Operations Capacity Planning Guide

I. Introduction

In today's fast-paced business environment, effective operations capacity planning is critical to the success of [Your Company Name]. As a US marketing company, ensuring that we have the right resources in place to meet customer demands without overextending our capabilities is essential for maintaining competitive advantage and operational efficiency. Operations capacity planning is not just about estimating future needs but also about strategically aligning our resources with our business objectives.

At [Your Company Name], our operations capacity planning process is designed to address the complexities of fluctuating market demands, technological advancements, and the ever-changing regulatory landscape. By integrating capacity planning into our overall strategic planning, we can anticipate potential challenges, optimize resource allocation, and make informed decisions that support our long-term growth and sustainability.

This guide provides a comprehensive overview of the key elements of operations capacity planning, including demand forecasting, resource management, and contingency planning. Whether you are a manager, a team leader, or a member of our operations team, this guide will equip you with the knowledge and tools necessary to effectively plan and manage our operational capacity, ensuring that [Your Company Name] remains agile, resilient, and well-positioned to meet the needs of our clients.

II. Understanding Capacity Planning

Capacity planning is a fundamental aspect of operational management that determines the necessary production capacity to meet demand. It plays a critical role in ensuring that [Your Company Name] can efficiently manage resources, avoid bottlenecks, and maintain the ability to respond swiftly to market changes.

By thoroughly understanding capacity planning, [Your Company Name] can align its production capabilities with market needs, optimize resource usage, and reduce operational costs. This proactive approach not only improves internal efficiency but also enhances customer satisfaction by ensuring timely delivery of products and services.

A. Definition and Importance

Capacity planning is the strategic process of assessing and determining the optimal production capacity required to meet fluctuating market demands. At [Your Company Name], this involves evaluating our ability to produce enough goods or deliver services efficiently without overcommitting resources. Proper capacity planning ensures that we can scale operations to meet customer needs while maintaining cost-effectiveness.

The importance of capacity planning lies in its ability to balance supply with demand, allowing [Your Company Name] to avoid production shortfalls or resource wastage. By accurately forecasting and aligning capacity with market trends, we can maximize operational efficiency and ensure sustained profitability.

B. Objectives

Ensure optimal resource utilization.

Align production with market demand.

Improve cost efficiency and reduce waste.

Enhance customer satisfaction by meeting delivery times.

