Defect Root Cause Analysis

Prepared By: [Your Name]

Date: May 16, 2060

I. Introduction

Defect Root Cause Analysis (RCA) is a systematic and structured approach used to identify the underlying causes of defects or problems within a process, product, or system. The primary objective of RCA is to find and address the root causes of defects to prevent their recurrence, thereby improving the overall quality and reliability of processes or products. This document presents a comprehensive analysis of a defect identified within a generic manufacturing process and outlines the steps taken to identify, analyze, and rectify the root cause.

II. Problem Statement

A. Background

The manufacturing process under review has been exhibiting a recurring defect in the final product, which has resulted in increased customer complaints, higher return rates, and a decline in overall product quality. This defect was first identified in January 2051, and subsequent investigations have confirmed its recurrence in multiple production batches.

B. Description of the Defect

The defect involves a structural weakness in the assembled product, leading to premature failure during use. Specifically:

Defect Manifestation: The assembled product exhibits cracks in the housing, particularly around the joints.

Impact: The defect compromises the durability of the product, leading to customer dissatisfaction and potential safety risks.

C. Initial Observations

Initial observations were made by the quality control team in early February 2051, and the following key symptoms were noted:

Symptom | Description |

|---|---|

Symptom 1 | Cracks appear in the same location across multiple units. |

Symptom 2 | Increased rate of failure during quality assurance stress tests. |

Symptom 3 | Higher-than-normal rejection rates during final inspection. |

III. Data Collection and Analysis

A. Data Collection Methods

Data was collected from the following sources to support the analysis:

Operational Logs: Detailed logs of the production process during the periods when the defect was observed.

Material Quality Reports: Historical data on the quality of materials used in the affected production batches.

Operator Interviews: Interviews with assembly line workers and supervisors who have handled the production of the affected units.

Defect Reports: Summarized defect reports from customer returns and warranty claims.

