Accident Root Cause Analysis

Prepared By: [YOUR NAME]

Date: April 11, 2060

I. Introduction

The purpose of this analysis is to examine the root causes of workplace accidents and determine how deficiencies in training and education may contribute to these incidents. By understanding these root causes, we can implement effective training programs to reinforce safety practices and minimize future risks.

II. Identification of Training and Education Gaps

A. Initial Assessment

An initial assessment involves reviewing current training materials, employee competencies, and accident reports to identify gaps in knowledge and practice.

Review of current training materials

Assessment of employee competency levels

Analysis of recent accident reports

B. Table: Summary of Training and Education Gaps

Area | Finding | Implication |

|---|---|---|

Training Duration | Insufficient time allocated | Employees may not fully grasp safety protocols |

Training Content | Lack of focus on key safety procedures | Employees may overlook critical safety steps |

Training Frequency | Irregular training sessions | Employees may forget important safety information |

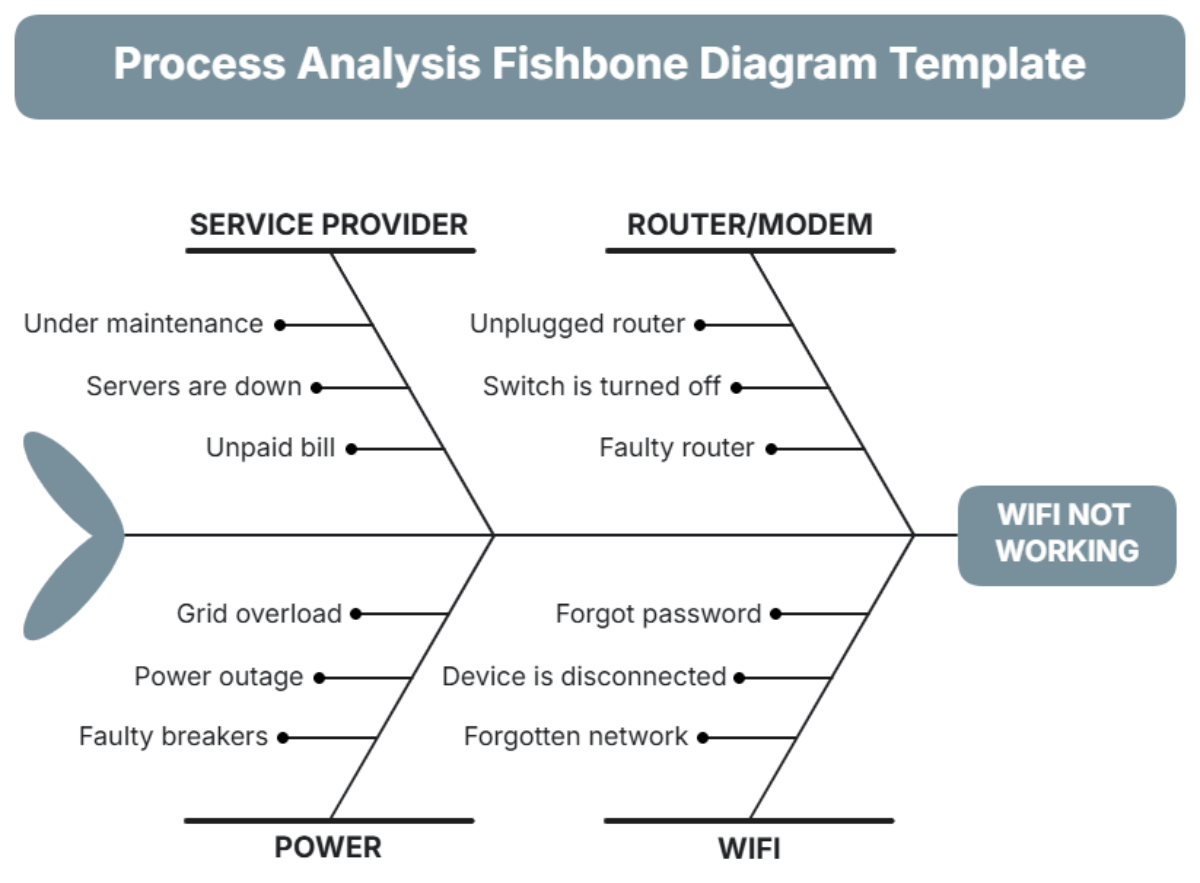

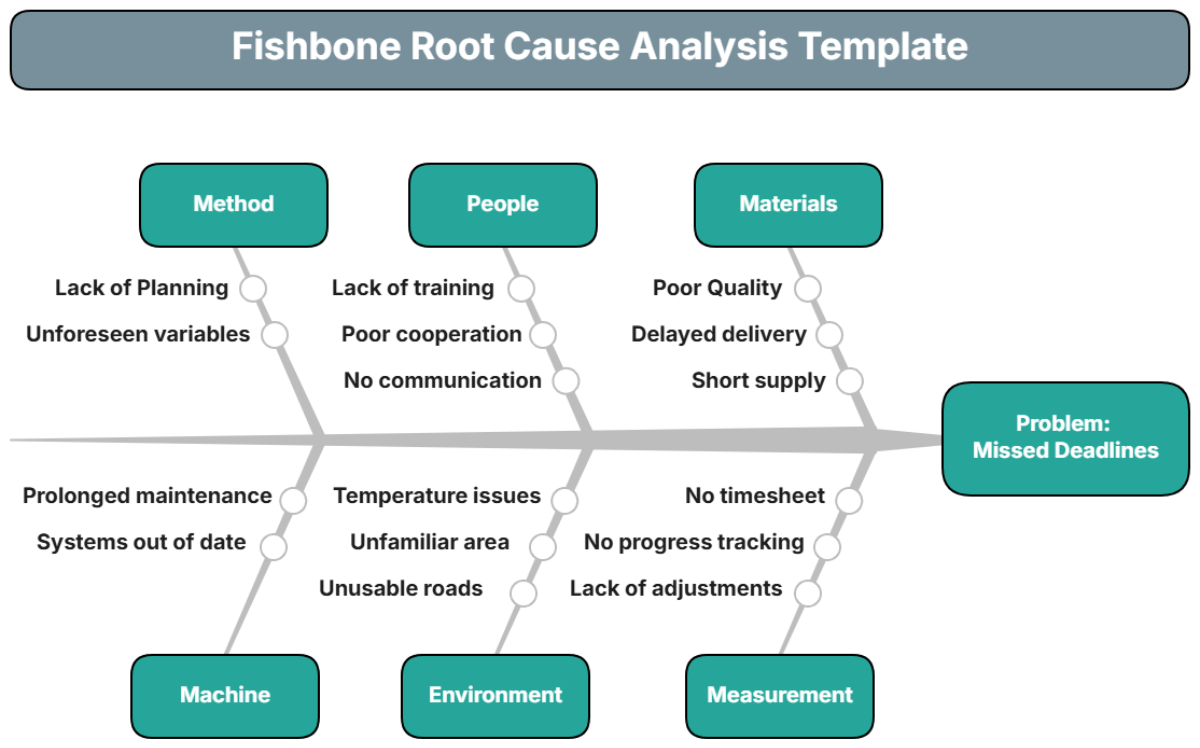

III. Root Causes Linked to Training and Education

A. Findings from Accident Reports

A thorough review of accident reports reveals several recurring themes that indicate training and education deficiencies as root causes of accidents.

Improper use of machinery due to inadequate training

Lack of awareness of emergency procedures

Failure to use personal protective equipment (PPE)

B. Table: Linking Root Causes to Training Deficiencies

Root Cause | Training Deficiency | Recommended Action |

|---|---|---|

Improper use of machinery | Lack of hands-on training | Include practical sessions in training programs |

Lack of emergency procedure awareness | No refresher courses | Establish regular refresher training sessions |

Failure to use PPE | Inadequate emphasis on PPE importance | Incorporate PPE usage into daily safety briefings |

IV. Developing Effective Training Programs

A. Training Program Components

An effective training program should encompass the following components to address identified gaps and root causes:

Comprehensive curriculum covering all safety protocols

Hands-on practical sessions for skill development