III. Key Concepts in Capacity Planning

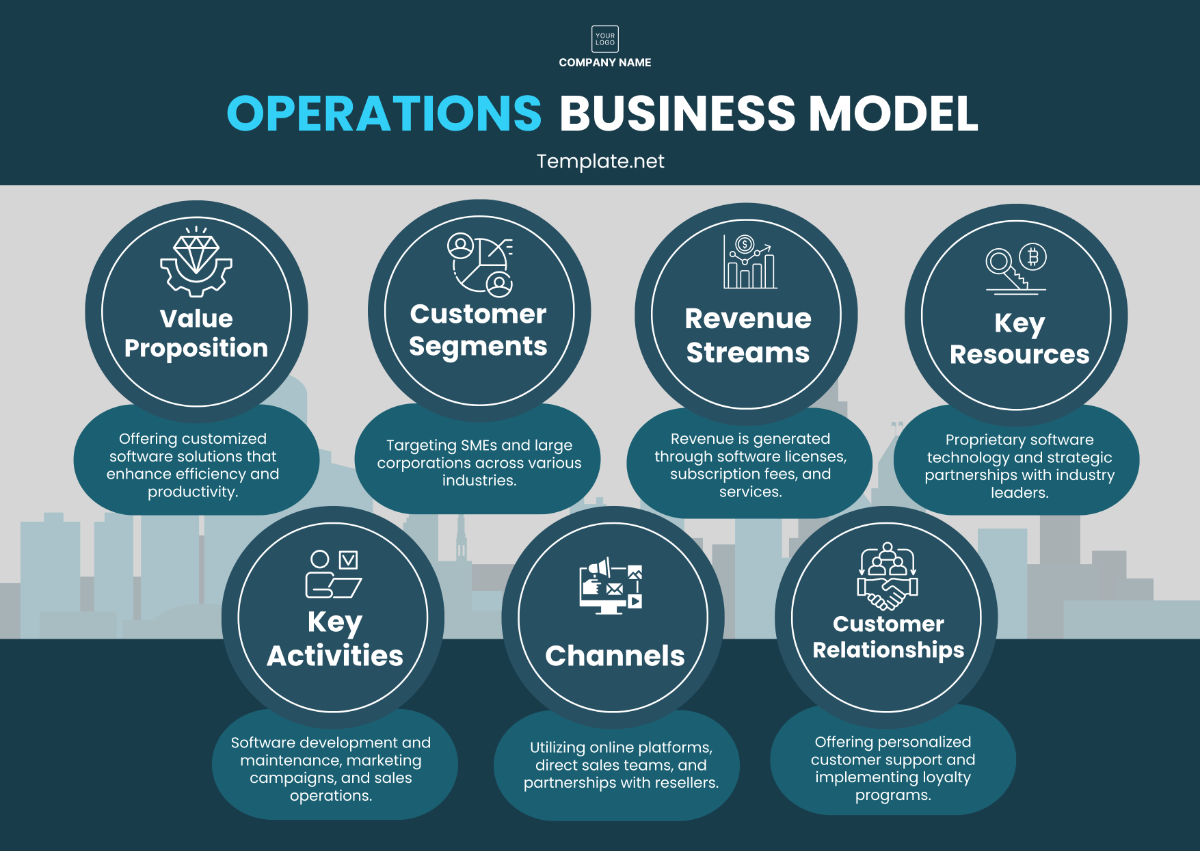

Understanding the core concepts of capacity planning is crucial for optimizing operational efficiency at [Your Company Name]. Key concepts like capacity versus demand and different types of capacity help us navigate the challenges of aligning production with market needs. By grasping these concepts, we can make informed decisions that enhance our ability to meet customer expectations.

Capacity planning isn't just about knowing what we can produce but also about recognizing what is realistically achievable given various constraints. This section delves into the distinctions between capacity and demand and the different types of capacity, providing the foundational knowledge needed for effective planning.

A. Capacity vs. Demand

To effectively plan for future operations, it's essential to differentiate between capacity and demand. The table below provides a clear visual representation of the relationship between these two factors, helping us better understand the challenges in balancing them.

Capacity | Demand |

|---|---|

The maximum output [Your Company Name] can achieve with available resources under specific conditions. Example: Our marketing team can manage 100 client campaigns per month with current staff and technology. | The actual market need or desire for [Your Company Name]'s products or services at a particular time. Example: During peak seasons, demand may rise to 120 campaigns per month, exceeding our current capacity. |

B. Types of Capacity

Understanding the different types of capacity is essential for effective capacity planning. These types help [Your Company Name] gauge operational limits and set realistic production goals.

Design Capacity: The maximum output that can theoretically be achieved under ideal conditions.

Effective Capacity: The maximum output that can realistically be achieved, considering regular operational interruptions.

Actual Capacity: The actual output achieved during a specific period.