B. Data Analysis

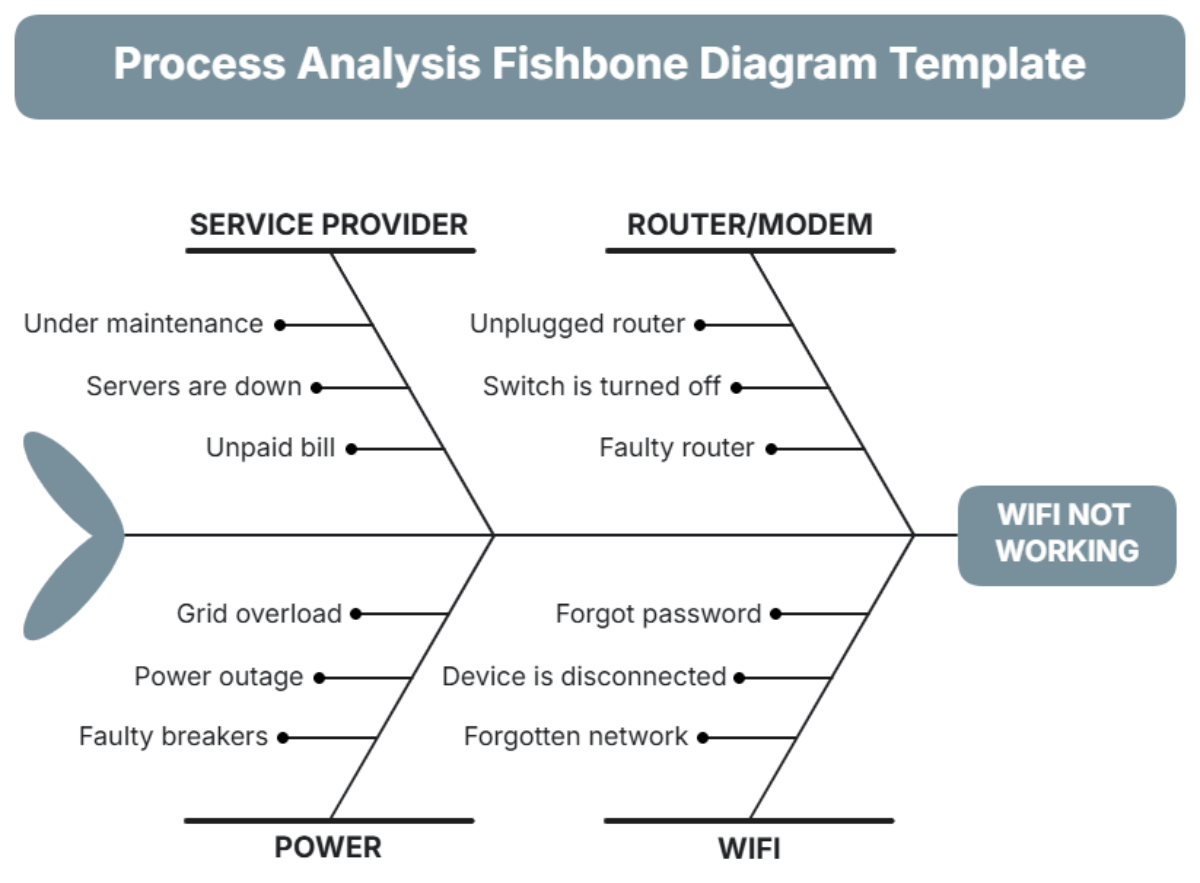

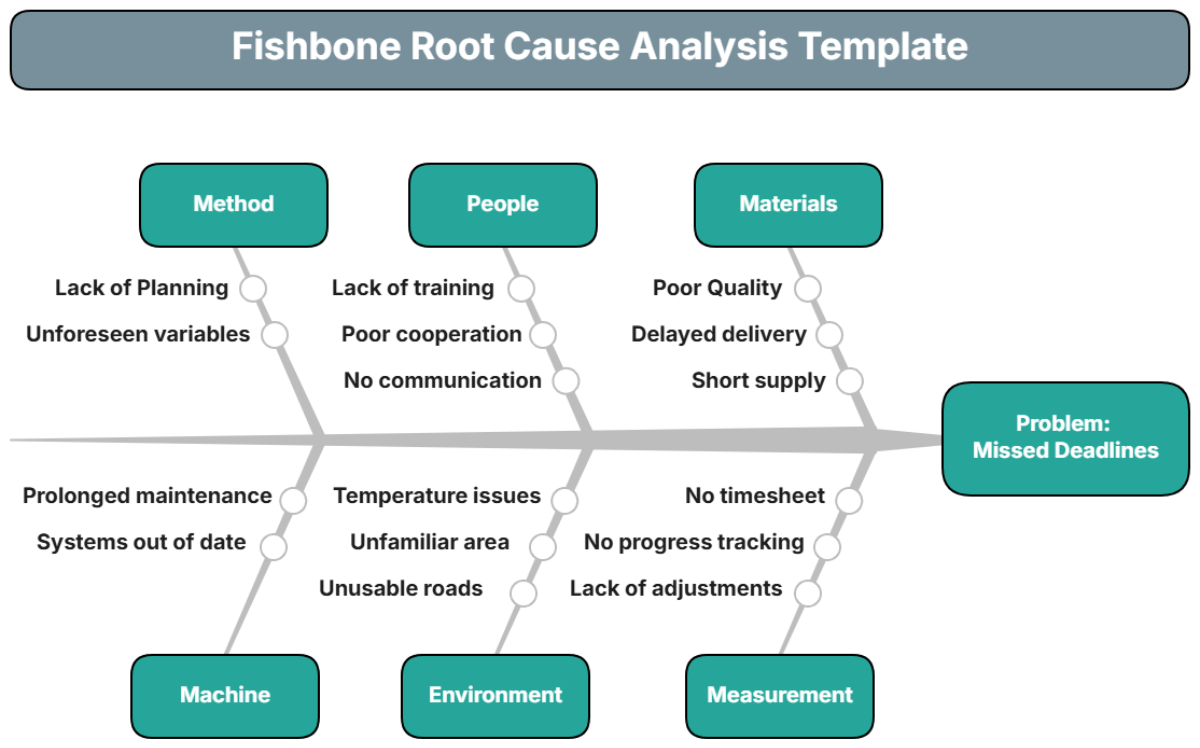

The collected data was analyzed using various techniques to identify patterns and correlations that could indicate potential root causes. The following analysis methods were employed:

Trend Analysis: Analysis of production logs revealed that the defect occurs more frequently in batches produced during peak production periods, suggesting a possible link to production pressure.

