Basic Root Cause Analysis

Prepared By: [Your Name]

Date: June 19, 2060

I. Introduction

A Basic Root Cause Analysis (RCA) is a systematic approach used to identify the underlying causes of problems or defects within a system, process, or product. The purpose of this analysis is to uncover the root issues that lead to undesirable outcomes so that effective solutions can be implemented to prevent recurrence. This document provides a detailed RCA for a manufacturing process experiencing frequent machine breakdowns.

II. Details of the Analysis

Problem Identification

Aspect | Details |

|---|---|

Issue | Frequent breakdowns in the Model X3000 manufacturing machine. |

Impact |

|

Background | Over the past six months, the Model X3000 machine has experienced intermittent failures, causing significant disruptions in the production line and impacting overall efficiency. |

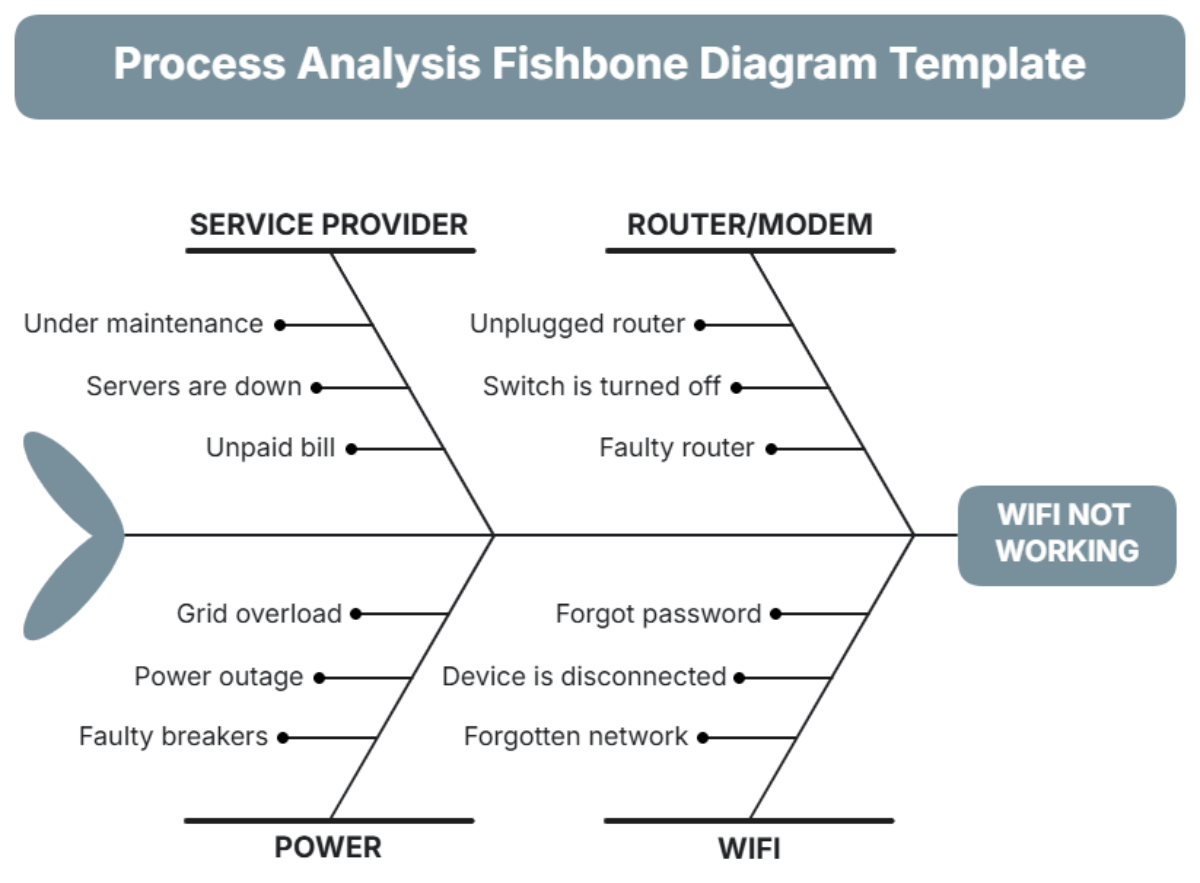

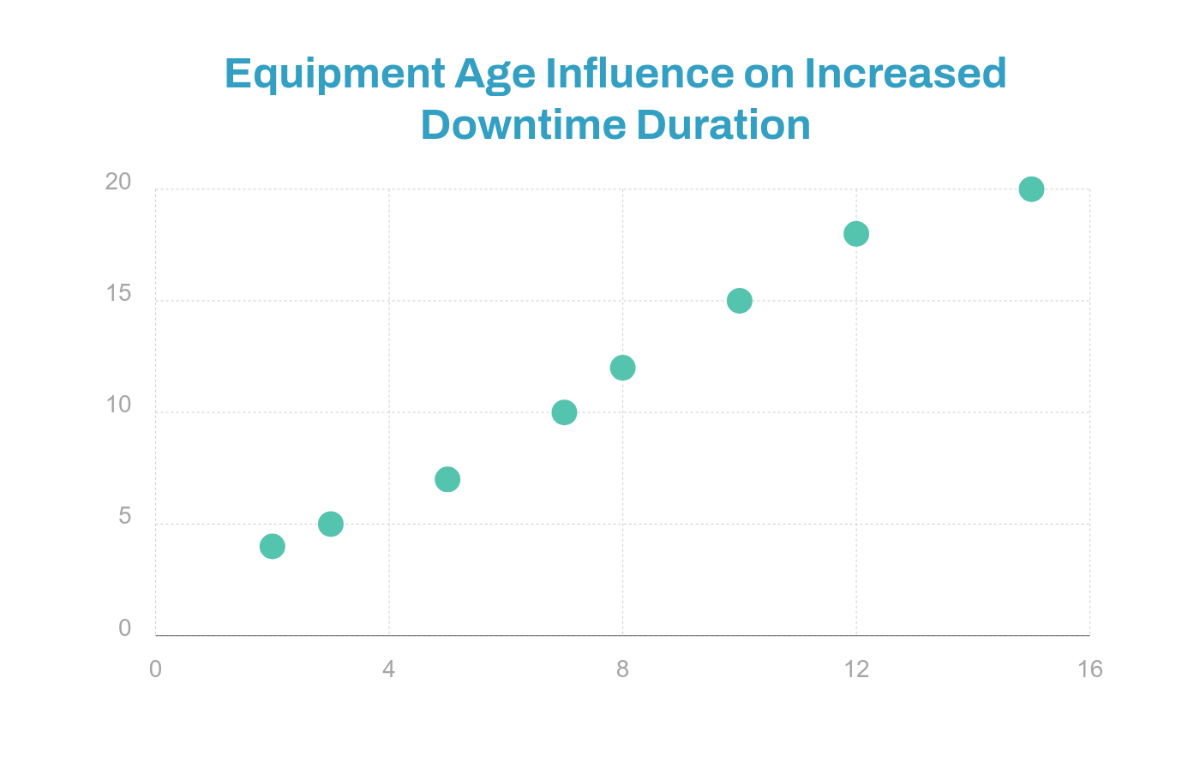

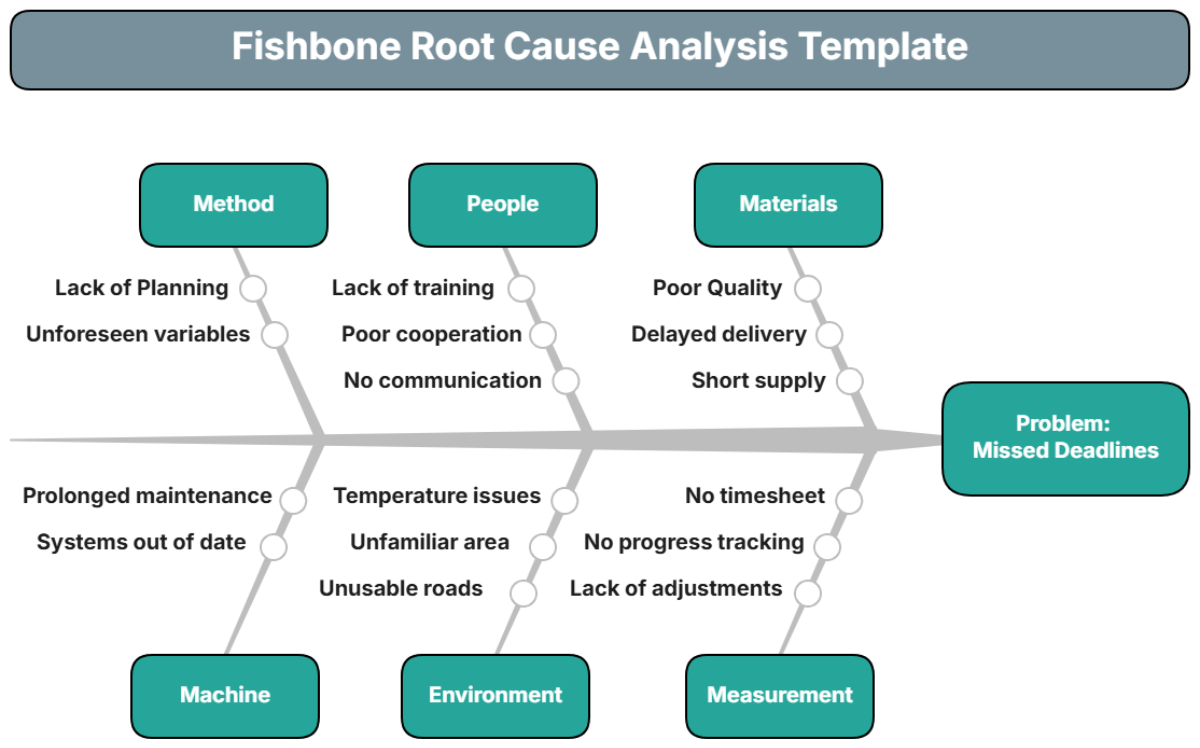

III. Root Cause Identification

Method Used: Fishbone Diagram (Ishikawa).

Causes Identified:

Category | Cause |

|---|---|

Mechanical Issues |

|

Operational Issues |

|

Maintenance Issues | Inadequate Lubrication: The lubrication schedule is not being followed |

IV. Solution Recommendations

Category | Recommendation |