IV. Steps in Capacity Planning

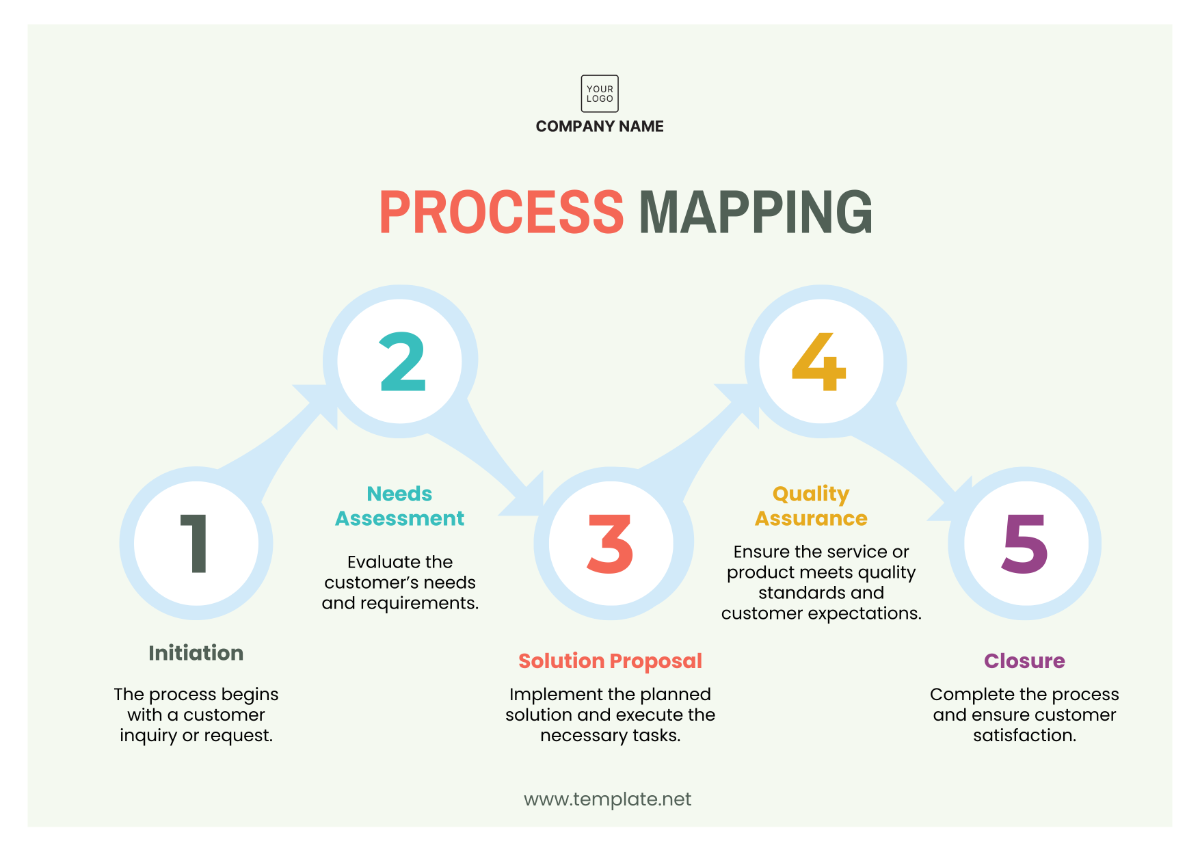

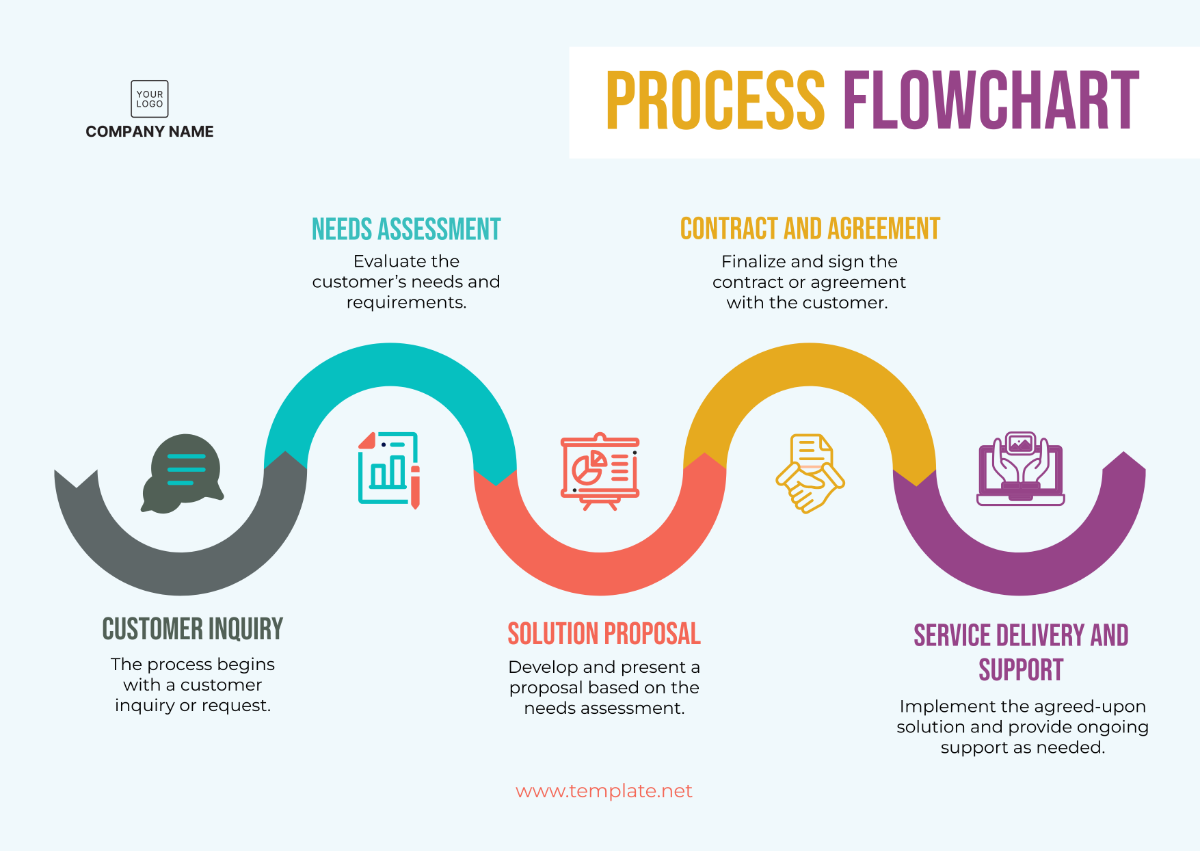

Effectively managing capacity requires a structured approach to ensure that [Your Company Name] can meet future demands without overextending resources. By following a systematic process, we can identify and address potential capacity issues before they impact our operations. Each step in the capacity planning process is designed to build a comprehensive understanding of our current capabilities, anticipate future needs, and implement solutions that align with our strategic goals.

