident is reported, a preliminary assessment is conducted to determine the severity and immediate risks. If necessary, emergency actions are taken to secure the area and prevent further harm.

Investigation Team: A team, typically consisting of a safety officer, the employee’s supervisor, and other relevant personnel, is assembled to conduct a thorough investigation. The team's goal is to identify the root cause of the incident and develop recommendations for corrective actions.

Root Cause Analysis: The investigation focuses on understanding the underlying factors that contributed to the incident, including environmental conditions, equipment failure, human error, or procedural gaps.

Corrective Actions: Based on the findings, specific corrective actions are implemented to prevent recurrence. These may include revising safety procedures, providing additional training, or making changes to the work environment.

Reporting to Authorities

Regulatory Compliance: If the incident meets the criteria for reporting to regulatory bodies such as OSHA, the safety officer will ensure that all necessary reports are submitted within the required timeframe.

Monitoring and Follow-Up

Tracking and Monitoring: All incidents are recorded in a central log for tracking and trend analysis. This allows [Your Company Name] to identify patterns and areas of concern.

Review and Follow-Up: Post-incident, the effectiveness of corrective actions is reviewed, and additional measures are taken if necessary to enhance workplace safety.

VII. Workplace Inspections

Workplace inspections are a critical component of our Occupational Health and Safety (OHS) program at [Your Company Name]. These inspections help us identify potential hazards, ensure compliance with safety regulations, and verify that safety measures are effectively implemented. Regular inspections provide an opportunity to proactively address risks before they result in incidents, fostering a safer work environment for all employees.

Types of Inspections

Routine Inspections: These are conducted regularly, such as daily, weekly, or monthly, depending on the nature of the work area and the associated risks. Routine inspections focus on general workplace conditions, including housekeeping, equipment status, and the proper use of Personal Protective Equipment (PPE).

Scheduled Inspections: These are more comprehensive inspections carried out at specific intervals, such as quarterly or annually. Scheduled inspections often involve a detailed review of safety procedures, equipment maintenance records, and compliance with OHS standards. They may also include specialized inspections for areas with higher risk, such as those involving hazardous materials.

Unscheduled Inspections: These are surprise inspections conducted without prior notice to ensure that safety practices are consistently followed. Unscheduled inspections are particularly effective in identifying issues that might not be apparent during scheduled reviews.

Inspection Process

Pre-Inspection Preparation: Before conducting an inspection, the inspection team reviews previous inspection reports, incident logs, and relevant safety standards. This preparation helps the team focus on areas of concern and identify any recurring issues.

Conducting the Inspection: During the inspection, the team systematically examines the workplace, using a checklist to ensure all areas are covered. Observations are documented, including any unsafe conditions, non-compliance issues, or potential hazards.

Reporting and Follow-Up: After the inspection, a report is generated detailing the findings, including any identified hazards and recommended corrective actions. The report is shared with relevant departments, and corrective actions are monitored to ensure timely implementation.

Employee Involvement

Participation: Employees are encouraged to participate in workplace inspections, either as part of the inspection team or by providing feedback on potential safety concerns. Their involvement helps identify issues that may be overlooked and promotes a culture of safety throughout the organization.

Feedback Loop: Employees are also encouraged to provide input on the effectiveness of inspections and suggest improvements, creating a continuous feedback loop that enhances the overall safety inspection process.

VIII. Records and Documentation

Maintaining accurate records and thorough documentation is vital to the effectiveness of [Your Company Name]'s Occupational Health and Safety (OHS) program. Proper documentation not only ensures compliance with legal requirements but also provides a reliable reference for evaluating the success of our safety initiatives. Well-organized records allow us to track incidents, monitor training, and verify that safety inspections and corrective actions have been completed. This transparency and accountability are essential for continuous improvement in workplace safety.

Types of Records and Documentation

Incident Reports: Detailed records of all workplace incidents, including near misses, injuries, and illnesses. These reports include information on the date, time, location, and nature of the incident, as well as any corrective actions taken.

Training Records: Documentation of all safety training sessions, including dates, topics covered, and participant attendance. These records help ensure that all employees receive the necessary education to perform their duties safely.

Inspection Reports: Records of all workplace inspections, including findings, identified hazards, and recommended corrective actions. Inspection reports are crucial for tracking the effectiveness of our safety measures over time.

Maintenance Logs: Documentation of regular maintenance and safety checks on equipment and machinery. These logs help ensure that all equipment is functioning safely and according to standards.

Compliance Records: Documentation of compliance with OHS regulations, including any required reports submitted to regulatory bodies like OSHA.

Storage and Accessibility

Confidentiality: All records are stored securely, with access limited to authorized personnel to maintain confidentiality.

Accessibility: Records are organized and stored in a manner that allows for easy retrieval and review during audits, inspections, or safety meetings. Digital records are backed up regularly to prevent data loss.

These practices support a robust safety culture and ensure that [Your Company Name] remains compliant with all applicable laws and regulations.

IX. Program Evaluation and Continuous Improvement

Regular evaluation of our Occupational Health and Safety (OHS) program is essential to ensure its effectiveness and relevance. At [Your Company Name], we conduct periodic reviews of the OHS program to assess its performance and identify areas for improvement. This evaluation process involves analyzing incident reports, safety inspections, training records, and feedback from employees. The goal is to determine whether the program is meeting its objectives, complying with regulations, and effectively mitigating risks.

Performance Metrics

Incident Rates: Analyze trends in incident rates to identify patterns or recurring issues.

Training Effectiveness: Assess the impact of safety training by evaluating employee performance and incident rates before and after training sessions.

Inspection Findings: Review the results of safety inspections to determine if identified hazards have been adequately addressed.

Continuous Improvement

Action Plans: Based on evaluation findings, develop and implement action plans to address any identified weaknesses or gaps in the OHS program. This may include updating procedures, enhancing training programs, or improving safety equipment.

Employee Feedback: Encourage employees to provide feedback on the OHS program and suggest improvements. Incorporating their insights helps to make the program more effective and relevant.

Regular Updates: Continuously update the OHS program to reflect changes in regulations, industry standards, and organizational needs, ensuring ongoing compliance and safety enhancement.

By systematically evaluating and improving our OHS program, we enhance workplace safety and foster a culture of continuous improvement.

The [Your Company Name] OHS Safety Program Manual serves as a critical guide to ensuring a safe and healthy workplace. By adhering to these safety policies, participating in training, and actively engaging in our safety practices, we all contribute to a secure environment where everyone can thrive. Remember, safety is a shared responsibility, and your commitment is essential to our collective success. Together, we can maintain a workplace that prioritizes health and safety at all times.