Fault Tree Analysis (FTA): FTA identified potential failure points, particularly in the joint assembly process where the cracks were consistently appearing.

Pareto Analysis: Pareto analysis indicated that 80% of the defects were associated with a specific supplier's materials, highlighting a potential issue with material quality.

IV. Root Cause Identification

A. Root Cause Hypotheses

Based on the data analysis, the following hypotheses were developed to explain the root cause of the defect:

Hypothesis | Description |

|---|---|

Hypothesis 1 | The material used in the housing is substandard and prone to cracking under stress. |

Hypothesis 2 | The assembly process, particularly the joint welding technique, is inadequate, leading to weak structural integrity. |

Hypothesis 3 | Production pressure during peak periods leads to rushed assembly, compromising quality control. |

B. Testing and Validation

Each hypothesis was tested through targeted experiments and simulations to validate or refute the proposed root causes:

Test | Description | Outcome |

|---|---|---|

Test 1 | Material samples from different suppliers were subjected to stress tests to assess their durability. | Materials from the primary supplier had a higher failure rate. |

Test 2 | A review and adjustment of the welding technique were conducted, followed by a series of controlled assembly tests. | The revised technique significantly reduced the occurrence of cracks. |

Test 3 | The production schedule was modified to reduce peak pressure, and quality checks were intensified. | Fewer defects were observed in subsequent batches. |

C. Identified Root Cause

The root cause of the defect was determined to be a combination of substandard material quality from a specific supplier and an inadequate welding technique in the assembly process. This conclusion was supported by the following evidence:

Material Failure: Stress tests confirmed that the material from the primary supplier was more prone to cracking under load.

Process Weakness: Adjustments to the welding technique led to a marked decrease in the defect rate.

Production Pressure: Reducing production pressure improved overall quality, though this was a contributing factor rather than the primary cause.

V. Corrective Actions

A. Immediate Corrective Actions

To address the identified root cause, the following immediate corrective actions were implemented:

Material Supplier Change: All affected materials were replaced with higher-quality alternatives from a different supplier.

Welding Technique Revision: The welding process was updated with a new technique that ensures stronger joints and all operators were retrained.

Quality Control Enhancements: Additional quality checks were introduced at critical points in the assembly process to catch any defects early.

B. Long-Term Preventive Measures

To prevent the recurrence of similar defects in the future, long-term preventive measures were also proposed:

Supplier Quality Audits: Regular audits of all material suppliers will be conducted to ensure adherence to quality standards.

Process Optimization: Continuous improvement initiatives will focus on optimizing the assembly process to prevent future defects.

Employee Training: Ongoing training programs will be implemented to keep all assembly line workers up-to-date on best practices and new techniques.

C. Monitoring and Evaluation

The effectiveness of the corrective actions will be monitored through regular inspections and performance evaluations. A review schedule has been established as follows:

Review Date | Activity | Responsible Team |

|---|---|---|

March 2051 | Inspect all newly produced units for signs of cracking | Quality Control Team |

June 2051 | Review supplier quality audit reports | Procurement Team |

September 2051 | Conduct a full process audit to evaluate improvements | Operations Management |

VI. Conclusion

The Defect Root Cause Analysis has successfully identified the root causes of the structural weakness in the assembled product as substandard material quality and an inadequate welding technique. The implementation of immediate corrective actions, such as switching suppliers and updating the welding process, along with long-term preventive measures, will help eliminate the defect and improve the overall reliability and performance of the product. Continuous monitoring and evaluation will ensure that the corrective measures are effective and that similar defects do not recur in the future.