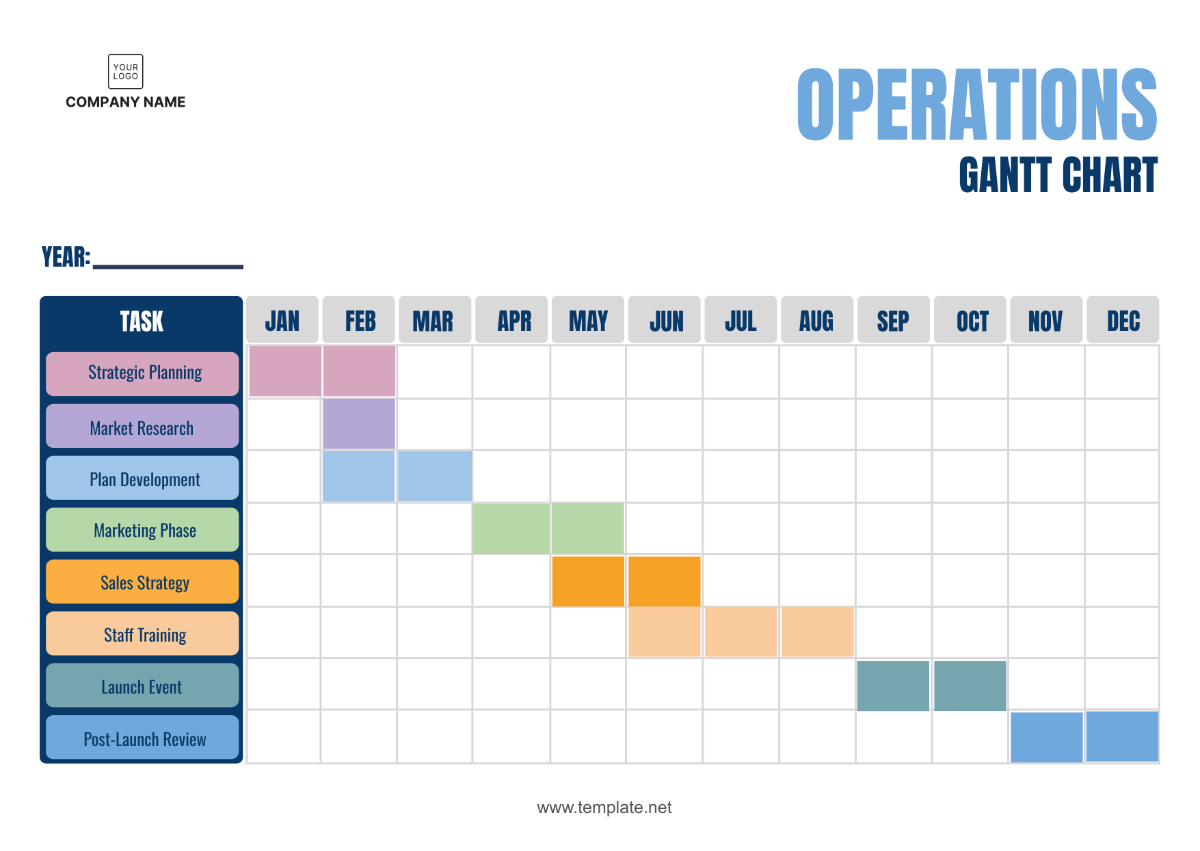

Below is a clear, step-by-step outline of the capacity planning process, from assessing current resources to implementing and monitoring the capacity plan. This visual representation helps in understanding how each stage contributes to a well-rounded capacity strategy.

Step | Description |

|---|---|

| The first step is to evaluate the current capacity of the organization. This involves analyzing existing resources, production rates, and workforce capabilities. |

| Accurate demand forecasting is integral to capacity planning. This requires the use of historical data, market analysis, and trend evaluation to predict future demand. |

| After assessing current capacity and forecasting future demand, the next step is to identify any gaps between the two. This helps in recognizing areas that require expansion or reduction. |

| Create a detailed plan that outlines how to address capacity gaps. This plan should include resource allocation, timeline, budget, and contingency measures. |

| Implement the capacity plan and continuously monitor performance to ensure objectives are being met. Regular reviews and adjustments are necessary for optimal results. |

V. Tools and Techniques for Capacity Planning

To effectively plan and manage capacity, [Your Company Name] employs a variety of tools and techniques tailored to both quantitative and qualitative aspects of capacity planning. These methods help in analyzing complex data, forecasting needs, and making informed decisions that align with our operational goals. By integrating these tools into our planning processes, we can better navigate uncertainties and optimize resource allocation.

A. Quantitative Techniques

Quantitative techniques use mathematical and statistical methods to analyze capacity needs. Tools like linear programming and simulation models enable precise predictions and optimizations, providing data-driven insights for effective capacity planning.

Linear Programming: A mathematical technique used to determine the best possible outcome, such as maximum profit or lowest cost.

Simulation Models: Used to create a digital replica of real-world processes to test different scenarios and outcomes.

B. Qualitative Techniques

Qualitative techniques rely on expert insights and structured methods to inform capacity planning. Approaches such as expert judgment and the Delphi technique leverage industry knowledge and consensus to guide strategic decision-making.

Expert Judgment: Using insights and experience from industry experts to make informed capacity planning decisions.