Regular refresher courses to reinforce knowledge

Assessments to gauge competency and understanding

B. Detailed Training Schedule

Day | Activity | Description |

|---|---|---|

Day 1 | Introduction to Safety Protocols | Cover basic safety procedures and emergency response |

Day 2 | Machinery Handling | Hands-on training with machinery |

Day 3 | PPE Training | Focus on the proper use of personal protective equipment |

Day 4 | Emergency Drills | Conduct mock drills for various emergency scenarios |

Day 5 | Assessment and Feedback | Conduct competency assessments and provide feedback |

V. Implementation and Monitoring

A. Execution Plan

Implementing the training program requires a structured approach to ensure all employees receive the necessary education and training.

Develop detailed training materials and schedules

Assign qualified trainers and facilitators

Communicate training plans to all employees

Monitor training sessions and gather feedback

B. Training Implementation Checklist

Task | Status | Completion Date |

|---|---|---|

Develop training materials | In Progress | 01/10/2050 |

Assign trainers | Completed | 05/10/2050 |

Communicate training plans | Not Started | 10/10/2050 |

Monitor sessions | Not Started | Ongoing |

VI. Evaluation and Improvement

A. Continuous Improvement

Continuous improvement is crucial for the success of the training program. Regular evaluations and updates ensure that the program remains effective and relevant.

Conduct regular reviews of training materials and practices

Collect and analyze feedback from participants

Update training content based on emerging safety trends and incidents

Implement additional training modules as needed

B. Evaluation Metrics

Metric | Description | Frequency |

|---|---|---|

Participant Feedback | Comments and ratings from employees | Post-training |

Accident Reduction Rate | Decrease in accident occurrences | Bi-annual |

Knowledge Retention | Assessment results over time | Annual |

Training Completion Rate | Percentage of employees completing training | Quarterly |

VII. Conclusion

Effective training and education are critical components in the prevention of workplace accidents. By identifying training deficiencies and implementing structured programs, we can significantly reduce the likelihood of accidents and ensure a safer work environment for all employees.