|---|---|

Mechanical Issues |

|

Operational Issues |

|

Maintenance Issues |

|

V. Action Plan

Step | Action | Responsible Party | Timeline |

|---|---|---|---|

1. Replace Bearings | Procure and install new high-quality bearings. | Maintenance Team | 2 weeks |

2. Upgrade Motor | Replace the old motor with a new, reliable motor. | Maintenance Team | 3 weeks |

3. Recalibrate Settings | Update and distribute new machine settings protocols. | Engineering Department | 1 week |

4. Conduct Training | Develop and deliver training sessions for machine operators. | HR Department | 1 month |

5. Enforce Lubrication | Develop and implement a strict lubrication schedule. | Maintenance Supervisor | 2 weeks |

6. Implement Maintenance | Set up a preventive maintenance schedule and follow-up procedures. | Maintenance Supervisor | 3 week |

VI. Follow-Up and Monitoring

Metrics for Success:

Reduction in Machine Breakdowns: Aim for a 50% reduction in machine breakdown frequency within 3 months.

Decrease in Maintenance Costs: Target a 30% reduction in unplanned maintenance costs.

Improved Product Quality: Seek to restore product quality to pre-issue levels.

Follow-Up Schedule:

Monthly Reviews: Evaluate the effectiveness of implemented solutions and make necessary adjustments.

Quarterly Reports: Prepare detailed reports on progress and improvements, including cost savings and operational efficiency.

VII. Summary Table

Section | Overview | Key Points |

|---|---|---|

Problem Identification | Defines the issue and its impact. | Frequent breakdowns cause production delays and increased costs. |

Root Cause Identification | Identifies fundamental causes of the problem. | Mechanical wear, incorrect settings, and inadequate maintenance. |

Solution Recommendations | Propose actionable solutions. | Replace bearings and motor, update settings, and improve training. |

Action Plan | Outlines steps, timelines, and responsibilities. | Detailed steps including procurement, training, and scheduling. |

Follow-Up and Monitoring | Details metrics for success and review schedule. | Reduction in breakdowns, cost savings, and improved quality with regular reviews. |

VIII. Conclusion

The Basic Root Cause Analysis has identified the underlying issues causing frequent breakdowns in the Model X3000 manufacturing machine. By addressing mechanical wear, operational errors, and maintenance lapses with targeted solutions, the organization aims to improve production efficiency, reduce costs, and enhance product quality. Implementing and monitoring these solutions will help prevent recurrence and drive long-term improvements.