Delphi Technique: A structured communication method that relies on a panel of experts to reach a consensus on capacity planning issues.

VI. Best Practices in Capacity Planning

Implementing best practices in capacity planning is essential for achieving operational efficiency and aligning with [Your Company Name]'s strategic objectives. Adhering to these best practices ensures that our capacity planning process is both effective and adaptable to changing circumstances. By integrating proven methodologies, we can optimize resource utilization and improve our ability to meet market demands.

Here, we outline the key best practices for capacity planning, focusing on alignment with strategic goals, data-driven approaches, stakeholder engagement, and ongoing adjustments. Each practice plays a critical role in refining our capacity planning process and ensuring that our operations remain agile and responsive.

Align Capacity with Strategic Goals

Ensuring that capacity planning aligns with [Your Company Name]'s strategic goals is crucial for effective resource management. By synchronizing our capacity plans with overall business objectives, we can prioritize resource allocation more effectively and make strategic decisions that support long-term growth and competitive advantage.

Use Data-Driven Approaches

Leveraging data analytics and forecasting tools is essential for precise capacity planning. By utilizing historical data, analyzing market trends, and employing predictive analytics, [Your Company Name] can enhance the accuracy of our capacity forecasts and make informed decisions that align with future demand.

Engage Stakeholders

Involving stakeholders from diverse departments, including production, finance, and sales, is key to comprehensive capacity planning. By gathering insights from various perspectives, [Your Company Name] ensures that our plans are well-rounded, addressing different needs and fostering alignment across the organization.

Regular Review and Adjustment

Capacity planning requires continuous evaluation and adaptation. Regularly reviewing and adjusting plans based on actual performance, market fluctuations, and technological advancements helps [Your Company Name] stay responsive and maintain operational efficiency in a dynamic business environment.

VII. Case Study: Successful Capacity Planning

Consider Company XYZ, a leading player in its industry, which demonstrated exceptional success through effective capacity planning. Faced with increasing market demand, Company XYZ recognized the need for a robust capacity planning strategy to sustain its growth and maintain operational efficiency. The company embarked on a comprehensive approach, leveraging advanced data analytics and fostering collaboration among key stakeholders.

To begin, Company XYZ utilized sophisticated data analytics tools to gather and analyze historical data, market trends, and predictive insights. This data-driven approach enabled the company to forecast future demand with greater accuracy, aligning production capabilities with market needs. By integrating these insights into their capacity planning, they were able to anticipate and address potential bottlenecks before they became issues.

Simultaneously, Company XYZ engaged stakeholders from various departments, including production, finance, and sales, to ensure a holistic view of the company’s capacity requirements. This collaborative effort led to a more informed decision-making process, aligning resource allocation with strategic goals and optimizing production processes.

The results were notable: Company XYZ achieved a significant reduction in operational costs by streamlining processes and eliminating inefficiencies. Additionally, their enhanced capacity planning allowed for timely fulfillment of customer orders, leading to improved customer satisfaction and a strengthened market position.

This case study illustrates how strategic capacity planning, supported by data analytics and stakeholder engagement, can drive operational success and foster sustainable growth. Company XYZ’s approach serves as a valuable example for [Your Company Name] in pursuing effective capacity management.

VIII. Path Forward in Capacity Planning

Effective capacity planning is a cornerstone of operational success at [Your Company Name]. By systematically assessing current capabilities, forecasting future demands, and implementing strategic plans, we can ensure that our resources are optimally utilized and aligned with market needs. The ability to manage capacity effectively not only prevents resource wastage but also positions us to meet customer expectations consistently and efficiently.

Adopting best practices in capacity planning, such as data-driven approaches and stakeholder engagement, further enhances our ability to adapt to changing conditions and achieve long-term goals. As we continue to refine our capacity planning processes, [Your Company Name] will be better equipped to navigate the complexities of the market, drive operational excellence, and maintain a competitive edge. Embracing these principles will enable us to achieve sustained growth and success in an ever-evolving business landscape.